Dodge Pickup Repair Guide for Enthusiasts

This section provides an extensive overview of the essential procedures and techniques necessary for the upkeep of robust transportation models. Understanding the intricacies involved in maintaining these vehicles can significantly enhance their performance and longevity.

From troubleshooting common issues to performing routine checks, this guide aims to equip owners with the knowledge required for effective care. By familiarizing oneself with various components and systems, individuals can address potential problems proactively and ensure optimal operation.

Whether you are an experienced enthusiast or a novice, this resource will serve as a valuable tool for anyone looking to deepen their understanding of vehicle maintenance. Embracing these practices not only contributes to a smoother driving experience but also fosters a sense of ownership and responsibility for your automobile.

Essential Tools for Dodge Pickup Repairs

When it comes to maintaining your vehicle, having the right instruments is crucial for ensuring efficient and effective work. Whether you’re addressing minor issues or tackling more complex tasks, a well-equipped toolkit can make all the difference. This section highlights the fundamental tools that every enthusiast should consider for optimal performance and reliability.

Basic Hand Tools

Starting with the essentials, a variety of hand tools forms the backbone of any effective toolkit. Wrenches and sockets are vital for loosening or tightening bolts, while screwdrivers in different sizes and types help with various fasteners. Plier sets can assist in gripping and bending components, making them invaluable for many tasks.

Diagnostic Equipment

In addition to traditional hand tools, having access to diagnostic equipment can significantly enhance your ability to troubleshoot issues. Tools such as OBD-II scanners allow for reading error codes and monitoring vehicle performance. Multimeters are also essential for electrical diagnostics, helping to identify wiring problems and voltage issues efficiently.

Understanding Engine Maintenance Procedures

Proper upkeep of an engine is essential for ensuring optimal performance and longevity. This section outlines fundamental practices that can enhance the functionality and efficiency of your vehicle’s powertrain. Regular maintenance not only helps prevent unforeseen breakdowns but also contributes to improved fuel efficiency and reduced emissions.

Key Maintenance Tasks

- Regular oil changes

- Inspecting and replacing air filters

- Monitoring fluid levels and conditions

- Checking and replacing spark plugs

- Ensuring belts and hoses are in good condition

Benefits of Routine Upkeep

- Increased engine lifespan

- Enhanced fuel economy

- Reduction in harmful emissions

- Improved overall performance

Following these procedures can lead to a more reliable and efficient vehicle. Adhering to a regular maintenance schedule is crucial for optimal engine health.

Common Issues in Dodge Pickups

Vehicles of this brand often encounter a range of frequent complications that can affect performance, safety, and longevity. Understanding these common problems can help owners proactively address them, ensuring a smoother driving experience and potentially reducing repair costs.

Some of the typical concerns include engine performance issues, transmission troubles, and electrical system malfunctions. Recognizing the signs early can prevent further damage and enhance reliability.

| Issue | Description | Possible Solution |

|---|---|---|

| Engine Misfire | Uneven engine operation, leading to reduced power and efficiency. | Inspect ignition components and replace faulty spark plugs or coils. |

| Transmission Slippage | Unexpected changes in gear or loss of power during acceleration. | Check fluid levels and quality; consider a fluid change or professional assessment. |

| Electrical Failures | Malfunctions in lighting, starting, or charging systems. | Examine wiring and connections; replace blown fuses or faulty components. |

| Brake Wear | Squeaking or grinding noises when braking, indicating worn pads or rotors. | Inspect brake components and replace as necessary for safety. |

| Suspension Problems | Uneven tire wear or a rough ride due to suspension wear. | Check shocks and struts; replace worn components to improve handling. |

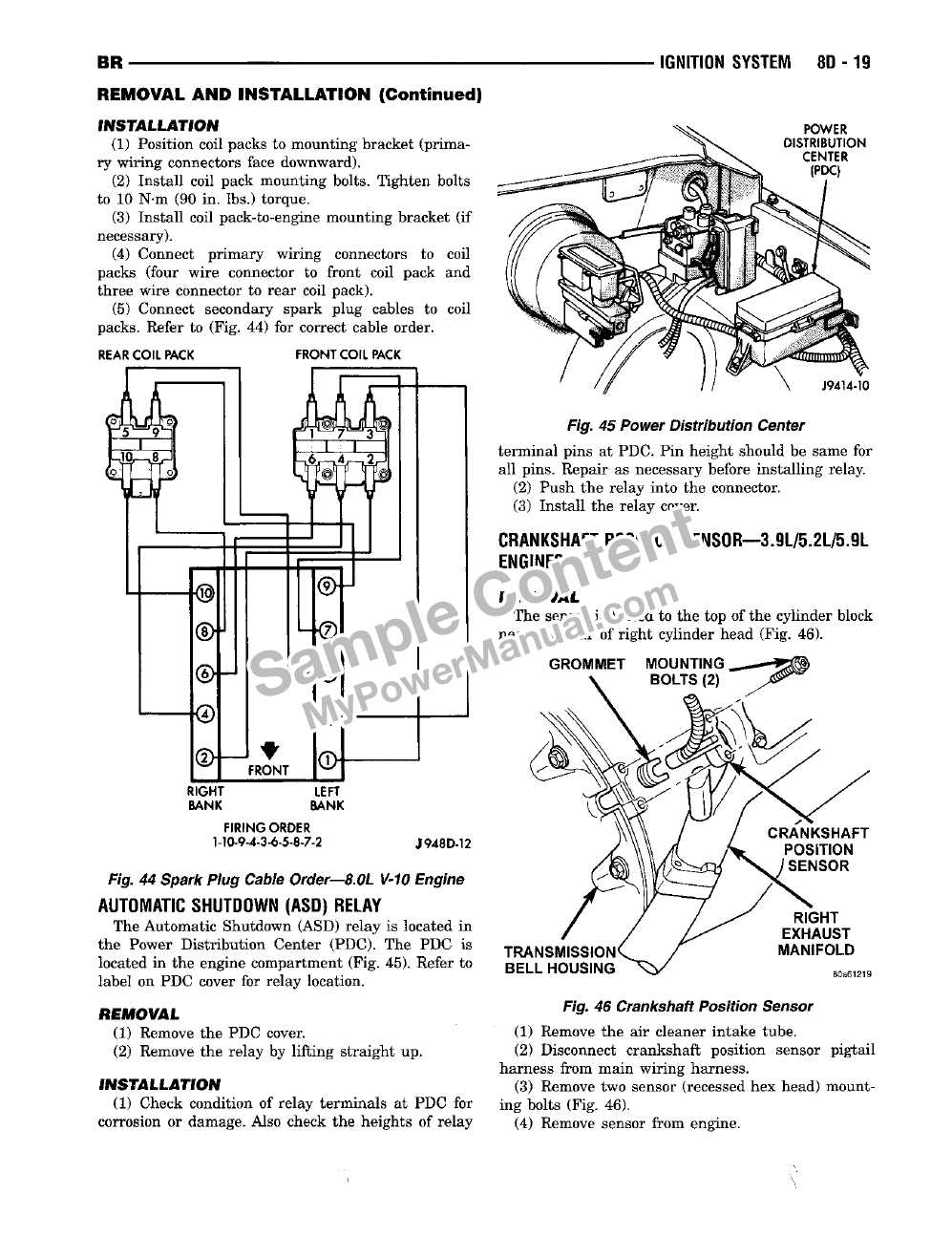

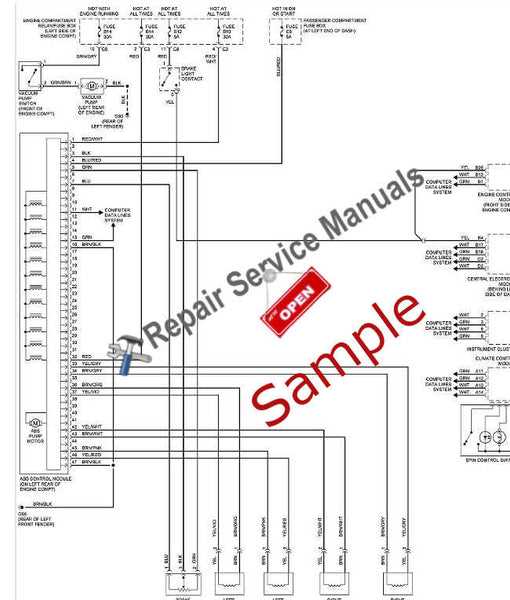

How to Troubleshoot Electrical Problems

Tackling electrical issues can often be a daunting task, but understanding the basic principles of troubleshooting can simplify the process. Identifying the root cause of a malfunctioning system involves systematic examination and a methodical approach to isolate potential failures. By following specific steps, one can effectively diagnose and resolve various electrical dilemmas.

Begin with Safety: Before diving into diagnostics, ensure that safety measures are in place. Disconnect the power source to prevent any accidental shocks or short circuits while inspecting wiring and components.

Visual Inspection: Start by examining all visible connections, wires, and components. Look for signs of damage, corrosion, or loose connections that could disrupt the electrical flow. Pay attention to frayed wires and burnt terminals, as these can indicate a problem.

Utilize Diagnostic Tools: Employ a multimeter to measure voltage, resistance, and continuity within the circuit. This tool is essential for checking if power is reaching different parts of the system. Start by testing the battery and work your way through the circuit.

Check Fuses and Relays: Inspect all fuses and relays associated with the electrical system. A blown fuse or malfunctioning relay can cause complete system failure. Replace any faulty components and recheck the system.

Follow Wiring Diagrams: Refer to the electrical schematics for the specific system. These diagrams provide valuable insights into how components are interconnected and can guide you in pinpointing areas that may require further investigation.

Test Components Individually: If issues persist, isolate individual components such as switches, motors, and sensors. By testing these parts independently, you can determine if they are functioning correctly or need replacement.

Consult Professional Help: If the problem remains unresolved despite thorough troubleshooting, seeking assistance from a qualified technician can save time and prevent further complications. Their expertise can be invaluable in addressing complex electrical issues.

Fluid Replacement Intervals Explained

Regularly changing vital liquids in vehicles is crucial for maintaining optimal performance and longevity. Understanding the recommended schedules for these replacements can help ensure that all systems function smoothly, reducing the likelihood of unexpected breakdowns and costly repairs.

Engine oil is one of the most critical fluids, as it lubricates moving parts and prevents wear. It’s generally advised to replace it every 5,000 to 7,500 miles, though this can vary based on driving conditions and oil type.

Transmission fluid plays a vital role in ensuring smooth gear transitions and should be replaced approximately every 30,000 to 60,000 miles. Regular checks can help identify any signs of contamination or degradation early on.

Coolant is essential for regulating engine temperature. A typical interval for changing coolant is every 30,000 miles, but it’s essential to monitor the fluid’s condition regularly, as factors like leaks or overheating can accelerate its breakdown.

Brake fluid is another critical liquid that should not be overlooked. It’s advisable to replace it every two years or 24,000 miles to maintain the effectiveness of the braking system.

Lastly, power steering fluid should be checked regularly, with replacements suggested every 50,000 miles to ensure proper steering functionality and prevent wear on the components.

By adhering to these fluid replacement intervals, vehicle owners can help ensure their automobile runs efficiently, prolong its lifespan, and enhance overall safety on the road.

Step-by-Step Brake System Overhaul

This section outlines the comprehensive procedure for refreshing the braking mechanism of your vehicle. A well-functioning braking system is crucial for safety and performance. The following guide will walk you through each phase, ensuring a systematic approach to enhance the efficiency and reliability of your braking components.

Preparation and Safety Measures

Before commencing the overhaul, it is essential to gather the necessary tools and components. Make sure to prioritize safety by wearing protective gear and working in a well-ventilated space. Below is a list of required tools and materials:

| Tools | Materials |

|---|---|

| Socket set | Brake pads |

| Wrench set | Brake rotors |

| Jack and jack stands | Brake fluid |

| Brake cleaner | New hardware (if needed) |

Step-by-Step Procedure

Follow these steps to successfully overhaul the braking system:

- Lift the vehicle using a jack and secure it with jack stands.

- Remove the wheels to gain access to the braking assembly.

- Detach the calipers by unscrewing the bolts and carefully sliding them off the rotors.

- Replace the old brake pads with new ones, ensuring proper alignment.

- Inspect and, if necessary, replace the brake rotors to prevent uneven wear.

- Reassemble the calipers, ensuring all bolts are tightened to the manufacturer’s specifications.

- Refill the brake fluid reservoir and bleed the system to eliminate any air pockets.

- Reinstall the wheels and lower the vehicle back to the ground.

- Conduct a thorough test of the braking system to ensure everything functions smoothly.

Transmission Diagnostics and Solutions

Understanding the intricacies of a vehicle’s transmission system is essential for effective troubleshooting and maintenance. This section provides insights into common issues that can arise within this critical component and offers guidance on identifying and resolving them efficiently.

Common Symptoms and Their Causes

Vehicles may exhibit various symptoms indicating transmission troubles. Slipping gears can often point to low fluid levels or worn components, while unusual noises might suggest internal damage or improper lubrication. Additionally, hesitation during acceleration could be a sign of failing sensors or electronic control issues.

Troubleshooting Techniques

To diagnose transmission problems accurately, start with a thorough inspection of the fluid condition and levels. Utilizing diagnostic tools can help retrieve error codes that provide insight into electronic malfunctions. Visual checks for leaks and damage can also reveal underlying issues. Once the problem is identified, implementing appropriate solutions, such as fluid replacement or component repairs, will restore optimal functionality.

Body Repair Techniques for Beginners

Learning the fundamentals of automotive bodywork is essential for those looking to enhance their skills. This section will cover various methods that can help novices gain confidence in fixing and restoring vehicle exteriors. Understanding these techniques can lead to effective solutions for minor damages and overall improvements in appearance.

Here are some key techniques to get started:

- PDR (Paintless Dent Removal): This method involves gently massaging the metal back to its original shape without damaging the paint. It’s ideal for small dents and dings.

- Filler Application: When dealing with larger imperfections, using body filler can help restore the surface. Proper sanding and shaping are critical for achieving a smooth finish.

- Rust Treatment: Addressing rust early is crucial. Sanding down affected areas and applying rust-inhibiting primer can prevent further deterioration.

- Painting: Matching paint color is essential for a seamless look. Beginners should practice blending techniques and learn about spray patterns to achieve a professional appearance.

- Panel Replacement: For severely damaged sections, replacing panels may be necessary. Learning to remove and install panels properly is an important skill to master.

Each of these techniques can be learned through practice and patience. Beginners should start with minor projects to build their confidence and understanding before tackling more complex tasks.

Suspension System Adjustments Made Easy

Ensuring optimal performance of your vehicle’s suspension is crucial for a smooth and safe ride. This section will guide you through essential modifications and settings that can enhance handling and comfort. By following straightforward procedures, you can achieve a well-balanced and responsive system.

Understanding Suspension Components

Familiarizing yourself with the various parts of the suspension is the first step toward effective adjustments. Key components include:

- Shock absorbers

- Springs

- Control arms

- Ball joints

- Stabilizer bars

Steps for Adjustment

To achieve the desired performance, follow these simple steps:

- Inspect the components for wear and damage.

- Check the alignment to ensure proper handling.

- Adjust the shock absorbers for stiffness or softness based on your driving needs.

- Modify the spring height for improved ground clearance or handling.

- Test drive the vehicle to assess the changes and make further adjustments if necessary.

By implementing these adjustments, you will significantly improve your vehicle’s ride quality and stability, enhancing overall driving enjoyment.

Understanding the Exhaust System Components

The exhaust system plays a vital role in directing harmful gases away from the engine while enhancing performance and minimizing noise. Understanding its various parts is essential for effective maintenance and troubleshooting.

At the core of the exhaust system is the manifold, which collects exhaust gases from the engine cylinders and funnels them into the piping. This component is critical for efficient gas flow and engine performance. Connected to the manifold, the catalytic converter serves to reduce harmful emissions by facilitating chemical reactions that transform pollutants into less harmful substances.

Following the converter is the muffler, designed to dampen the noise produced during the exhaust process. This part is essential not only for comfort but also for compliance with noise regulations. Finally, the exhaust pipe expels the treated gases into the atmosphere, ensuring that the entire system functions seamlessly.

Regular inspection and maintenance of these components can lead to improved performance, increased fuel efficiency, and extended lifespan of the vehicle. Understanding how each part contributes to the overall system allows for better-informed decisions regarding repairs and enhancements.

Preventive Maintenance for Longevity

Ensuring the extended lifespan of your vehicle requires consistent care and attention. By implementing regular checks and services, you can avoid costly repairs and enhance performance. This section outlines essential strategies for maintaining your automobile in optimal condition, thereby increasing reliability and reducing wear over time.

Key Maintenance Tasks

Regular upkeep involves a variety of tasks aimed at preserving the functionality of critical components. Adopting a routine inspection schedule can significantly contribute to the vehicle’s longevity. Below are fundamental actions to incorporate into your maintenance plan:

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 5,000 miles | Replacing engine oil helps prevent sludge buildup and ensures smooth engine operation. |

| Tire Rotation | Every 6,000 miles | Changing the position of tires promotes even wear and extends their life. |

| Brake Inspection | Every 10,000 miles | Checking brake pads and rotors ensures safe stopping power and prevents damage. |

| Fluid Levels Check | Monthly | Regularly checking and topping off fluids (coolant, brake fluid, transmission fluid) maintains optimal vehicle performance. |

| Battery Check | Every 6 months | Testing battery health and connections prevents unexpected failures. |

Benefits of Preventive Care

Investing time in maintenance yields numerous advantages. Not only does it enhance safety, but it also promotes fuel efficiency and preserves vehicle value. Additionally, addressing minor issues before they escalate into significant problems ensures a smoother driving experience and reduces downtime.

Upgrading Parts for Improved Performance

Enhancing vehicle components can lead to significant improvements in overall functionality and efficiency. By investing in superior parts, owners can experience enhanced power, better handling, and increased durability. This section explores various upgrades that can elevate your vehicle’s performance and driving experience.

Key Components to Consider

When focusing on upgrades, several crucial parts play a vital role in optimizing performance. From engine enhancements to suspension modifications, each component contributes uniquely to the vehicle’s capabilities.

| Component | Upgrade Type | Benefits |

|---|---|---|

| Engine | Cold Air Intake | Increased airflow for improved horsepower and torque |

| Exhaust System | Performance Muffler | Enhanced exhaust flow for better engine efficiency |

| Suspension | Upgraded Shocks | Improved handling and ride comfort |

| Brakes | High-Performance Pads | Quicker stopping power and reduced fade |

Conclusion

Investing in high-quality components can transform your vehicle’s performance. Each upgrade not only enhances specific features but also contributes to an overall better driving experience. Consider your priorities and choose the right modifications to achieve the desired results.