Comprehensive Guide to Repairing the 1996 Sea-Doo GTX

Maintaining personal watercraft is crucial for ensuring longevity and optimal performance. Owners of such vessels often encounter challenges that require comprehensive knowledge and practical skills. This guide aims to provide essential insights into troubleshooting, upkeep, and restoration, empowering enthusiasts to handle various issues confidently.

Whether you’re dealing with mechanical failures or routine checks, understanding the intricacies of your craft is key. From engine diagnostics to electrical system management, every aspect plays a vital role in enhancing your riding experience. Familiarity with your vessel not only improves reliability but also enriches your time on the water.

In this section, we will delve into common problems faced by watercraft owners and explore effective solutions. Emphasizing a hands-on approach, the information presented here will guide you through the necessary steps to ensure your vessel remains in peak condition. Get ready to dive into the world of aquatic maintenance!

Understanding the 1996 Seadoo GTX

This section provides an overview of a popular personal watercraft model known for its performance and reliability. Designed for both recreational and utility purposes, it has become a favored choice among enthusiasts. Understanding its features, mechanics, and maintenance needs is essential for optimal operation and longevity.

Key Features

- Powerful engine providing impressive acceleration

- Advanced handling characteristics for improved stability

- Comfortable seating accommodating multiple passengers

- Innovative storage solutions for personal belongings

- Robust safety features enhancing rider protection

Maintenance Considerations

- Regular inspections of the engine and electrical systems

- Routine cleaning of the exterior and interior components

- Checking fluid levels, including oil and fuel

- Monitoring wear and tear on propellers and hull

- Ensuring proper winterization processes during off-season

Familiarizing oneself with these aspects can significantly improve the user experience and ensure the craft remains in excellent condition for years to come.

Common Issues with the GTX Model

Watercraft of this type often encounter a variety of challenges that can affect their performance and longevity. Understanding these typical problems can help owners maintain their machines effectively and enjoy their time on the water without unexpected interruptions.

Engine Performance Problems

One of the most prevalent concerns involves engine inefficiency. This can manifest as difficulty starting, stalling during operation, or reduced power output. Often, these issues stem from fuel delivery problems, such as clogged filters or malfunctioning fuel pumps. Regular checks and timely maintenance are crucial to prevent these complications from escalating.

Electrical System Failures

Another frequent issue relates to the electrical components. Owners may experience difficulties with the ignition system, leading to failure to start or inconsistent operation. Additionally, battery-related problems, including poor connections or depleted batteries, can further complicate matters. Ensuring all electrical connections are secure and batteries are maintained will help mitigate these risks.

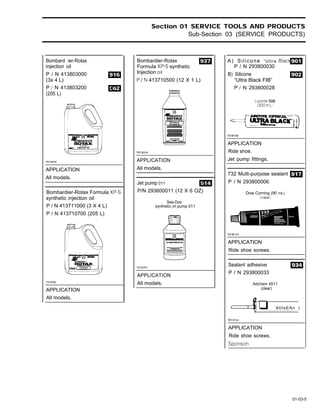

Essential Tools for Repairing GTX

When it comes to maintaining and fixing personal watercraft, having the right equipment is crucial for efficient and effective work. Various tools are necessary to tackle different aspects of service and restoration, ensuring both performance and safety. Understanding which implements to use can greatly enhance the overall experience and success in your maintenance endeavors.

Basic Hand Tools

Every maintenance kit should include fundamental hand tools such as wrenches, screwdrivers, and pliers. These versatile implements allow you to handle common tasks, from tightening bolts to removing panels. Investing in a quality set will ensure durability and reliability during your work sessions.

Specialized Equipment

In addition to standard tools, certain specialized equipment is essential for more complex procedures. A multimeter is invaluable for diagnosing electrical issues, while a compression tester helps assess engine health. Furthermore, having a torque wrench ensures that fasteners are tightened to the manufacturer’s specifications, preventing potential damage during operation.

Step-by-Step Maintenance Procedures

Regular upkeep of your watercraft is essential for ensuring optimal performance and longevity. This section provides a systematic approach to maintaining your vessel, helping you identify key tasks that should be performed periodically to keep everything running smoothly.

1. Check the Oil Level

Start by inspecting the oil level using the dipstick. Ensure that the oil is clean and at the recommended level. If it appears dark or gritty, it’s time for an oil change.

2. Inspect the Fuel System

Examine the fuel lines for any signs of wear or leaks. Replace any damaged components to prevent fuel-related issues. Additionally, ensure that the fuel filter is clean and replace it if necessary.

3. Clean the Spark Plugs

Remove the spark plugs and check for carbon buildup. Clean them thoroughly or replace them if they show signs of wear. Properly functioning spark plugs are crucial for engine efficiency.

4. Examine the Battery

Check the battery terminals for corrosion and ensure a tight connection. Test the battery voltage and replace it if it fails to hold a charge. Regular maintenance of the battery will prevent unexpected failures.

5. Inspect the Hull

Carefully examine the hull for any cracks or signs of damage. Repair any issues promptly to avoid leaks. Regularly cleaning the hull will also help maintain its integrity and appearance.

6. Test the Steering and Throttle Controls

Ensure that the steering system moves freely and that throttle controls respond accurately. Lubricate any moving parts if necessary to maintain smooth operation.

7. Winterization

If you are storing your watercraft for the season, follow a winterization process. This includes draining the cooling system, adding antifreeze, and removing the battery for safe storage.

By following these steps, you can maintain the performance and reliability of your watercraft, ensuring countless enjoyable outings on the water.

Electrical System Troubleshooting Tips

Tackling issues within an electrical system can be challenging, yet understanding some fundamental approaches can significantly simplify the process. This guide offers valuable insights into diagnosing common electrical problems, ensuring that you can effectively identify and resolve faults in the system.

Identifying Common Symptoms

Start by observing the symptoms of the malfunction. Frequent indicators include flickering lights, unresponsive controls, or unusual noises from electrical components. Taking note of these signs helps narrow down potential issues and informs your troubleshooting process.

Basic Diagnostic Steps

Begin by checking the battery’s condition. A weak or dead battery can lead to various electrical failures. Ensure all connections are secure and free of corrosion. Next, inspect fuses and relays for any signs of damage or wear. Replacing faulty components can often restore functionality. Lastly, using a multimeter can aid in verifying voltage levels and continuity, guiding you toward the source of the problem.

Engine Overhaul: What You Need

An engine overhaul is a crucial process aimed at restoring optimal performance and longevity. This task involves a series of meticulous steps that ensure each component functions harmoniously. Understanding the requirements and preparing adequately will greatly influence the outcome of the operation.

To begin, it’s essential to gather the necessary tools and materials. Common tools include wrenches, sockets, and torque wrenches, which are vital for disassembling and reassembling the engine. Additionally, having a variety of gaskets, seals, and other replacement parts on hand is imperative to avoid delays during the process.

Next, create a clean and organized workspace. A clutter-free environment helps in maintaining focus and ensures that all parts are easily accessible. Consider using labeled containers for small components to prevent misplacement.

Finally, familiarizing yourself with the specific procedures related to your engine model is crucial. Each engine has unique specifications and tolerances that must be adhered to for a successful overhaul. Investing time in research or consulting documentation can significantly enhance your understanding and execution of the task.

Replacing the Fuel System Components

Maintaining optimal performance in watercraft often requires attention to the fuel delivery system. Over time, various components can deteriorate or become clogged, leading to inefficient operation. This section provides a detailed approach to replacing these essential parts, ensuring that your vessel runs smoothly and efficiently.

Before starting the replacement process, gather the necessary tools and components:

- New fuel lines

- Fuel filter

- Fuel pump

- Seals and gaskets

- Basic hand tools (screwdrivers, wrenches, etc.)

- Safety equipment (gloves, goggles)

Follow these steps to successfully replace the fuel system components:

- Preparation: Ensure the engine is cool and the fuel supply is turned off. Disconnect the battery to prevent any electrical hazards.

- Accessing Components: Remove any panels or covers to reach the fuel system components. Take note of the assembly for reinstallation.

- Removing Old Parts: Carefully detach the fuel lines, filter, and pump. Inspect for wear or damage as you remove each piece.

- Installing New Components: Begin by attaching the new fuel pump, followed by the filter and fuel lines. Ensure all connections are secure and leak-free.

- Testing the System: Reconnect the battery and turn the fuel supply back on. Check for any leaks and verify that the system operates as intended.

By following these guidelines, you can effectively maintain the fuel system, enhancing the overall performance and longevity of your watercraft.

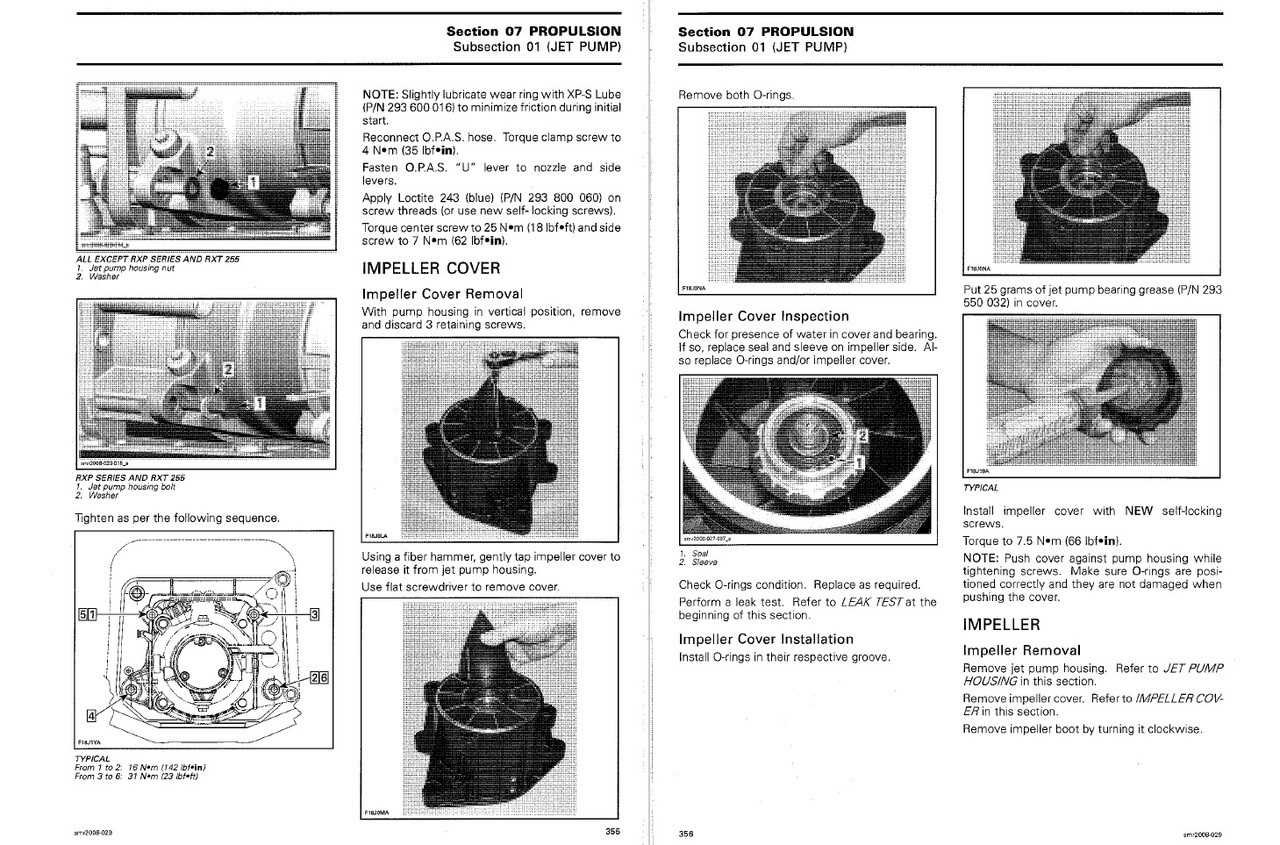

Tips for Jet Pump Maintenance

Maintaining the propulsion system is crucial for ensuring optimal performance and longevity of your watercraft. Regular upkeep can prevent costly repairs and enhance the overall experience on the water. Here are some essential tips to keep in mind for effective maintenance.

Routine Inspection

Conduct regular inspections to identify any signs of wear or damage. Pay close attention to the impeller, housing, and associated components. Look for cracks, corrosion, or debris that may hinder performance. Early detection of issues can save time and resources in the long run.

Cleaning and Flushing

After each outing, it’s beneficial to flush the system with fresh water. This practice helps remove salt, sand, and other contaminants that could cause buildup or corrosion. Utilize a dedicated flushing attachment if available, and ensure that all passages are clear. Regular cleaning keeps the system functioning smoothly and extends its lifespan.

Handling Corrosion and Rust Problems

Corrosion and rust can significantly impact the lifespan and performance of various watercraft components. Addressing these issues promptly not only ensures safety but also maintains the overall integrity of the vessel. Understanding the causes and implementing preventive measures is crucial for effective management of these common challenges.

Causes of Corrosion

The primary factors contributing to corrosion include exposure to moisture, saltwater, and chemicals. These elements accelerate the degradation of metals, leading to rust formation. Environmental conditions, such as humidity and temperature fluctuations, also play a significant role in the corrosion process.

Preventive Measures

To combat corrosion effectively, consider the following strategies:

| Strategy | Description |

|---|---|

| Regular Cleaning | Thoroughly wash the surface after use, especially in saltwater environments, to remove corrosive elements. |

| Protective Coatings | Apply marine-grade paint or sealants to form a barrier against moisture and corrosive substances. |

| Routine Inspections | Conduct regular checks for signs of rust or wear, addressing issues before they escalate. |

| Use of Anodes | Install sacrificial anodes made of zinc or aluminum to protect more critical components from corrosion. |

By understanding the factors contributing to corrosion and implementing effective preventive measures, owners can extend the life of their watercraft and ensure optimal performance. Regular maintenance and vigilance are key to mitigating rust-related problems.

Optimizing Performance with Adjustments

Enhancing the efficiency of your watercraft involves fine-tuning various components to achieve peak performance. By making strategic modifications, you can significantly improve speed, handling, and overall responsiveness. This section outlines essential adjustments that can elevate your machine’s capabilities.

| Component | Adjustment Type | Description |

|---|---|---|

| Carburetor | Mixture Tuning | Adjusting the air-fuel mixture for optimal combustion efficiency. |

| Throttle Control | Cable Tension | Ensuring proper cable tension for immediate throttle response. |

| Propeller | Pitch Adjustment | Modifying the pitch for enhanced acceleration and top speed. |

| Intake System | Filter Upgrade | Installing a high-performance filter for better airflow. |

| Engine Timing | Advanced Timing | Adjusting timing for improved torque and power output. |

By systematically addressing these areas, you can unlock greater potential in your vessel, making your experience on the water both thrilling and efficient.

Finding Genuine Replacement Parts

Locating authentic components is crucial for maintaining the performance and longevity of your watercraft. Using original parts ensures that the machinery operates as intended, minimizing the risk of malfunction and enhancing overall reliability.

Why Choose Authentic Components?

- Quality Assurance: Genuine parts are designed to meet specific standards, guaranteeing compatibility and durability.

- Enhanced Performance: Original components work seamlessly with existing systems, providing optimal efficiency.

- Manufacturer Support: Utilizing authentic parts often comes with warranty benefits and support from the manufacturer.

Where to Find Authentic Parts

- Authorized Dealers: Visit certified dealers who specialize in the brand to ensure authenticity.

- Official Online Stores: Check the brand’s official website for an online shop that sells genuine parts.

- Reputable Distributors: Research trusted distributors known for dealing in authentic replacement components.

- Online Forums and Communities: Engage with fellow enthusiasts to find recommendations for reliable sources.

By prioritizing genuine components, you can ensure that your watercraft remains in peak condition, providing a safe and enjoyable experience on the water.

Safety Precautions During Repairs

Ensuring safety while performing maintenance on watercraft is paramount. Engaging in mechanical tasks can involve various risks, and adhering to certain guidelines can help mitigate potential hazards. This section outlines essential safety measures to consider before and during any work on your vessel.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is crucial. This includes items such as gloves, goggles, and ear protection to safeguard against chemicals, debris, and loud noises. Additionally, consider wearing a durable apron to protect against sharp tools and materials.

Work Environment Considerations

Maintaining a clean and organized workspace is essential for safety. Ensure that the area is well-lit and free from clutter to prevent accidents. Proper ventilation is also important, especially when working with solvents or other chemicals. Be aware of your surroundings and keep all tools and materials securely stored when not in use.