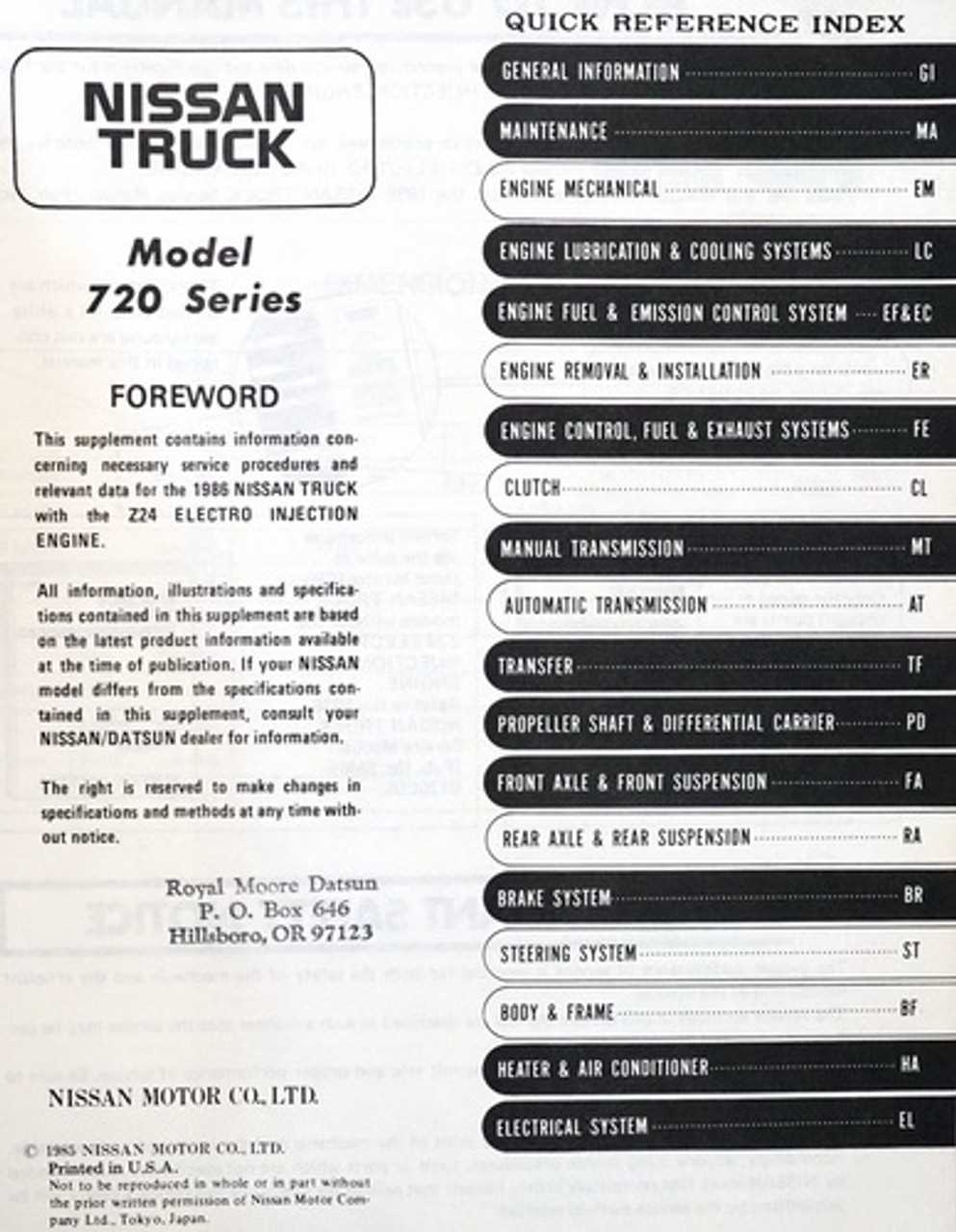

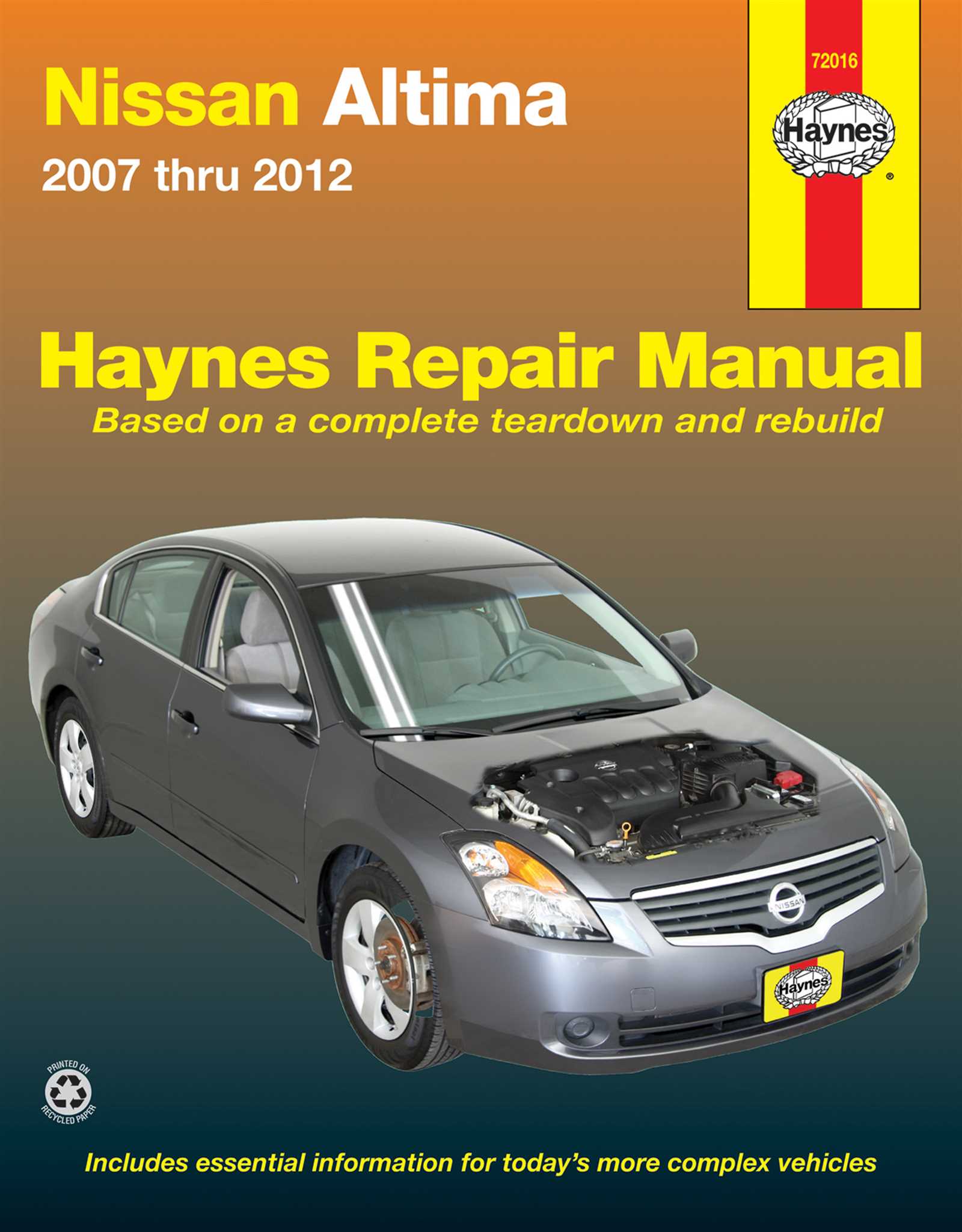

Nissan Z24 Engine Repair Manual Guide for Effective Maintenance

In this section, we delve into the essential steps and techniques for breathing new life into a well-known power unit. Known for reliability and durability, this model has been a steadfast choice among enthusiasts and professionals alike. Our guide offers a structured approach, designed to help both novices and experienced technicians understand each part of the process.

Every detail matters when working on a complex mechanical system, from addressing wear in vital components to ensuring seamless function in critical areas. We emphasize a thorough examination and practical guidance, allowing readers to gain a clear view of the key stages. Precision and care are at the forefront of this restoration process, ensuring every part is returned to optimal condition.

This manual aims to clarify common challenges encountered with this model, offering step-by-step insights into troubleshooting and enhancing longevity. By following these guidelines, you’ll be able to restore peak performance and enjoy the satisfaction of a well-maintained and robust system. Through this guide, we bring together the collective wisdom of experts to help you confidently tackle each phase of the project.

Nissan Z24 Engine Repair Guide

This section provides a comprehensive overview of maintaining and restoring the power unit commonly found in various vehicles, emphasizing practical steps and methods to improve performance and longevity. Understanding the essentials of the internal mechanics and frequently addressing common issues can prevent potential breakdowns, keeping the machinery in optimal condition.

Initial Assessment: Begin by thoroughly examining all critical components, such as the fuel delivery and ignition systems. Look for any signs of wear, loose connections, or damage, as early detection often prevents more serious complications. Ensure that fluids are topped up and within the recommended levels, as inadequate lubrication can accelerate wear on internal parts.

Routine Inspection of Key Parts: Regular checks on areas like the cooling system, belts, and gaskets are essential. These components play vital roles in regulating temperatures and ensuring efficient function. Replace parts showing signs of wear immediately, as failure can lead to overheating and further damage to the system.

Detailed Cleaning Process: Removing built-up debris from critical areas, such as intake and exhaust pathways, allows for smoother operation and helps prevent blockages that may impact efficiency. Cleaning these areas periodically is a proactive way to enhance the overall lifespan and performance of the mechanism.

Testing and Final Adjustments: After completing maintenance or part replacements, conduct tests to verify that each element operates as expected. Tuning components like timing and fuel flow will improve efficiency

Identifying Common Issues with the Z24 Engine

Understanding typical problems that can arise in this type of engine is essential for keeping it in optimal condition and avoiding costly repairs. This section highlights frequent symptoms and concerns, helping to recognize signs of wear or potential malfunction early.

- Overheating: Frequent overheating is a sign of potential issues in the cooling system, often due to blocked radiator passages, a faulty thermostat, or worn hoses. Routine inspection of these components can prevent severe overheating damage.

- Oil Leaks: Oil seepage around certain areas can indicate worn seals or gaskets. Regularly checking for leaks near valve covers and oil pans helps ensure engine lubrication remains consistent.

- Reduced Power: Loss of power or sluggish response may result from inadequate fuel delivery or ignition system wear. Examining spark plugs, fuel filters, and injectors can often reveal the cause and prevent further complications.

- Unusual Noises: Clicking or knocking sounds, especially during acceleration, often suggest valve or timing issues. These noises should be checked promptly to avoid more extensive damage.

- Poor Fuel Efficiency: A noticeable drop in fuel efficiency might indicate problems within the fuel or air intake systems. Clean or replace air filters and inspect fuel injectors regularly to maintain optimal performance.

Being aware of these signs can extend the lifespan of the engine and improve overall functionality. Proper maintenance and early detection of these issues will aid in achieving reliable performance and reduce the need for significant repairs.

Necessary Tools for Effective Z24 Repairs

To ensure a smooth and efficient approach to mechanical maintenance, having a well-organized set of tools is essential. This section covers the specific items that contribute to precision and safety during complex procedures, highlighting key equipment that supports a thorough and reliable outcome.

Basic Tool Kit Essentials

For most mechanical tasks, a quality set of ratchets, torque wrenches, and assorted screwdrivers is invaluable. These essentials allow you to tackle bolts, screws, and various fasteners with ease, ensuring both precision and consistency in every adjustment. The torque wrench, in particular, prevents over-tightening, a crucial aspect for preserving the integrity of components.

Advanced Equipment for Fine-Tuning

Beyond basic tools, certain specialized items are required for more intricate work. Compression testers and cylinder leak-down testers help evaluate the condition of internal parts, providing insights into areas needing attention. Meanwhile, high-quality pliers and an impact wrench save time and reduce strain when dealing with resistant or worn parts. These tools enhance control and accuracy, especially when addressing intricate sections that demand extra precision.

Equipped with these essentials, every mechanic can approach tasks with confidence, achieving reliable and consistent results that extend the life and performance of the machinery.

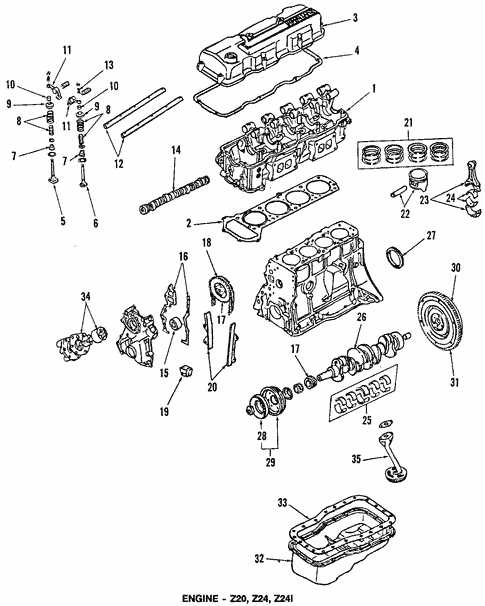

Understanding the Z24 Engine Components

In this section, we explore the crucial parts and systems that work together to ensure smooth functionality in this power unit. Each element, from intake to exhaust, plays a unique role in overall operation, contributing to efficiency, power output, and longevity. Understanding these details helps identify potential issues and supports effective maintenance routines.

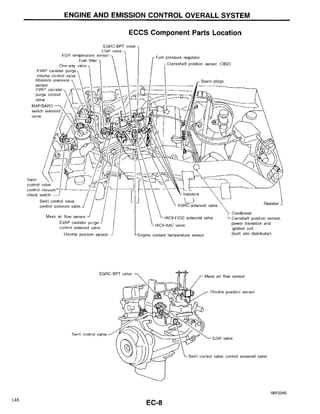

- Intake System: This part regulates the air-fuel mix entering the system, directly impacting combustion quality and fuel efficiency. The intake setup is designed for optimal flow, ensuring balanced air distribution to all cylinders.

- Fuel Distribution: With the help of injectors or carburetors, the system manages the fuel supply, precisely delivering it to the combustion chamber for efficient burning. Proper fuel delivery is essential to maximize performance and avoid unnecessary wear.

- Ignition Setup: Comprising spark plugs and other electrical components, this part initiates the combustion process. Consistent ignition timing is crucial for efficient operation, as it influences power output and smoothness.

- Cylinder Block: The core structure houses the pistons and combustion chambers, serving as the foundation for mechanical motion. This area must withstand high pressures and temperatures, highlighting the importance of durable construction.

- Exhaust System: This assembly is responsible for expelling gases from the chamber, ensuring that the process remains efficient. Efficient removal of exhaust gases reduces backpressure and supports the power cycle.

- Cooling System: Heat generated by constant combustion is managed by a cooling mechanism, preventing overheating and maintaining optimal operating conditions. Proper cooling reduces wear and prolongs lifespan.

Each component has a unique purpose and is carefully designed to function harmoniously. Regular inspection and understanding of these parts can prevent common issues, helping to maintain peak performance and operational reliability.

Steps for Safe Engine Disassembly

Disassembling a complex mechanical system requires careful planning and attention to detail to prevent damage and ensure a smooth reassembly process. The following steps outline essential practices to handle each component safely and efficiently.

- Prepare the Workspace

- Choose a clean, well-lit area with sufficient space for all parts.

- Gather necessary tools, and arrange them for easy access.

- Ensure proper ventilation to work safely with any fluids or chemicals.

- Drain All Fluids

- Safely drain any remaining liquid to prevent spills and hazards.

- Collect and dispose of fluids according to local regulations.

- Label Each Component

- As each part is removed, label it clearly to identify its position.

- Place small items, like bolts, in labeled bags to keep track of them.

- Remove Parts in Order

- Start with external components, working gradually toward internal parts.

- Follow a logical sequence to avoid missing any critical piece.

- Inspect Parts for Wear

- Examine each removed item for any signs of damage or wear.

- Set aside damaged parts for repair or replacement as needed.

- Store Components Properly

- Organize each piece in a secure area to prevent loss or contamination.

- Cover delicate items to shield them from dust or moisture.

- Socket and wrench set

- Torque wrench

- Screwdriver set

- Replacement timing chain kit

- Safety gloves and goggles

Replacing Timing Chain on the Z24

The timing chain is a critical component that synchronizes various parts, ensuring optimal performance. Over time, it can experience wear, requiring replacement to prevent damage and maintain functionality. This section outlines the process of replacing the chain, including tools needed, removal steps, and reassembly guidance.

Preparation and Required Tools

Before starting, gather the necessary tools to ensure a smooth process. Commonly needed items include:

Step-by-Step Timing Chain Replacement

Follow these steps to carefully replace the timing chain. Ensure the vehicle is cool before beginning.

- Disconnect Power: Disconnect the battery to avoid accidental starts during the replacement.

- Remove Necessary Components: Take off components obstructing access, such as the timing cover and fan assembly.

- Align Timing Marks: Rotate to align timing marks on the camshaft and crankshaft for accurate timing.

- Remove Old Chain: Carefully detach the old chain along with any guides or tensioners that need replacement.

- Install New Chain: Position the new chain on the sprockets, ensuring it aligns with the timing marks.

-

Cleaning and Reassembling Vital Parts

Proper care and thorough reassembly of essential components are crucial steps in restoring peak performance. By meticulously cleaning each part and following the recommended procedures for reassembly, you ensure that all mechanisms work in harmony, reducing wear and extending the system’s overall lifespan.

Step-by-Step Cleaning Process

Begin by preparing a workspace free of contaminants and gather appropriate cleaning agents for each specific part. Use brushes, compressed air, and cloths to remove debris and residues from surfaces. For areas prone to corrosion, apply a protective solution after cleaning to prevent future damage. Allow each component to fully dry before continuing to the next phase to avoid moisture-related issues during reassembly.

Reassembling Components with Precision

During reassembly, ensure that all bolts, seals, and gaskets are securely and correctly positioned. Reference diagrams for the precise alignment of moving parts, and apply lubricants where necessary to optimize function and reduce friction. Carefully follow the tightening sequence and torque specifications to avoid misalignment or strain on individual parts. Performing these steps attentively will restore the unit’s functionality, allowing it to perform smoothly and reliably.

Troubleshooting Ignition System Failures

Addressing issues within the ignition system is crucial for maintaining optimal performance. An effective approach involves systematic diagnostics to pinpoint the source of the malfunction. By understanding the components involved and their functions, one can effectively isolate and resolve problems.

Common symptoms of ignition system failures may include:

- Difficulty starting the vehicle

- Engine misfires during operation

- Poor acceleration and reduced power

- Increased fuel consumption

To methodically troubleshoot these issues, follow these steps:

- Inspect the Battery: Ensure that the battery is fully charged and the terminals are clean and tight.

- Check the Ignition Coil: Test the coil for proper resistance and look for signs of damage or corrosion.

- Examine Spark Plugs: Remove and inspect each spark plug for wear, deposits, or improper gap settings.

- Test the Ignition Wires: Inspect the wires for fraying or damage, and ensure they are securely connected.

- Evaluate the Ignition Timing: Use a timing light to check if the ignition timing is within the specified range.

By carefully following these diagnostic procedures, you can effectively identify and rectify ignition system failures, ensuring reliable operation and performance.

Optimizing Fuel System for Best Performance

Enhancing the efficiency of the fuel delivery system is crucial for achieving optimal operation in any vehicle. A well-tuned setup not only improves power output but also maximizes fuel economy and reduces emissions. This section explores essential strategies for fine-tuning the components involved in fuel distribution.

To ensure peak performance, consider the following aspects:

- Fuel Quality: Always use high-quality fuel that meets the required specifications. This can lead to better combustion efficiency and overall performance.

- Regular Maintenance: Schedule periodic checks and cleanings of the fuel injectors and filters. Clogged injectors can significantly hinder performance.

- Fuel Pressure: Maintain optimal fuel pressure as specified by the manufacturer. An accurate fuel pressure regulator is essential for consistent operation.

- Intake Air Management: Ensure that the air intake system is free from restrictions. A clean air filter promotes better airflow, enhancing combustion.

- Engine Tuning: Consider reprogramming the engine control unit (ECU) to optimize the air-fuel mixture for performance enhancements. This can lead to significant gains in power and efficiency.

By focusing on these key elements, drivers can achieve substantial improvements in their vehicle’s performance, leading to a more responsive and enjoyable driving experience.

Preventive Maintenance Tips for Longevity

Ensuring the long-lasting performance of your vehicle requires regular care and attention. Implementing effective preventive measures can significantly extend the lifespan of critical components and enhance overall reliability.

Regular Fluid Checks

Maintaining optimal fluid levels is essential for the efficient operation of various systems. Here are key fluids to monitor:

- Oil: Change at recommended intervals to ensure smooth operation.

- Coolant: Check levels and top up to prevent overheating.

- Brake Fluid: Inspect for clarity and replace if it appears contaminated.

- Transmission Fluid: Ensure it’s at the right level to facilitate smooth gear shifting.

Regular Inspections and Servicing

Routine inspections help identify potential issues before they become serious problems. Consider these practices:

- Inspect belts and hoses for wear or cracks.

- Check tire pressure and tread depth regularly.

- Examine the battery for corrosion and ensure terminals are secure.

- Replace air filters as needed to maintain optimal airflow.

Adhering to these preventive measures will not only promote a reliable driving experience but also help in avoiding costly repairs in the future.

Reassembly and Final Adjustments Checklist

This section outlines essential steps to ensure proper reassembly and fine-tuning of mechanical components. Following a systematic approach will help guarantee optimal performance and longevity of the system after disassembly. The checklist is designed to assist you in verifying that all parts are correctly positioned and adjusted before the final assembly is completed.

Start by inspecting all components for cleanliness and damage. Remove any debris or old lubricant, and replace worn or broken parts as needed. Once the pieces are prepped, carefully reassemble them in the reverse order of disassembly, making sure to tighten fasteners to the specified torque settings.

Next, pay special attention to any seals and gaskets. Ensure they are seated correctly to prevent leaks. After the main components are secured, check all fluid levels and top them off if necessary. It’s also crucial to reconnect any electrical connectors and ensure they are functioning properly.

Finally, conduct a series of tests to confirm that the system operates smoothly. Start with a visual inspection, followed by running the mechanism under its intended load to check for unusual noises or vibrations. Monitor all gauges for any abnormalities. Make necessary adjustments based on the results of these tests to achieve the desired performance standards.