Comprehensive Guide to Yamaha F115 Repair Manual

Proper maintenance of marine propulsion systems is essential for ensuring optimal performance and longevity. A well-documented reference can greatly assist owners and technicians in understanding the intricacies of their equipment. This guide serves as a valuable resource for addressing common issues and performing necessary upkeep tasks.

Within this framework, users will find detailed information on troubleshooting, component specifications, and essential servicing procedures. Emphasizing clarity and ease of understanding, the content is designed to empower individuals to tackle repairs with confidence. Whether you are a seasoned professional or a dedicated hobbyist, having access to reliable documentation is crucial for effective management.

In the following sections, you will discover a wealth of practical advice and step-by-step instructions tailored to enhance your technical knowledge. This compilation aims to streamline your maintenance efforts, ensuring that your marine engine operates smoothly and efficiently for years to come.

Understanding Yamaha F115 Outboard Basics

This section aims to provide a foundational understanding of a specific marine propulsion unit, focusing on its core components and functionality. Gaining insight into how this engine operates can greatly enhance the user experience, allowing for better maintenance and troubleshooting.

Core Components

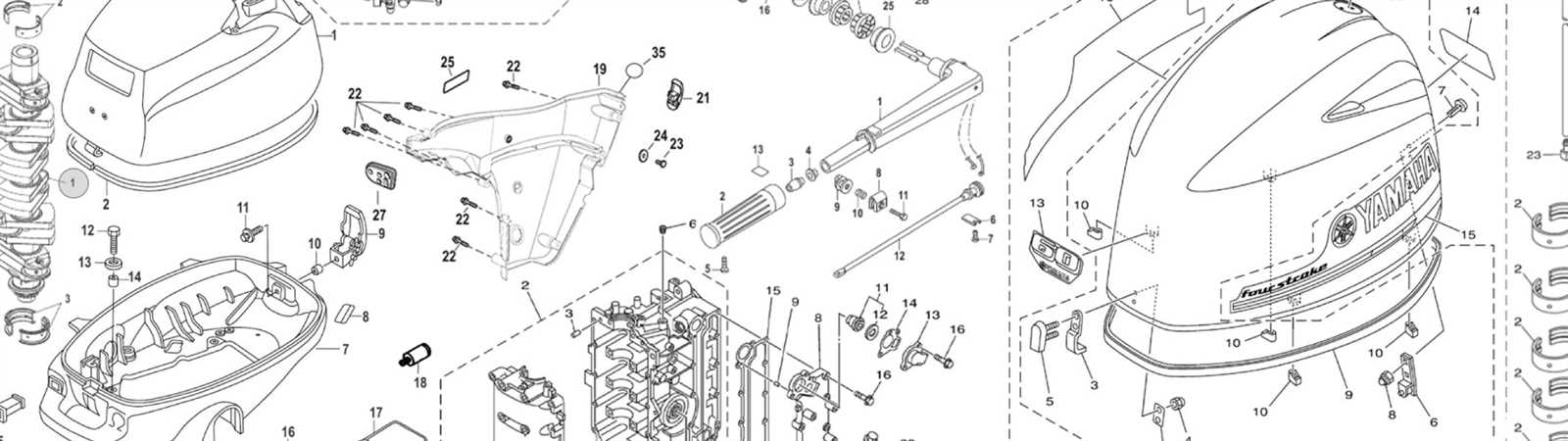

At the heart of any outboard engine lies a combination of essential parts that work together to deliver reliable performance. The powerhead contains the combustion chamber, where fuel and air mix and ignite, generating the necessary power to propel the vessel. The lower unit houses the gear assembly, responsible for transmitting this power to the propeller, enabling smooth navigation through water.

Operating Principles

Understanding the operating principles of a marine engine is crucial for any boat owner. The engine operates on a four-stroke cycle, which consists of intake, compression, power, and exhaust strokes. This cycle efficiently converts fuel into mechanical energy, while also minimizing emissions. Regular monitoring of fuel quality and proper maintenance practices can significantly extend the lifespan of the engine, ensuring optimal performance during use.

Common Issues with Yamaha F115

Understanding typical challenges associated with marine outboard motors can help ensure smooth operation and longevity. Various factors can lead to performance issues, requiring attention to maintain efficiency and reliability on the water.

Frequent Problems

- Engine Misfires: Often caused by fuel delivery issues or spark plug malfunctions.

- Overheating: May result from clogged cooling passages or faulty thermostats.

- Unusual Noises: Can indicate mechanical wear or issues with the propeller.

- Fuel Leaks: Commonly arise from damaged lines or fittings, leading to safety concerns.

- Starting Difficulties: Typically linked to battery health or ignition system failures.

Maintenance Tips

- Regularly check and replace fuel filters to prevent clogs.

- Inspect the cooling system for blockages or leaks.

- Monitor battery condition and clean terminals to ensure proper connection.

- Keep an eye on oil levels and quality to ensure smooth operation.

- Consult a professional for complex mechanical issues to avoid further damage.

Essential Tools for Repairs

When it comes to maintaining and fixing various equipment, having the right set of instruments is crucial. These tools not only enhance efficiency but also ensure that tasks are completed safely and accurately. A well-organized toolkit can make all the difference in achieving optimal results during maintenance tasks.

| Tool | Purpose |

|---|---|

| Wrench Set | For tightening and loosening bolts and nuts. |

| Screwdriver Set | Essential for driving screws of various sizes. |

| Socket Set | Useful for fasteners in tight spaces. |

| Pliers | For gripping, twisting, and cutting wire. |

| Torque Wrench | To apply a specific torque to fasteners. |

| Multimeter | For measuring voltage, current, and resistance. |

| Oil Filter Wrench | Designed specifically for removing oil filters. |

Equipped with these essential instruments, individuals can tackle a wide range of maintenance tasks with confidence. Ensuring that each tool is well-maintained and readily accessible further streamlines the process, promoting a productive working environment.

Step-by-Step Maintenance Procedures

Regular upkeep of your outboard engine is essential for optimal performance and longevity. This guide outlines a series of detailed procedures designed to ensure that your equipment remains in excellent working condition. By following these steps diligently, you can prevent potential issues and enhance the overall efficiency of your motor.

The following table summarizes the key maintenance tasks, their frequency, and brief descriptions:

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 100 hours or annually | Replace the engine oil and filter to ensure smooth operation. |

| Fuel System Inspection | Every 100 hours | Check for leaks, inspect filters, and clean injectors as needed. |

| Cooling System Flush | Every 200 hours | Flush the cooling system to remove debris and prevent overheating. |

| Propeller Check | Every outing | Inspect for damage and ensure proper attachment to the shaft. |

| Battery Maintenance | Monthly | Check connections and charge levels; clean terminals as necessary. |

| Visual Inspection | Before each use | Look for any signs of wear, leaks, or corrosion on components. |

By adhering to these maintenance protocols, you can significantly extend the life of your engine and enjoy a more reliable boating experience. Regular checks and timely interventions will help avoid costly repairs in the future.

Diagnosing Engine Problems Effectively

Identifying issues within an engine can be a challenging yet crucial task for maintaining optimal performance. An effective approach involves systematic observation and analysis, enabling one to pinpoint the source of malfunctions. By understanding common symptoms and utilizing appropriate diagnostic techniques, users can tackle problems with confidence.

Step one is to gather information regarding the symptoms exhibited by the engine. Listen for unusual noises, monitor performance metrics, and pay attention to any warning indicators. This initial assessment serves as a foundation for further investigation.

Next, it is essential to conduct a visual inspection. Check for visible signs of wear, leaks, or disconnections in the system. Components such as fuel lines, electrical connections, and air intake paths should be scrutinized for any abnormalities.

Furthermore, employing diagnostic tools can greatly enhance the troubleshooting process. Utilizing multimeters, compression testers, and other specialized equipment allows for precise measurements and insights into the engine’s health.

Finally, keeping a detailed record of findings and actions taken throughout the diagnostic process can be invaluable. This documentation aids in future troubleshooting efforts and contributes to a deeper understanding of the engine’s operational dynamics.

Replacing Spark Plugs Safely

Changing spark plugs is a vital maintenance task that enhances engine performance and fuel efficiency. Properly executing this procedure not only ensures a smoother operation but also extends the lifespan of the engine. Adhering to safety protocols is crucial to avoid any hazards during the replacement process.

Preparation Steps

- Ensure the engine is cool to the touch to prevent burns.

- Disconnect the battery to avoid any electrical issues.

- Gather necessary tools, including a spark plug socket, ratchet, and torque wrench.

- Consult the manufacturer’s specifications for the correct spark plug type and gap settings.

Replacement Process

- Remove the ignition coil or wire connected to the spark plug carefully.

- Use the spark plug socket to unscrew the old plug, turning it counterclockwise.

- Inspect the old plug for wear and carbon buildup to assess engine health.

- Prepare the new spark plug by adjusting the gap as needed and applying a small amount of anti-seize compound to the threads.

- Screw in the new plug by hand to avoid cross-threading, then tighten it with the torque wrench to the specified setting.

- Reattach the ignition coil or wire securely.

Completing this task with attention to detail will contribute significantly to the engine’s reliability and efficiency. Always follow safety guidelines to ensure a successful and hazard-free experience.

Fuel System Troubleshooting Tips

When dealing with fuel delivery issues, a systematic approach can help identify and resolve common problems efficiently. Understanding the key components and their functions is essential for effective diagnostics.

- Check Fuel Quality: Ensure the fuel is clean and free from contaminants. Old or stale fuel can cause performance issues.

- Inspect Fuel Lines: Look for cracks, leaks, or blockages in the fuel lines that may hinder flow.

- Examine Filters: Replace any clogged filters to maintain optimal fuel flow and system efficiency.

- Verify Fuel Pump Operation: Listen for unusual noises and check for proper pressure to confirm the pump is functioning correctly.

- Inspect Carburetors or Injectors: Clean or service these components to prevent fuel delivery problems.

By following these guidelines, you can delve deeper into troubleshooting and ensure the fuel system operates at its ultimate efficiency.

Electrical Components: Repair and Care

Maintaining the functionality of electrical systems is crucial for optimal performance and longevity. Proper attention to these components can prevent minor issues from escalating into significant problems. Understanding the nuances of each part and implementing routine checks ensures reliable operation in various conditions.

Common Electrical Issues

Various malfunctions can affect electrical components, such as poor connections, corrosion, or component failure. Identifying symptoms early on is vital. Symptoms may include inconsistent power delivery, failure to start, or unusual noises. Regular inspections and cleaning can mitigate many of these concerns, enhancing overall reliability.

Maintenance Practices

Routine care includes checking connections for tightness and cleanliness, ensuring that terminals are free from oxidation. Applying a protective lubricant can help prevent corrosion. Additionally, it’s advisable to test electrical systems periodically, using appropriate diagnostic tools to catch potential faults before they lead to significant failures.

Cooling System Maintenance Essentials

Maintaining the cooling system of an outboard engine is crucial for optimal performance and longevity. Regular attention to this component helps prevent overheating and ensures efficient operation. By following essential practices, you can safeguard the engine and enhance its reliability during use.

Routine Inspections

Conducting routine inspections of the cooling system is vital. Check for any signs of wear or damage in hoses and connections. Look for debris that might obstruct water flow and ensure that the intake screen is clear. Regularly flushing the system with fresh water can help eliminate salt and mineral buildup, promoting better cooling efficiency.

Fluid Checks and Changes

Monitoring and replacing the coolant fluid is another key aspect of maintenance. Ensure that the fluid level is adequate and the mixture is appropriate for the operating conditions. Over time, the fluid can become contaminated, leading to potential issues. Regular changes of the coolant not only keep the system functioning smoothly but also extend the lifespan of the engine components.

Adjusting the Propeller for Performance

Optimizing the propeller is crucial for enhancing the overall performance of your marine vessel. Proper adjustments can lead to improved speed, fuel efficiency, and maneuverability. Understanding how to fine-tune the propeller settings ensures that your craft operates at its best in various water conditions.

Several factors influence propeller performance, including pitch, diameter, and material. Each of these elements can significantly affect how well your boat accelerates and maintains speed. By making informed adjustments, you can achieve a balance between power and efficiency tailored to your specific needs.

| Factor | Description | Impact |

|---|---|---|

| Pitch | The angle of the blades relative to the hub | Affects acceleration and top speed |

| Diameter | The width of the propeller | Influences thrust and drag |

| Material | Type of material used for the propeller | Determines durability and weight |

When making adjustments, it is essential to consider the vessel’s intended use. For example, if quick acceleration is desired for water sports, a propeller with a lower pitch may be more suitable. Conversely, for cruising at higher speeds, a higher pitch might be advantageous. Regular testing and feedback will help fine-tune the setup to achieve the desired outcomes.

Important Safety Precautions During Repairs

When engaging in maintenance tasks, ensuring safety should be the foremost priority. Taking the necessary precautions can prevent accidents and injuries, safeguarding both the individual performing the work and the equipment itself. This section outlines critical safety measures to observe while conducting maintenance activities.

General Safety Measures

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and steel-toed boots.

- Ensure the work area is well-ventilated to avoid inhaling harmful fumes or vapors.

- Keep the workspace organized and free from clutter to reduce the risk of slips and falls.

- Disconnect power sources before beginning any service to prevent accidental startups.

Tool and Equipment Safety

- Inspect tools regularly for damage and replace any that are worn or broken.

- Use tools for their intended purposes only to avoid misuse and potential hazards.

- Store tools properly after use to prevent accidents.

- Follow manufacturer instructions for all equipment to ensure safe operation.

Where to Find Replacement Parts

Finding suitable components for your marine engine can be crucial for maintaining optimal performance. Various sources offer the necessary items, ensuring you can easily restore functionality to your equipment.

One of the best places to start is authorized dealers, who typically carry genuine parts that match your specifications. Additionally, online marketplaces provide a wide selection, often at competitive prices. Be sure to check customer reviews and seller ratings for quality assurance.

For those seeking budget-friendly options, consider local salvage yards or specialized forums where enthusiasts sell spare parts. Networking with other owners can also lead to recommendations and leads on hard-to-find items.