Comprehensive Guide to Repairing Isuzu 4HE1 Engine

Understanding the intricacies of maintaining automotive power sources is crucial for longevity and performance. This section aims to provide essential insights into the upkeep and troubleshooting of a specific model’s power unit, ensuring optimal functionality and reliability.

By following structured guidelines and recommendations, vehicle owners can effectively address common issues that may arise. This resource emphasizes practical techniques and safety measures that enhance the overall maintenance experience, making it accessible to both novice and experienced individuals.

Whether dealing with routine checks or more complex challenges, having a clear framework can significantly ease the process. Empowering oneself with knowledge in this field not only contributes to better performance but also fosters a deeper appreciation for the mechanics involved.

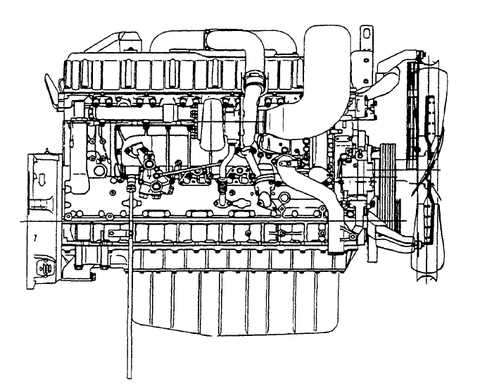

This section provides a comprehensive introduction to a specific type of power unit known for its reliability and efficiency. Understanding its components and functioning is essential for maintenance and troubleshooting. This overview will guide readers through the essential aspects of this unit, highlighting its significance in various applications.

Key Features

The power unit is characterized by its robust design and advanced technology, making it suitable for a range of vehicles and machinery. Some of the notable features include:

- Durability and longevity

- Fuel efficiency

- Easy access to parts for maintenance

Applications

This type of power unit is widely utilized in multiple industries, providing the necessary power for various tasks. Its versatility allows it to be found in:

- Commercial vehicles

- Construction equipment

- Agricultural machinery

| Specification | Details |

|---|---|

| Cylinder Configuration | Inline |

| Displacement | 2.8L |

| Power Output | Approx. 100 hp |

| Torque | 240 Nm |

Common Issues and Symptoms

This section focuses on frequent problems and their associated signs that may arise in mechanical units, helping users identify potential malfunctions early. Understanding these symptoms can assist in timely intervention and maintenance.

| Issue | Symptoms |

|---|---|

| Overheating | High temperature readings, steam, or coolant leaks |

| Unusual Noises | Knocking, ticking, or grinding sounds during operation |

| Loss of Power | Difficulty accelerating, sluggish performance |

| Excessive Smoke | Visible smoke from the exhaust, varying in color |

| Fluid Leaks | Puddles or spots of oil, coolant, or other fluids under the unit |

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the prolonged performance of your machinery. By adhering to a few straightforward practices, you can significantly extend the lifespan and efficiency of your equipment. Implementing these tips will help you avoid common pitfalls and keep your system running smoothly.

Regular Inspections

Conducting periodic checks is crucial. Inspect all components for wear and tear, ensuring that any potential issues are addressed promptly. Regular assessments can prevent minor problems from escalating into major repairs, saving both time and resources.

Proper Lubrication

Ensuring that all moving parts are adequately lubricated is vital for optimal functionality. Utilize high-quality lubricants and follow the manufacturer’s guidelines regarding intervals. This practice minimizes friction, reduces wear, and contributes to overall efficiency.

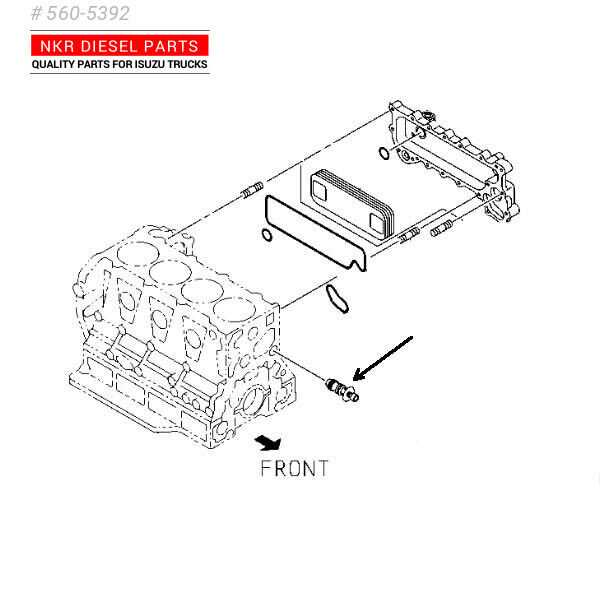

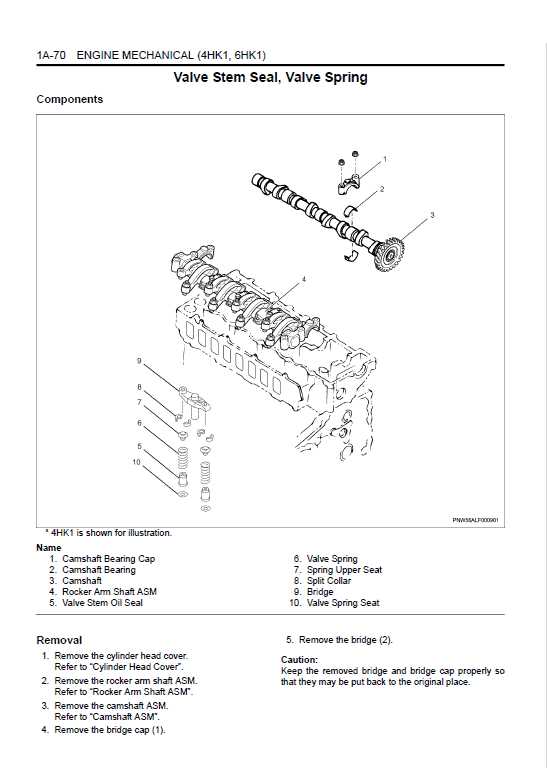

Disassembly Process Explained

This section provides a comprehensive overview of the procedure for taking apart a complex mechanical unit. Understanding the proper steps and techniques is crucial for ensuring that each component is handled with care and precision.

Before starting, it is important to gather the necessary tools and prepare a clean workspace. Each part should be organized systematically to facilitate reassembly later. Below is a summary of key steps involved in the disassembly process.

| Step | Description |

|---|---|

| 1 | Remove external covers and fasteners to access internal components. |

| 2 | Detach various assemblies carefully, ensuring no damage occurs. |

| 3 | Label and store components to avoid confusion during reassembly. |

| 4 | Inspect each part for wear or damage as they are removed. |

Reassembly Guidelines to Follow

Proper reassembly is crucial to ensure the longevity and functionality of any mechanical unit. Following specific protocols can significantly reduce the risk of errors and enhance performance. This section outlines essential practices to keep in mind during the reassembly process.

Preparation is Key: Before beginning, ensure that all components are clean and free from debris. Having a well-organized workspace can help in easily locating parts when needed.

Use Quality Parts: Always opt for high-quality components when replacing any parts. Utilizing original or reputable aftermarket components can help maintain optimal performance.

Follow Manufacturer Specifications: Refer to the specifications provided by the manufacturer for torque settings and assembly sequences. Adhering to these guidelines is essential to prevent malfunctions.

Double-Check Connections: Ensure all connections are secure and that seals and gaskets are in place to avoid leaks. A thorough inspection before finalizing the assembly can save time and resources later.

Document Your Work: Keeping a detailed record of the reassembly process can be beneficial for future reference. Note any changes made or parts replaced for easy tracking.

By following these guidelines, you can enhance the reliability and efficiency of the unit upon reassembly.

Tools Required for Repairs

When undertaking maintenance tasks, having the right instruments is essential for ensuring efficiency and precision. Proper tools not only facilitate the process but also enhance safety during operations.

The following is a list of necessary equipment:

- Wrenches of various sizes

- Screwdrivers (flathead and Phillips)

- Socket set

- Torque wrench

- Pliers and cutters

- Diagnostic tools

Additionally, it is beneficial to have the following items on hand:

- Lubricants and sealants

- Cleaning supplies

- Safety gear (gloves, goggles)

Being equipped with these tools will streamline the maintenance process and contribute to successful outcomes.

Understanding Engine Specifications

When delving into the complexities of vehicle power units, it is crucial to grasp the fundamental characteristics that define their performance and functionality. These specifications encompass various aspects, including displacement, compression ratios, and power output, which together determine how effectively the system operates under different conditions.

Familiarity with these parameters enables enthusiasts and professionals alike to make informed decisions regarding maintenance and upgrades. By understanding the implications of each specification, one can better appreciate how modifications may enhance overall efficiency and responsiveness, ensuring optimal performance in diverse driving scenarios.

Diagnostic Techniques for Troubleshooting

Effective diagnostics are essential for identifying issues in various mechanical systems. This section focuses on systematic approaches to detect malfunctions, ensuring efficient problem resolution.

Common Diagnostic Methods

Several techniques can be employed to diagnose problems effectively:

- Visual Inspection: Checking for obvious signs of wear, leaks, or damage.

- Sound Analysis: Listening for unusual noises that may indicate underlying issues.

- Performance Testing: Measuring operational parameters to identify discrepancies.

Utilizing Diagnostic Tools

Employing specialized tools can enhance the troubleshooting process:

- Multimeter: Used to check electrical components and circuits.

- Compression Tester: Measures the pressure within the system to ensure proper functionality.

- Scan Tool: Analyzes electronic systems and retrieves error codes for further investigation.

Parts Replacement Recommendations

Maintaining optimal performance and longevity of a power unit requires regular assessment and timely replacement of critical components. This section highlights essential recommendations for part substitutions to ensure smooth operation.

Here are key components that may require replacement over time:

- Filters:

- Air filters should be replaced regularly to maintain airflow efficiency.

- Oil filters need replacement at scheduled intervals to ensure proper lubrication.

- Fuel filters should be checked and replaced to prevent contamination.

- Belts and Hoses:

- Timing belts should be inspected and replaced as recommended to avoid breakdowns.

- Radiator hoses need regular checks for cracks or leaks and should be replaced as necessary.

- Gaskets and Seals:

- Gaskets may wear over time, requiring replacement to prevent leaks.

- Seals should be examined and replaced to maintain pressure and fluid integrity.

By following these recommendations, users can enhance the reliability and efficiency of their machinery.

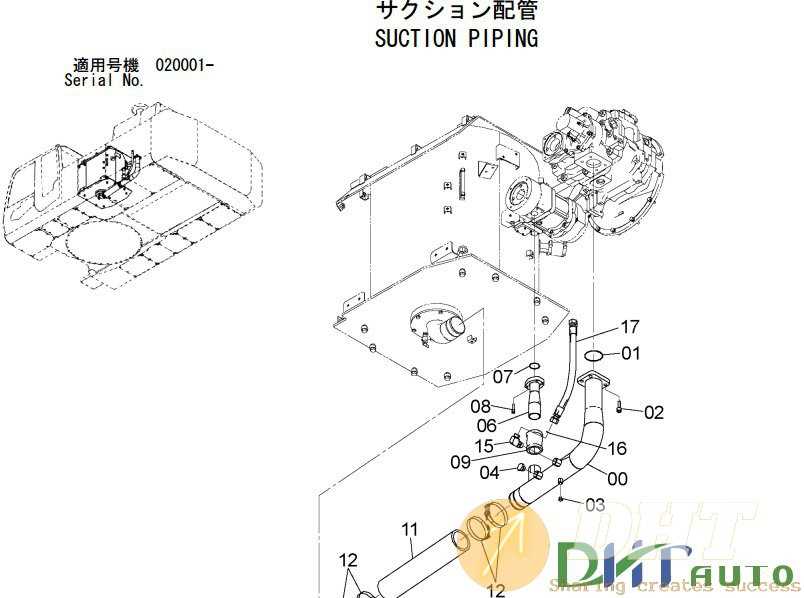

Fuel System Maintenance Steps

Proper upkeep of the fuel system is crucial for optimal performance and longevity of the vehicle. Regular maintenance not only enhances fuel efficiency but also prevents potential issues that may arise from neglecting this vital component.

Inspection Procedures

Conducting routine inspections is essential to identify any irregularities within the fuel system. Follow these steps:

- Check for fuel leaks around the fuel lines and connections.

- Inspect the fuel filter for signs of clogs or contamination.

- Examine the fuel pump for proper operation and pressure levels.

Maintenance Actions

Implementing regular maintenance actions can significantly improve the efficiency of the fuel system:

- Replace the fuel filter according to the manufacturer’s recommendations.

- Clean or replace fuel injectors if necessary.

- Ensure that the fuel lines are free from obstructions and damage.

Cooling System Repair Insights

The cooling system plays a vital role in maintaining optimal operating temperatures within a vehicle’s mechanism. Ensuring its efficiency is crucial to prevent overheating and to prolong the lifespan of components. This section delves into common issues and solutions related to this essential system.

Regular inspection of hoses, radiators, and pumps can help identify potential leaks or blockages. It’s important to check coolant levels frequently and to replace old fluid with a suitable mixture to maintain proper heat transfer. Addressing any signs of corrosion or wear promptly can prevent larger issues down the line.

When servicing the cooling system, consider using high-quality parts to ensure compatibility and longevity. Proper installation techniques are essential to avoid future problems. Familiarizing oneself with the system’s layout will aid in efficient troubleshooting and maintenance.

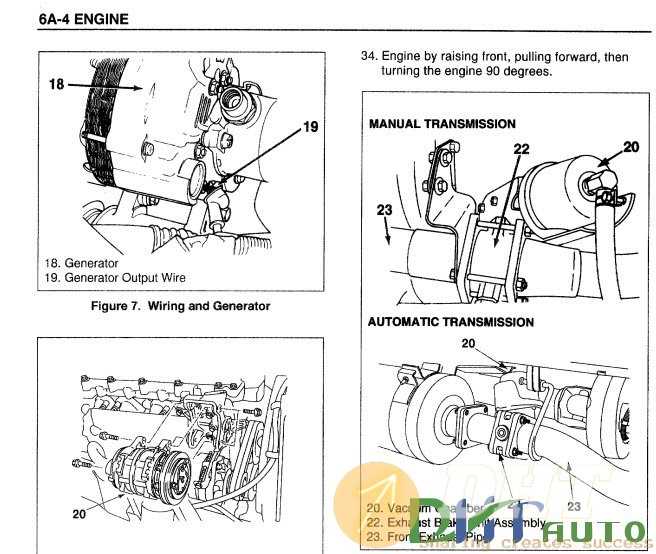

Electrical System Check Procedures

This section outlines essential steps for verifying the functionality of the electrical components within the system. A thorough examination helps ensure optimal performance and longevity, reducing the likelihood of future issues.

Initial Inspection Steps

Before conducting detailed checks, perform an initial inspection to identify any visible issues. Follow these steps:

- Examine all wiring for signs of wear or damage.

- Check battery connections for corrosion or looseness.

- Inspect fuses for integrity and replace if necessary.

Functional Testing

After the initial inspection, proceed with functional testing of key components:

- Test the battery voltage using a multimeter. Ensure it meets specified levels.

- Evaluate the alternator output under load conditions.

- Check the starter motor operation and connections for reliability.

Safety Precautions During Repairs

When conducting maintenance tasks on mechanical systems, it is crucial to prioritize safety to prevent accidents and injuries. Following proper guidelines ensures a secure environment for both the technician and the equipment involved.

Firstly, always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and sturdy footwear. This gear minimizes the risk of injury from sharp objects or hazardous substances.

Secondly, ensure that the workspace is well-ventilated and free from any flammable materials. Proper ventilation helps to dissipate potentially harmful fumes that may be released during maintenance activities.

Additionally, familiarize yourself with the tools and materials you will be using. Understanding the operation of each tool can prevent misuse and enhance efficiency.

Finally, keep a first-aid kit readily accessible in case of emergencies. Being prepared for unforeseen incidents is vital in maintaining a safe working environment.