Comprehensive Guide to Diesel Injection Pump Repair

The efficient functioning of any combustion engine heavily relies on a well-calibrated fuel delivery mechanism. This essential component ensures that the correct amount of fuel is delivered to the engine, optimizing performance and reducing emissions. Understanding the intricacies of this system is crucial for both enthusiasts and professionals seeking to maintain or enhance engine functionality.

In this detailed exploration, we will delve into the various aspects of maintaining and enhancing the fuel distribution assembly. From diagnosing common issues to implementing effective solutions, this guide aims to provide readers with the knowledge needed to navigate the complexities of the system. Each section will outline fundamental principles, troubleshooting techniques, and step-by-step procedures, making it accessible to those with varying levels of expertise.

Whether you are a seasoned mechanic or a curious novice, gaining insights into this vital aspect of engine operation can lead to improved vehicle performance and longevity. By equipping yourself with the right information, you can ensure that your engine remains in optimal condition, ready to meet the demands of the road.

Understanding Diesel Injection Pumps

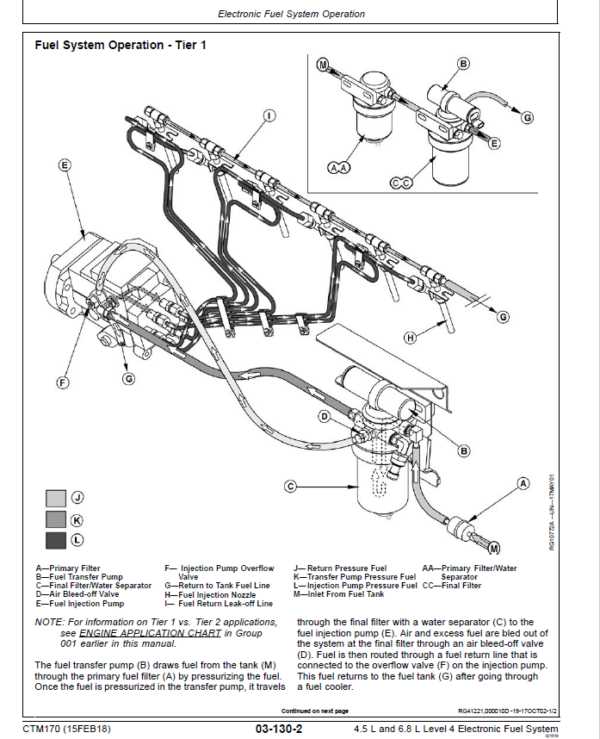

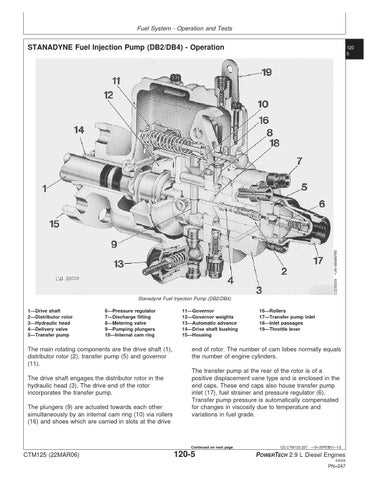

The intricate mechanism behind fuel delivery systems plays a crucial role in engine performance and efficiency. These systems ensure that the proper amount of fuel is supplied to the combustion chamber at the right time, significantly influencing power output and emissions.

At the heart of these systems lies a sophisticated assembly designed to manage fuel pressure and timing. Precision is essential; even minor deviations can lead to inefficient combustion and increased wear on engine components. Understanding the components and their functions is vital for diagnosing issues and optimizing performance.

Key elements include the control unit, which regulates the flow, and various sensors that monitor engine conditions. Familiarity with these parts enables technicians to identify malfunctions and apply corrective measures effectively. Proper maintenance and periodic checks can prevent costly repairs and enhance the lifespan of the engine.

Ultimately, comprehending the operation of fuel delivery systems empowers vehicle owners and professionals alike, ensuring optimal performance and reliability.

Common Issues with Diesel Pumps

Understanding the frequent challenges faced by fuel delivery systems is essential for maintaining optimal engine performance. These systems are crucial for ensuring that fuel is efficiently supplied to the combustion chamber, and any malfunction can lead to significant operational issues.

One of the most prevalent problems is inadequate fuel delivery, which can result from clogged filters or malfunctioning components. This often manifests as reduced engine power or difficulty starting the vehicle. Additionally, air leaks within the system can create pressure imbalances, further hindering performance.

Another common issue is excessive wear of internal parts due to contaminated fuel. Impurities can cause abrasion, leading to premature failure of critical components. Regular maintenance and the use of high-quality fuel can help mitigate these risks.

Inconsistent pressure regulation is also a frequent concern, often caused by faulty regulators or incorrect settings. This can lead to uneven fuel flow, affecting engine efficiency and emissions. Addressing these issues promptly is vital for ensuring smooth operation.

Finally, electronic control failures can disrupt the system’s functionality, resulting in poor performance and increased emissions. Diagnosing and resolving these electrical issues requires specialized knowledge and tools.

Signs of a Failing Pump

Recognizing the indicators of a malfunctioning fuel delivery system is crucial for maintaining optimal engine performance. Various symptoms can signal underlying issues that, if left unaddressed, may lead to significant operational problems. Being aware of these signs can help in timely diagnostics and maintenance.

Common Symptoms

One of the most noticeable signs is irregular engine performance, such as misfiring or stalling during acceleration. Additionally, a decrease in power and efficiency often accompanies these issues, leading to increased fuel consumption. Unusual noises, such as knocking or whining sounds, may also indicate that the system is not functioning as intended.

Fluid Leaks and Warning Lights

Another critical sign is the presence of fluid leaks around the engine area, which could point to a compromised seal or fitting. Furthermore, dashboard warning lights may illuminate, signaling the need for immediate attention. Addressing these symptoms promptly can prevent further damage and ensure the longevity of the engine.

Essential Tools for Repair

To successfully address issues in fuel delivery systems, having the right set of instruments is crucial. This section outlines the key equipment needed for effective troubleshooting and maintenance. Each tool plays a significant role in ensuring precise diagnostics and efficient work processes.

- Wrenches: Various sizes are necessary for loosening and tightening components.

- Screwdrivers: A range of flathead and Phillips screwdrivers aids in accessing different parts.

- Torque Wrench: Ensures that fittings are tightened to the manufacturer’s specifications.

- Diagnostic Tools: Electronic testers help in assessing system performance and identifying faults.

- Fuel Line Disconnect Tools: Specialized tools facilitate safe separation of fuel lines without damage.

In addition to the basics, certain advanced instruments can enhance efficiency:

- Pressure Gauges: Measure fuel pressure accurately to ensure optimal system function.

- Cleaning Kits: Essential for maintaining cleanliness in components and preventing contamination.

- Micrometer: Used to measure precise dimensions of parts for optimal fitting.

Having these essential instruments at hand will significantly streamline the process, ensuring that all tasks can be completed with accuracy and effectiveness.

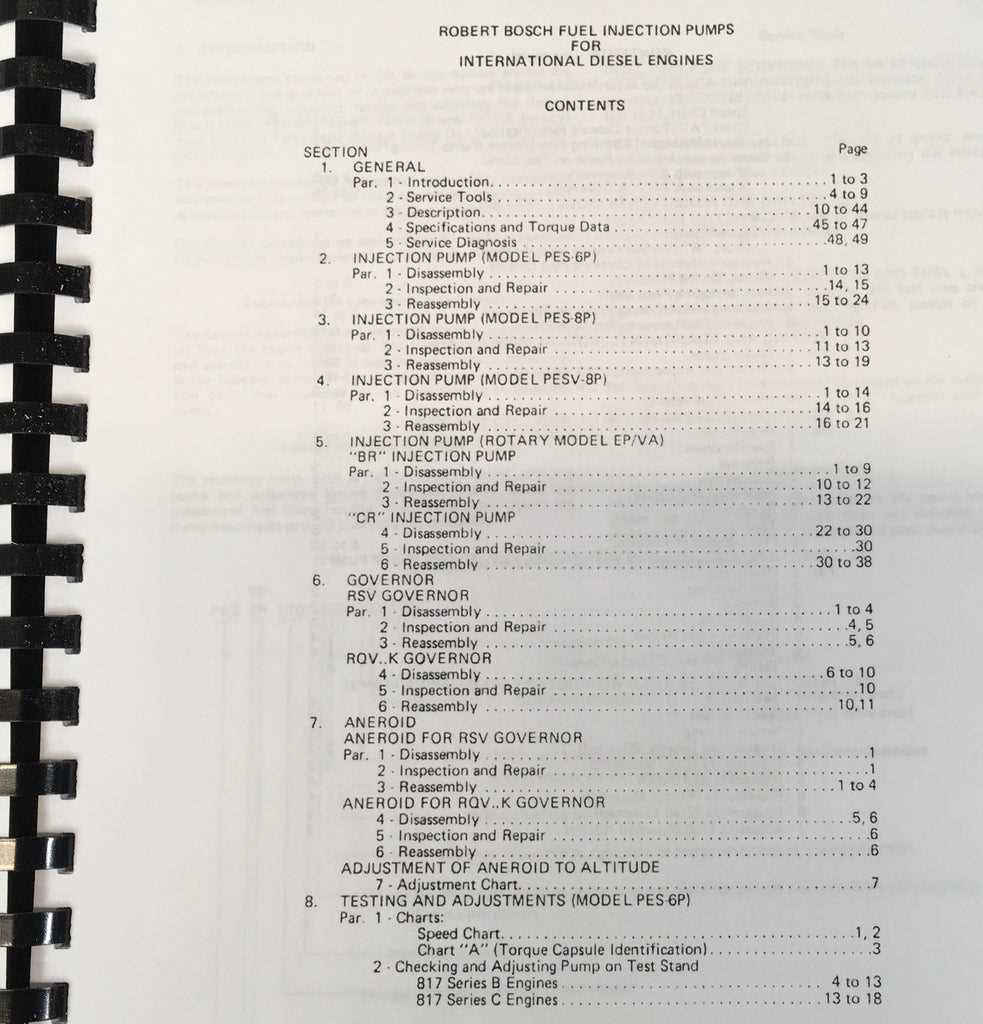

Step-by-Step Repair Guide

This section provides a comprehensive approach to restoring the functionality of a critical component within a specific engine system. Following these detailed instructions will help you understand each stage of the process, ensuring accuracy and efficiency in your work.

Preparation and Tools

Before starting the process, gather all necessary tools and materials. Having the right equipment at hand, such as wrenches, screwdrivers, and diagnostic instruments, is essential. Additionally, ensure that your workspace is clean and organized to facilitate smooth operation.

Disassembly Process

Begin by carefully removing the component from the engine. Follow a systematic approach to disassemble each part, noting the order and orientation of components. This meticulous attention will aid in the reassembly phase. As you work, examine each piece for wear and damage, documenting any findings for future reference.

Remember to handle all parts with care, and keep them organized to avoid confusion during reassembly.

Testing Pump Performance

Evaluating the efficiency of fuel delivery mechanisms is crucial for ensuring optimal operation and longevity of the engine. Accurate performance assessment allows for the identification of issues that may affect the system’s functionality, leading to improved reliability and reduced downtime. This section outlines essential methodologies for effectively testing the performance of these devices.

Assessment Techniques

Several methods can be employed to analyze the effectiveness of the fuel delivery apparatus. One common technique involves measuring flow rates under varying pressure conditions. By observing how the system responds to different loads, one can determine if it meets the required specifications. Additionally, utilizing diagnostic equipment can reveal inconsistencies in performance that may indicate wear or malfunction.

Interpreting Results

Once performance data is collected, it is essential to interpret the findings accurately. Comparing the observed metrics against manufacturer standards helps in identifying deviations. Regular monitoring and documentation of performance trends can provide insights into maintenance needs, enabling proactive interventions that enhance operational efficiency.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment requires consistent care and attention to detail. By adopting a proactive approach, you can minimize wear and enhance performance, ultimately leading to fewer disruptions and lower operational costs.

Regular Inspections: Conduct frequent assessments of your machinery to identify any potential issues early. Look for signs of wear, leaks, or irregularities that could indicate a need for attention.

Quality Fluids: Utilize high-grade fluids tailored for your system. This not only helps in maintaining optimal performance but also protects against corrosion and build-up that can shorten the lifespan of components.

Cleanliness is Key: Maintain a clean environment around your equipment. Dust, dirt, and debris can contribute to damage over time. Regular cleaning of the area and components will prevent contamination.

Temperature Management: Monitor operating temperatures to avoid overheating. Implement cooling solutions if necessary, as excessive heat can lead to premature failure.

Timely Replacements: Adhere to a schedule for replacing worn parts. Proactive replacement is far more economical than waiting for a breakdown to occur.

Professional Servicing: Engage qualified technicians for routine servicing. Their expertise can uncover hidden issues and ensure that all systems are functioning optimally.

By following these practices, you can significantly enhance the durability and reliability of your machinery, allowing it to perform effectively for many years to come.

Diagnosing Fuel Delivery Problems

Understanding issues related to fuel delivery is essential for ensuring optimal performance of an engine. When fuel fails to reach the combustion chamber effectively, it can lead to a range of operational challenges. This section outlines key steps for identifying and resolving these issues.

Common symptoms of inadequate fuel supply may include:

- Difficulty starting the engine

- Engine misfires or stalling

- Poor acceleration and reduced power

- Unusual noises from the engine

To diagnose these problems, follow these steps:

- Inspect the fuel system: Check for leaks, cracks, or damage in fuel lines and connectors.

- Examine the fuel filter: A clogged filter can restrict flow, so ensure it is clean and replace it if necessary.

- Test the fuel pressure: Use a gauge to measure pressure; inadequate pressure can indicate issues with components.

- Evaluate the delivery mechanism: Ensure that the system responsible for moving fuel is functioning properly.

- Check electrical connections: Verify that all sensors and pumps have solid connections and no corrosion.

By systematically addressing these areas, you can effectively pinpoint the source of fuel delivery problems and take appropriate corrective measures.

Replacing Pump Components

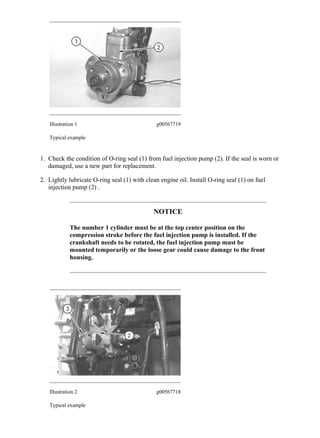

When maintaining fuel delivery systems, the need to replace specific elements arises to ensure optimal functionality and efficiency. This process involves careful assessment, selection, and installation of new parts to restore the system’s performance. Understanding the steps involved can enhance the reliability of the entire assembly.

Identifying Worn Parts

The first step in the replacement process is to identify components that show signs of wear or malfunction. This can include issues such as leaks, irregular operation, or diminished performance. Visual inspections, alongside diagnostic tools, can help pinpoint the exact parts that need to be replaced.

Installation of New Components

Once the faulty elements have been identified, the next phase involves installing new parts. It is crucial to follow manufacturer specifications and guidelines during this procedure. Proper alignment, torque settings, and sealing techniques must be adhered to in order to ensure the system operates effectively after the replacement.

Safety Precautions During Repairs

When undertaking maintenance tasks on machinery, ensuring a safe working environment is paramount. Proper precautions not only protect the technician but also enhance the efficiency of the work being performed. Adhering to safety measures minimizes risks associated with the tools and materials involved in the process.

Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and protective clothing. This gear acts as a barrier against potential hazards, such as sharp components or harmful substances. Ensure your workspace is well-ventilated to prevent the accumulation of harmful fumes, and keep it organized to reduce the chances of accidents.

Before beginning any maintenance work, familiarize yourself with the machinery’s specifications and potential hazards. Disconnect power sources and relieve any pressure in the system to avoid unexpected releases. Regularly inspect tools and equipment for damage, and use them only for their intended purpose to prevent injury.

Stay focused and avoid distractions during the maintenance process. If you are unsure about any procedure, consult relevant documentation or seek assistance from a knowledgeable colleague. Maintaining a high level of awareness and following these guidelines will contribute to a safer and more effective maintenance experience.

When to Seek Professional Help

Understanding when to enlist the expertise of a professional can significantly impact the efficiency and longevity of your system. While many minor issues can be addressed with basic knowledge and tools, some situations demand specialized skills and experience to ensure optimal performance and safety.

Signs You Should Consult an Expert

- Persistent Issues: If problems recur despite your attempts at troubleshooting, it’s a signal that deeper issues may exist.

- Unusual Noises: Unexplained sounds during operation often indicate mechanical failures that require professional assessment.

- Performance Decline: Noticeable drops in performance can stem from various underlying causes that are best evaluated by a specialist.

- Warning Lights: Dashboard indicators that remain illuminated suggest that an expert’s diagnostic tools are needed for proper analysis.

Benefits of Professional Assistance

- Expertise: Professionals possess advanced knowledge and training that allows them to identify and resolve complex issues efficiently.

- Specialized Tools: Access to sophisticated equipment ensures that repairs are conducted accurately and safely.

- Time-Saving: Engaging a specialist can save you time and reduce the likelihood of repeated issues.

- Warranty Protection: Professional service may be required to maintain warranty coverage, safeguarding your investment.