Comprehensive Guide to Ford 555D Repair Manual

Maintaining heavy machinery is essential for ensuring its longevity and optimal performance. Understanding the intricacies of your equipment can significantly enhance its reliability and efficiency. This section delves into essential procedures and techniques necessary for the upkeep of your vehicle.

Detailed insights into components and systems play a vital role in preventing unexpected breakdowns. Familiarity with operational mechanisms not only aids in routine checks but also equips operators with the knowledge to address issues promptly. This knowledge can be invaluable in minimizing downtime and maintaining productivity.

In this guide, you will discover step-by-step instructions tailored to various aspects of equipment handling. From basic inspections to more complex troubleshooting, each element is designed to empower users with the skills necessary for effective maintenance. Equip yourself with the tools and knowledge to keep your machinery running smoothly.

Overview of Ford 555D Specifications

This section provides an insight into the fundamental characteristics of a specific model of heavy machinery renowned for its robust performance and versatility. Understanding these essential features is crucial for effective operation and maintenance.

Engine Performance: The power unit of this machine is designed to deliver substantial torque and horsepower, enabling it to handle demanding tasks with ease. Its efficient fuel consumption contributes to longer operational periods between refuels.

Dimensions and Weight: This equipment boasts a compact yet sturdy build, making it suitable for various job sites. The overall weight provides stability during operation, allowing for precise maneuvering in confined spaces.

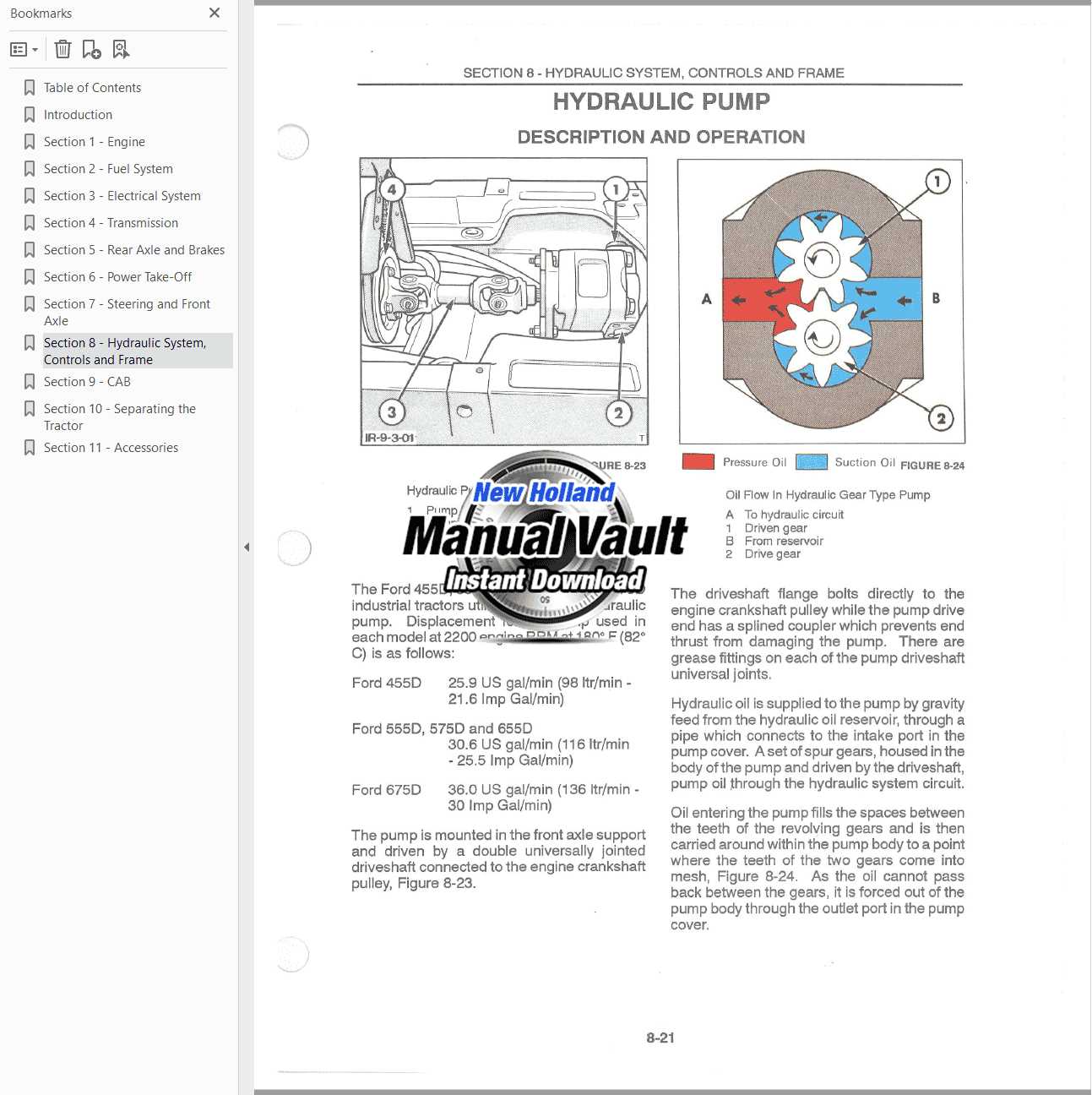

Hydraulic System: Equipped with an advanced hydraulic system, this model excels in lifting and digging capabilities. The hydraulic pressure is optimized to enhance the effectiveness of attachments, ensuring that tasks are completed efficiently.

Transmission Features: The transmission system offers multiple speed settings, allowing operators to adapt to different working conditions. This adaptability enhances productivity and reduces the risk of equipment strain during operation.

Understanding these specifications not only aids in effective utilization but also informs users about the machine’s capabilities and potential limitations, ensuring better performance and longevity.

Common Issues with Ford 555D

Heavy machinery often encounters various challenges during operation, impacting performance and reliability. Identifying these frequent problems can aid in timely intervention and maintenance, ensuring optimal functionality and longevity.

One prevalent issue is hydraulic system failure, which can manifest through sluggish response or complete unresponsiveness of the equipment. Regular checks of fluid levels and the condition of seals are crucial to prevent this complication.

Another common concern involves the electrical system, where wiring wear and tear can lead to malfunctioning controls. Routine inspections and replacements of damaged components can mitigate these risks and enhance safety.

Additionally, overheating engines can pose a serious threat to performance. Ensuring proper cooling system maintenance and monitoring for leaks can help maintain appropriate operating temperatures.

Finally, worn-out components, such as tracks or tires, can significantly affect maneuverability. Timely replacement of these parts is essential for maintaining optimal traction and stability.

Tools Required for Maintenance

To ensure optimal performance and longevity of heavy machinery, having the right equipment is essential. A well-equipped toolkit not only facilitates routine checks but also aids in addressing unforeseen issues efficiently. This section outlines the necessary instruments that will help maintain and troubleshoot effectively.

Basic Hand Tools: A variety of hand tools is fundamental for everyday tasks. Wrenches, screwdrivers, and pliers should be included to manage various fasteners and components. Having both metric and standard sizes can be beneficial, as it accommodates different specifications.

Diagnostic Equipment: For comprehensive assessments, specialized diagnostic tools are invaluable. Multimeters and pressure gauges allow for precise measurements, helping to identify electrical and hydraulic system anomalies. Investing in advanced diagnostic scanners can further enhance troubleshooting capabilities.

Maintenance Supplies: Regular upkeep requires specific materials. Oils, lubricants, and filters are crucial for ensuring smooth operation and minimizing wear. Keep a stock of replacement parts on hand, as this can reduce downtime significantly.

Safety Gear: Never overlook the importance of safety equipment. Proper gloves, goggles, and helmets protect users while performing maintenance tasks, ensuring a safe working environment.

Step-by-Step Repair Procedures

This section provides a comprehensive guide to addressing various maintenance tasks for your equipment. Each procedure is designed to simplify the process, ensuring that you can achieve effective results with clarity and efficiency. By following these structured steps, you can enhance the performance and longevity of your machinery.

Essential Tools and Materials

- Wrenches and sockets

- Screwdrivers (flat and Phillips)

- Pliers and cutters

- Lubricants and sealants

- Cleaning supplies

Procedure Overview

- Begin by ensuring the machine is turned off and all safety measures are in place.

- Gather the necessary tools and materials specified for the task.

- Access the components that require attention, following any guidelines related to disassembly.

- Inspect all parts for wear or damage and replace as needed.

- Reassemble the unit carefully, ensuring all fasteners are secure.

- Test the machinery to confirm that the task has been completed successfully.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is crucial for both personnel and equipment. Adhering to certain guidelines can significantly reduce the risk of accidents and injuries, promoting a secure working environment. This section highlights essential practices that should be observed while handling machinery.

Personal Protective Equipment (PPE) is fundamental. Workers must wear appropriate gear, including gloves, safety goggles, and steel-toed boots, to protect against potential hazards. These items act as a barrier against sharp objects, chemical splashes, and heavy equipment.

Proper training is another vital aspect. Individuals involved in maintenance must be well-informed about the machinery they are operating. Understanding the functions and risks associated with various components can prevent mistakes that might lead to injury or equipment failure.

Lastly, maintaining a clean and organized workspace cannot be overstated. A clutter-free environment minimizes the chances of accidents. Tools should be stored correctly, and any spills must be addressed immediately to prevent slips or falls.

Parts Replacement Guidelines

When maintaining heavy machinery, ensuring the correct replacement of components is essential for optimal performance and longevity. Following structured guidelines can help technicians efficiently identify, source, and install new parts, minimizing downtime and enhancing reliability.

Assessment and Identification

Before initiating any component substitution, conduct a thorough evaluation of the equipment. Identify worn or damaged elements, taking note of their specifications. Consult technical resources to ensure compatibility with the existing setup, which will aid in selecting appropriate replacements.

Installation Procedures

Once new parts have been acquired, follow systematic installation procedures. Begin by ensuring that all necessary tools are available and that safety measures are in place. Carefully remove the old component, following guidelines to avoid damaging surrounding structures. Install the new part with precision, verifying that all connections are secure and functioning as intended.

Maintenance Tips for Longevity

Ensuring the durability of heavy machinery requires regular attention and care. Implementing a consistent maintenance routine can significantly enhance the lifespan of your equipment while minimizing the likelihood of unexpected failures.

- Regularly inspect all components for wear and tear. Look for signs of damage or degradation that could lead to bigger issues if not addressed promptly.

- Keep the machinery clean and free of debris. Accumulation of dirt and grime can impede functionality and lead to premature wear.

- Monitor fluid levels frequently. Maintaining proper levels of oil, coolant, and hydraulic fluid is crucial for optimal performance.

- Schedule routine lubrication of moving parts. Proper lubrication reduces friction and prevents unnecessary wear on critical components.

- Ensure all connections are tight and secure. Loose connections can cause operational inefficiencies and pose safety risks.

By following these guidelines, operators can help extend the life of their machinery, ensuring reliable performance for years to come.

Troubleshooting Electrical Problems

Addressing issues related to electrical systems can be challenging but essential for maintaining optimal performance. Understanding common symptoms and knowing where to look can significantly aid in diagnosing faults effectively.

When facing electrical malfunctions, a systematic approach is crucial. Begin by checking the most accessible components and connections, as these often contribute to larger issues. Below is a table highlighting common electrical concerns and their potential solutions:

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| No power | Dead battery or faulty connections | Inspect battery condition and tighten or replace connections. |

| Intermittent function | Worn wiring or corroded terminals | Check wiring integrity and clean or replace terminals. |

| Flickering lights | Loose connections or weak power source | Examine connections for tightness and test power supply. |

| Electrical component failure | Overheating or damage | Replace damaged components and ensure proper ventilation. |

Following these guidelines can help identify and rectify electrical issues promptly, ensuring continued reliability and efficiency.

Hydraulic System Repairs Explained

The functionality of hydraulic systems is crucial for the performance of many heavy machinery. Understanding how to address common issues can enhance efficiency and prolong the lifespan of these systems. This section delves into the essential aspects of maintaining and troubleshooting hydraulic components, offering insights into effective solutions for various challenges.

Common problems may arise in hydraulic circuits, leading to inefficiencies or failures. Recognizing the signs of these issues is the first step toward resolving them. Here is a table outlining typical symptoms, potential causes, and suggested solutions:

| Symptom | Potential Cause | Suggested Solution |

|---|---|---|

| Inconsistent pressure | Worn seals or damaged hoses | Inspect and replace seals; check hoses for leaks |

| Slow operation | Low fluid levels or contamination | Refill fluid and filter; clean the system |

| Unusual noises | Air in the system or failing components | Bleed the system; check for damaged parts |

By systematically addressing these issues, operators can ensure their hydraulic systems function optimally, minimizing downtime and enhancing productivity.

Finding Genuine Replacement Parts

Ensuring the longevity and optimal performance of machinery relies heavily on sourcing authentic components. The market is flooded with alternatives, but selecting genuine items guarantees compatibility and reliability, which are crucial for effective operation.

Benefits of Genuine Components

Authentic parts are specifically designed for your equipment, providing several advantages:

| Advantage | Description |

|---|---|

| Quality Assurance | Manufactured to meet stringent standards, ensuring durability. |

| Perfect Fit | Engineered for precise compatibility, reducing installation issues. |

| Warranty Coverage | Often come with warranties that protect your investment. |

Where to Find Authentic Parts

Locating reliable suppliers is essential. Authorized dealers and reputable online retailers typically offer genuine items, providing peace of mind with each purchase. It’s wise to verify the seller’s credibility and check for certifications to ensure you receive authentic components.