Comprehensive Guide to Repairing the 1996 Suzuki King Quad 300

Maintaining an all-terrain vehicle is crucial for ensuring optimal performance and longevity. Proper knowledge of the intricate systems and components is key to addressing any issues that may arise. This guide serves as a comprehensive resource for enthusiasts and owners alike, providing insights into the common challenges and solutions associated with these robust machines.

Understanding the mechanics behind your vehicle not only enhances its functionality but also empowers you to tackle repairs with confidence. From engine diagnostics to electrical systems, being well-informed is invaluable. This section aims to equip you with the necessary tools and information to keep your vehicle in peak condition, minimizing downtime and maximizing enjoyment.

Whether you’re a seasoned mechanic or a novice, familiarizing yourself with troubleshooting techniques and maintenance practices is essential. With detailed instructions and practical tips, you’ll be well-prepared to handle a variety of situations that may come your way. Let’s delve into the specifics that will help you maintain your vehicle effectively and efficiently.

Overview of the 1996 Suzuki King Quad 300

This section provides a comprehensive look at a notable all-terrain vehicle renowned for its reliability and performance in various conditions. The design reflects a blend of ruggedness and advanced engineering, catering to both recreational users and those in need of a sturdy workhorse.

Key Features

- Powerful engine designed for optimal torque and efficiency

- Durable chassis suitable for rough terrains

- Versatile four-wheel drive system for enhanced traction

- Comfortable seating arrangement for extended rides

- Robust suspension system to absorb shocks and bumps

Performance and Usage

Known for its exceptional handling and stability, this vehicle is ideal for a variety of applications. From agricultural tasks to outdoor adventures, its capabilities make it a preferred choice among enthusiasts.

- Excellent maneuverability in tight spaces

- Ability to tow substantial loads

- Impressive fuel economy for long-distance journeys

Overall, this all-terrain vehicle stands out for its practical design and user-friendly features, making it a reliable option for a wide range of users.

Common Issues with King Quad 300

Many users encounter typical challenges with their all-terrain vehicles, which can affect performance and reliability. Understanding these frequent problems can help owners maintain their machines effectively and ensure a smoother riding experience.

- Starting Difficulties: Owners often report issues with ignition systems or battery failures that can prevent the vehicle from starting.

- Fuel System Problems: Clogs in fuel lines or issues with the carburetor can lead to poor engine performance or stalling.

- Transmission Issues: Shifting difficulties may arise due to worn gears or inadequate fluid levels, impacting overall handling.

- Electrical Failures: Problems with wiring or blown fuses can cause various electrical components to malfunction.

- Brake Wear: Regular use can lead to brake pad wear, necessitating timely replacements for safety.

Addressing these issues promptly can prolong the lifespan of the vehicle and enhance the riding experience. Regular maintenance checks and attentive care can mitigate many of these common challenges.

Essential Tools for Repairs

When it comes to maintaining and restoring your vehicle, having the right equipment is crucial. A well-equipped workspace can make the difference between a successful project and a frustrating experience. The following tools are fundamental for tackling a variety of tasks, ensuring that you can address issues efficiently and effectively.

First and foremost, a quality set of hand tools, including wrenches, sockets, and screwdrivers, is indispensable. These tools allow for precise adjustments and facilitate the removal or installation of components with ease. Additionally, a torque wrench ensures that all fasteners are tightened to the manufacturer’s specifications, promoting safety and performance.

Furthermore, investing in a reliable tool chest helps keep your workspace organized. An assortment of pliers, hammers, and cutting tools will also come in handy for various applications. For electrical work, having a multimeter can assist in diagnosing issues, while wire strippers and connectors enable effective repairs.

Lastly, don’t overlook the importance of safety gear. Gloves, goggles, and other protective equipment are vital when working on any mechanical project. With the right tools at your disposal, you can approach each task with confidence, ensuring that your vehicle remains in top condition.

Step-by-Step Maintenance Procedures

Proper upkeep of your all-terrain vehicle is essential for ensuring optimal performance and longevity. This section outlines a series of systematic procedures that should be followed to maintain your machine effectively. Each step is designed to address different aspects of maintenance, helping you keep your vehicle in top condition.

Begin with routine inspections, checking fluid levels such as oil and coolant. Ensure that brakes are functioning correctly and that the tires are adequately inflated. A thorough visual inspection can reveal potential issues before they become serious problems.

Next, focus on cleaning the air filter. A clean filter allows for better airflow, enhancing engine efficiency. Follow this by inspecting the spark plug and replacing it if necessary, as this component is crucial for ignition and overall engine performance.

Regularly examine the drive chain or belt, looking for wear and proper tension. Lubricate moving parts as recommended to reduce friction and prevent premature wear. Don’t overlook the importance of battery maintenance; check connections and fluid levels to ensure reliable starting.

Finally, consult the vehicle’s specifications for any seasonal maintenance tasks, such as winterizing or preparing for storage. Adhering to these step-by-step guidelines will contribute significantly to the reliability and performance of your vehicle over time.

Electrical System Troubleshooting Guide

This section provides essential insights for diagnosing and resolving issues related to the electrical components of your vehicle. A well-functioning electrical system is crucial for optimal performance, and understanding potential problems can save time and enhance reliability.

Begin by inspecting the battery connections. Ensure that terminals are clean, tight, and free from corrosion. A poor connection can lead to insufficient power supply, causing various electrical failures.

Next, examine the fuses. A blown fuse may interrupt critical circuits, affecting lights, ignition, or other electronic systems. Replace any faulty fuses with the correct amperage to restore functionality.

Inspect the wiring harness for any signs of wear, fraying, or damage. Look for exposed wires that could lead to short circuits or intermittent failures. Repair or replace any compromised wiring to ensure a stable electrical flow.

Check the alternator’s output using a multimeter. A malfunctioning alternator can lead to battery drainage or inconsistent power delivery. If the voltage readings are outside the recommended range, consider servicing or replacing the alternator.

Lastly, test all switches and relays. A malfunctioning switch can prevent circuits from functioning properly. Verify that all components operate as intended and replace any defective parts to maintain system integrity.

Engine Repair Tips and Tricks

Maintaining and fixing an engine can be a rewarding yet challenging task. Understanding the nuances of engine components and systems can significantly enhance performance and longevity. Here are some essential strategies to consider when tackling engine issues.

- Regular Inspections: Periodically check for leaks, wear, and unusual noises. Early detection of problems can save time and resources.

- Cleanliness is Key: Keep the engine and surrounding areas clean. Dirt and grime can lead to overheating and other complications.

- Follow Manufacturer Guidelines: Refer to service documentation for specifications regarding oil types, fluid levels, and maintenance schedules.

When addressing specific problems, consider the following:

- Overheating: Ensure the cooling system is functioning properly. Check coolant levels, hoses, and the thermostat.

- Fuel Issues: Examine fuel lines and filters for clogs or leaks. Use quality fuel to prevent deposit buildup.

- Electrical System: Inspect battery connections and wiring for corrosion or frays. A multimeter can help diagnose electrical issues.

Utilizing the right tools is crucial:

- Quality Tools: Invest in good quality hand tools and specialized equipment for efficiency and precision.

- Diagnostic Equipment: Use scanners and gauges to monitor engine performance and identify faults accurately.

Lastly, always prioritize safety. Wear protective gear, and ensure you work in a well-ventilated area to avoid hazards. With patience and attention to detail, you can effectively troubleshoot and enhance engine performance.

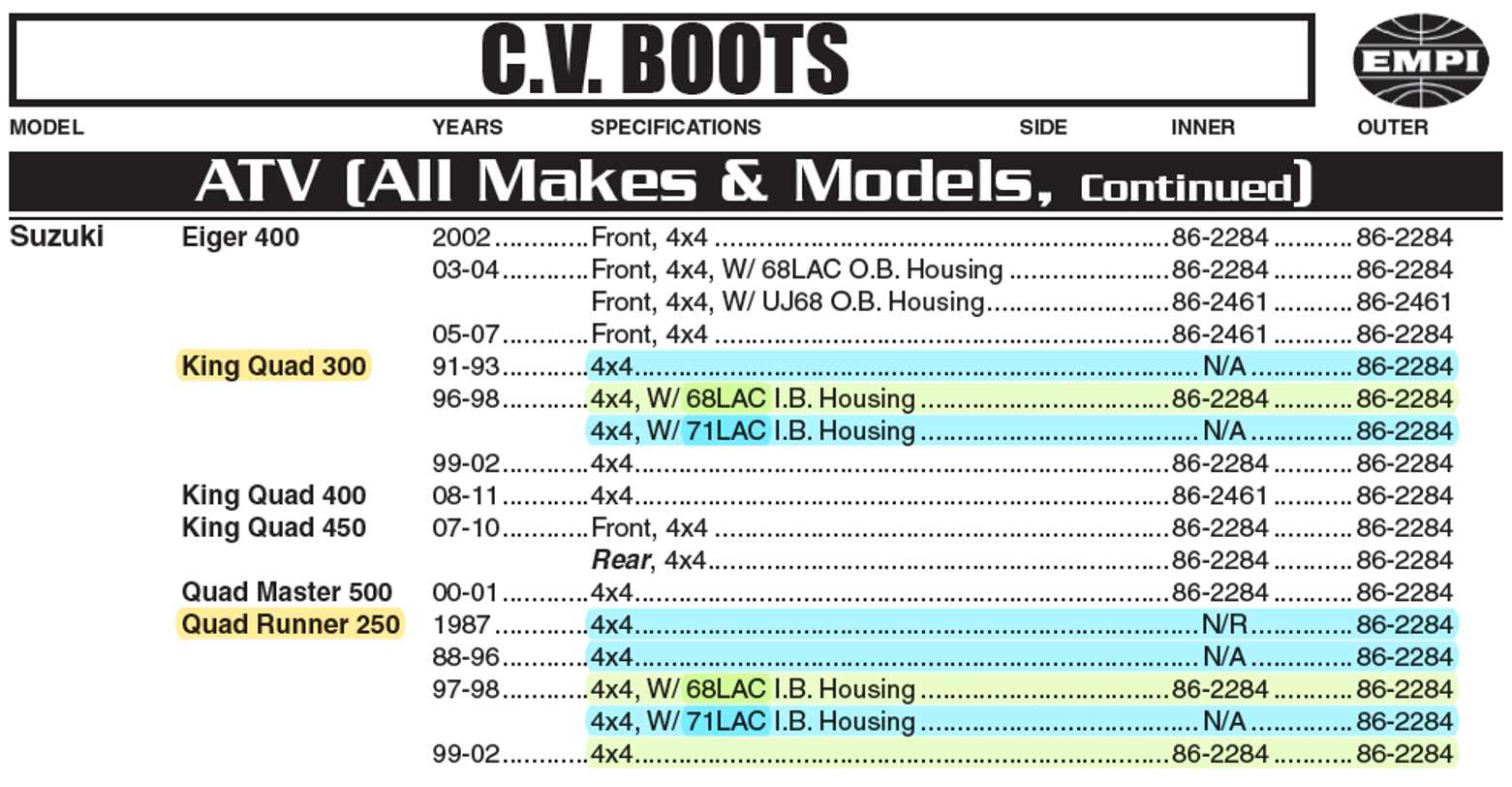

Transmission and Drivetrain Insights

Understanding the intricacies of the transmission and drivetrain is essential for maintaining optimal performance in all-terrain vehicles. These components work in tandem to ensure that power is effectively transferred from the engine to the wheels, providing the necessary torque and speed for various terrains. A thorough comprehension of their functionality can aid in diagnosing issues and implementing effective solutions.

The transmission is responsible for altering the vehicle’s gear ratios, allowing it to adapt to different driving conditions. The drivetrain, encompassing the driveshaft, axles, and differential, facilitates the transfer of power to the wheels, ensuring smooth acceleration and traction. Regular inspection and maintenance of these systems can prevent breakdowns and prolong the lifespan of the vehicle.

| Component | Function |

|---|---|

| Transmission | Modifies gear ratios for varying speeds and loads |

| Driveshaft | Transmits power from the transmission to the wheels |

| Differential | Allows for wheel speed variation during turns |

| Axles | Connects the wheels to the differential, supporting weight and rotation |

Regular maintenance tasks, such as checking fluid levels and inspecting for wear, can significantly enhance the reliability of these systems. By paying close attention to the transmission and drivetrain, operators can ensure a smoother and more efficient ride, even in challenging environments.

Suspension Adjustments and Maintenance

The suspension system plays a crucial role in ensuring optimal performance and comfort during rides. Regular adjustments and maintenance are essential for preserving the integrity of this system, enhancing ride quality, and extending the lifespan of the vehicle. Proper attention to suspension components can significantly improve handling and stability, allowing for a more enjoyable experience on various terrains.

Key Components to Monitor

When maintaining the suspension, several key components should be regularly inspected and adjusted. These include shock absorbers, springs, and linkage systems. Each element contributes to the overall functionality, and any wear or damage can affect performance.

| Component | Signs of Wear | Maintenance Tips |

|---|---|---|

| Shock Absorbers | Leaking fluid, excessive bounce | Replace if damaged, check mounting points |

| Springs | Visible sagging, uneven height | Inspect for corrosion, replace as needed |

| Linkage Systems | Loose connections, unusual noises | Lubricate regularly, tighten bolts |

Adjustment Techniques

To achieve the best performance, proper adjustments to the suspension settings are necessary. This includes tuning preload, damping, and ride height. Following the manufacturer’s specifications will provide a baseline for these adjustments, allowing for fine-tuning based on personal preferences and specific riding conditions.

How to Change Fluids Properly

Maintaining optimal performance and longevity of your vehicle requires regular fluid changes. Properly executing this task ensures that all components operate smoothly and efficiently. This process not only enhances functionality but also helps prevent potential damage due to contamination or degradation of vital fluids.

To begin, gather the necessary tools and materials, including the correct type of fluid, a funnel, a drain pan, and any required wrenches. Ensure the vehicle is on a level surface and safely secured to prevent any accidents. Once ready, locate the appropriate fill and drain points for the fluid you intend to replace.

When draining old fluid, remove the drain plug and allow it to flow completely into the pan. This step is crucial for eliminating any impurities that could compromise performance. After draining, replace the drain plug securely before adding new fluid. Utilize a funnel for precise filling, ensuring you don’t overfill, as this can lead to pressure issues.

After the new fluid is in place, start the engine and allow it to run for a few minutes. This circulation step helps distribute the fresh fluid throughout the system. Check the levels again, as some may have settled, and add more if necessary. Finally, inspect for leaks around the drain plug and fill points to confirm a successful change.

Regularly changing fluids is an essential aspect of vehicle upkeep. Following these guidelines will help maintain the health of your machinery, ensuring it operates at its best for years to come.

Safety Precautions During Repairs

When undertaking maintenance tasks on vehicles, ensuring a safe working environment is paramount. Taking the right precautions can significantly reduce the risk of accidents and injuries, allowing for a smoother and more efficient process. Awareness and preparation are key components to a successful and safe repair experience.

Essential Safety Measures

- Always wear appropriate personal protective equipment (PPE), including gloves, safety goggles, and steel-toed boots.

- Work in a well-ventilated area to minimize exposure to fumes and harmful substances.

- Ensure the vehicle is on a stable surface and use jack stands when lifting it to prevent collapse.

- Disconnect the battery before starting any electrical work to avoid short circuits or shocks.

- Keep a fire extinguisher nearby in case of emergency, especially when working with flammable materials.

Tool and Workspace Safety

- Inspect tools for damage before use; avoid using broken or worn equipment.

- Organize your workspace to reduce clutter and the risk of tripping hazards.

- Store hazardous materials properly, ensuring they are out of reach of children and pets.

- Be mindful of your surroundings; ensure no one is in the way while using power tools.

By adhering to these guidelines, you can create a safer environment for yourself and others during maintenance tasks. Prioritizing safety not only protects you but also enhances the overall efficiency of the work being performed.

Resources for Further Information

For those seeking additional insights and guidance related to maintenance and troubleshooting of all-terrain vehicles, numerous resources are available. These materials can provide valuable support, whether you’re a seasoned mechanic or a novice enthusiast.

- Online Forums: Engage with communities where experienced users share tips, advice, and personal experiences.

- Video Tutorials: Platforms like YouTube host a variety of instructional videos that visually demonstrate repairs and maintenance procedures.

- Manufacturer Websites: Official sites often feature downloadable resources, including specifications, part catalogs, and FAQs.

- Books and Guides: Comprehensive literature is available, detailing both basic and advanced maintenance techniques.

- Local Workshops: Consider enrolling in workshops or classes that focus on vehicle upkeep and repair skills.

Utilizing these resources can enhance your understanding and proficiency in caring for your vehicle, ensuring optimal performance and longevity.