Comprehensive Guide to Ford F53 Repair Manual

When it comes to ensuring the longevity and performance of a large vehicle, having access to detailed information is crucial. Understanding the intricacies of various components can significantly impact the overall functionality and safety. This resource is designed to provide invaluable insights into the upkeep of specific models, facilitating smoother operations for owners and technicians alike.

In the realm of automotive care, familiarity with systematic procedures can save both time and resources. From troubleshooting common issues to performing regular checks, a structured approach allows for effective management of any vehicle. Knowledge of specifications and techniques is essential for those looking to enhance their skills and tackle challenges with confidence.

Equipping oneself with the right information not only promotes better maintenance practices but also empowers users to make informed decisions. With a focus on clarity and accessibility, this guide aims to break down complex topics into manageable sections, catering to both novices and experienced individuals. By embracing this knowledge, vehicle owners can navigate the complexities of maintenance more effectively.

Overview of Specifications

This section provides a comprehensive understanding of the key characteristics and technical details of a prominent chassis model. These specifications are crucial for assessing performance, compatibility, and overall functionality, ensuring that users can make informed decisions regarding maintenance and modifications.

| Attribute | Details |

|---|---|

| Engine Type | V8 Gasoline Engine |

| Horsepower | 350 hp |

| Torque | 468 lb-ft |

| Transmission | 6-Speed Automatic |

| Wheelbase | 158 inches |

| GVWR | 22,000 lbs |

| Fuel Capacity | 55 gallons |

| Brakes | Disc Brakes |

| Rear Axle Ratio | 4.10:1 |

Understanding these specifications can help in diagnosing issues and planning for any required adjustments or upgrades. Familiarity with the fundamental attributes enhances the ability to ensure optimal performance and reliability.

Common Issues with Ford F53

Vehicle owners often encounter various challenges that can arise over time, affecting performance and reliability. Understanding these frequent problems can help in taking proactive measures to ensure optimal functionality and longevity.

Engine Performance Troubles

One prevalent issue involves engine performance, where drivers may experience reduced power or stalling. This can be attributed to several factors, including fuel delivery problems, clogged filters, or ignition system failures. Regular maintenance checks are crucial to identify these issues early and avoid costly repairs.

Transmission Complications

Transmission-related difficulties are another common concern. Symptoms such as slipping gears, delayed engagement, or unusual noises can indicate underlying problems. It’s essential to monitor fluid levels and schedule routine inspections to prevent significant damage and ensure smooth operation.

Addressing these common challenges promptly can greatly enhance the overall driving experience and maintain the vehicle’s reliability.

Essential Tools for Repairing Ford F53

Maintaining a large vehicle requires a specific set of instruments to ensure effective and efficient servicing. Having the right tools at hand not only simplifies the process but also enhances the quality of the work. Below are some essential items that should be part of your toolkit when working on these robust machines.

Basic Hand Tools

- Socket set – Various sizes for different fasteners.

- Wrenches – Both standard and adjustable for versatility.

- Screwdrivers – Flathead and Phillips in multiple sizes.

- Pliers – Needle-nose and standard for gripping and bending.

Specialized Equipment

- Torque wrench – Ensures bolts are tightened to the correct specifications.

- Jack stands – Provides safety when lifting the vehicle.

- Oil filter wrench – Aids in easy removal of filters.

- Multimeter – Essential for electrical diagnostics.

Equipping yourself with these tools will facilitate a smoother and more successful maintenance experience, ensuring your vehicle remains in top condition.

Step-by-Step Repair Procedures

This section provides a comprehensive guide for troubleshooting and addressing common issues encountered with the vehicle. By following systematic methods, you can ensure that each task is executed effectively, leading to optimal performance and longevity.

1. Preparation: Begin by gathering all necessary tools and parts required for the task. Ensure that you have a clean workspace to facilitate efficient work.

2. Safety First: Always prioritize safety by wearing appropriate gear, including gloves and goggles. Disconnect the battery to prevent any electrical mishaps.

3. Diagnosis: Identify the specific problem by conducting a thorough assessment. Use diagnostic tools to read any error codes, and perform visual inspections to pinpoint issues.

4. Disassembly: Carefully remove components that obstruct access to the affected area. Label each part to avoid confusion during reassembly.

5. Repair or Replacement: Based on your findings, either repair the damaged component or replace it with a new one. Ensure that all replacements are compatible with your specific model.

6. Reassembly: Reattach all components in the reverse order of disassembly. Double-check that all connections are secure and that nothing is left loose.

7. Testing: Once reassembled, conduct a test to confirm that the issue has been resolved. Monitor the vehicle for any unusual noises or performance issues.

8. Documentation: Finally, document the work performed, including any parts replaced and observations made during the process. This record will be useful for future reference.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended life and optimal performance of any vehicle. Regular attention to various components not only enhances functionality but also prevents costly repairs down the line. Here are some effective strategies to maintain your vehicle’s health over time.

Routine Checks

- Perform regular inspections of fluid levels, including oil, coolant, and transmission fluid.

- Check tire pressure monthly and ensure proper tread depth for safety and efficiency.

- Examine brake systems for wear, and replace pads as necessary to maintain stopping power.

Scheduled Maintenance

- Adhere to the manufacturer’s recommended service schedule, which outlines essential tasks.

- Replace air and fuel filters at designated intervals to optimize engine performance.

- Keep an eye on the battery condition and clean terminals to avoid electrical issues.

By implementing these tips consistently, you can significantly enhance the lifespan and reliability of your vehicle, ensuring it remains in excellent condition for years to come.

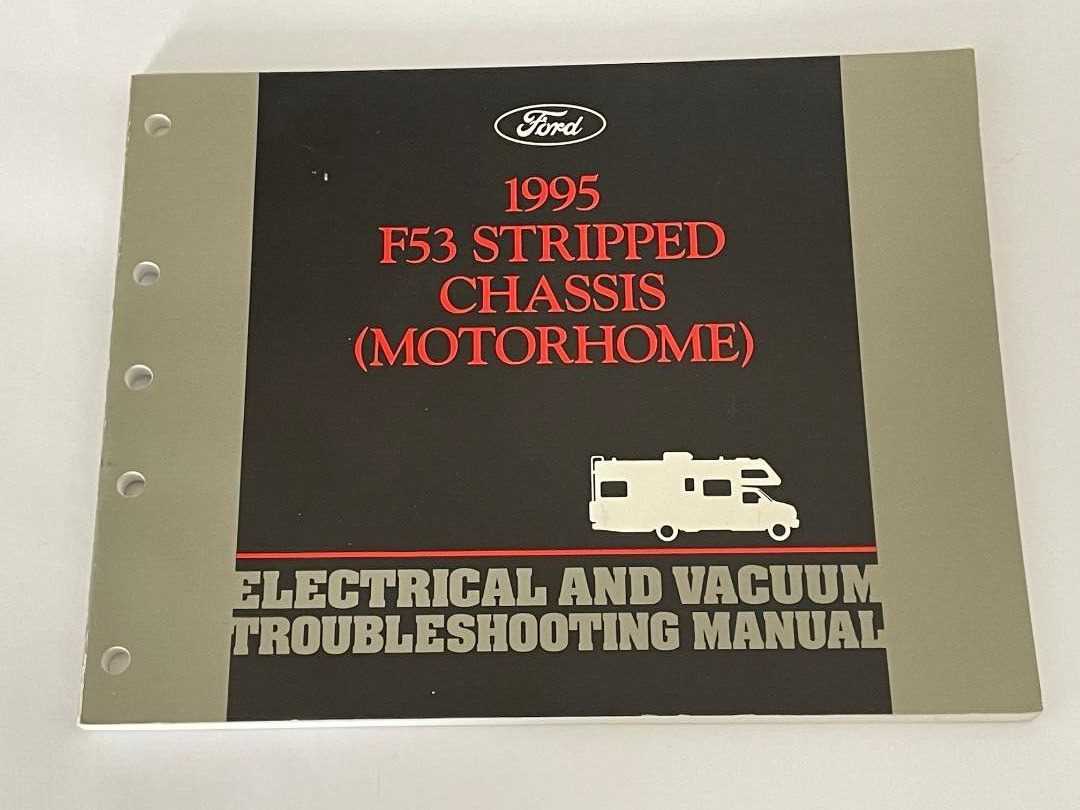

Understanding the Electrical System

The electrical system of a vehicle plays a crucial role in its overall functionality and performance. It consists of various components that work together to ensure efficient operation and reliability. A thorough comprehension of this system is essential for diagnosing issues and performing maintenance effectively.

Key components of the electrical system include:

- Battery: The primary source of electrical energy, providing power for starting the engine and operating electrical accessories.

- Alternator: Responsible for charging the battery and powering electrical systems while the engine is running.

- Wiring Harness: A network of wires that connects various electrical components, facilitating communication and power distribution.

- Fuses and Relays: Safety devices that protect the electrical circuits from overload and ensure proper functioning of various components.

- ECU (Electronic Control Unit): The brain of the vehicle, managing engine functions and various electronic systems.

Understanding how these components interact is vital. Here are some common issues that may arise within the electrical system:

- Battery failure due to age or corrosion.

- Alternator malfunction leading to insufficient charging.

- Damaged wiring causing shorts or open circuits.

- Blown fuses affecting critical systems.

- ECU errors disrupting performance and diagnostics.

By familiarizing oneself with the electrical system and its components, vehicle owners can better troubleshoot problems and maintain their vehicles in optimal condition.

Transmission Troubleshooting Techniques

When facing challenges with a vehicle’s shifting system, identifying the root cause is essential for effective resolution. A systematic approach can help diagnose issues, ensuring proper functioning and longevity of the component.

Begin by observing any symptoms, such as slipping gears, unusual noises, or delayed engagement. These indicators can provide valuable insights into the underlying problems. Listening carefully to sounds during operation may reveal issues with components like bearings or clutches.

Next, check fluid levels and quality. Low or contaminated fluid can significantly impact performance. Assess the color and texture; dark or gritty fluid may indicate the need for a change or further investigation into potential leaks.

Using diagnostic tools can enhance your understanding of the situation. Scanning for error codes can pinpoint specific malfunctions within the electronic control systems, guiding you toward appropriate actions. Regular maintenance and inspections are key in preventing more severe complications.

Finally, consider consulting technical documentation for specific models, as they may provide additional insights tailored to unique designs. Adopting a thorough, methodical approach will lead to more effective troubleshooting and resolution of transmission issues.

Engine Diagnostics and Solutions

The process of assessing engine performance is crucial for identifying issues that may affect vehicle efficiency and longevity. Understanding how to diagnose problems and apply appropriate solutions ensures that the engine operates smoothly and effectively. This section provides an overview of common diagnostic techniques and remedies to keep the engine in optimal condition.

Common Diagnostic Techniques

Various methods can be employed to diagnose engine-related issues. Utilizing advanced tools and technologies allows for precise identification of malfunctions. Below is a table summarizing some prevalent diagnostic techniques:

| Technique | Description |

|---|---|

| OBD-II Scanning | Utilizing an onboard diagnostic scanner to retrieve trouble codes and assess performance issues. |

| Compression Testing | Measuring the pressure in the cylinders to evaluate the engine’s internal condition. |

| Visual Inspection | Conducting a thorough examination of engine components for wear and damage. |

| Leak-Down Testing | Assessing the integrity of the cylinders by measuring air loss. |

Effective Solutions

Once diagnostics are completed, implementing suitable solutions is essential. Addressing the identified issues promptly can prevent further damage and enhance performance. Here are some common solutions:

| Problem | Solution |

|---|---|

| Poor Fuel Efficiency | Cleaning or replacing fuel injectors to improve fuel delivery. |

| Engine Overheating | Checking and replacing the thermostat or radiator if necessary. |

| Rough Idle | Inspecting and adjusting the ignition system components. |

| Excessive Smoke | Determining oil leaks and replacing damaged seals or gaskets. |

Brake System Maintenance Guidelines

Ensuring the optimal performance of the braking mechanism is crucial for vehicle safety and reliability. Regular upkeep and timely inspections can prevent issues that may compromise effectiveness and lead to costly repairs. Following these maintenance recommendations will help prolong the lifespan of your braking components and enhance overall driving experience.

The maintenance of the brake system involves several key practices, including inspection, cleaning, and replacement of worn parts. Below is a summary of essential guidelines to follow:

| Maintenance Task | Frequency | Description |

|---|---|---|

| Visual Inspection | Every Month | Check for signs of wear, leaks, and corrosion on brake components. |

| Brake Pad Replacement | Every 20,000-30,000 Miles | Replace pads when thickness falls below 3 mm to maintain stopping power. |

| Fluid Check and Change | Every 2 Years | Inspect brake fluid for contamination; replace if necessary to ensure effective braking. |

| Brake Rotor Inspection | Every 30,000 Miles | Check for warping or scoring; resurfacing may be required. |

| Brake Line Inspection | Every Year | Look for cracks, corrosion, and leaks; replace damaged lines immediately. |

Adhering to these guidelines will significantly reduce the likelihood of brake failure and enhance your vehicle’s safety on the road. Always consult a professional if you notice any irregularities during your inspections.

Finding Quality Replacement Parts

When it comes to maintaining vehicles, sourcing high-quality components is crucial for ensuring longevity and optimal performance. Selecting the right parts can greatly influence not only the efficiency but also the overall safety of your automobile. It is essential to approach the process with a keen eye for quality and reliability.

Research is key. Start by exploring reputable suppliers and manufacturers known for their durability and precision. Look for reviews and testimonials from other users to gauge their experiences. Additionally, consider whether the components are OEM (Original Equipment Manufacturer) or aftermarket. While OEM parts typically offer guaranteed compatibility and quality, aftermarket options can provide cost savings and unique features.

Moreover, understanding specifications is vital. Ensure that any replacement part meets or exceeds the original equipment standards. This knowledge can help you avoid subpar alternatives that may lead to future complications or repairs.

Finally, building relationships with trusted vendors can be invaluable. Establishing a rapport with reliable suppliers can lead to better deals, informed advice, and timely service. These connections can also provide insights into upcoming trends and new products in the market.

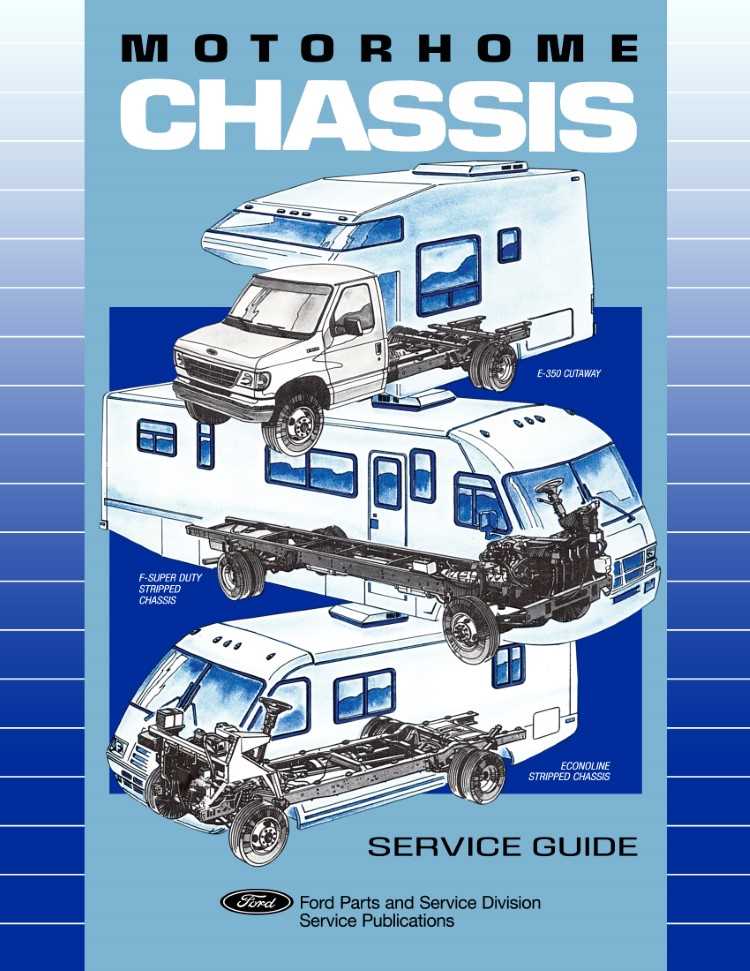

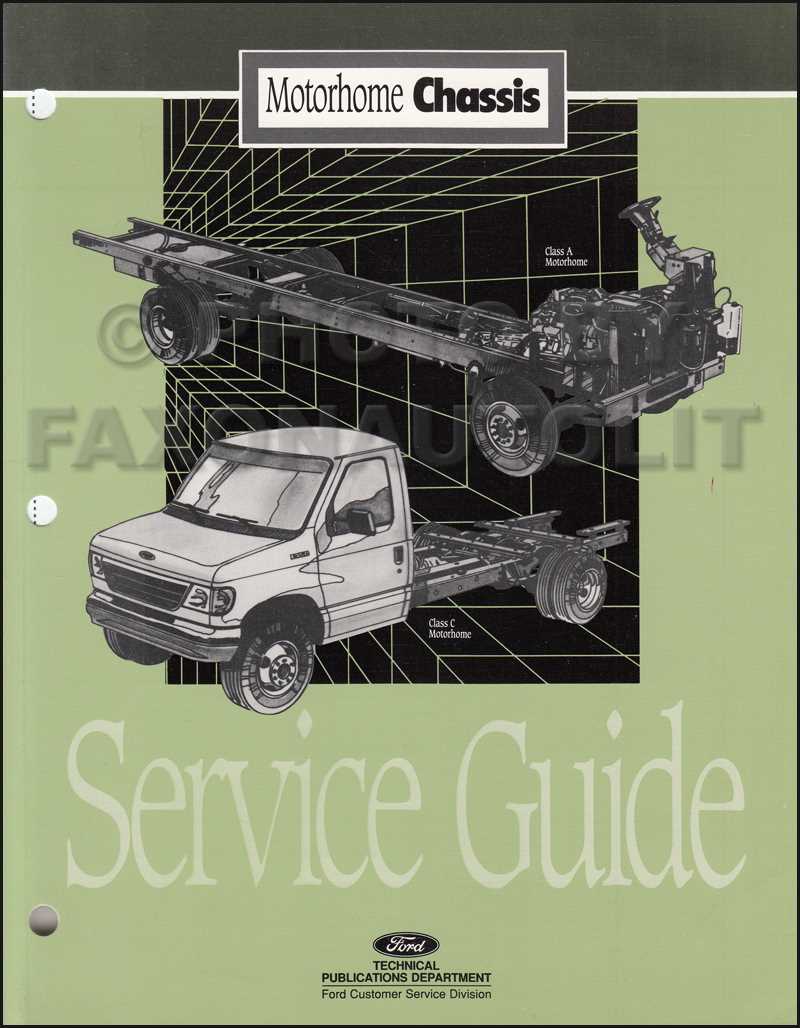

Using the Repair Manual Effectively

Maximizing the benefits of a service guide requires a strategic approach. By understanding how to navigate and utilize the resource, users can efficiently address vehicle issues and perform maintenance tasks. This section provides insights on how to get the most out of your reference material.

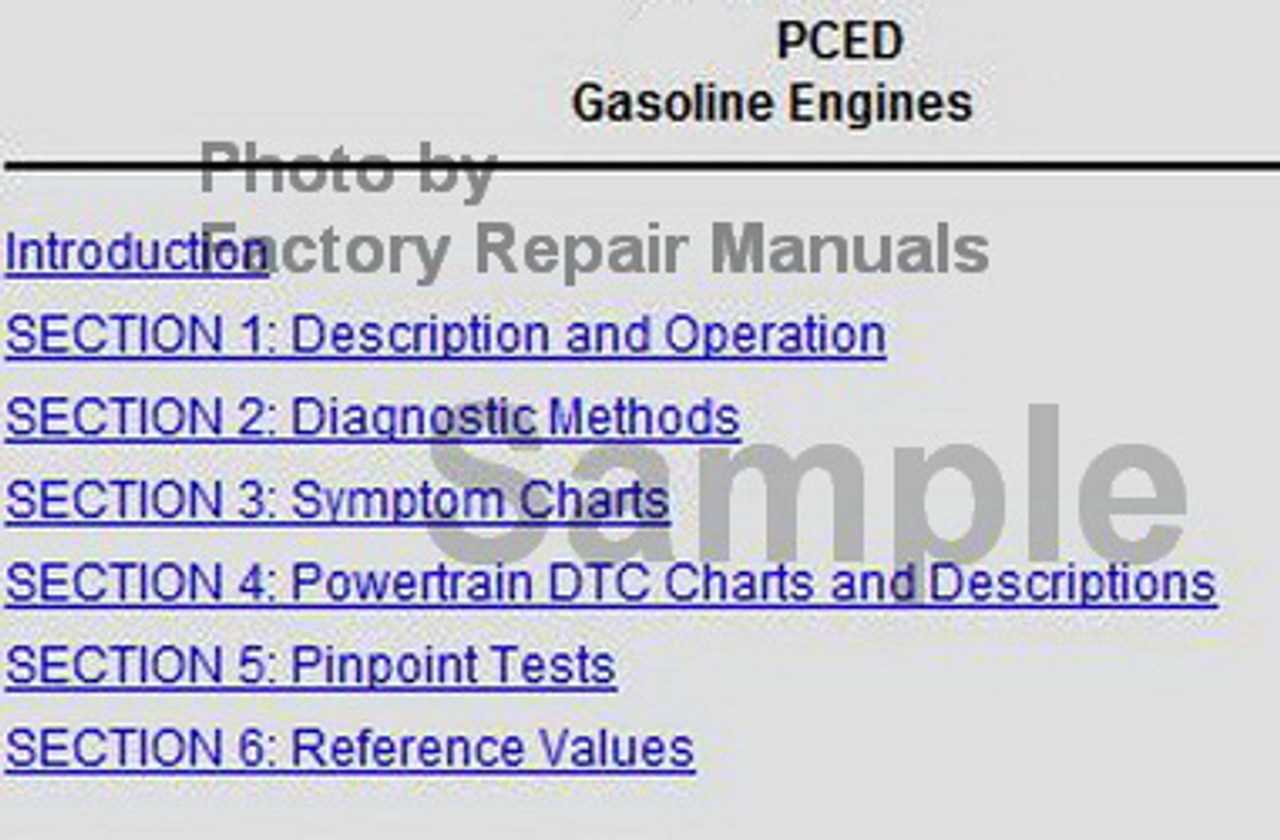

Familiarize Yourself with the Structure

Before diving into repairs, take time to familiarize yourself with the layout of the document. Typically, it includes sections on troubleshooting, step-by-step instructions, and diagrams. Recognizing where to find specific information can save valuable time and prevent frustration during the repair process.

Utilize Visual Aids

Many guides include images and schematics that can enhance understanding. Pay attention to these visual elements, as they often illustrate complex processes more clearly than text alone. Use them as a companion to the written instructions to ensure accuracy in your work.

| Section | Purpose |

|---|---|

| Troubleshooting | Identifies common problems and potential solutions. |

| Maintenance | Provides routine checklists and procedures for upkeep. |

| Diagrams | Offers visual references for parts and assembly. |

By applying these strategies, users can enhance their proficiency and confidence when working on their vehicles. Embrace the guide as a valuable tool in your maintenance journey.