Comprehensive Repair Manual for the 2007 Hyundai Tiburon

In the realm of automotive care, having access to a thorough guide can make all the difference. Such resources not only assist in understanding the intricate workings of a specific model but also empower enthusiasts and everyday drivers alike to tackle common issues with confidence. A well-structured reference can streamline the repair process, ensuring that each step is executed with precision.

When faced with challenges, it’s crucial to have a dependable source that details specifications, procedures, and troubleshooting techniques. This allows individuals to diagnose problems effectively and perform necessary interventions without unnecessary delays. A carefully curated collection of information can transform daunting tasks into manageable projects.

Furthermore, understanding the nuances of your vehicle enhances its longevity and performance. Armed with the right knowledge, you can navigate repairs and maintenance tasks with ease. Emphasizing the importance of regular check-ups and the timely resolution of issues will not only extend the life of your automobile but also contribute to safer driving experiences.

Overview of the 2007 Hyundai Tiburon

This section provides an insight into a compact sports coupe known for its striking design and spirited performance. With a focus on blending style and functionality, this vehicle appeals to enthusiasts and everyday drivers alike, offering an engaging driving experience.

The model features a sleek, aerodynamic silhouette that captures attention on the road. Inside, it combines comfort with a driver-centric layout, ensuring that both aesthetic and practical needs are met. The vehicle is equipped with a range of modern amenities, enhancing the overall appeal.

Under the hood, a selection of robust engines delivers commendable power and responsiveness, making it suitable for both city driving and spirited highway maneuvers. The suspension system is designed to provide a balanced ride, enhancing handling while maintaining comfort.

This coupe is not just about performance; it also emphasizes safety and reliability. Various safety features are integrated to protect occupants, demonstrating a commitment to well-rounded engineering. Overall, this model represents a harmonious blend of style, performance, and practicality.

Common Issues Faced by Owners

Many vehicle owners encounter a range of typical challenges that can affect performance and reliability. Understanding these common problems can help in proactive maintenance and troubleshooting. From electrical systems to mechanical components, awareness of potential issues is crucial for ensuring longevity and safety on the road.

Electrical System Failures

One prevalent concern among drivers involves the electrical system. Malfunctions in components such as the battery, alternator, and wiring can lead to starting difficulties or unexpected shutdowns. Owners often report flickering lights and issues with the dashboard indicators, signaling the need for careful inspection of the electrical circuitry.

Suspension and Steering Problems

Another frequent issue relates to the suspension and steering mechanisms. Drivers may notice excessive noise when driving over bumps or a lack of responsiveness in steering. These symptoms often indicate worn-out components, such as struts or bushings, which can compromise both comfort and safety while driving.

Essential Tools for Repairs

When embarking on maintenance tasks, having the right set of instruments is crucial for achieving effective results. A well-equipped toolkit not only simplifies the process but also ensures safety and precision in every undertaking. Whether you’re addressing minor adjustments or more extensive modifications, understanding the necessary gear is fundamental.

Basic Hand Tools

Every enthusiast should start with a collection of basic hand tools that serve various functions. These instruments are versatile and can be used in numerous situations.

| Tool | Purpose |

|---|---|

| Wrenches | For tightening and loosening bolts and nuts. |

| Screwdrivers | Essential for driving screws of different types. |

| Pliers | Useful for gripping, twisting, and cutting wires. |

| Socket Set | Allows for easier access to fasteners in tight spaces. |

Specialized Equipment

In addition to basic tools, specialized equipment can enhance the efficiency of more complex tasks. Investing in these items can make significant differences in both ease of use and outcome.

| Equipment | Function |

|---|---|

| Jack and Stands | For safely lifting and supporting the vehicle. |

| Torque Wrench | Ensures fasteners are tightened to specified levels. |

| Diagnostic Scanner | Identifies issues through vehicle computer systems. |

| Fluid Extractor | For removing and replacing fluids efficiently. |

Engine Specifications and Maintenance Tips

Understanding the intricacies of your vehicle’s power unit is essential for ensuring optimal performance and longevity. This section delves into critical characteristics of the engine, alongside practical advice for upkeep, aimed at enhancing reliability and efficiency.

Engine Characteristics

The power unit typically features a four-cylinder layout, providing a balance between performance and fuel efficiency. With a displacement around 2.0 liters, this configuration allows for spirited driving while maintaining respectable mileage. The engine operates with a multi-point fuel injection system, ensuring precise fuel delivery for smooth acceleration and responsiveness.

Maintenance Recommendations

Regular upkeep is vital for the engine’s health. Change the engine oil every 5,000 to 7,500 miles to maintain optimal lubrication and prevent wear. Using high-quality oil and a reliable filter can significantly impact performance. Additionally, inspect and replace the air filter every 15,000 miles to ensure adequate airflow and efficiency.

Cooling System Care

The cooling system plays a crucial role in maintaining operating temperature. Check the coolant level regularly and replace it every two years to avoid overheating. Ensure that hoses and connections are free from leaks and damage.

Timing and Drive Belts

Inspect timing and drive belts at regular intervals, typically every 60,000 to 100,000 miles. A worn belt can lead to significant engine damage, so replacing them proactively is advisable.

Conclusion

By adhering to these specifications and maintenance tips, you can ensure the engine remains in peak condition, providing a reliable driving experience for years to come.

Step-by-Step Brake Replacement Guide

Replacing the braking components of your vehicle is essential for maintaining safety and performance. This guide provides a clear, structured approach to assist you in replacing the brakes effectively, ensuring that your ride remains smooth and secure.

Tools and Materials Needed: Before beginning, gather all necessary tools including a jack, lug wrench, socket set, and brake pads. Ensure you have a clean workspace and all required components ready for the task.

Step 1: Prepare the Vehicle – Park the vehicle on a flat surface and engage the parking brake. Loosen the lug nuts on the wheels where you’ll be working but do not remove them yet.

Step 2: Lift the Vehicle – Use the jack to raise the vehicle securely, then place jack stands under the frame for added safety. Remove the loosened lug nuts and take off the wheel to access the braking system.

Step 3: Remove Old Brake Pads – Locate the caliper, which houses the brake pads. Use the appropriate socket to remove the caliper bolts. Carefully slide the caliper off and hang it using a bungee cord or similar device to avoid straining the brake line. Remove the old pads.

Step 4: Install New Brake Pads – Position the new pads into the caliper bracket. Ensure they are seated correctly and make contact with the rotor surface.

Step 5: Reattach the Caliper – Carefully place the caliper back over the new pads and align it with the mounting holes. Reinsert and tighten the caliper bolts to the manufacturer’s specifications.

Step 6: Reassemble the Wheel – Place the wheel back onto the hub, hand-tighten the lug nuts, and lower the vehicle. Once it is safely on the ground, use the lug wrench to fully tighten the nuts in a crisscross pattern for even distribution.

Step 7: Test the Brakes – Before hitting the road, pump the brake pedal several times to ensure the pads are properly seated against the rotor. Check for any unusual noises or issues before driving.

Following this guide will help you confidently replace the braking components and maintain optimal vehicle performance. Always refer to your specific vehicle documentation for any unique requirements or specifications.

Transmission Troubleshooting Techniques

Diagnosing issues with the transmission system can be a complex task that requires a systematic approach. Understanding the symptoms and identifying potential causes are essential for effective resolution. This section will explore various methods to pinpoint problems related to the shifting mechanism and overall functionality.

Begin by observing the behavior of the vehicle during operation. Common signs such as slipping gears, unusual noises, or difficulty in shifting should be noted. It is crucial to document these symptoms, as they provide valuable insight into the underlying issue.

Next, check the transmission fluid level and condition. Low fluid levels or contaminated fluid can lead to poor performance and should be addressed promptly. Ensure that there are no leaks present, as they can exacerbate transmission problems.

Utilize diagnostic tools to retrieve error codes from the vehicle’s computer system. These codes can direct attention to specific components that may be malfunctioning, streamlining the troubleshooting process. Pay special attention to sensors related to the transmission, as their failure can significantly impact functionality.

Lastly, consider the possibility of mechanical wear or damage. Inspecting components such as the clutch, torque converter, and solenoids can reveal hidden issues. A thorough visual inspection, combined with a test drive, can often uncover the root cause of transmission problems.

Electrical System Diagnostics Explained

Understanding the intricacies of an automobile’s electrical system is crucial for effective troubleshooting and maintenance. This section delves into the principles of diagnosing electrical issues, emphasizing the importance of systematic evaluation to ensure optimal performance and reliability.

Key Components and Their Functions

The electrical architecture of a vehicle comprises several critical components, including the battery, alternator, fuses, and wiring harnesses. Each part plays a vital role in delivering power and facilitating communication within the system. Identifying malfunctioning elements is essential for resolving issues that may lead to performance degradation or complete failure.

Diagnostic Techniques

Effective diagnostics involve a range of techniques, such as visual inspections, multimeter testing, and onboard diagnostic systems. Employing a methodical approach allows technicians to pinpoint faults accurately, from simple shorts to complex circuit failures. Regular diagnostics not only enhance vehicle longevity but also contribute to safer driving experiences.

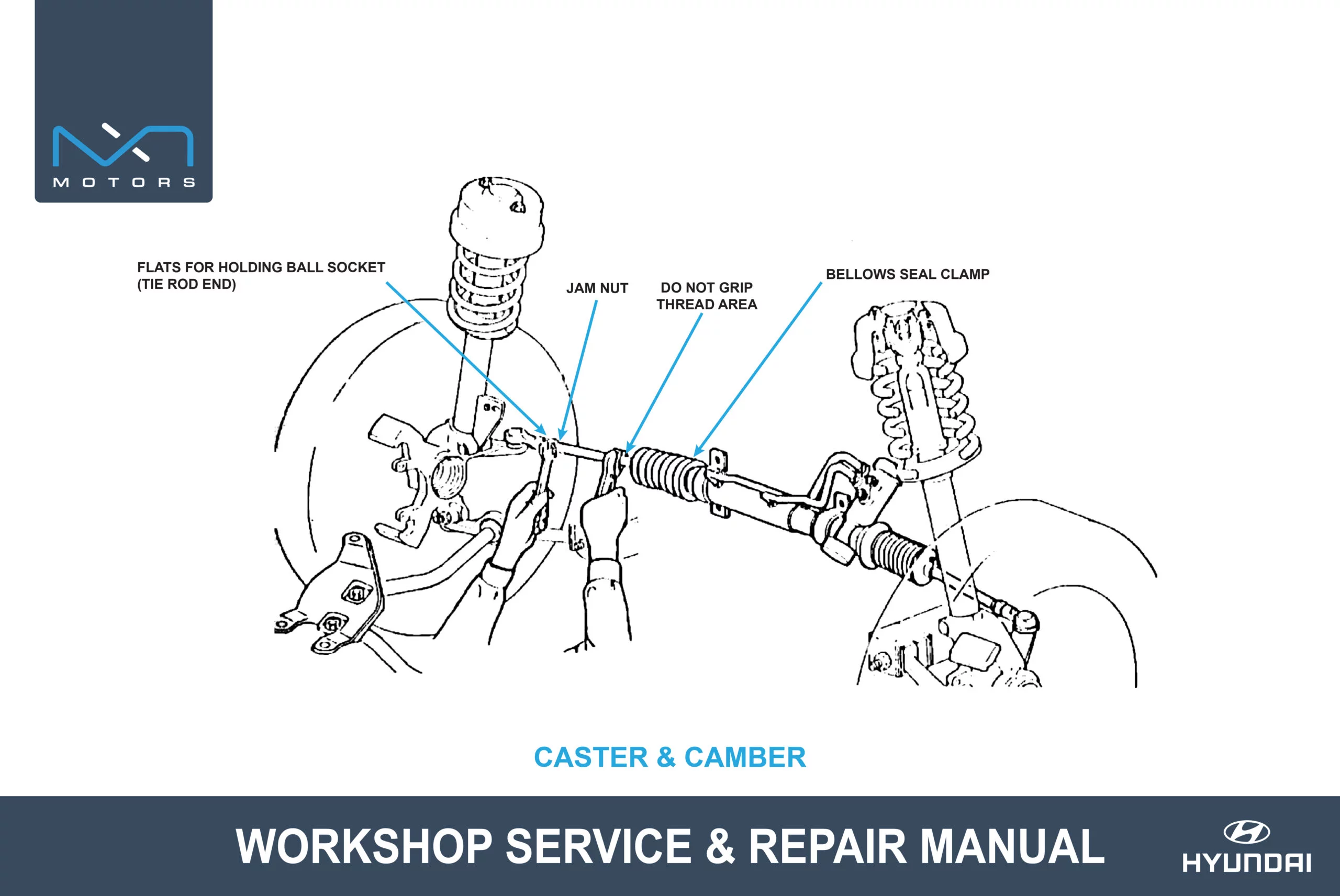

Suspension and Steering Repair Essentials

The suspension and steering systems are vital components that ensure a vehicle’s stability and handling. Maintaining these systems is crucial for a smooth driving experience and overall safety. Understanding the fundamentals of their construction and operation can empower you to identify issues and execute necessary adjustments or replacements effectively.

Components of the Suspension System include springs, shock absorbers, and control arms. Each part plays a specific role in absorbing shocks from the road and maintaining tire contact, contributing to ride comfort and vehicle control. Regular inspections can help detect wear and tear before they escalate into more significant problems.

Steering Mechanisms consist of the steering wheel, column, rack, and pinion system. These elements work together to translate driver input into precise vehicle movement. Issues like loose steering or unusual noises can indicate a need for attention, making it essential to familiarize yourself with these components and their typical behaviors.

Maintenance Tips: Regularly check for leaks in the suspension and steering fluids, inspect bushings for cracks, and ensure that all mounting points are secure. Alignments should also be performed periodically to prevent uneven tire wear and enhance handling precision.

In summary, being knowledgeable about the suspension and steering systems can help you maintain optimal performance and ensure a safe driving experience. Proactive care and timely interventions are key to prolonging the life of these critical systems.

Cooling System Maintenance Best Practices

Maintaining the cooling system of your vehicle is crucial for ensuring optimal engine performance and longevity. A well-functioning cooling system helps regulate engine temperature, preventing overheating and related damage. Regular upkeep can extend the life of essential components and enhance overall reliability.

To keep the cooling system in top condition, consider the following best practices:

| Practice | Description |

|---|---|

| Regular Inspections | Check for leaks, cracks, or corrosion in hoses and connections. Look for signs of coolant deterioration. |

| Coolant Replacement | Change the coolant according to the manufacturer’s recommendations to prevent buildup and maintain effective heat transfer. |

| Thermostat Check | Ensure the thermostat opens and closes properly to regulate coolant flow and maintain optimal engine temperature. |

| Radiator Maintenance | Flush the radiator periodically to remove debris and improve efficiency. Check for blockages that could restrict airflow. |

| Water Pump Functionality | Inspect the water pump for leaks and ensure it operates smoothly to circulate coolant effectively. |

By adhering to these practices, you can help ensure your vehicle’s cooling system operates efficiently, thus protecting the engine from overheating and prolonging its life.

Bodywork and Interior Repair Instructions

This section provides essential guidelines for maintaining and restoring the exterior and interior components of your vehicle. Understanding the necessary procedures and tools will help ensure that both aesthetics and functionality are preserved. From addressing minor scratches to handling more significant structural issues, following these instructions will facilitate a smoother restoration process.

| Task | Tools Required | Steps |

|---|---|---|

| Fixing Minor Dents | Dent puller, heat gun, soft cloth |

|

| Painting Scratches | Touch-up paint, brush, clear coat |

|

| Replacing Interior Upholstery | Screwdriver, upholstery glue, new fabric |

|

By following these straightforward procedures, you can enhance the longevity and appearance of both the body and interior of your vehicle. Regular maintenance not only improves aesthetics but also contributes to the overall driving experience.

Useful Resources for DIY Mechanics

Engaging in automotive maintenance and repair can be a rewarding experience for enthusiasts. Access to quality information and tools is essential for successfully tackling various projects. Fortunately, a wealth of resources is available to assist both novice and experienced mechanics in their endeavors.

Online Communities and Forums

Participating in online forums dedicated to automotive topics can provide invaluable support. Enthusiasts share their knowledge, tips, and experiences, creating a collaborative environment. Websites such as Reddit or specialized automotive forums often feature discussions on specific makes and models, troubleshooting advice, and even step-by-step guides from fellow hobbyists.

Video Tutorials and Educational Content

Video platforms offer a treasure trove of tutorials that visually demonstrate repair techniques and maintenance tasks. Channels focused on automotive care often provide clear explanations, making it easier to understand complex processes. By watching experienced mechanics in action, DIY enthusiasts can gain confidence and improve their skills.

Safety Precautions During Repairs

Ensuring a secure environment is essential when performing maintenance tasks on vehicles. Awareness of potential hazards can significantly reduce the risk of accidents and injuries. By following specific guidelines, individuals can create a safer workspace and promote effective procedures.

First and foremost, always wear appropriate personal protective equipment (PPE). This includes gloves, safety glasses, and steel-toed boots, which protect against sharp objects and harmful substances. Additionally, ensure that the area is well-ventilated, particularly when working with chemicals or fuels.

Keep tools organized and in good condition. Regularly inspect equipment for damage or wear, as faulty tools can lead to mishaps. Furthermore, maintain a clean workspace to avoid tripping hazards and ensure efficient workflow.

Be mindful of electrical systems and other components that could pose risks. Always disconnect the battery before starting work on electrical circuits. Furthermore, be cautious when lifting heavy parts, using proper lifting techniques to avoid injury.

Lastly, stay informed about the specific vehicle being serviced. Understanding its components and systems can help in identifying potential dangers and ensuring a safe repair process.