Comprehensive Guide to Servicing Your Chinese 110cc ATV

When it comes to maximizing the performance and longevity of your off-road vehicle, understanding the intricacies of its upkeep is essential. Regular maintenance not only ensures smooth operation but also prevents potential issues that could arise during your adventures. This guide serves as a comprehensive resource for enthusiasts looking to enhance their knowledge and skills in maintaining their machines.

Within these sections, you will find detailed insights into various aspects of care, from routine inspections to more complex adjustments. Each topic is designed to empower owners with the confidence to tackle common challenges independently. Whether you are a seasoned rider or a newcomer, this information will prove invaluable in keeping your vehicle in optimal condition.

Furthermore, recognizing early signs of wear and understanding the necessary steps for troubleshooting can save time and money. By familiarizing yourself with the components and functions of your vehicle, you will not only enhance your riding experience but also develop a deeper connection with your machine. Embrace the journey of learning, and equip yourself with the tools to maintain your off-road companion effectively.

Understanding 110cc ATV Basics

When it comes to off-road vehicles, it’s essential to grasp the fundamental concepts that govern their operation and maintenance. A basic understanding of these vehicles can greatly enhance your riding experience and ensure longevity.

Key aspects to consider include:

- Engine Performance: The heart of any vehicle is its engine. Familiarizing yourself with engine specifications, including power output and fuel type, is crucial.

- Transmission System: Understanding how the vehicle shifts gears and how this affects acceleration can improve handling.

- Suspension Setup: The suspension system determines ride comfort and stability on rough terrain. Knowing how it works helps in adjusting for different conditions.

- Braking Mechanism: A reliable braking system is vital for safety. Learning about the types of brakes and their maintenance is necessary.

Additionally, regular upkeep is fundamental for peak performance. Key maintenance practices include:

- Checking oil levels and changing it regularly.

- Inspecting air filters and cleaning or replacing them as needed.

- Examining tire pressure and tread for optimal grip.

- Monitoring brake functionality to ensure responsiveness.

By understanding these essential components and practices, you can enjoy a smoother, safer experience while navigating various terrains.

Common Issues in Chinese ATVs

When it comes to off-road vehicles, owners often encounter a variety of challenges that can affect performance and longevity. Understanding these typical problems can help enthusiasts maintain their rides and enhance their overall experience.

Electrical Problems: One of the most frequent issues involves the electrical system. Faulty wiring, poor connections, or weak batteries can lead to starting difficulties or intermittent power loss. Regularly checking connections and replacing worn components can mitigate these risks.

Fuel System Concerns: Issues with the fuel system are also common, including clogged filters or malfunctioning carburetors. Ensuring clean fuel and timely maintenance can help prevent performance dips and engine stalling.

Suspension Wear: The suspension components may wear out quicker than expected, resulting in a rough ride and decreased handling. Routine inspections and timely replacements of shocks and bushings can keep the vehicle performing optimally.

Brake System Failures: Another area that often requires attention is the braking system. Worn pads and fluid leaks can lead to diminished stopping power. Regular checks and replacements are crucial for safety.

General Maintenance: Beyond these specific issues, neglecting regular maintenance can lead to a host of problems. Keeping up with oil changes, filter replacements, and overall inspections will ensure the vehicle remains in peak condition.

Essential Tools for Repairs

Having the right instruments on hand is crucial for effective maintenance and restoration tasks. A well-equipped toolkit not only streamlines the process but also enhances the quality of the work performed. Here are some indispensable items that should be part of any technician’s arsenal.

- Wrenches: A set of adjustable and fixed wrenches is vital for loosening and tightening bolts and nuts.

- Screwdrivers: Both flat-head and Phillips screwdrivers are essential for handling various screws and components.

- Socket Set: A comprehensive socket set allows for quick and efficient work on fasteners in tight spaces.

- Pliers: Needle-nose and standard pliers can help grip, twist, and cut wires or small components.

- Torque Wrench: Ensures that fasteners are tightened to the correct specifications, preventing damage.

In addition to the basic tools, consider including the following specialized equipment:

- Multimeter: Essential for diagnosing electrical issues.

- Oil Filter Wrench: Necessary for easy removal of oil filters during maintenance.

- Grease Gun: For applying lubricant to moving parts, ensuring longevity and smooth operation.

Equipping yourself with these tools will make any maintenance task more efficient and effective, ensuring optimal performance of the machinery.

Step-by-Step Maintenance Guide

Proper upkeep is essential for ensuring the longevity and performance of your vehicle. This guide provides a comprehensive approach to routine care, highlighting critical tasks and schedules to keep your machine in optimal condition.

Essential Maintenance Tasks

- Oil Change: Regularly check and replace the engine oil to ensure smooth operation.

- Air Filter Cleaning: Inspect and clean or replace the air filter to maintain airflow and engine efficiency.

- Tire Inspection: Examine tire pressure and tread depth to ensure safety and handling.

- Brake Check: Regularly assess the brake pads and fluid levels for effective stopping power.

- Chain Lubrication: Keep the chain well-lubricated to prevent wear and improve performance.

Maintenance Schedule

- Every 20 hours of use:

- Change engine oil

- Inspect air filter

- Every 50 hours of use:

- Check brake system

- Inspect tires for wear

- Every 100 hours of use:

- Clean and lubricate the chain

- Check all fluid levels

By following these maintenance steps and adhering to the schedule, you can enhance the performance and reliability of your vehicle, ensuring it remains a dependable companion for all your adventures.

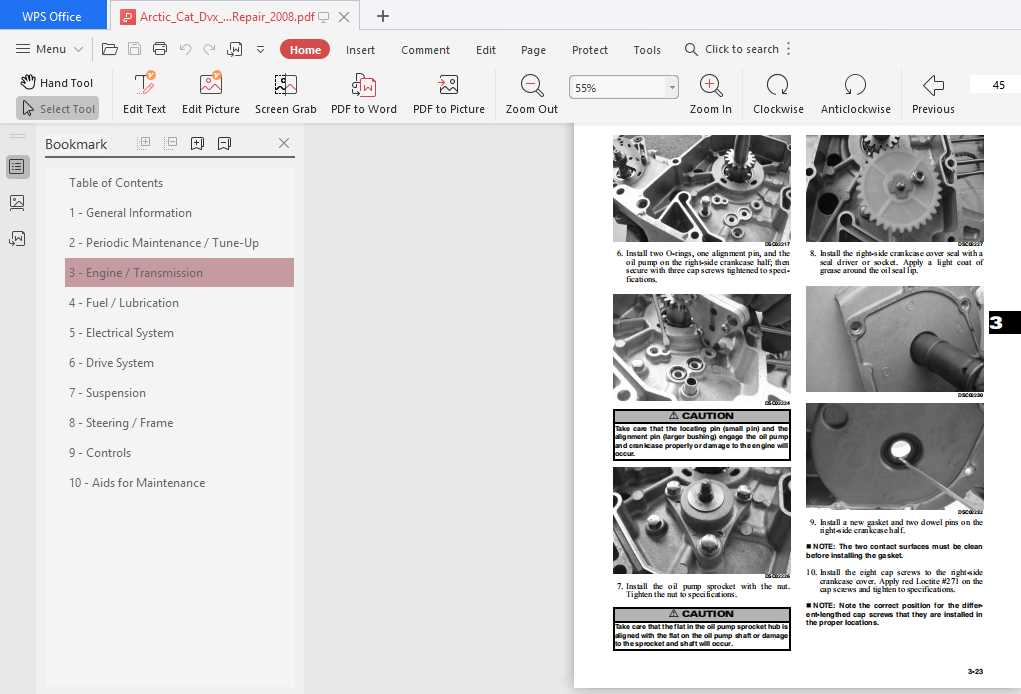

Engine Troubleshooting Techniques

Troubleshooting an engine involves a systematic approach to identify and resolve issues affecting performance. This process requires an understanding of the various components and their functions, as well as the symptoms that may indicate a malfunction. By applying effective diagnostic methods, one can isolate problems and implement corrective actions efficiently.

Begin by observing any irregularities during operation, such as unusual noises, vibrations, or performance drops. These signs often provide initial clues about potential faults. Next, check essential systems, including fuel delivery, ignition, and exhaust, to ensure they are functioning correctly. Utilizing a multimeter can help in diagnosing electrical issues, while compression tests can assess the health of the internal components.

Consulting schematics and wiring diagrams can be invaluable for understanding the layout and connections within the engine. This knowledge aids in pinpointing potential short circuits or component failures. Additionally, maintaining a log of past repairs and ongoing issues can offer insights into recurring problems, guiding more effective troubleshooting strategies in the future.

Electrical System Diagnostics

The evaluation of the electrical components is crucial for ensuring optimal performance and reliability of any vehicle. Proper diagnostics can identify issues that may cause malfunctions, enhance safety, and extend the lifespan of the machinery. Understanding how to assess the electrical framework allows for timely interventions and effective maintenance.

Start by examining the battery, as it serves as the heart of the electrical system. Check for corrosion on terminals, ensure connections are secure, and measure the voltage using a multimeter. A healthy battery should typically read around 12.6 volts when fully charged. If readings are low, consider charging or replacing the battery.

Next, inspect the wiring harness for any signs of wear, fraying, or damage. Pay special attention to areas where wires may rub against sharp edges or heat sources. A compromised wire can lead to shorts or open circuits, resulting in erratic behavior or total system failure.

After verifying the battery and wiring, assess the fuses. A blown fuse indicates an overload or short circuit somewhere in the system. Replace any faulty fuses and investigate the underlying cause to prevent future occurrences.

Lastly, evaluate the various electrical components, including the starter motor, ignition system, and lights. Utilize a multimeter to check for continuity and proper operation. Identifying faulty components early can save time and reduce the risk of further damage.

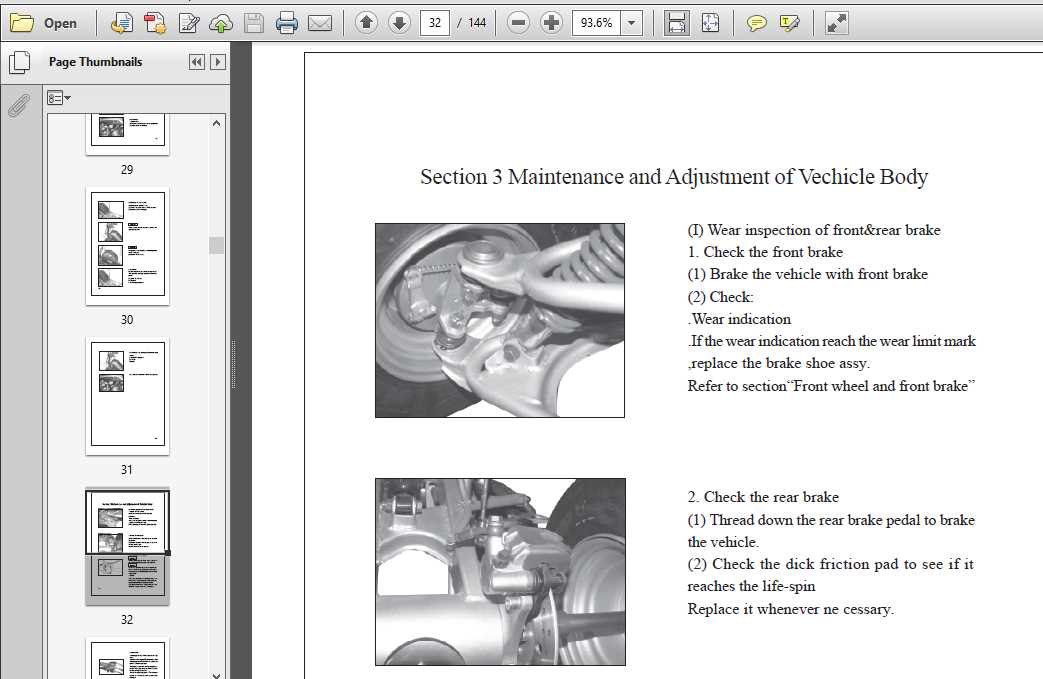

Braking System Maintenance Tips

Proper upkeep of the braking mechanism is crucial for ensuring safety and optimal performance. Regular checks and maintenance can prevent potential issues, enhance the longevity of components, and provide a smoother riding experience. Understanding key practices will help maintain the effectiveness of this essential system.

Begin by routinely inspecting the brake pads for wear. Look for signs of thinning or damage, as worn pads can compromise braking efficiency. Replacing them promptly will prevent further damage to the rotors.

Ensure that the brake fluid is at the correct level and free from contaminants. Low or dirty fluid can lead to diminished braking power. If necessary, flush and replace the fluid to maintain responsive braking action.

Examine the brake lines for any signs of leaks or cracks. Damaged lines can lead to fluid loss and subsequent braking failure. Address any issues immediately to ensure a reliable braking system.

Additionally, it’s important to check the brake discs or drums for signs of warping or scoring. Uneven surfaces can lead to vibrations and decreased stopping power. Resurfacing or replacing them may be required to maintain optimal function.

Lastly, keep the entire braking assembly clean and free from debris. Regular cleaning helps in identifying potential problems early and ensures that all components work seamlessly together.

Transmission Service Procedures

This section outlines essential steps for maintaining and optimizing the performance of the drive system. Regular attention to this area ensures longevity and reliability, allowing for smooth operation under various conditions.

Inspection Steps

- Check fluid levels and condition.

- Examine seals and gaskets for wear or leaks.

- Inspect the drive belts for signs of damage or fraying.

- Assess the overall cleanliness of the components.

Maintenance Tasks

- Replace the transmission fluid as per the recommended interval.

- Clean or replace filters to prevent contaminants from affecting performance.

- Adjust tension on the drive belts to ensure optimal engagement.

- Lubricate moving parts to reduce friction and wear.

Suspension Adjustments and Repairs

Proper maintenance of the suspension system is crucial for optimal performance and safety. Adjusting and servicing these components ensures that the vehicle can handle various terrains effectively, providing a smooth ride while minimizing wear and tear on other parts. Understanding the mechanisms and their adjustments can greatly enhance both comfort and control.

Key Components of Suspension

The suspension system consists of several key elements, each playing a vital role in overall functionality. Regular checks and adjustments can help identify issues before they escalate.

| Component | Function | Adjustment Tips |

|---|---|---|

| Shock Absorbers | Dampen impacts from rough terrain | Inspect for leaks; adjust stiffness as needed |

| Springs | Support vehicle weight and absorb shocks | Check for sag; replace if worn |

| Control Arms | Connect suspension to the chassis | Ensure they are aligned; tighten bolts if loose |

Common Issues and Solutions

Identifying and addressing common suspension problems can prevent further complications. Regular inspections are key to maintaining the integrity of the system.

Fuel System Cleaning Methods

Maintaining optimal performance in any engine requires a clean and efficient fuel delivery system. Over time, deposits and contaminants can accumulate, hindering fuel flow and affecting combustion efficiency. This section outlines effective methods to restore cleanliness in the fuel system, ensuring smooth operation and longevity.

Common Cleaning Techniques

There are several techniques to achieve a clean fuel system. Each method varies in complexity and effectiveness, depending on the level of contamination and the specific components involved.

| Method | Description | Pros | Cons |

|---|---|---|---|

| Fuel Additives | Chemical solutions that help dissolve deposits in the fuel system. | Easy to use; cost-effective. | May not eliminate severe buildup. |

| Manual Cleaning | Physically disassembling components to clean them with solvents. | Thorough cleaning; effective for stubborn deposits. | Time-consuming; requires expertise. |

| Ultrasonic Cleaning | Using high-frequency sound waves to agitate a cleaning solution. | Highly effective; penetrates hard-to-reach areas. | Requires special equipment; can be expensive. |

Preventive Measures

To minimize future contamination, consider implementing routine maintenance practices. Using high-quality fuel, regularly changing filters, and periodic system cleaning can significantly enhance the longevity and performance of the fuel system.

Safety Precautions During Repairs

When engaging in maintenance tasks, ensuring personal safety and the integrity of the equipment is paramount. Proper precautions can prevent accidents and damage, making the process more efficient and enjoyable. Following specific guidelines will help you navigate the repair process with confidence and care.

Essential Safety Guidelines

Before commencing any work, it is crucial to familiarize yourself with the potential hazards associated with the task. Here are some fundamental measures to keep in mind:

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use gloves, goggles, and other appropriate attire to safeguard against injuries. |

| Work in a Ventilated Area | Ensure the workspace is well-ventilated to avoid inhaling harmful fumes. |

| Disconnect Power Sources | Before starting any task, disconnect all power sources to prevent electrical hazards. |

| Use Proper Tools | Utilize the correct tools for the job to avoid injuries and ensure effective work. |

| Keep Workspace Organized | Maintain a clean and tidy area to minimize the risk of accidents and confusion. |

Post-Repair Considerations

Once the maintenance work is complete, it is important to conduct a thorough inspection to ensure everything is functioning correctly. Reassessing the environment and tools used can also help in identifying any overlooked hazards. Taking these steps not only enhances safety but also promotes longevity and reliability of the equipment.

Resources for Further Learning

Expanding your knowledge in maintenance and troubleshooting can significantly enhance your experience with off-road vehicles. This section offers various resources that can provide deeper insights and practical skills essential for effective handling and care of your machinery.

Online Tutorials and Videos

There are numerous platforms where you can find video tutorials and step-by-step guides tailored to different aspects of vehicle upkeep. Websites like YouTube host a plethora of channels dedicated to mechanics, showcasing everything from basic maintenance techniques to advanced diagnostic procedures. Engaging with these visual resources can enhance your understanding and boost your confidence in performing repairs.

Books and Manuals

Investing in literature focused on vehicle maintenance can serve as an invaluable reference. Look for comprehensive guides that cover various models and maintenance procedures. Additionally, forums and online communities often recommend specific texts that have proven beneficial for enthusiasts and professionals alike. These resources can help you stay informed about best practices and new developments in the field.