Comprehensive Guide to Yamaha EF2400IS Repair Manual

Understanding the complexities of your portable energy source is essential for optimal performance and longevity. Whether you’re facing issues with its functionality or simply wish to enhance its efficiency, having a well-structured guide can make all the difference. This resource provides crucial insights and practical advice to ensure your device operates smoothly.

In this section, we will delve into various troubleshooting techniques and maintenance practices tailored specifically for your power unit. By following these guidelines, you can address common problems effectively and learn preventative measures to avoid future complications. Equip yourself with the knowledge necessary to keep your machine running at peak efficiency.

From basic checks to more advanced adjustments, our aim is to empower you with the skills needed for successful upkeep. Whether you’re a novice or an experienced user, you will find valuable tips and strategies that cater to all levels of expertise. Get ready to embark on a journey to mastery, ensuring that your generator serves you well for years to come.

Yamaha EF2400is Overview

This compact and efficient generator offers reliable power solutions for various applications. With its advanced features and user-friendly design, it caters to both casual users and professionals looking for a dependable energy source. The model is particularly suitable for outdoor activities, job sites, and home backup needs.

Key Features

- Lightweight design for easy portability

- Quiet operation, ideal for residential areas

- Inverter technology for stable voltage output

- Eco-friendly mode for fuel efficiency

- Multiple outlets for versatile usage

Applications

- Camping and recreational use

- Powering tools and equipment on job sites

- Backup power for home appliances

- Outdoor events and gatherings

This generator stands out for its blend of performance and convenience, making it an excellent choice for those in need of a portable power source. Its thoughtful engineering ensures durability and efficiency, catering to the demands of diverse environments.

Common Issues and Their Solutions

When operating portable generators, users may encounter various challenges that can affect performance and reliability. Understanding these common problems and their corresponding solutions is crucial for maintaining efficiency and ensuring longevity.

1. Insufficient Power Output: One frequent issue is the generator not producing enough power to run appliances. This may result from overloading or an improper setting on the control panel. To resolve this, check the load capacity and ensure it does not exceed the generator’s limits. Additionally, verify that all connections are secure and that the device settings are correctly configured.

2. Difficulty Starting: If the unit fails to start, it could be due to fuel issues or battery problems. Ensure there is enough fuel in the tank and that it is fresh, as old fuel can cause starting issues. If the battery is weak, consider charging or replacing it to restore functionality.

3. Excessive Noise Levels: Some users may notice that the generator operates louder than expected. This could indicate loose parts or a need for maintenance. Check for any loose screws or components and tighten them as necessary. Regular maintenance, including oil changes and air filter cleaning, can also help reduce noise.

4. Overheating: Overheating can occur if the generator is used for extended periods or if the ventilation is blocked. To prevent this, allow the unit to rest periodically during operation and ensure that air vents are unobstructed. Regular cleaning of the cooling system is also essential to avoid buildup that can cause overheating.

5. Electrical Issues: Flickering lights or failure to power devices may signal electrical problems. Inspect the circuit breakers and fuses to ensure they are functioning properly. If necessary, reset the breakers and replace any blown fuses. For persistent issues, consulting a professional may be required.

Addressing these common problems promptly can enhance the performance and durability of your portable generator, ensuring it meets your power needs effectively.

Essential Tools for Repairs

When undertaking maintenance tasks on equipment, having the right instruments is crucial for ensuring efficient and effective outcomes. A well-equipped toolkit not only simplifies the process but also enhances safety and accuracy during troubleshooting and fixing operations. Below is a compilation of indispensable items that every technician should have at their disposal.

| Tool | Description |

|---|---|

| Screwdriver Set | A variety of screwdrivers, including flathead and Phillips, is essential for accessing different types of fasteners. |

| Multimeter | This device measures voltage, current, and resistance, helping diagnose electrical issues effectively. |

| Wrench Set | A complete set of wrenches allows for the loosening and tightening of nuts and bolts in various sizes. |

| Pliers | Various types of pliers, including needle-nose and slip-joint, are useful for gripping, twisting, and cutting wires. |

| Socket Set | Socket wrenches provide a means to apply torque to fasteners, making them easier to work with in tight spaces. |

| Flashlight | A reliable light source is essential for illuminating dark areas, enabling better visibility during inspections. |

| Safety Gear | Protective eyewear and gloves ensure safety while working, minimizing the risk of injury from sharp tools or hazardous materials. |

Step-by-Step Maintenance Procedures

Regular upkeep is essential for ensuring optimal performance and longevity of your portable power generator. By following systematic maintenance steps, you can identify potential issues before they become serious problems and keep your device running smoothly.

Tools and Equipment Needed

- Socket wrench set

- Philips and flathead screwdrivers

- Air filter cleaner

- Fresh fuel

- Oil for engines

- Cleaning cloths

- Safety gloves and goggles

Maintenance Steps

- Check the Oil Level: Ensure the oil level is adequate by removing the dipstick. If low, add the appropriate engine oil until the correct level is reached.

- Change the Oil: After every 50 hours of operation, drain the old oil and replace it with fresh oil to maintain engine health.

- Inspect and Clean the Air Filter: Remove the air filter cover, take out the filter, and clean it with an air filter cleaner. Replace it if it appears damaged or excessively dirty.

- Examine the Spark Plug: Remove the spark plug and inspect it for wear. Clean or replace it if necessary to ensure proper ignition.

- Clean the Fuel System: Drain old fuel and replace it with fresh fuel. Consider adding a fuel stabilizer if the generator will not be used for an extended period.

- Inspect Electrical Connections: Check for loose or corroded connections. Tighten or clean as needed to ensure efficient operation.

- Test the Battery: If equipped with an electric start, check the battery for charge and condition. Replace if it shows signs of deterioration.

- Run the Generator: After completing maintenance, run the generator under load to ensure everything operates correctly.

Performing these maintenance tasks regularly can significantly extend the life of your generator and improve its reliability during use.

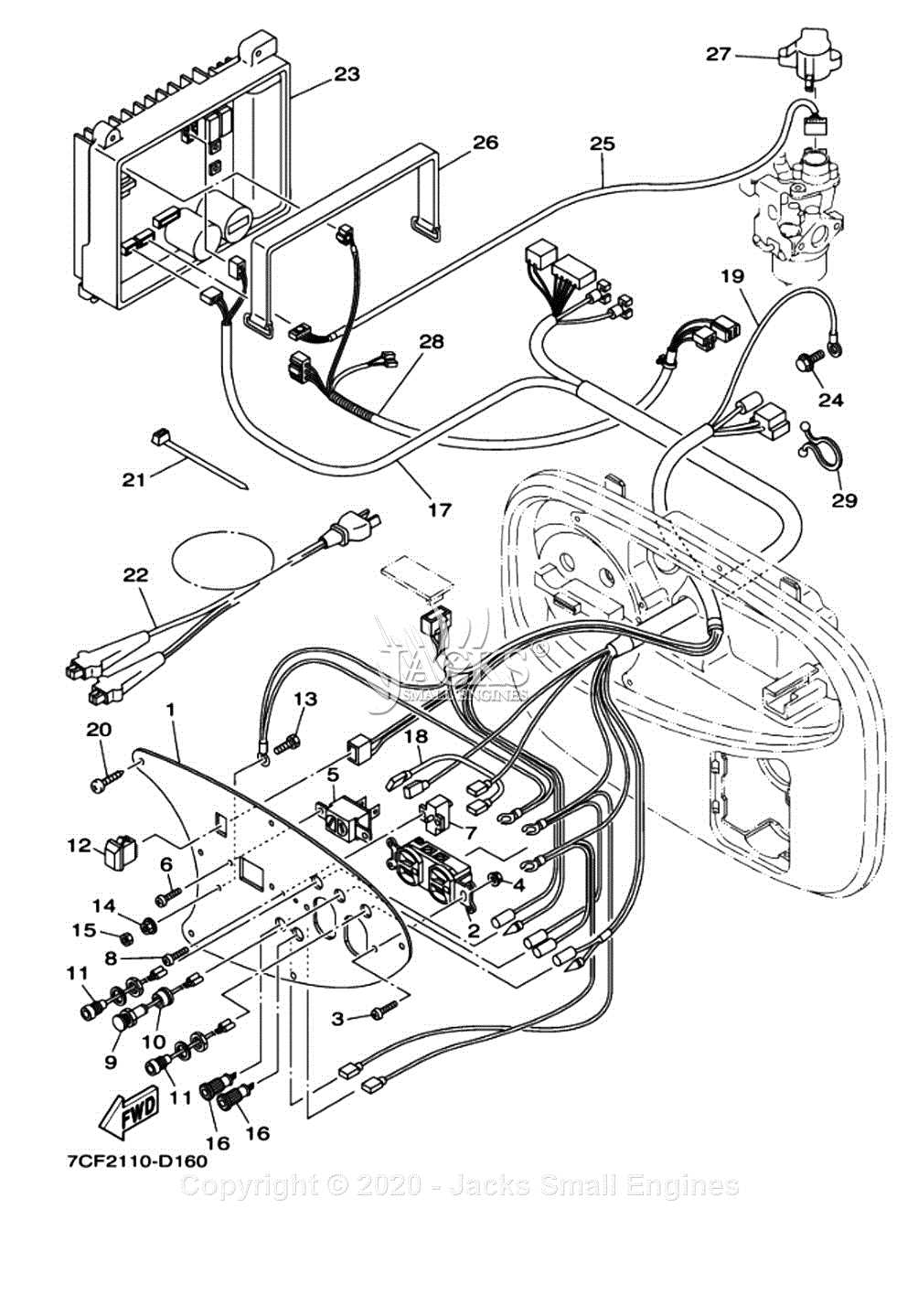

Understanding the Electrical System

The electrical system is a crucial component of any portable power generator, playing a vital role in its overall functionality and efficiency. It encompasses various elements that work together to convert mechanical energy into electrical energy, ensuring reliable power output for various applications. Understanding the intricacies of this system can greatly aid in troubleshooting issues and optimizing performance.

At its core, the electrical system consists of several key components, including the engine, alternator, battery, and control panel. The engine generates mechanical energy, which is then converted into electricity by the alternator. The battery serves as a power source for starting the engine and stabilizing the output voltage during operation. Additionally, the control panel provides essential functions such as voltage regulation and monitoring, allowing users to maintain optimal performance.

Electrical connections and wiring are fundamental to the system’s operation. Properly functioning connections ensure that power is efficiently distributed to various components and prevent potential issues such as short circuits or power loss. Regular inspection and maintenance of these connections can help prolong the life of the generator and enhance its reliability.

Furthermore, understanding the role of fuses and circuit breakers is essential for safety and functionality. These protective devices prevent overloading and short circuits, safeguarding the generator’s internal components from damage. Familiarity with their operation can assist users in quickly identifying and resolving electrical issues, ensuring seamless performance during use.

Overall, a solid grasp of the electrical system enhances the user’s ability to maintain and troubleshoot the generator effectively, leading to improved longevity and operational efficiency.

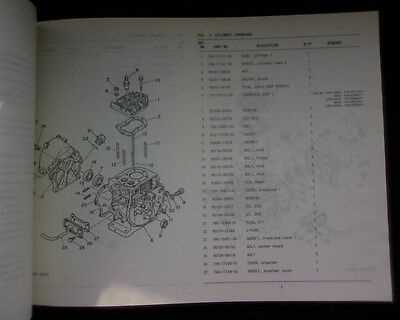

Fuel System Troubleshooting

The fuel system is a critical component that ensures the engine operates efficiently and reliably. When issues arise within this system, it can lead to poor performance, stalling, or failure to start. This section aims to guide you through common problems associated with the fuel system and offer systematic approaches for diagnosing and resolving these issues.

Understanding the typical signs of fuel system malfunctions is essential. Here are some common symptoms you may encounter:

| Symptoms | Possible Causes |

|---|---|

| Engine does not start | No fuel delivery, clogged fuel filter, or faulty fuel pump |

| Engine stalls unexpectedly | Fuel starvation, air leaks in the fuel lines, or contaminated fuel |

| Poor acceleration | Restricted fuel flow, clogged injectors, or incorrect fuel pressure |

| Unusual engine noise | Air in the fuel line, malfunctioning fuel pump, or low-quality fuel |

To effectively troubleshoot the fuel system, start by checking the fuel level and quality. Ensure that the fuel is clean and free from contaminants. Next, inspect the fuel filter for clogs and replace it if necessary. Additionally, verify the operation of the fuel pump by listening for its activation when the engine is turned on.

If problems persist after these initial checks, further investigation may be required. Testing fuel pressure with a gauge can help determine if the pump is functioning correctly. Inspect all connections and lines for leaks or damage, as these can significantly impact fuel delivery.

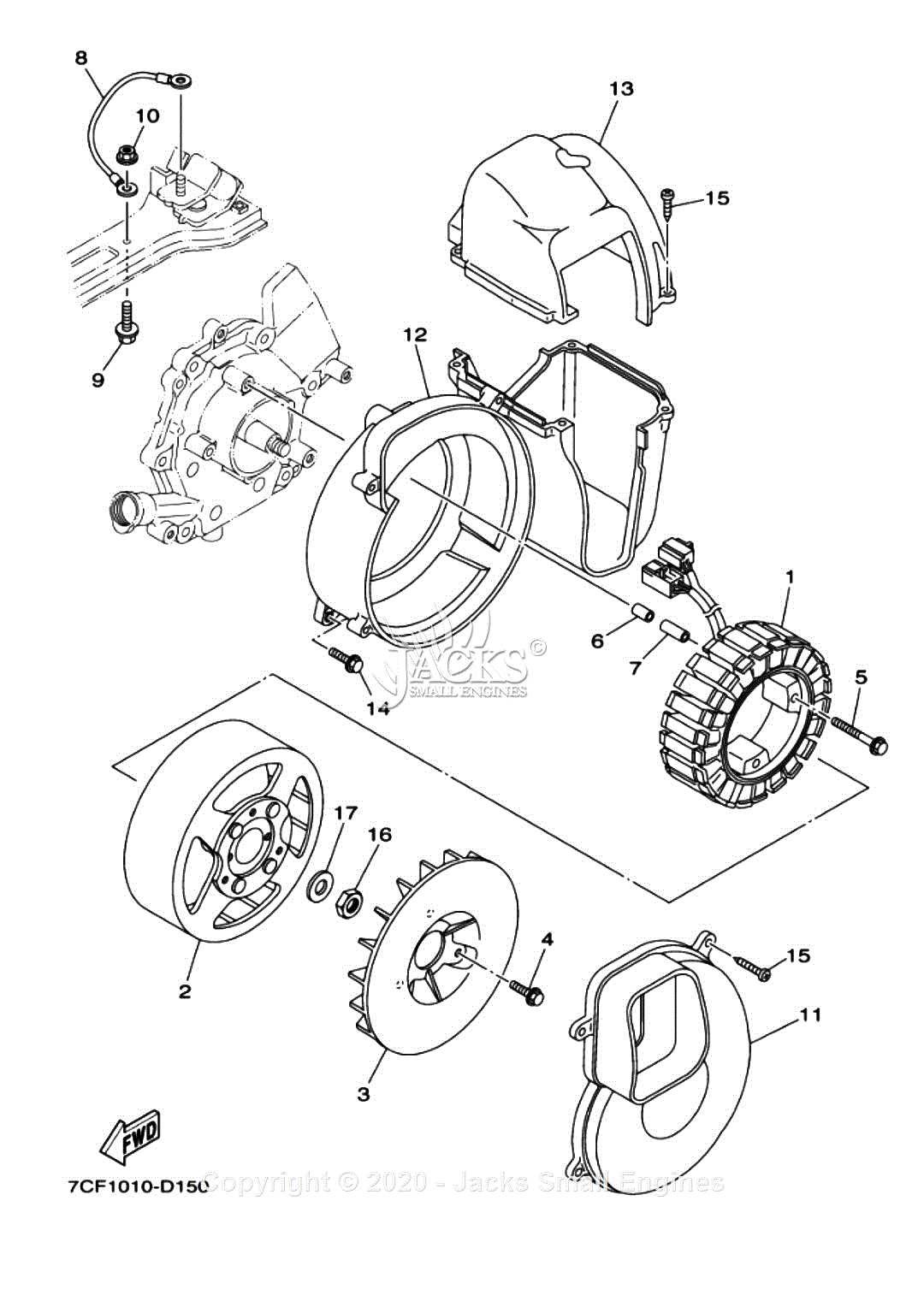

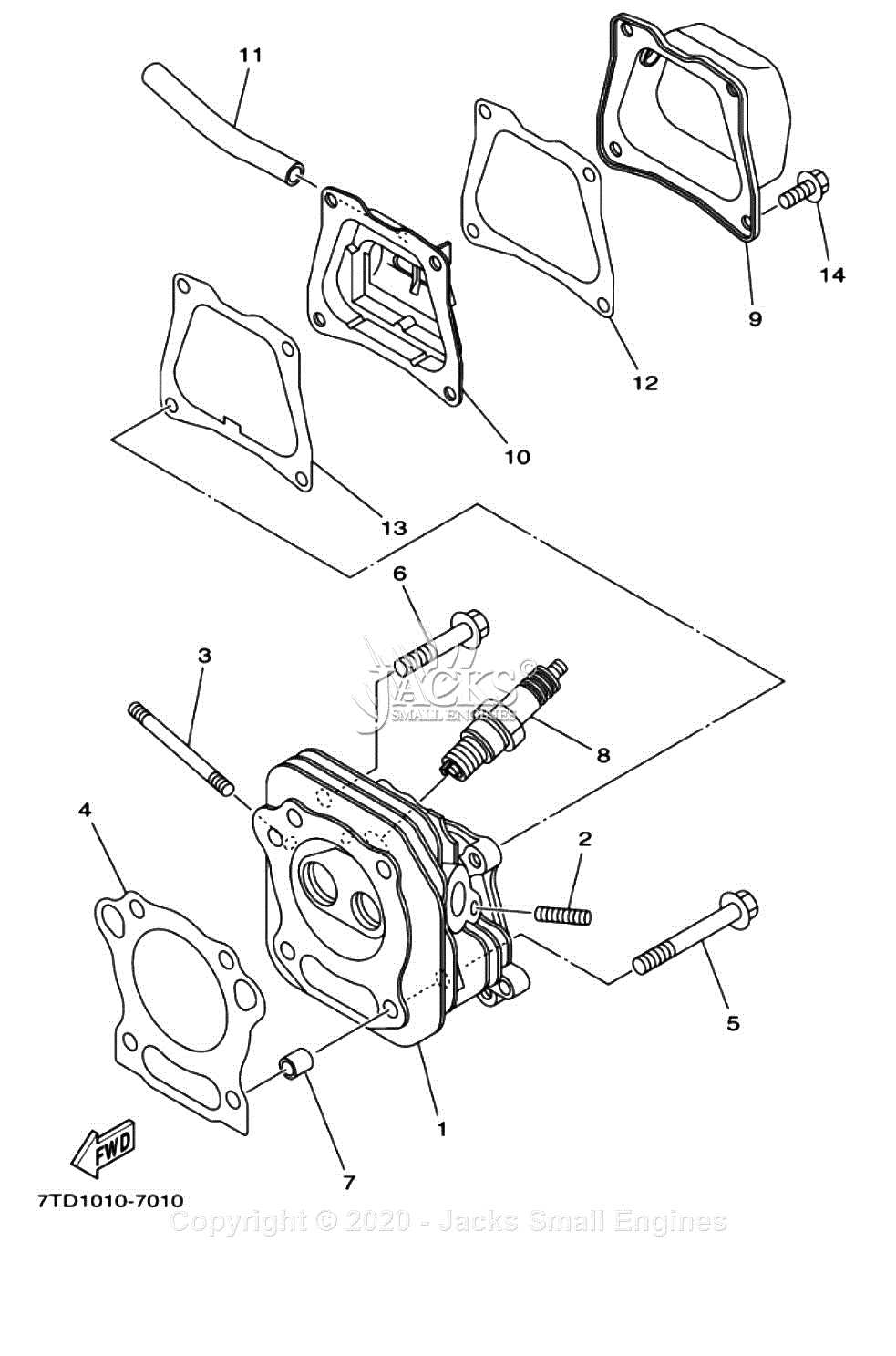

Inspecting the Engine Components

Regular examination of engine components is essential for maintaining optimal performance and extending the lifespan of your equipment. Identifying potential issues early can prevent costly repairs and ensure the reliability of the unit. This section will guide you through the key areas to inspect and the steps to take for a thorough evaluation.

Key Components to Inspect

- Air Filter: Ensure the air filter is clean and free from debris. A clogged filter can restrict airflow and affect engine efficiency.

- Fuel System: Check the fuel lines for leaks, cracks, or any signs of deterioration. Ensure the fuel filter is clean and replace it if necessary.

- Ignition System: Inspect the spark plug for wear and carbon buildup. A worn spark plug can lead to starting issues and poor engine performance.

- Cooling System: Examine the cooling fins for blockages and ensure the cooling system is functioning correctly to prevent overheating.

Inspection Steps

- Start by removing the outer casing to access the engine components.

- Check each component systematically, beginning with the air filter and moving through to the cooling system.

- Use a flashlight to inspect hard-to-see areas and take note of any irregularities.

- Document any findings, including the condition of each part and any recommended actions.

- Reassemble the casing once all components have been inspected and any necessary maintenance has been performed.

Conducting regular inspections not only enhances performance but also promotes safety during operation. Adhering to these practices will ensure the longevity and reliability of your engine.

Replacing Worn Out Parts

Maintaining optimal performance in your generator involves timely replacement of aged components. As parts experience wear and tear from regular usage, it becomes essential to identify and replace these elements to ensure the unit operates smoothly and efficiently.

When considering part replacement, it’s crucial to first diagnose the specific components that may be degraded. Commonly affected parts include filters, spark plugs, and fuel lines. Regular inspections can help you recognize signs of wear, such as decreased output, unusual noises, or difficulty starting the engine. Addressing these issues promptly can prevent more severe damage and extend the lifespan of your equipment.

Before embarking on any replacement task, gather the necessary tools and replacement parts. Consult the manufacturer’s specifications to select compatible components. Once you have the right items, follow a systematic approach: disconnect the power source, remove the worn part, and install the new one carefully. After the replacement, ensure all connections are secure and conduct a thorough test run to verify functionality.

In conclusion, regularly replacing worn components is vital for maintaining efficiency and reliability. By prioritizing this practice, you can enhance the overall performance of your generator and enjoy uninterrupted service for years to come.

Safety Precautions During Repair

When undertaking maintenance tasks on electrical devices, it is essential to prioritize safety to prevent accidents and injuries. Ensuring a secure working environment not only protects the individual performing the work but also extends the lifespan of the equipment being serviced.

1. Disconnect the Power Source: Before starting any maintenance, always disconnect the device from its power source. This eliminates the risk of electric shock and prevents accidental activation while handling components.

2. Use Personal Protective Equipment: Equip yourself with appropriate safety gear, including gloves, goggles, and protective footwear. This gear serves as a barrier against potential hazards such as sharp edges, falling objects, or electrical components.

3. Work in a Well-Ventilated Area: Ensure that the workspace is adequately ventilated. Fumes from batteries or other materials can pose health risks. Fresh air circulation is crucial for maintaining a safe atmosphere.

4. Avoid Water and Moisture: Keep the work area dry. Water and electrical components do not mix, and moisture can lead to short circuits or other malfunctions.

5. Familiarize Yourself with the Device: Understanding the specific components and their functions is vital. Consult relevant resources to gain knowledge about the equipment before proceeding with any work.

6. Keep Tools Organized: Use the proper tools for the job and keep them organized. This practice minimizes the risk of accidents and ensures efficiency during the task.

By adhering to these safety guidelines, individuals can significantly reduce the likelihood of accidents and ensure a smooth and effective maintenance process.

Performance Optimization Tips

To ensure your portable generator operates at its best, implementing a few optimization techniques can significantly enhance its efficiency and longevity. These strategies focus on maintaining optimal performance, maximizing fuel efficiency, and ensuring reliability during use.

Regular Maintenance

Routine checks are crucial for identifying potential issues before they escalate. Regularly inspect the air filter, oil level, and spark plug condition. Cleaning or replacing these components as needed helps maintain peak performance. Additionally, ensure that the fuel system is free from contaminants to prevent operational disruptions.

Load Management

Understanding the power requirements of your devices is essential for efficient operation. Avoid overloading the unit by connecting devices that exceed its rated capacity. Distributing the load evenly can also help maintain stability and prevent overheating. By prioritizing essential equipment and managing power distribution, you can enhance the generator’s overall efficiency.

When to Seek Professional Help

Understanding when to consult an expert can significantly impact the longevity and performance of your equipment. Some issues may seem minor, but without the right knowledge and tools, they can escalate into major problems. Recognizing the signs that indicate the need for professional intervention is crucial for effective maintenance.

Here are some common scenarios where seeking expert assistance is advisable:

- Unusual Noises: If your device starts making strange sounds, it could indicate underlying issues that require professional evaluation.

- Frequent Breakdowns: If you find yourself needing to troubleshoot repeatedly, it may be time to get a qualified technician involved.

- Difficulty Starting: Persistent starting problems are often a sign of more complex issues that need expert attention.

- Visible Damage: Any signs of physical damage, such as cracks or leaks, should prompt immediate consultation with a professional.

- Electrical Issues: Problems with wiring or electrical components can be hazardous and should always be addressed by a skilled technician.

Taking prompt action when faced with these issues not only enhances the safety of your equipment but also extends its operational lifespan.