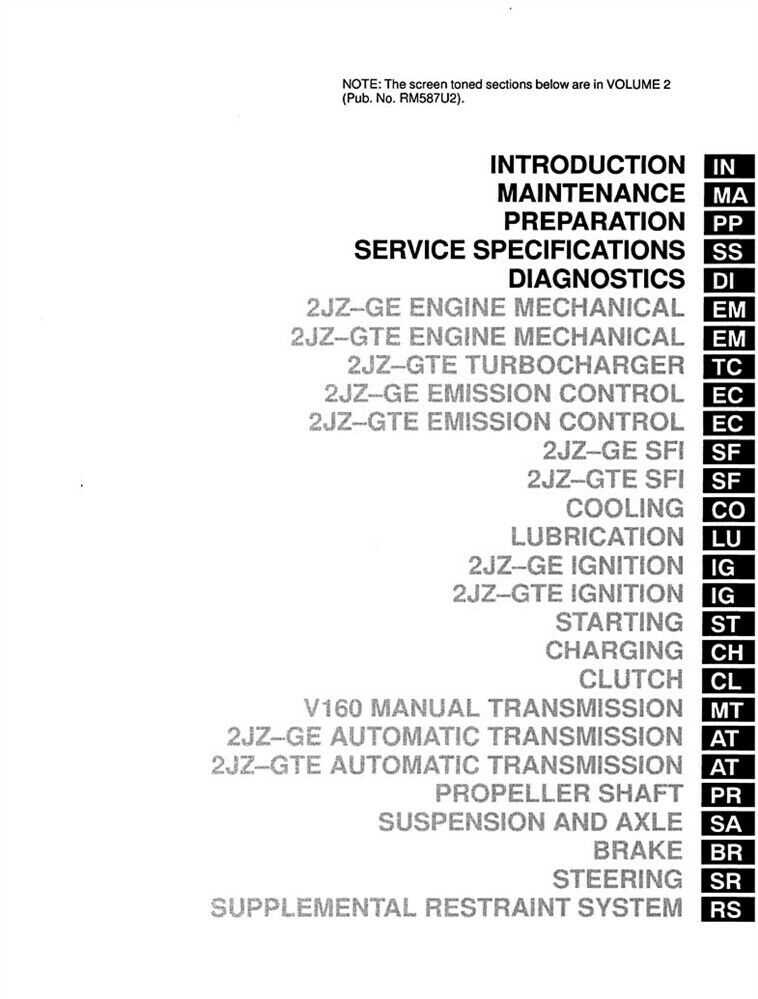

Comprehensive Guide to 2JZ GE Repair Manual

Ensuring the longevity and performance of a high-performance powertrain requires a thorough understanding of its components and their upkeep. This section delves into the intricate details of maintaining a renowned engine, known for its engineering excellence and resilience. Enthusiasts and professionals alike will find invaluable insights tailored to enhance their knowledge and skills.

Key aspects of effective maintenance involve not only routine checks but also understanding the potential challenges that may arise. By exploring the essential procedures and techniques, users can optimize performance and mitigate risks associated with wear and tear. This guide serves as a vital resource for those aiming to elevate their expertise in managing such a complex mechanical system.

Whether you are an avid car enthusiast or a skilled technician, mastering the nuances of this engine’s upkeep is crucial. With a focus on practical applications, this section provides a structured approach to troubleshooting and optimizing performance, ensuring that every aspect is covered. Engage with the material to unlock the full potential of your engine and keep it running smoothly for years to come.

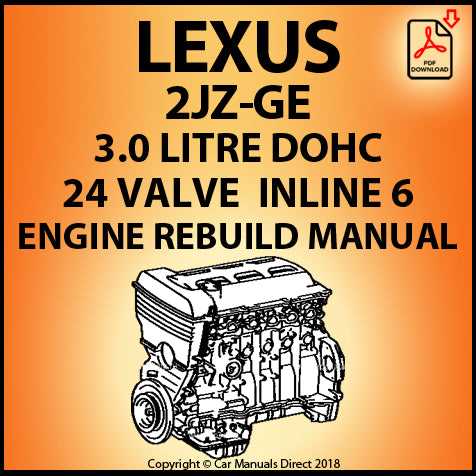

Understanding the 2JZ GE Engine

The engine in question is a renowned powerplant known for its impressive performance and durability. It has gained a reputation for being a favorite among enthusiasts and builders alike, thanks to its robust design and engineering excellence. This unit delivers a balance of efficiency and power, making it suitable for various applications.

Key Features: One of the standout characteristics of this engine is its inline-six configuration, which contributes to smooth operation and balance. Additionally, the incorporation of a dual overhead camshaft design enhances its breathing capabilities, allowing for improved performance at higher RPMs.

Performance Potential: Many aficionados appreciate the tuning potential of this engine, as it responds well to modifications. With a solid foundation, it can support significant horsepower increases while maintaining reliability. Its compatibility with various aftermarket components further amplifies its versatility.

Overall, understanding the intricacies of this engine involves delving into its design philosophy, operational dynamics, and the modifications that can enhance its already impressive capabilities. Whether for daily driving or motorsport, this engine remains a cornerstone in automotive performance circles.

Common Issues and Symptoms

Identifying the typical problems and their corresponding indicators is crucial for maintaining optimal performance in any high-performance engine. Understanding these common signs can help in diagnosing underlying issues before they escalate into more severe complications.

Performance Decline

A noticeable decrease in power output can be a significant symptom of various mechanical concerns. Drivers may experience sluggish acceleration or an inability to reach desired speeds. Such performance declines may indicate issues with the fuel delivery system, ignition components, or air intake mechanisms.

Unusual Noises

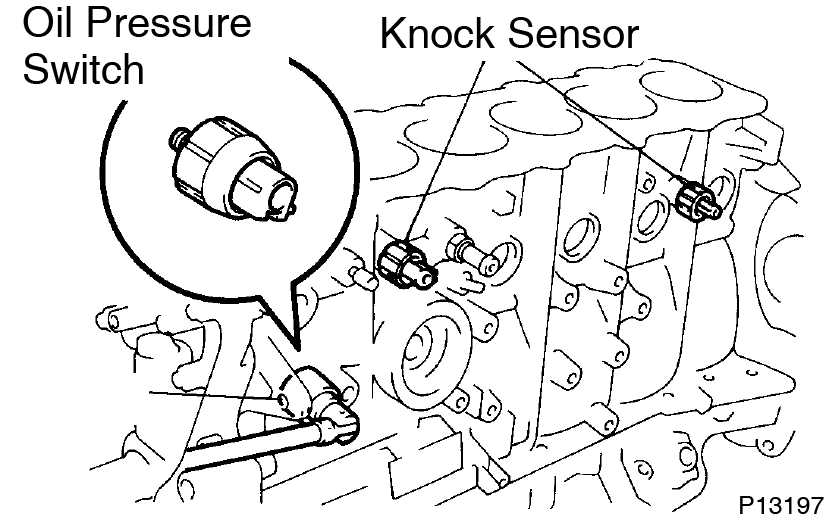

Strange sounds emanating from the engine compartment can signal a range of malfunctions. Common auditory signs include knocking, rattling, or hissing. These noises may point to problems with internal components, such as bearings or timing mechanisms, and should not be ignored, as they could lead to serious damage if left unaddressed.

Essential Tools for Repairs

When tackling automotive projects, having the right equipment is crucial for success. A well-equipped workshop can make complex tasks simpler and more efficient, ensuring that every job is performed with precision and care. Below are some key instruments that will significantly enhance your ability to work on various mechanical components.

Wrenches and Sockets: A diverse set of wrenches and socket sets is fundamental. These tools allow you to tighten or loosen fasteners securely. Consider both standard and metric sizes to cover a wide range of applications.

Torque Wrench: Achieving the correct torque is vital to avoid damage and ensure longevity. A torque wrench allows you to apply the precise amount of force needed, making it an indispensable part of your toolkit.

Diagnostic Tools: Investing in diagnostic equipment, such as OBD-II scanners, can help identify issues quickly. These devices provide valuable data that can guide you in troubleshooting effectively.

Basic Hand Tools: A good selection of screwdrivers, pliers, and hammers is essential. These basic tools are often required for various tasks, from removing covers to adjusting components.

Lift and Jack: Having a reliable lift or jack ensures safe access to the vehicle’s undercarriage. This is particularly important when working on critical systems that require you to be underneath the vehicle.

Safety Gear: Don’t overlook the importance of personal safety equipment. Goggles, gloves, and appropriate footwear protect you from potential hazards while working on machinery.

By equipping yourself with these essential tools, you will be better prepared to handle any challenges that arise during your automotive projects, ensuring both safety and efficiency throughout the process.

Step-by-Step Engine Disassembly

Disassembling an engine requires careful planning and methodical execution to ensure all components are handled properly. This process allows for inspection, cleaning, and potential replacement of parts. By following a structured approach, one can avoid mistakes and facilitate efficient reassembly.

1. Preparation: Begin by gathering all necessary tools, including sockets, wrenches, and screwdrivers. A clean workspace is essential to prevent the loss of small components and to maintain organization throughout the task.

2. Disconnecting Components: Start by removing the battery and disconnecting any electrical connections. Drain the fluids, including oil and coolant, to prevent spills during disassembly. Take notes or photographs of the connections to assist with reassembly.

3. Removing Accessories: Detach any external accessories such as the intake manifold, exhaust manifold, and any attached systems. Label each part and its corresponding fasteners to streamline the process later.

4. Cylinder Head Removal: Once external components are removed, carefully unscrew the cylinder head bolts in the proper sequence. Lift the head off gently, taking care to avoid damaging the gasket surface.

5. Disassembling the Block: With the cylinder head removed, proceed to take out the pistons and connecting rods. Ensure that each part is marked for identification. Remove the crankshaft and inspect it for wear or damage.

6. Cleaning and Inspection: After disassembly, clean all components thoroughly. Inspect for signs of wear, cracks, or other damage. This evaluation will guide decisions on whether parts need replacement or refurbishment.

By following these steps, one can systematically disassemble an engine, ensuring each stage is executed with precision. This careful approach not only aids in repair but also enhances overall understanding of engine mechanics.

Replacing Gaskets and Seals

Maintaining the integrity of your engine requires regular attention to gaskets and seals. These components are vital for preventing leaks and ensuring that fluids remain contained within their respective chambers. Over time, wear and environmental factors can lead to deterioration, necessitating their replacement to uphold optimal performance.

Identifying the Need for Replacement

Signs of wear may include fluid leaks, noticeable drops in performance, or unusual engine noises. It is crucial to inspect these parts regularly, as early detection can prevent more extensive damage and costly repairs down the line.

Preparation for Replacement

Before embarking on the replacement process, gather the necessary tools and materials. This typically includes a set of wrenches, a gasket scraper, and the appropriate replacement components. Ensuring a clean working environment is also essential to prevent contamination during the installation.

Steps to Replace Gaskets and Seals

Begin by safely removing the components surrounding the gaskets and seals. Carefully clean the surfaces to eliminate any remnants of old material, as this will facilitate a better seal. Apply the new gaskets or seals, ensuring proper alignment, and reassemble the parts in reverse order of disassembly.

Final Checks

After completing the installation, it is wise to check for leaks and monitor performance closely. Regular maintenance of gaskets and seals not only enhances reliability but also extends the lifespan of your engine.

Tuning the Engine for Performance

Tuning an engine is a crucial step for enthusiasts aiming to enhance their vehicle’s capabilities. This process involves adjusting various parameters to improve power output, efficiency, and overall responsiveness. By optimizing specific components, drivers can achieve a more exhilarating experience on the road or track.

One of the primary areas of focus in performance tuning is the air-fuel mixture. Ensuring the engine receives the right amount of fuel and air can significantly boost horsepower. This can be achieved through the installation of high-flow air filters and upgraded fuel injectors. Additionally, recalibrating the engine’s electronic control unit (ECU) allows for precise adjustments to fuel maps and ignition timing, maximizing performance.

Another vital aspect is the exhaust system. Upgrading to a high-performance exhaust can reduce back pressure, allowing gases to exit more freely. This not only enhances the engine’s efficiency but also contributes to a more aggressive sound that many enthusiasts crave. Combined with headers and a performance catalytic converter, these modifications can lead to substantial gains in power.

Finally, attention should be given to the vehicle’s suspension and braking systems. As power increases, it is essential to ensure that the car can handle the added performance safely. Investing in quality suspension components and high-performance brakes will improve handling and overall driving dynamics, creating a well-rounded, thrilling driving experience.

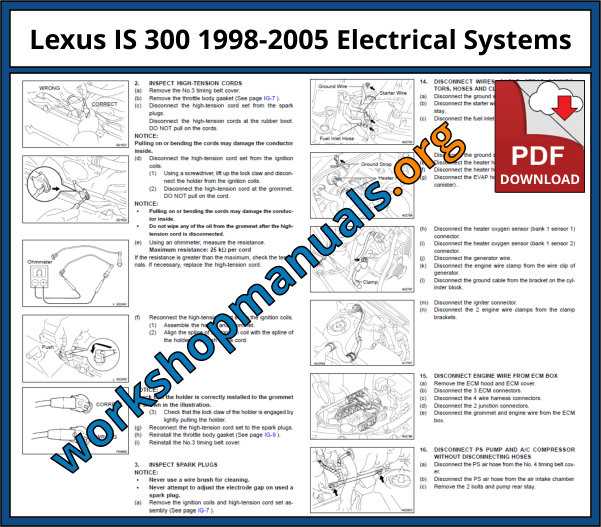

Wiring and Electrical Troubleshooting

This section focuses on identifying and resolving issues related to the electrical systems and wiring components. Proper diagnostics are essential to ensure optimal performance and safety, preventing potential damage or malfunctions.

Understanding the Basics

Electrical systems rely on a network of wires and connectors that transmit power and signals throughout the vehicle. Familiarity with these components is crucial for effective troubleshooting. Common problems may include shorts, open circuits, or faulty connections.

Step-by-Step Diagnostics

Start by visually inspecting the wiring harness for any signs of wear, corrosion, or damage. Pay close attention to connectors, as loose or dirty terminals can lead to intermittent issues. Utilize a multimeter to check for continuity and voltage levels at various points, which helps pinpoint the source of the malfunction.

Common Issues and Solutions

Electrical faults can manifest in various ways, such as flickering lights or non-responsive components. If you encounter these symptoms, consider the following:

- Check ground connections to ensure proper electrical return.

- Inspect fuses for any blown circuits and replace them as needed.

- Look for frayed wires that may cause shorts or open circuits.

Documentation and Resources

Referencing detailed schematics can aid in understanding the electrical layout and assist in troubleshooting. Having access to reliable information sources is invaluable when diagnosing complex issues.

Rebuilding the Cylinder Head

Reconstructing the cylinder head is a crucial aspect of engine maintenance that can significantly enhance performance and longevity. This process involves disassembling the head, inspecting each component for wear and damage, and reconditioning or replacing parts as necessary. Proper attention to detail during this phase ensures optimal engine functionality.

Initially, it is essential to remove the cylinder head from the engine block carefully. This requires disconnecting various components, such as the intake and exhaust manifolds, camshafts, and timing mechanisms. Once detached, the head should be thoroughly cleaned to remove any carbon deposits or grime that could affect the inspection process.

Next, a meticulous examination of the valves, guides, and seats is vital. Any signs of erosion, bending, or cracking must be addressed. In many cases, the valves can be reconditioned through a process called lapping, which improves their seal within the seats. If any component is deemed irreparable, it should be replaced with a high-quality alternative.

After inspecting and servicing the internal parts, the gasket surface must be checked for flatness. A warped surface can lead to leaks and inefficient operation. If necessary, the head can be machined to restore its integrity. This step is critical for ensuring a proper seal once reassembled.

Finally, once all components are either refurbished or replaced, the cylinder head can be reassembled. It is crucial to follow the manufacturer’s specifications for torque settings when attaching it back to the engine block. Proper alignment and sequencing during this process will contribute to the engine’s overall reliability and performance.

Fuel System Maintenance Tips

Ensuring the longevity and efficiency of your vehicle’s fuel system is crucial for optimal performance. Regular maintenance not only enhances fuel efficiency but also prevents costly repairs down the line. Here are some essential tips to keep your fuel system in top shape.

- Regularly check and replace fuel filters to prevent contaminants from damaging the system.

- Use high-quality fuel to minimize the build-up of deposits in the injectors and combustion chamber.

- Monitor the fuel pressure and inspect the pump for any signs of wear or failure.

- Perform periodic inspections of fuel lines for leaks, cracks, or corrosion.

In addition to these basic checks, consider implementing the following practices:

- Run a fuel system cleaner through the system every few months to maintain cleanliness.

- Keep an eye on the fuel gauge; regularly running on low fuel can lead to sediment buildup.

- Ensure that the fuel cap is tightly sealed to prevent vapor leaks and contamination.

By following these maintenance guidelines, you can help ensure that your vehicle’s fuel system operates efficiently and reliably, extending its lifespan and enhancing performance.

Recommended Upgrades for Longevity

To ensure the extended life of your engine, several enhancements can significantly contribute to its durability and performance. By focusing on quality components and effective modifications, you can optimize reliability and minimize wear over time.

Essential Modifications

- High-Quality Oil System: Upgrading to a superior oil pump and using synthetic lubricants can improve oil circulation and reduce friction.

- Cooling Enhancements: Installing an upgraded radiator and performance cooling fans helps maintain optimal operating temperatures.

- Improved Air Intake: A high-performance air filter and intake system can enhance airflow, promoting better combustion.

- Exhaust System Upgrade: A more efficient exhaust system allows for improved gas flow, reducing back pressure.

Preventive Maintenance Tips

- Regularly check and replace fluids to prevent contamination and wear.

- Monitor and replace worn components, such as belts and hoses, to avoid failures.

- Keep an eye on engine parameters to catch any irregularities early.

- Invest in quality aftermarket parts for longevity over cheap alternatives.

By implementing these upgrades and following preventive measures, you can significantly enhance the lifespan of your engine, ensuring it remains dependable and efficient for years to come.

Diagnosing Cooling System Problems

Identifying issues within the cooling system is crucial for maintaining engine performance and preventing potential damage. A well-functioning cooling system regulates temperature, ensuring that the engine operates within optimal conditions. When problems arise, recognizing the symptoms early can save time and resources.

Common signs of cooling system malfunctions include unusual engine temperatures, coolant leaks, and overheating. Checking the temperature gauge is a simple first step; if the needle moves into the red zone, immediate attention is required. Inspecting for leaks around hoses, the radiator, and connections can also reveal underlying issues, as coolant loss often indicates a compromised system.

Additionally, pay attention to the condition of the coolant itself. If it appears rusty or contaminated, it may suggest a need for flushing and replacing the fluid. Testing the thermostat for proper operation is another essential step, as a malfunctioning thermostat can disrupt the flow of coolant and lead to overheating.

Ultimately, thorough examination and prompt action when issues are detected can enhance the longevity and efficiency of the engine. Regular maintenance and vigilance are key to ensuring a reliable cooling system.

Best Practices for Regular Maintenance

Consistent upkeep is crucial for ensuring the longevity and optimal performance of any automotive engine. Implementing effective maintenance strategies not only enhances reliability but also minimizes the risk of unexpected failures. By adhering to a structured approach, vehicle owners can significantly improve engine health and overall driving experience.

Routine Checks and Fluid Changes

Conducting regular inspections is essential. Check oil levels, coolant, and other vital fluids frequently. Timely oil changes, typically every 5,000 to 7,500 miles, ensure that the engine runs smoothly and efficiently. Additionally, monitoring coolant levels helps prevent overheating, which can lead to severe damage over time.

Filter and Spark Plug Maintenance

Replacing air and fuel filters at recommended intervals is vital for maintaining optimal airflow and fuel efficiency. Clogged filters can hinder engine performance. Similarly, regular inspection and replacement of spark plugs help maintain ignition efficiency and prevent misfires, ensuring the engine runs smoothly.

Finding Quality Replacement Parts

When it comes to maintaining and upgrading automotive performance, sourcing high-quality components is crucial. The durability and efficiency of your vehicle largely depend on the reliability of the parts you choose. This section will guide you through effective strategies to locate superior replacement components that meet your needs.

Researching Suppliers

Identifying reputable suppliers is the first step in acquiring dependable parts. Consider the following tips:

- Look for established companies with positive customer reviews.

- Check for warranties or guarantees on products.

- Compare prices across multiple platforms to ensure competitive rates.

Understanding Specifications

It’s essential to comprehend the specifications of the components you need. This knowledge will help you avoid purchasing incompatible items. Here are some key points to consider:

- Consult your vehicle’s documentation for part numbers.

- Research compatibility with your specific model.

- Seek advice from automotive forums or communities for insights.

By investing time in thorough research and understanding, you can significantly enhance the performance and longevity of your vehicle through high-quality replacement parts.