Comprehensive Guide to Gray TSL-50 Repair Manual

In the world of machinery, ensuring optimal functionality is paramount. Regular maintenance and understanding common issues can significantly extend the lifespan of your devices. This section aims to provide essential insights into the intricacies of restoring functionality to various systems, making it a valuable resource for both novices and seasoned professionals alike.

Familiarizing yourself with the components and potential complications can save time and resources. From diagnosing malfunctions to implementing effective solutions, the process can be straightforward when armed with the right information. This guide delves into the critical aspects of upkeep, offering practical tips and detailed procedures to address frequent challenges encountered in the field.

Whether you are facing minor inconveniences or significant breakdowns, knowing how to navigate these situations is key. Each subsection of this guide is designed to empower you with knowledge, enabling informed decisions that enhance performance and reliability. Embrace the opportunity to transform potential setbacks into manageable tasks, ensuring your equipment remains in peak condition.

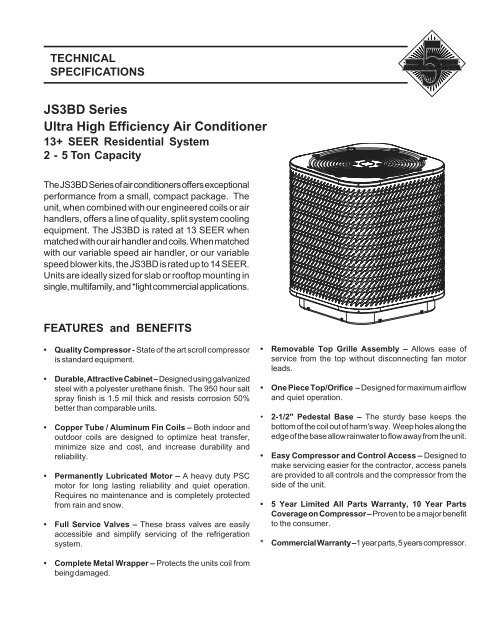

Understanding Gray TSL-50 Features

This section explores the distinct characteristics and functionalities of a specific equipment model. By examining its design elements and operational capabilities, users can gain a deeper appreciation for how these features contribute to overall performance and efficiency.

One of the standout attributes of this model is its intuitive interface, which simplifies user interaction and enhances usability. The combination of tactile controls and clear displays allows for seamless adjustments, making it accessible even to those with minimal experience.

Additionally, the construction quality is noteworthy, ensuring durability and reliability in various environments. Materials used in manufacturing not only provide strength but also aid in reducing maintenance needs over time.

| Feature | Description |

|---|---|

| Intuitive Interface | Designed for ease of use, facilitating smooth operation. |

| Durable Construction | Built with high-quality materials for longevity. |

| Versatile Applications | Suitable for a range of tasks across different settings. |

| Efficient Performance | Optimized for high output with minimal energy consumption. |

In conclusion, understanding these key features allows users to maximize the potential of the device, ensuring effective operation and longevity in service.

Common Issues with Gray TSL-50

Devices of this type often encounter a range of challenges that can hinder their performance. Identifying these common problems early can lead to effective solutions, ensuring that the unit operates smoothly. Understanding these issues is crucial for anyone working with such equipment.

Electrical Failures

One of the most prevalent issues involves electrical components. Short circuits or power surges can disrupt functionality, leading to unexpected shutdowns. Regular checks of the wiring and connections can help prevent these disruptions.

Mechanical Wear and Tear

Over time, various parts may experience significant wear. This can result in reduced efficiency or even complete operational failure. Regular maintenance and timely replacement of worn-out components are essential for prolonging the lifespan of the equipment.

Essential Tools for Repairing TSL-50

When it comes to maintaining and restoring machinery, having the right instruments at your disposal is crucial for achieving optimal performance. A well-equipped toolkit can significantly streamline the process, ensuring that each component is addressed with precision and care. This section highlights the indispensable items that every technician should consider when tackling maintenance tasks.

Basic Hand Tools

Starting with the fundamentals, a set of quality hand tools is essential for any technician. This includes screwdrivers of various sizes, pliers, and wrenches, which are vital for loosening or tightening fasteners. Additionally, having a reliable utility knife and a set of hex keys can be invaluable for accessing hard-to-reach areas and ensuring that every part is secure.

Diagnostic Equipment

Incorporating diagnostic instruments into your toolkit enhances your ability to troubleshoot issues effectively. Multimeters and oscilloscopes are excellent for testing electrical components, while pressure gauges can provide insights into the operational state of various systems. These tools not only help identify problems but also assist in verifying that repairs have been executed successfully.

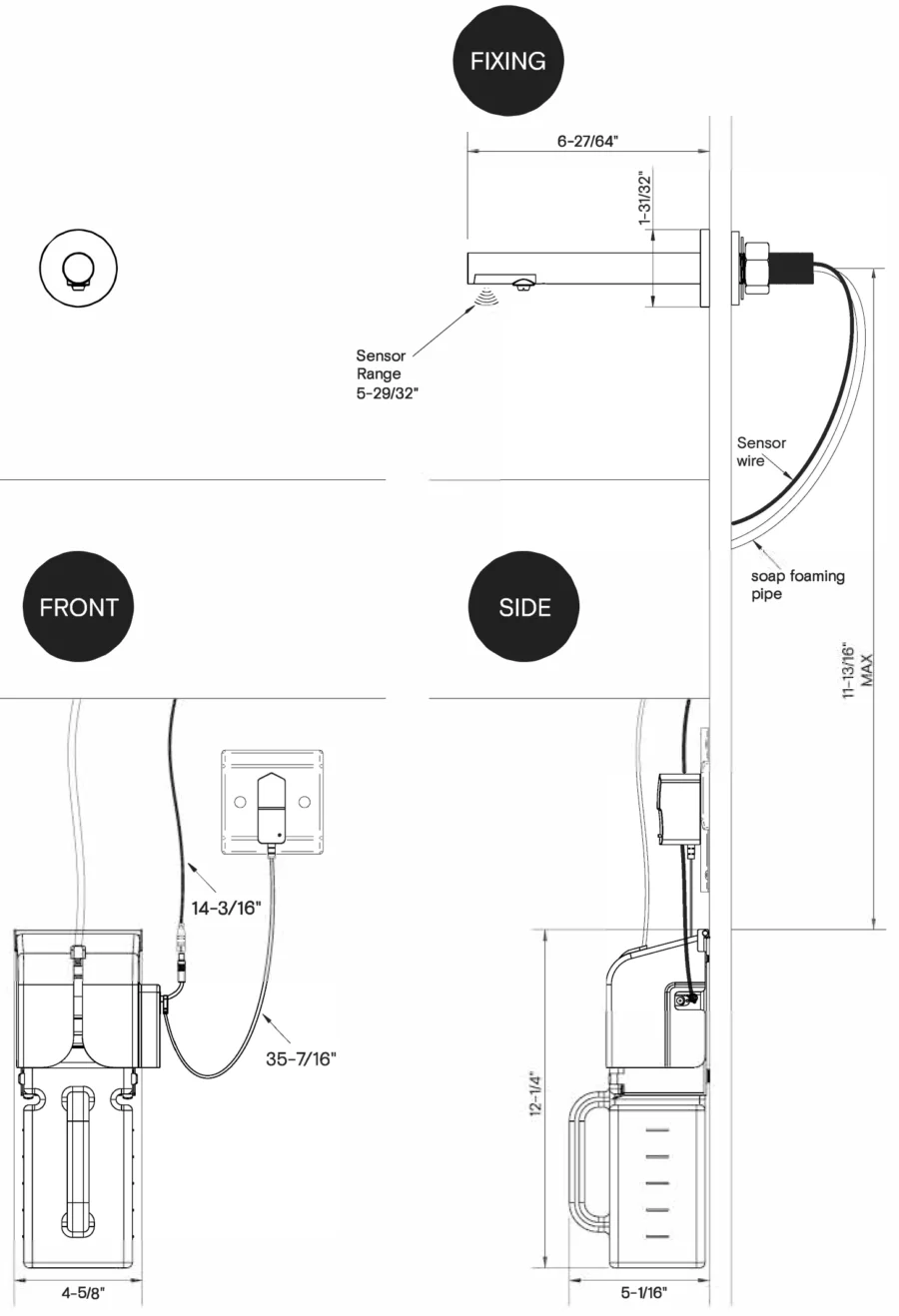

Step-by-Step Repair Process

This section outlines a detailed procedure to address common issues encountered with the equipment. By following a systematic approach, users can efficiently diagnose problems and implement solutions, ensuring optimal functionality and longevity of the device.

1. Initial Assessment: Begin by examining the unit for any visible signs of damage or wear. Check connections, components, and the overall condition to identify any obvious faults.

2. Gather Tools and Materials: Prepare the necessary tools such as screwdrivers, pliers, and any replacement parts. Having everything on hand will streamline the process and minimize interruptions.

3. Disassembly: Carefully take apart the equipment, noting the arrangement of components. Use a systematic approach to avoid losing small parts, and document the process if needed.

4. Inspection: Thoroughly inspect internal parts for signs of damage or malfunction. Pay close attention to electrical connections and mechanical components, as these are often the root of issues.

5. Problem Identification: Utilize diagnostic tools to test specific functions. Identify any malfunctioning parts that require attention, based on your inspection and testing results.

6. Replacement and Repair: Replace any damaged components with new or refurbished parts. If repairs are possible, ensure that they are executed with precision and care to restore full functionality.

7. Reassembly: Once repairs are completed, reassemble the unit carefully. Follow your earlier documentation to ensure that all parts are returned to their correct positions.

8. Testing: After reassembly, conduct a thorough test to verify that the equipment operates as expected. This step is crucial to confirm that all issues have been resolved.

9. Final Inspection: Perform a final check to ensure that everything is in order. Look for any loose parts or potential issues that may arise after testing.

10. Documentation: Record the work done, including parts replaced and any observations made during the process. Keeping a detailed log can be helpful for future reference and maintenance.

Safety Precautions During Repair

When undertaking maintenance or servicing tasks, ensuring a secure environment is paramount. Adhering to safety measures not only protects the individual performing the work but also safeguards the equipment and surrounding area. Awareness of potential hazards and appropriate precautions can significantly reduce the risk of accidents.

General Safety Guidelines

- Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and masks.

- Keep the workspace tidy and organized to prevent trips and falls.

- Ensure adequate ventilation in the area, especially when dealing with fumes or chemicals.

Handling Tools and Equipment

- Inspect all tools for damage before use and replace any defective items.

- Use tools as intended; do not improvise or use makeshift solutions.

- Disconnect power sources before beginning work on any electrical components.

By following these guidelines, individuals can create a safer working environment, minimizing risks and enhancing the overall efficiency of the task at hand.

Parts Replacement for Gray TSL-50

Ensuring optimal functionality of equipment often requires attention to its components. Timely substitution of worn-out or malfunctioning parts can significantly enhance performance and prolong lifespan. This section outlines essential considerations for component exchange in the system, ensuring it operates efficiently and reliably.

Identifying Worn Components

The first step in the process involves recognizing which parts need to be replaced. Regular inspections can reveal signs of wear such as unusual noises, decreased efficiency, or visible damage. It’s crucial to maintain a log of performance issues to facilitate effective troubleshooting.

Choosing Replacement Parts

Selecting high-quality substitutes is vital for maintaining the integrity of the equipment. Always refer to specifications to ensure compatibility. Utilizing OEM (Original Equipment Manufacturer) components is recommended, as they provide assurance of quality and performance standards. Additionally, consulting with experts or reliable sources can aid in making informed decisions regarding part selection.

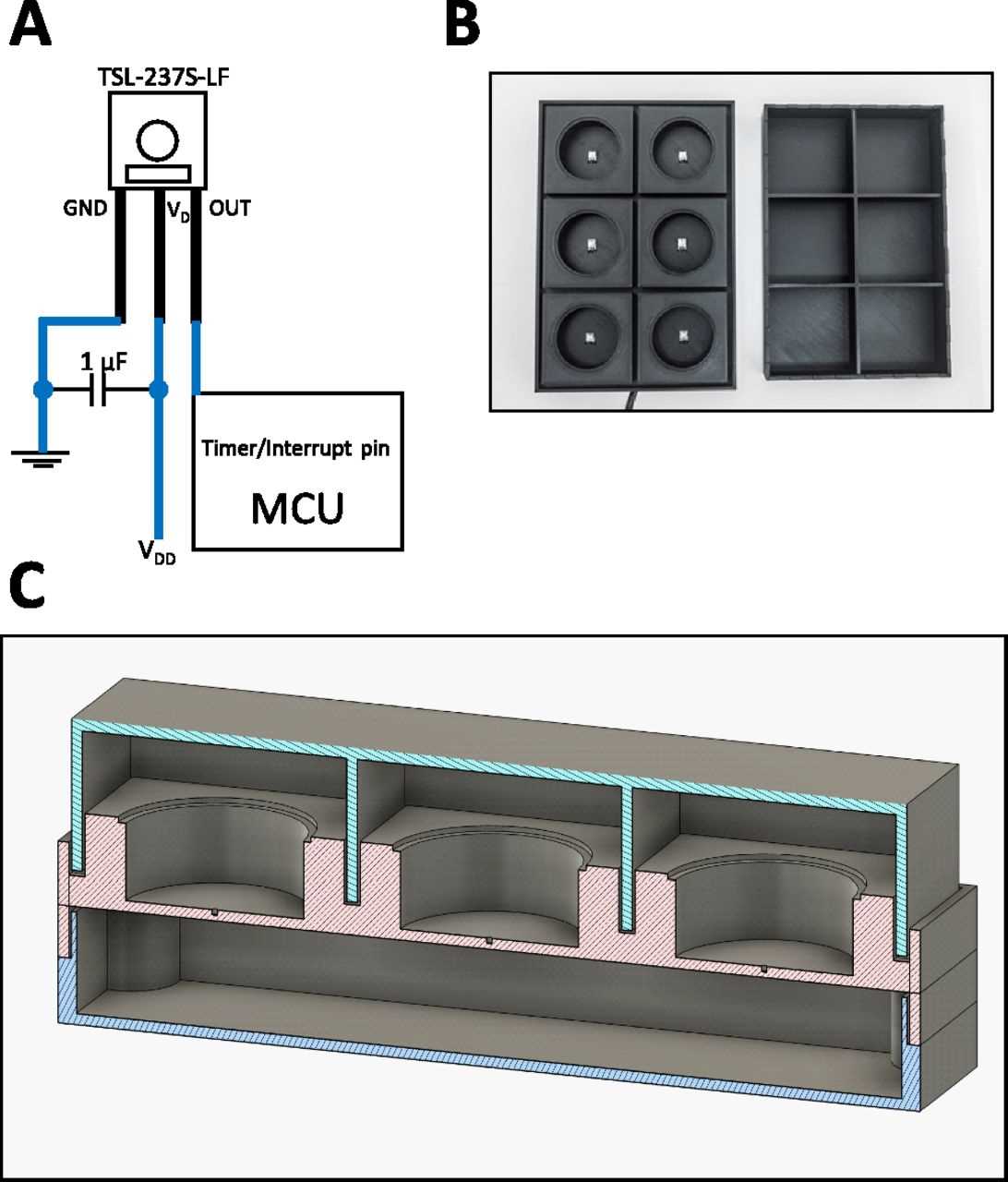

Troubleshooting Electrical Problems

Identifying and resolving electrical issues can often be a daunting task. By following a systematic approach, you can effectively diagnose common malfunctions. This section provides a framework for pinpointing problems and implementing solutions to restore functionality.

Begin by gathering the necessary tools, including a multimeter, wire stripper, and screwdriver. Familiarity with basic electrical concepts will aid in the process. Always ensure safety first; disconnect power before inspecting any components.

| Issue | Potential Causes | Suggested Solutions |

|---|---|---|

| No Power | Blown fuse, tripped circuit breaker | Check and replace fuses; reset breakers |

| Intermittent Operation | Loose connections, faulty components | Tighten connections; replace defective parts |

| Overheating | Overloaded circuits, poor ventilation | Reduce load; improve airflow |

| Unusual Noises | Worn bearings, debris in motors | Lubricate bearings; clean the area |

After implementing solutions, restore power and test the system. Continuous monitoring will help prevent future complications. Document any changes made for reference in subsequent troubleshooting efforts.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires regular upkeep and mindful practices. A proactive approach to maintenance not only extends the lifespan but also enhances efficiency, saving both time and resources in the long run.

First and foremost, establish a consistent cleaning routine. Accumulated dust and debris can impede functionality and lead to premature wear. Use appropriate cleaning tools to avoid damaging sensitive components. Additionally, inspect all moving parts regularly for signs of friction or damage; lubrication is essential to maintain smooth operation.

Check connections and wiring periodically. Loose or corroded connections can cause electrical issues that may affect performance. Replace worn components promptly to prevent further complications. Furthermore, adhere to recommended operational guidelines to avoid overloading the machinery, which can significantly reduce its lifespan.

Finally, keep an eye on the environment where the equipment is stored and used. Temperature extremes, humidity, and exposure to harsh chemicals can negatively impact performance. Maintaining a controlled environment will contribute greatly to the longevity of your device.

Resources for TSL-50 Owners

For enthusiasts and users of this particular device, having access to reliable information and support can greatly enhance the overall experience. A wealth of resources exists to assist owners in maintaining and troubleshooting their equipment effectively. Whether you’re looking for technical specifications, user communities, or expert advice, these tools can help you navigate any challenges you may encounter.

Online Forums and Communities: Engaging with fellow users through dedicated online platforms can provide valuable insights and shared experiences. These communities often host discussions that cover a range of topics, from common issues to advanced modifications. Participating in these forums can be a great way to connect with other owners and gain practical knowledge.

Official Documentation: Accessing the original guides and specifications can offer detailed information on operation and features. These documents typically include troubleshooting tips and maintenance schedules that can help prolong the life of your device.

Video Tutorials: Visual learners may find video content particularly beneficial. Platforms like YouTube host numerous tutorials that demonstrate various procedures, making complex tasks easier to understand and follow. These resources often showcase step-by-step guides tailored for different skill levels.

Local Service Providers: For those who prefer hands-on assistance, identifying local technicians or service centers can be crucial. These professionals are equipped to handle repairs and maintenance, ensuring your device remains in optimal condition. Checking reviews and recommendations can help you choose a reputable service provider.

Replacement Parts Suppliers: When repairs are necessary, sourcing quality components is essential. Numerous suppliers specialize in offering authentic or compatible parts, making it easier to find what you need for repairs or upgrades. Always ensure that you choose reputable vendors to maintain the integrity of your device.

By leveraging these resources, owners can enhance their knowledge and ensure their equipment operates smoothly for years to come.