Complete Guide to Repairing Your Kirby Sentria

Maintaining your household cleaning device is crucial for ensuring its longevity and optimal performance. Proper upkeep not only enhances the efficiency of your equipment but also contributes to a healthier living environment. This section will explore the vital steps necessary for preserving the functionality of your cleaning system.

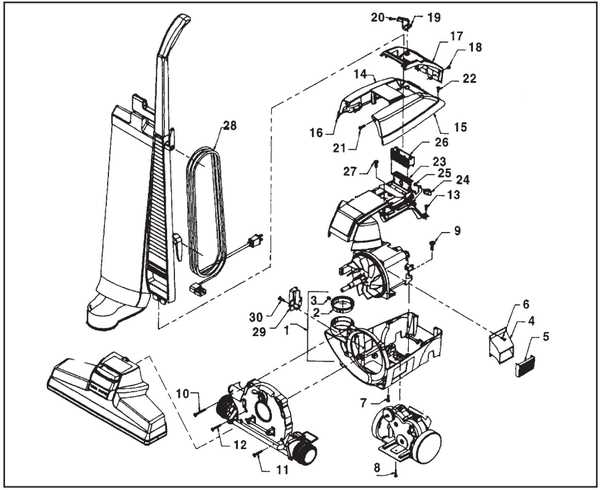

Understanding the various components of your device is key to effective maintenance. Each part plays a significant role in its overall operation, and knowing how to care for them will empower you to troubleshoot common issues. Regular inspections and timely interventions can prevent minor problems from escalating into major repairs.

In this comprehensive guide, you will find detailed instructions and practical tips tailored to help you navigate through the process of sustaining your cleaning appliance. Whether you’re addressing performance drops or performing routine checks, this information will serve as a valuable resource to keep your system in peak condition.

Understanding Kirby Sentria Basics

This section aims to provide a foundational overview of a versatile cleaning device designed to enhance home maintenance. Familiarity with its components and functionalities will enable users to maximize efficiency and effectiveness.

Key features include:

- Powerful suction capabilities

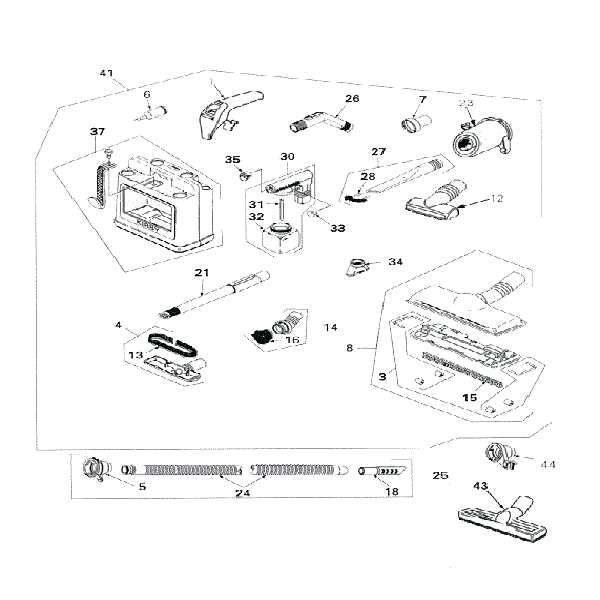

- Interchangeable attachments for various tasks

- Durable construction ensuring longevity

- Filtration systems for improved air quality

Users should consider the following aspects to optimize their experience:

- Maintenance: Regular upkeep is essential for performance longevity.

- Attachments: Understanding the purpose of each accessory can enhance cleaning effectiveness.

- Operating Instructions: Familiarizing oneself with the device’s controls simplifies usage.

By grasping these fundamentals, users can ensure that their cleaning experience is both efficient and satisfying.

Common Issues with Kirby Sentria

When dealing with high-performance cleaning devices, users may encounter a variety of frequent complications that can impact functionality and efficiency. Understanding these challenges can lead to better maintenance practices and improved longevity of the equipment.

Loss of Suction: One of the most reported problems is a noticeable decrease in suction power. This can often be attributed to clogged filters or a full dust collection bag. Regular inspection and timely replacement of these components are essential for optimal performance.

Unusual Noises: Another issue is the emergence of strange sounds during operation. These noises may indicate problems such as a blocked hose or worn-out brushes. Addressing these concerns promptly can prevent further damage and ensure smooth operation.

Power Issues: Users may also experience difficulties with power supply, such as the device not turning on or unexpectedly shutting off. Checking the power cord for frays and ensuring the outlet is functioning properly can help identify the root cause.

Brush Roll Problems: The brush roll can sometimes become ineffective, leading to poor cleaning results. Hair and debris can become entangled, so regular cleaning of the brush roll is vital to maintain its effectiveness.

Overheating: Lastly, overheating is a concern that can arise from prolonged use without adequate cooling periods. Ensuring the machine has adequate breaks during extensive cleaning tasks can mitigate this risk and enhance the device’s lifespan.

By being aware of these common issues, users can take proactive measures to maintain their cleaning equipment and ensure it operates efficiently for years to come.

Essential Tools for Repairs

When it comes to maintaining your cleaning device, having the right equipment is crucial for effective servicing. The proper tools not only simplify the process but also enhance the overall outcome, ensuring your appliance performs optimally. Below is a list of indispensable items that can make your maintenance tasks smoother and more efficient.

- Screwdrivers: A set of both flathead and Phillips screwdrivers will cover most fastening needs.

- Wrenches: Adjustable wrenches are perfect for loosening or tightening various components.

- Pliers: Needle-nose pliers can help reach tight spots, while standard pliers are useful for gripping and twisting.

- Vacuum Cleaner Maintenance Kit: This often includes brushes and tools specifically designed for cleaning and servicing.

- Multimeter: Essential for checking electrical connections and diagnosing issues.

- Lubricants: Keeping moving parts well-lubricated can prevent wear and tear.

- Cleaning Supplies: A variety of cloths and brushes are necessary for keeping the device free of debris.

Investing in these essential tools not only streamlines the upkeep process but also extends the lifespan of your appliance. Always ensure your toolkit is well-stocked before beginning any service task.

Step-by-Step Cleaning Procedures

Maintaining the performance and longevity of your cleaning device is essential for optimal results. This section outlines systematic approaches to ensure your equipment remains in top condition. Following these procedures will help enhance efficiency and prevent potential issues.

Initial Preparation

Before beginning the cleaning process, gather all necessary tools and materials. This typically includes a soft brush, microfiber cloths, and a mild cleaning solution. Ensure the device is unplugged to guarantee safety during maintenance. Remove any attachments or components that require cleaning separately.

Cleaning the Main Unit

Start by wiping down the exterior of the device with a damp cloth to remove dust and debris. Pay special attention to vents and crevices where dirt can accumulate. For stubborn spots, a gentle cleaning solution can be applied. After cleaning, dry all surfaces thoroughly to prevent moisture buildup, which can lead to malfunctions.

Replacing the Vacuum Bag Effectively

Changing the filtration bag is essential for maintaining optimal performance and ensuring the longevity of your cleaning device. A clean bag allows for efficient dirt and debris collection, enhancing suction power and overall functionality.

Step 1: Begin by turning off and unplugging the device to ensure safety. Locate the bag compartment, which is typically found at the back or top of the unit.

Step 2: Open the compartment carefully, following the manufacturer’s instructions. Gently remove the old bag, taking care not to spill any contents.

Step 3: Prepare the new filtration bag by ensuring it is the correct type and size. Insert it into the compartment, making sure it fits snugly and securely.

Step 4: Close the compartment firmly. Check that it is sealed properly to prevent any dust leaks during operation.

Step 5: Finally, plug the unit back in and turn it on. Verify that it is functioning efficiently, with strong suction and no unusual noises.

By following these steps, you can ensure a seamless transition to a new filtration system, ultimately prolonging the life of your cleaning equipment.

Troubleshooting Motor Problems

Addressing issues with the motor can often be a straightforward process. Understanding common symptoms and their underlying causes allows for effective diagnosis and resolution of performance problems. This guide outlines essential steps to identify and rectify motor-related challenges, ensuring optimal functionality.

Identifying Symptoms

First, observe any irregularities in operation. Unusual noises, such as grinding or buzzing, can indicate wear or malfunction. Additionally, a reduction in suction power may point to obstructions or motor strain. Regularly check for overheating, which can signal excessive load or electrical issues.

Common Solutions

Start by examining the power source; ensure that connections are secure and the outlet is functioning. If problems persist, inspect internal components for blockages or wear. Cleaning filters and checking for debris can often restore performance. If electrical faults are suspected, consider consulting a professional to address wiring or motor damage.

Remember: Regular maintenance can prevent many of these issues, extending the lifespan of the motor and maintaining peak performance.

Maintaining Filters for Optimal Performance

Ensuring that filtration components are well-maintained is essential for achieving peak functionality in any cleaning apparatus. Clean filters not only enhance suction power but also improve air quality, contributing to a healthier environment. Regular attention to these components can prevent inefficiencies and prolong the lifespan of the equipment.

Regular Inspection

Routine checks of the filtration system should be part of standard maintenance. Inspect for visible debris, damage, or wear that could impede airflow. Even small blockages can significantly affect overall performance. Scheduling regular inspections allows for timely interventions before minor issues escalate into major problems.

Cleaning and Replacement

Cleaning filters according to the manufacturer’s guidelines is crucial for optimal operation. Some filters can be washed, while others may require replacement after a certain period. Keeping track of cleaning schedules and replacement timelines ensures that the equipment remains efficient and effective. Always use the recommended products and methods to maintain the integrity of the filters.

Repairing the Brush Roll Mechanism

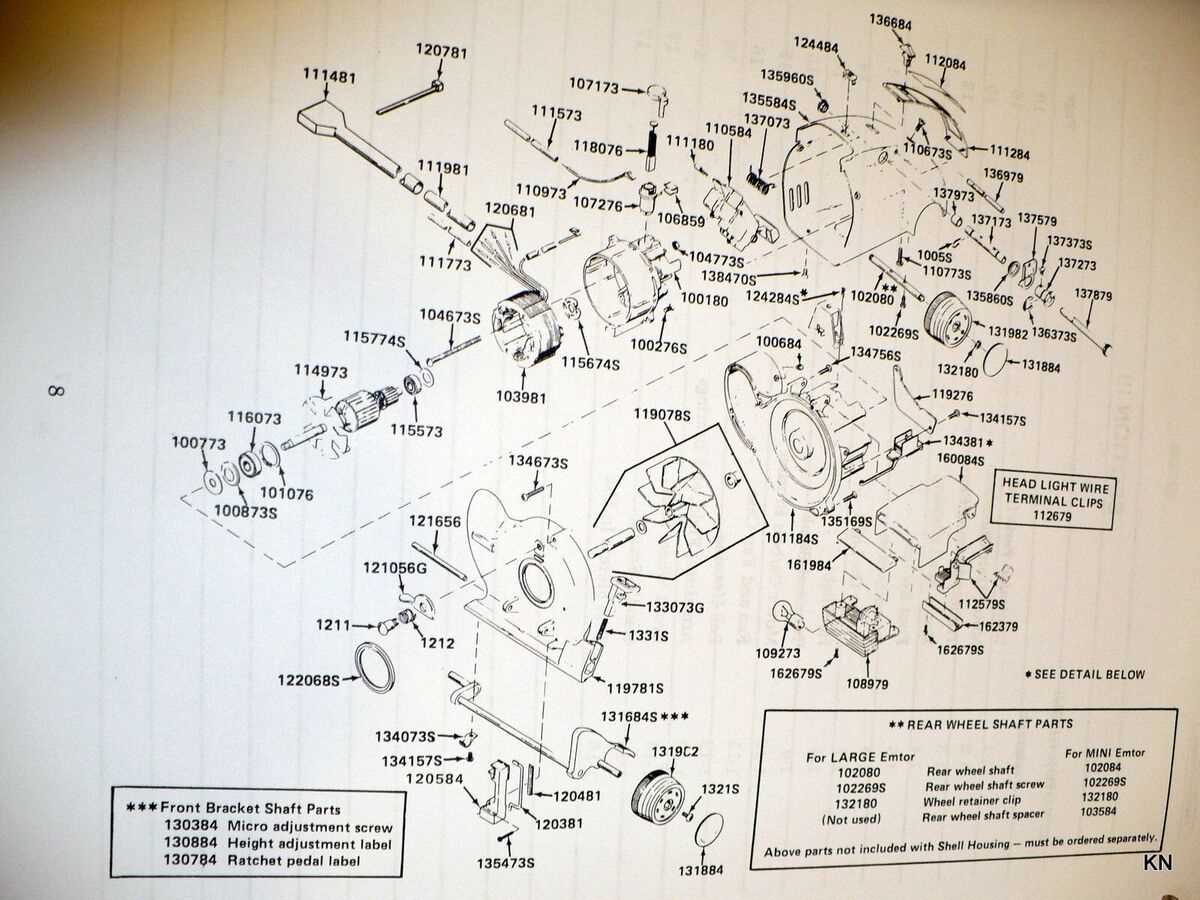

The brush roll component is essential for effective cleaning, ensuring that debris is effectively lifted from various surfaces. When issues arise within this mechanism, it can significantly impact performance. This section outlines the steps needed to restore functionality and maintain optimal cleaning power.

Identifying Common Issues

Before delving into solutions, it’s crucial to recognize typical problems that may affect the brush roll. Symptoms such as unusual noises, lack of rotation, or diminished suction can indicate underlying complications. Inspecting for tangled hair or debris is often the first step in troubleshooting.

Disassembling and Cleaning

To address the identified issues, begin by disassembling the brush roll unit. Ensure that the device is unplugged for safety. Remove any screws or fasteners holding the brush roll in place. Once detached, clean the roller thoroughly, removing any accumulated dirt or hair. If the bristles show signs of wear, consider replacing them to enhance performance. After cleaning, reassemble the unit securely, ensuring all components are properly aligned.

Once everything is back in place, test the functionality to confirm that the brush roll operates smoothly and effectively.

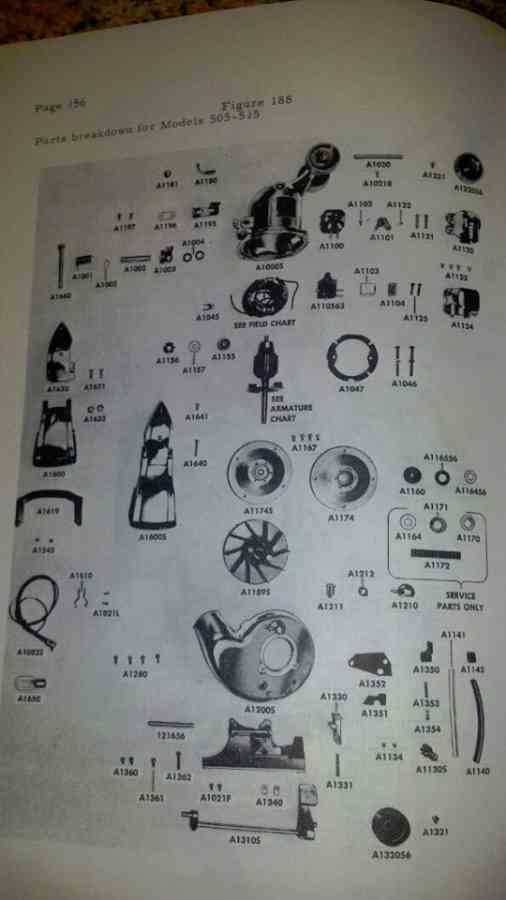

Electrical System Diagnostics

Effective assessment of an electrical framework is crucial for identifying issues that may impede functionality. This process involves examining various components to ensure they are operating within designated parameters. Proper evaluation can reveal underlying problems that could lead to decreased performance or potential failures.

Step 1: Initial Inspection – Begin with a thorough visual examination of the system. Look for signs of wear, frayed wires, or loose connections. Pay close attention to any burnt components or unusual odors that may indicate overheating.

Step 2: Testing Voltage – Utilize a multimeter to measure the voltage at key points in the system. Compare the readings against the specifications provided by the manufacturer. Inconsistent voltage levels can signal underlying issues that need to be addressed.

Step 3: Continuity Checks – Perform continuity tests to ensure that electrical pathways are intact. This can help identify broken circuits or faulty connections that could disrupt operation. A lack of continuity suggests a need for further investigation.

Step 4: Component Testing – Assess individual elements such as switches, motors, and sensors. Isolate each component and verify its performance. This step is vital for pinpointing malfunctioning parts that may affect overall system efficiency.

Step 5: Document Findings – Keep detailed records of all tests and observations. This documentation can be invaluable for future reference and assists in tracking recurring issues. An organized approach facilitates better understanding and quicker resolution of problems.

By following these diagnostic steps, one can effectively uncover electrical discrepancies, ensuring the system operates reliably and efficiently. Timely detection and resolution of issues will ultimately enhance performance and longevity.

Upgrading Accessories for Better Functionality

Enhancing the performance of your cleaning equipment often involves integrating superior attachments and tools designed for specific tasks. By selecting high-quality accessories, users can significantly improve efficiency and adaptability, ensuring a more thorough and effective cleaning experience.

Investing in specialized tools, such as advanced brushes or filtration systems, can address various surfaces and materials, maximizing versatility. For instance, a premium upholstery attachment may facilitate the cleaning of delicate fabrics without damage, while a more robust nozzle can handle tougher debris on carpets.

Additionally, utilizing modern components that incorporate innovative technology can lead to better results. Features like improved suction capabilities or ergonomic designs not only streamline the cleaning process but also reduce user fatigue. Adopting these upgrades can transform routine maintenance into a more manageable and effective task.

Regularly evaluating and updating your accessories ensures that you are taking full advantage of the capabilities of your equipment. This proactive approach will lead to enhanced functionality and a more satisfying cleaning experience overall.

DIY Maintenance Tips and Tricks

Keeping your home cleaning equipment in top shape is essential for optimal performance and longevity. Regular upkeep not only enhances efficiency but also saves you money on professional services. Here are some valuable strategies to maintain your device effectively.

- Regular Filter Cleaning: Ensure that filters are cleaned frequently to maintain airflow. Clogged filters can reduce suction power significantly.

- Brush Roll Maintenance: Check the brush roll for hair and debris. Remove any obstructions to ensure it spins freely.

- Check for Blockages: Periodically inspect hoses and attachments for clogs. A quick visual check can prevent bigger issues down the line.

- Lubricate Moving Parts: Apply a suitable lubricant to moving components to reduce friction and wear.

In addition to these tasks, it’s beneficial to perform a thorough inspection of the device regularly.

- Inspect all cords for damage, ensuring safe operation.

- Replace any worn or damaged parts promptly to avoid further issues.

- Keep the exterior clean by wiping it down with a damp cloth to prevent dust buildup.

By implementing these simple practices, you can enhance the performance and lifespan of your cleaning apparatus, ensuring it serves you well for years to come.

When to Seek Professional Help

Recognizing the right moment to consult an expert can significantly enhance the longevity and performance of your equipment. While some issues can be tackled independently, others may require specialized knowledge and tools to ensure proper functioning. Understanding the signs that indicate the need for professional intervention is crucial for maintaining the integrity of your device.

Consider reaching out to a technician when you notice persistent problems that do not resolve with standard troubleshooting methods. Additionally, if the device exhibits unusual noises, lacks suction power, or shows signs of physical damage, it may be time to call in a professional.

| Signs of Trouble | Action to Take |

|---|---|

| Persistent performance issues | Consult a specialist |

| Unusual sounds during operation | Seek expert evaluation |

| Visible damage or wear | Request professional assistance |

| Inability to resolve issues | Engage a qualified technician |

Taking prompt action can prevent further complications, saving you time and resources in the long run. It’s always better to err on the side of caution and ensure your device is handled by someone with the appropriate expertise.