2010 Dodge Nitro Repair Guide and Maintenance Tips

Every vehicle owner eventually faces the need to understand their car’s inner workings better. Whether you’re a new driver or have years of experience, knowing how to address potential issues and routine upkeep can be invaluable. Regular care not only ensures smoother rides but also prevents costly repairs down the line.

In this guide, we’ll walk through essential steps and advice for maintaining a well-functioning vehicle, from identifying warning signs to handling minor fixes independently. Practical knowledge of the components and how they operate can give you the confidence to handle many situations without always relying on mechanics.

This section aims to help enthusiasts and owners alike with various troubleshooting techniques, practical upkeep tips, and valuable insights into core systems. From diagnosing basic problems to performing periodic checks, we cover the basics needed to keep your vehicle in optimal condition.

2010 Dodge Nitro Repair Manual

This guide provides essential insights for maintaining and servicing your vehicle to ensure smooth operation and extend its lifespan. Here, you will find structured details on a variety of maintenance tasks, helping you understand each component’s unique requirements.

From routine inspections to specific adjustments, these instructions cover everything you need to keep your vehicle in top shape. The goal is to empower owners to handle basic upkeep confidently while knowing when to consult professionals for more technical needs.

Key topics include the engine, transmission, electrical systems, and brake functions. Every section is designed to break down complex steps into manageable actions, making maintenance approachable and effective.

Engine Maintenance and Troubleshooting

Regular upkeep and prompt issue resolution are essential for a smooth-running engine and ensuring a vehicle’s long-term reliability. Understanding essential maintenance practices and common troubleshooting techniques helps keep the engine performing efficiently and can prevent costly repairs.

Essential Engine Maintenance Practices

To maintain optimal engine performance, several key maintenance routines should be followed consistently:

- Oil and Filter Replacement: Regularly changing oil and filters reduces wear and tear on engine components, ensuring smoother operation and reducing buildup of harmful debris.

- Fluid Checks: Monitoring levels of coolant, brake fluid, and transmission fluid keeps the engine cool, safe, and functional. Low fluid levels can lead to overheating or compromised safety features.

- Air Filter Replacement: A clean air filter improves air intake, boosting fuel efficiency and engine responsiveness. Check the filter periodically to ensure unrestricted airflow.

Common Troubleshooting Techniques

If issues arise with engine performance, several basic troubleshooting steps can help identify the source of the problem:

- Inspect for Unusual Noises: Knocking or tapping sounds often indicate worn-out components, such as belts or bearings. Identifying these sounds early can prevent more extensive damage.

- Examine Warning Lights: When the engine light activates, use a diagnostic tool to read the error code, helping pinpoint any malfunction quickly. Ignoring these indicators can lead to further issues.

- Check for Leaks: Look for oil or coolant leaks under the vehicle, which can suggest worn seals or hoses. Catching leaks early helps prevent major engine failure.

Keeping these practices in mind can sig

Transmission Diagnostics and Repairs

Identifying and addressing transmission issues early is essential to ensure a vehicle’s smooth operation and longevity. This section will guide you through common indicators of transmission problems, key diagnostic steps, and effective repair strategies to maintain optimal performance.

Common Signs of Transmission Issues

Recognizing symptoms of transmission trouble can prevent more significant damage. Here are several typical signs to watch for:

- Delayed Shifting: A noticeable lag when shifting gears, either automatic or manual, could signal a transmission problem.

- Unusual Sounds: Whining, grinding, or clunking noises may point to issues within the transmission system.

- Fluid Leaks: Transmission fluid on the ground often indicates a seal or gasket issue, which requires prompt attention.

- Check Engine Light: Many vehicles alert drivers to potential transmission issues via dashboard lights, prompting a diagnostic review.

Basic Diagnostic Steps

Proper diagnostics help identify the root cause of transmission issues and determine the necessary repairs. Follow these steps:

- Check Fluid Levels: Ensure the transmission fluid level is adequate and the fluid is clean; discolored or burnt-smelling fluid may require replacement.

- Scan for Error Codes: Use a diagnostic tool to scan for codes that reveal potential issues within the transmission system.

- Inspect Mechanical Components: Visually check for any damage or wear on transmission parts, especially the linkage and mounts.

- Conduct a Road Test: Observing gear shifts, sounds, and performance during a test drive can provide insights into specific transmission

Brake System Repair Guidelines

Effective maintenance of the braking system is essential for vehicle safety and driving performance. A well-functioning brake setup helps ensure timely response during braking and enhances control, especially in challenging road conditions. In this section, we will discuss important practices for evaluating and servicing key components of the braking mechanism.

Inspecting Brake Components

Regular checks of parts such as brake pads, discs, and calipers can prevent wear-related issues. Monitoring these components helps in identifying early signs of damage, like thinning pads or warped discs, which can impact braking efficiency. Examine each part closely for rust or leaks, as these may indicate the need for immediate replacement.

Maintaining Brake Fluid Levels

The brake fluid is crucial for smooth and responsive braking action. Checking fluid levels periodically and ensuring they are topped up is essential. If the fluid appears cloudy or has particles, it should be replaced to maintain optimal performance. Bleeding the brakes during fluid changes also helps remove trapped air, which can reduce braking responsiveness.

Following these guidelines can contribute to a reliable braking system, enhancing safety and vehicle control. Addressing minor issues early can prevent costly repairs and ensure a stable, dependable braking experience on the road.

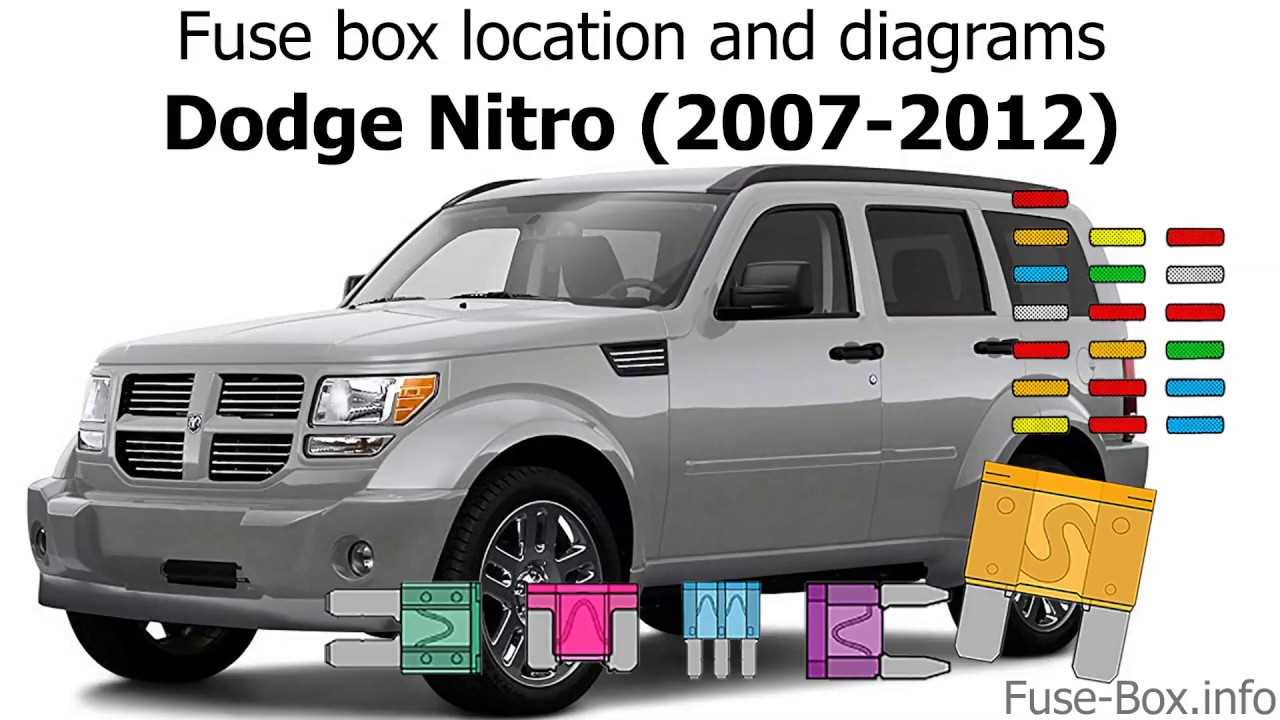

Electrical System Overview and Fixes

The electrical system is the backbone of any vehicle’s operation, ensuring functionality across all crucial components. Understanding the basics of this system and knowing how to address common issues can greatly enhance the reliability and safety of a vehicle.

Key Components of the Electrical System

The vehicle’s electrical network consists of several core elements that work together to power lights, ignition, climate control, and more. These parts often include:

- Battery: Supplies initial power needed for starting and maintaining system stability.

- Alternator: Recharges the battery and supports other electrical components while the engine runs.

- Starter Motor: Engages the engine to start the vehicle by drawing power from the battery.

- Fuses and Relays: Protect the system from electrical overloads and regulate power distribution.

Common Electrical Issues and Solutions

Electrical issues can arise from various sources, such as wiring faults, corrosion, or component wear. Here are some typical problems and troubleshooting tips:

- Dead Battery: Check battery terminals for corrosion, ensure secure connections, and consider replacing the battery if it frequently fails to hold a charge.

- Faulty Alternator: A weak or malfunctioning alternator can lead to dim lights or battery drainage. Testing with a voltmeter can confirm if it needs replacement.

- Wiring Issues: Inspect for damaged or frayed wires, especially around connectors, which may cause intermittent electrical failures.

- Blown Fuses: Regularly inspect fuses and replace any that have blown to restore functionality to affected components.

Regular maintenance and early detection are essential for a well-functioning electrical system. Addressing minor issues promptly can help prevent more extensive repairs and ensure a smoother driving experience.

Suspension and Steering Maintenance

Proper upkeep of the suspension and steering systems is crucial for ensuring a smooth driving experience and optimal vehicle handling. Regular maintenance not only enhances performance but also extends the lifespan of these components. Understanding the importance of each element within these systems is essential for effective care.

Routine inspections should focus on key components such as shocks, struts, control arms, and steering linkages. Checking for signs of wear or damage can prevent more significant issues down the line. Additionally, maintaining the appropriate fluid levels in power steering systems is vital for ensuring responsive handling.

It is advisable to follow a systematic approach when servicing suspension and steering elements. This includes checking alignment and balancing, as improper settings can lead to uneven tire wear and affect vehicle stability. Periodic replacement of worn-out parts will significantly improve ride quality and safety.

Cooling System Service Instructions

The cooling system plays a vital role in maintaining optimal engine performance by regulating temperatures. Proper maintenance and timely servicing are essential to prevent overheating and ensure the longevity of the vehicle.

Inspection of Components

Regular checks of the cooling components are crucial. Examine hoses for wear and tear, ensuring there are no cracks or leaks. The radiator should be free of obstructions and clean to facilitate proper airflow. Additionally, inspect the coolant level and quality, replacing it if necessary to prevent corrosion and scale buildup.

Fluid Replacement and System Bleeding

It is recommended to replace the coolant at specified intervals to maintain efficiency. When draining the system, ensure to dispose of old fluid properly. After refilling, bleed the system to eliminate air pockets, which can lead to inefficient cooling and possible damage. Following these guidelines will help in achieving a reliable and efficient cooling system.

Fuel System Repair Techniques

Proper maintenance and troubleshooting of the fuel system are crucial for optimal engine performance. Understanding various approaches to diagnose and fix issues within the fuel delivery mechanism ensures a smooth and efficient operation of the vehicle. This section covers essential methods and best practices for addressing common fuel system problems.

Common Issues and Diagnostic Approaches

Before attempting any repairs, it is essential to identify typical fuel system issues. These may include fuel leaks, clogged filters, or faulty injectors. Here are some common problems along with diagnostic methods:

Issue Diagnostic Technique Fuel Leak Visual inspection for damp areas or puddles, use of a pressure gauge Clogged Filter Check fuel flow rates, replace the filter as needed Faulty Injector Use a multimeter to test resistance, perform a balance test Repair Procedures

Once the issue is identified, appropriate repair techniques can be employed. Here are steps for some common repairs:

- For leaks, replace damaged hoses or fittings, ensuring proper sealing.

- To address a clogged filter, locate the filter and replace it with a new component, ensuring all connections are secure.

- For faulty injectors, consider cleaning or replacing them, followed by re-testing to confirm functionality.

Interior Components and Adjustments

The interior of a vehicle plays a crucial role in both comfort and functionality. Understanding the various components and their adjustments can significantly enhance the driving experience. This section will explore essential elements within the cabin, focusing on their features, maintenance, and adjustment techniques to ensure optimal performance.

Seating Arrangements: The seating system is designed for both driver and passenger comfort. It is essential to regularly check the adjustment mechanisms to ensure they operate smoothly. Adjustments may include modifying the height, tilt, and lumbar support for personalized comfort.

Dashboard Features: The dashboard houses critical controls and displays necessary for operation. Regular inspection of gauges, buttons, and electronic displays can prevent malfunction. Adjustments may involve recalibrating digital displays or replacing faulty switches to ensure accurate readings and functionality.

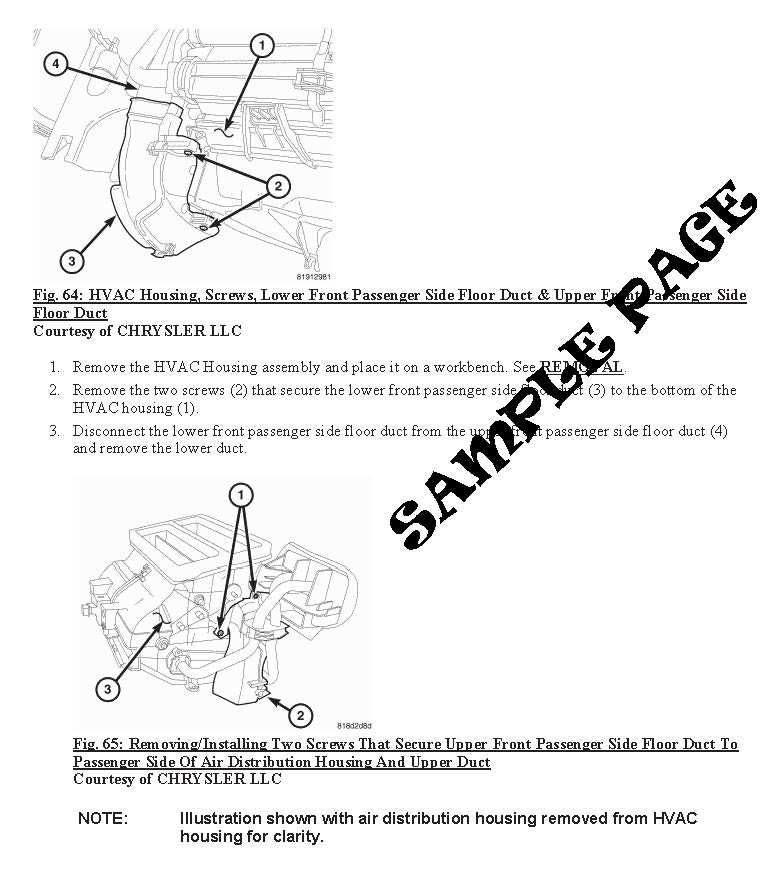

Climate Control Systems: Maintaining a comfortable interior temperature relies heavily on the climate control system. Regularly inspecting the HVAC (Heating, Ventilation, and Air Conditioning) components and adjusting settings for airflow direction and temperature can enhance passenger comfort.

Sound System: A quality sound system enhances the driving experience. Adjusting speaker settings, balance, and treble can optimize audio output. Periodic maintenance checks can help identify any issues with speakers or connectivity.

Understanding these interior components and making necessary adjustments will not only improve comfort but also contribute to a safer and more enjoyable journey.

Exterior Care and Part Replacements

Maintaining the outer appearance and functionality of a vehicle is essential for longevity and aesthetics. Proper care ensures that all components remain in optimal condition, preventing issues that may arise from neglect. This section outlines key practices for preserving the exterior and replacing necessary parts effectively.

Regular maintenance involves several crucial steps:

- Washing: Frequent washing helps remove dirt, grime, and contaminants that can damage the paint and surface.

- Waxing: Applying a protective wax layer enhances shine and safeguards the paint from UV rays and environmental factors.

- Inspections: Regularly check for scratches, dents, and rust to address any damage promptly.

When it comes to part replacements, consider the following components that may require attention:

- Bumpers: Inspect for cracks or misalignments and replace if necessary to ensure safety and aesthetics.

- Lights: Regularly check headlights, taillights, and indicators for functionality and replace burnt-out bulbs immediately.

- Windshield Wipers: Replace worn wipers to maintain visibility during adverse weather conditions.

- Mirrors: Check for any damage and replace broken or fogged mirrors for safety and enhanced visibility.

By adhering to these maintenance tips and promptly addressing part replacements, you can ensure that the vehicle remains in excellent condition while enhancing its visual appeal.

Safety Systems and Sensor Checks

This section focuses on the critical components that ensure the vehicle’s safety. Regular assessment of these systems is essential to maintain optimal performance and prevent potential hazards while driving. By understanding the various sensors and their functions, vehicle owners can ensure a safer driving experience.

Key Safety Features

- Anti-lock braking system (ABS)

- Traction control

- Electronic stability control (ESC)

- Airbag systems

- Advanced driver-assistance systems (ADAS)

Sensor Diagnostics

To ensure all safety features are operational, regular diagnostics of the sensors are necessary. Follow these steps for effective checks:

- Inspect sensor connections for corrosion or damage.

- Verify the functionality of warning indicators on the dashboard.

- Conduct a visual check of the sensor alignment.

- Utilize diagnostic tools to scan for error codes.

- Perform a test drive to assess real-time sensor performance.