Pfaff 1471 Repair and Maintenance Guide

Understanding the intricacies of sewing machinery is essential for achieving optimal performance and longevity. This guide aims to provide insights into the essential aspects of maintaining and troubleshooting a specific type of sewing device, ensuring that users can efficiently address common issues and enhance their sewing experience.

In this section, readers will discover various techniques and tips that empower them to take control of their equipment. By familiarizing themselves with the components and functionalities, users can gain confidence in their ability to perform necessary tasks, ultimately leading to a more satisfying and productive sewing journey.

Equipped with the right knowledge, individuals can not only resolve minor complications but also extend the lifespan of their devices. Emphasizing the importance of regular upkeep, this guide serves as a valuable resource for anyone looking to maintain their sewing apparatus in peak condition.

Common Issues with Sewing Machines

Sewing devices are vital tools for crafting, but they can encounter various challenges over time. Understanding these common problems can help users troubleshoot effectively and maintain their equipment in optimal condition.

Frequent complications include:

| Issue | Description |

|---|---|

| Thread Tension Problems | Improper tension can lead to loose or tight stitches, affecting the overall quality of the work. |

| Needle Issues | A dull or bent needle can cause skipped stitches and fabric snags, hindering the sewing process. |

| Bobbin Problems | Incorrectly wound or inserted bobbins may result in thread jams or inconsistent stitching. |

| Motor Malfunctions | A failure in the motor can prevent the machine from running, necessitating further investigation. |

| Feed Mechanism Failure | Issues with the feed dogs can lead to uneven fabric movement, impacting stitching accuracy. |

By recognizing these challenges, users can take proactive measures to ensure smooth operation and enhance their crafting experience.

Essential Tools for Maintenance

Regular upkeep of sewing machines is crucial for optimal performance and longevity. Having the right tools on hand ensures that minor adjustments and necessary tasks can be executed efficiently, keeping the machine running smoothly.

Here are some indispensable tools to consider for routine maintenance:

- Screwdrivers: A set of various-sized screwdrivers is essential for accessing internal components.

- Lint Brush: This tool helps remove dust and debris from hard-to-reach areas.

- Oiling Can: Proper lubrication is vital; an oil can facilitates precise application to moving parts.

- Needle Kit: A variety of needles is necessary for different fabrics and sewing techniques.

- Thread Cutter: A sharp thread cutter or scissors is useful for quick and clean thread removal.

Equipping yourself with these tools will enhance your ability to perform maintenance tasks effectively, prolonging the life of your sewing machine.

Step-by-Step Cleaning Process

Maintaining your sewing machine’s optimal performance requires a thorough cleaning routine. This process not only enhances functionality but also prolongs the lifespan of the equipment. Follow these steps to ensure a meticulous clean.

Gather Necessary Supplies: Start by collecting all essential cleaning tools. You will need a soft brush, lint-free cloths, machine oil, and a screwdriver. Having everything ready will streamline the process.

Remove the Needle and Presser Foot: Safely detach the needle and presser foot from the machine. This will allow for better access to hard-to-reach areas during the cleaning procedure.

Clean the Bobbin Area: Open the bobbin compartment and gently brush away any accumulated dust and lint. Ensure the area is free of debris to maintain smooth operation.

Check the Feed Dogs: Inspect the feed dogs for any fabric threads or lint that may hinder performance. Use a brush to clean these components thoroughly.

Wipe the Exterior: Take a lint-free cloth and wipe down the outer surfaces of the machine. This will remove fingerprints and dust, keeping your equipment looking pristine.

Oil Moving Parts: Apply a few drops of machine oil to the designated areas as indicated in your instruction guide. Proper lubrication is vital for maintaining optimal function.

Reassemble the Machine: Once cleaning is complete, carefully reattach the needle and presser foot. Ensure everything is securely in place before powering on the machine.

Following this systematic cleaning approach will help maintain your sewing equipment in excellent condition, ensuring reliable performance for all your projects.

Lubrication Guidelines for Smooth Operation

Proper lubrication is essential for the efficient functioning of sewing machines, ensuring longevity and optimal performance. Regular application of suitable lubricants can prevent wear and tear, minimize friction, and maintain the seamless operation of moving parts.

When lubricating, consider the following guidelines:

- Use the Right Lubricant: Select a high-quality oil specifically designed for sewing machines to avoid damage to internal components.

- Frequency of Application: Lubricate the machine every 8 to 10 hours of use or as recommended by the manufacturer.

- Key Areas to Lubricate: Focus on the following parts:

- Needle bar

- Hook area

- Feed dogs

- Bobbin case

- Clean Before Lubricating: Ensure that all areas are clean and free of dust or lint before applying oil.

- Apply Sparingly: Use a few drops of lubricant; excess oil can attract dirt and debris, leading to further issues.

By adhering to these lubrication practices, users can enhance the efficiency and lifespan of their sewing machines, ensuring a smooth and enjoyable sewing experience.

Troubleshooting Stitching Problems

When encountering issues with the quality of stitches, it is essential to identify the underlying causes to ensure optimal performance of the sewing apparatus. Various factors can influence stitch formation, including tension settings, needle condition, and thread compatibility. This section provides guidance on diagnosing common stitching irregularities and suggests solutions for effective resolution.

Common Issues and Solutions

The following table outlines frequent stitching problems along with their potential causes and recommended fixes:

| Problem | Possible Causes | Suggested Solutions |

|---|---|---|

| Uneven stitches | Incorrect tension, worn needle | Adjust tension settings, replace needle |

| Skipped stitches | Improper needle size, dull blade | Select correct needle size, replace with a new needle |

| Thread breaking | Low-quality thread, incorrect threading | Use high-quality thread, rethread machine |

Final Checks

After addressing the identified problems, it is advisable to conduct a test run with fabric scraps. This practice helps verify that the adjustments have rectified the stitching issues. Consistent maintenance and timely replacement of worn components will enhance the longevity and efficiency of the sewing equipment.

Replacing Worn Parts Effectively

Maintaining optimal performance in sewing machines often involves the timely replacement of components that have experienced wear over time. Identifying and addressing these issues not only enhances the machine’s longevity but also improves the quality of the finished products.

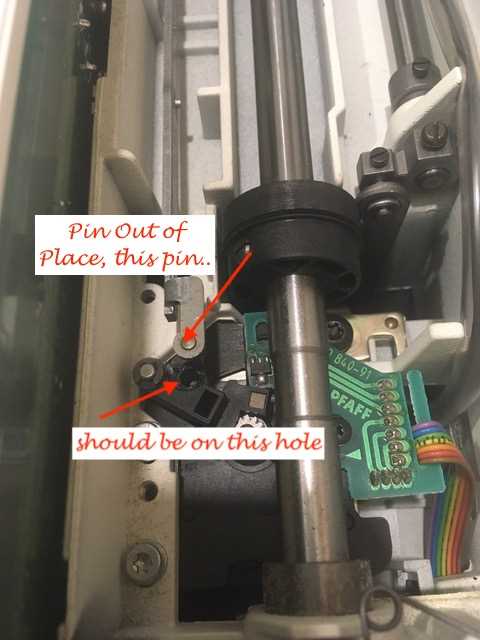

Identifying Worn Components

Before proceeding with replacements, it is crucial to accurately diagnose which parts are compromised. Common indicators of wear include unusual noises, inconsistent stitching, and visible signs of damage. Regular inspections can help detect these problems early, ensuring smoother operation.

Steps for Replacement

Once the worn components have been identified, follow these steps for effective replacement:

- Gather Tools: Ensure you have the necessary tools on hand, including screwdrivers, pliers, and replacement parts.

- Careful Disassembly: Take note of how components are assembled and use a methodical approach to disassemble the machine.

- Replace Parts: Install new parts carefully, ensuring they fit snugly and align correctly with surrounding components.

- Test Functionality: After reassembly, test the machine to confirm that the new parts operate as intended and the performance has improved.

By following these guidelines, one can effectively restore the functionality of the equipment and prolong its useful life.

Calibration Techniques for Precision

Achieving optimal accuracy in mechanical systems requires meticulous calibration methods that ensure components operate within desired parameters. This section delves into various strategies to enhance performance and reliability in complex equipment.

One effective approach is the use of reference standards to compare and adjust measurements. These benchmarks provide a reliable foundation for verifying the accuracy of instruments and ensuring they meet specified criteria.

Another essential technique involves systematic adjustments, which can be performed through iterative testing and fine-tuning. By making incremental changes and observing their effects, operators can pinpoint discrepancies and enhance the overall functionality of the device.

Utilizing specialized software for analysis also plays a crucial role in modern calibration practices. Advanced algorithms can process data more efficiently, identifying areas that require improvement and suggesting optimal settings for various conditions.

In summary, the implementation of these calibration techniques is vital for maintaining precision and achieving superior performance in intricate machinery. A proactive approach to adjustment and verification ensures long-lasting efficacy and reliability.

Understanding Electrical Components

Grasping the fundamentals of electrical components is essential for effective maintenance of sewing equipment. These components play a crucial role in the overall functionality, ensuring that the machinery operates smoothly and efficiently. By familiarizing oneself with the various elements, one can diagnose issues and enhance performance.

Key Elements of Electrical Systems

Electrical systems consist of several vital parts, each serving a specific function:

- Resistors: These components regulate current flow, preventing overloads and maintaining stable operation.

- Capacitors: Used to store and release electrical energy, capacitors help in smoothing out fluctuations in voltage.

- Transistors: Acting as switches or amplifiers, transistors control the flow of electricity in circuits.

- Diodes: These ensure that current flows in one direction only, protecting other components from damage.

Importance of Proper Maintenance

Regular inspection and maintenance of electrical components are vital to prolonging the lifespan of the machinery:

- Identify signs of wear, such as discoloration or corrosion.

- Check connections for looseness to prevent intermittent failures.

- Replace faulty components promptly to avoid cascading issues.

Understanding these elements and their maintenance requirements empowers users to keep their equipment in optimal condition, minimizing disruptions and ensuring reliable performance.

Managing Tension Settings Properly

Correctly adjusting the tension of sewing threads is essential for achieving flawless stitches and optimal fabric handling. Proper tension ensures that threads interlock accurately, preventing issues such as puckering or loose seams. Understanding the mechanics behind tension settings is crucial for both novice and experienced users alike.

Identifying the Ideal Tension requires careful observation. Start by experimenting with various fabrics and thread types, noting how each combination affects stitch quality. Regularly test stitches on scrap fabric to determine the most suitable settings for your projects.

Common Issues often stem from incorrect tension adjustments. If stitches appear uneven or tangled, revisit the tension settings. Tightening or loosening the tension slightly can lead to significant improvements. Always remember that each fabric may require different settings to achieve the best results.

Maintaining consistent tension is equally important. Ensure that the machine is properly threaded and that the thread spool is securely placed. Regularly check for any obstructions or worn components that could affect tension. By prioritizing these practices, you can enhance your sewing experience and produce high-quality results.

Storage and Care Tips

Proper maintenance and appropriate storage are essential for prolonging the lifespan of your sewing device. Adopting best practices can help maintain optimal performance and prevent unnecessary wear.

Storage Environment: Keep the machine in a cool, dry place away from direct sunlight. Excess moisture and extreme temperatures can damage sensitive components.

Cleaning: Regularly dust the exterior and remove any lint buildup from the interior. Use a soft, lint-free cloth to wipe surfaces. Ensure to follow the manufacturer’s recommendations for cleaning agents.

Protection: Use a protective cover when the device is not in use. This will shield it from dust and accidental scratches. If possible, store it in a sturdy case to prevent any physical damage.

Routine Checks: Periodically inspect the machine for any loose parts or signs of wear. Addressing small issues promptly can prevent more significant problems down the line.

Finding Replacement Parts Online

Locating suitable components for your sewing device can be a straightforward process with the right approach. The internet offers a wealth of resources where enthusiasts and professionals alike can source essential items needed for their equipment. Understanding how to navigate these platforms can significantly enhance your experience and ensure you find the correct parts efficiently.

Start by exploring specialized websites that focus on sewing machine components. Many retailers provide detailed catalogs, making it easy to find specific items. Additionally, user forums and online communities can be invaluable for recommendations and reviews on various suppliers.

| Resource Type | Examples |

|---|---|

| Specialty Retailers | sewingpartsonline.com, sewingmachine.com |

| Marketplace Platforms | eBay, Amazon |

| User Forums | sewing.org, quiltingboard.com |

| Local Dealers | Check with local sewing shops |

Always verify the compatibility of parts with your specific model before making a purchase. Reading customer reviews and ratings can provide insight into the reliability of the supplier and the quality of the components. With careful research, you can ensure your sewing apparatus continues to operate smoothly.

Resources for Further Learning

Expanding your knowledge on machine maintenance and troubleshooting can significantly enhance your skills. Numerous resources are available to deepen your understanding and refine your techniques.

- Online Tutorials: Explore video platforms for step-by-step guides.

- Books: Look for comprehensive texts focusing on sewing equipment care.

- Forums: Join communities where enthusiasts share experiences and solutions.

- Workshops: Attend local classes or webinars to gain hands-on experience.

- Manufacturer Websites: Utilize official sites for product insights and updates.

Utilizing these resources will ultimately empower you to troubleshoot and maintain various sewing machines with confidence.