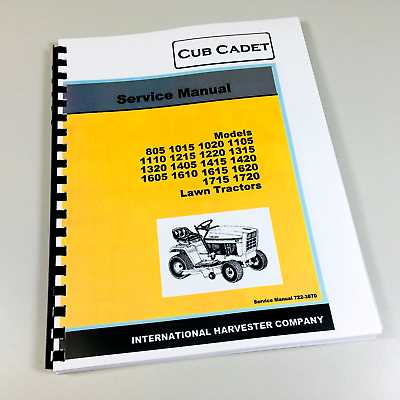

Complete Guide to Repairing Your Cub Cadet 1320

When it comes to ensuring the longevity and optimal performance of your outdoor equipment, understanding the intricacies of its operation is crucial. A comprehensive guide to upkeep and common issues can provide valuable insights, helping users navigate potential challenges with ease. With the right knowledge, even the most complex tasks can become manageable.

Equipping yourself with detailed instructions and troubleshooting tips allows for effective handling of various situations that may arise. Whether it’s routine care or unexpected malfunctions, having a structured approach can save time and effort. This resource serves as a pivotal tool for anyone looking to enhance their expertise and maintain their machinery in peak condition.

In this exploration, we will delve into the essential components and maintenance practices that are vital for sustaining performance. By familiarizing yourself with the necessary procedures and common pitfalls, you can ensure that your equipment remains reliable and efficient for years to come.

Overview

This section provides a comprehensive insight into a specific model designed for lawn care and outdoor maintenance. Known for its reliability and efficient performance, this machine is a popular choice among homeowners and professionals alike. It combines robust engineering with user-friendly features, making it an essential tool for those who prioritize lawn health and aesthetics.

Key Features

The machine boasts a powerful engine that delivers excellent torque, ensuring optimal performance even in challenging conditions. Its ergonomic design allows for easy maneuverability, while the intuitive controls enable users to operate it with minimal effort. Additionally, the durable construction ensures longevity, making it a wise investment for anyone seeking effective gardening solutions.

Applications

This equipment is suitable for various tasks, including mowing, mulching, and maintaining garden beds. Whether managing a small yard or larger landscaping projects, its versatility makes it an ideal choice for achieving pristine outdoor spaces. With proper maintenance and care, this model can provide years of dependable service, helping users maintain their property with ease.

Common Issues with Cub Cadet 1320

When operating a lawn tractor, various challenges may arise that can affect its performance and efficiency. Understanding these common problems can help users maintain their equipment effectively and prevent costly repairs.

Engine Problems

One of the frequent issues involves the engine failing to start. This can be due to a variety of factors, including a drained battery, clogged fuel lines, or a malfunctioning ignition system. Regular maintenance and checks can often prevent these complications. Inspecting the battery and ensuring that fuel is clean and free from contaminants are essential steps in maintaining optimal engine function.

Transmission Issues

Another common concern is related to the transmission system. Users may experience difficulty in shifting gears or notice unusual noises while operating the machine. This can result from low fluid levels or worn components within the transmission. Regular fluid changes and timely replacement of worn parts can help mitigate these issues, ensuring smoother operation and prolonging the lifespan of the equipment.

Essential Tools for Repairs

When it comes to maintaining and fixing machinery, having the right equipment is crucial. Proper tools not only enhance efficiency but also ensure the quality of the work performed. This section outlines the indispensable items that every enthusiast should consider for effective maintenance tasks.

Basic Hand Tools

Hand tools form the foundation of any repair kit. They are versatile and can handle a variety of tasks, from minor adjustments to more significant repairs. Here are some of the must-have items:

| Tool | Purpose |

|---|---|

| Wrenches | Used for loosening and tightening nuts and bolts. |

| Screwdrivers | Essential for driving screws in and out of various components. |

| Pliers | Useful for gripping, twisting, and cutting wires or small objects. |

| Socket Set | Ideal for dealing with various sizes of nuts and bolts. |

Specialized Equipment

In addition to basic hand tools, some tasks require more specialized equipment to ensure precision and ease of use. Here are a few key items:

| Tool | Purpose |

|---|---|

| Torque Wrench | Ensures bolts are tightened to the correct specifications. |

| Multimeter | Measures electrical parameters for troubleshooting electrical issues. |

| Grease Gun | Facilitates easy lubrication of moving parts. |

| Parts Cleaner | Helps maintain cleanliness of components for optimal performance. |

Engine Maintenance Tips

Proper care of your engine is essential for optimal performance and longevity. Regular maintenance not only ensures reliability but also enhances efficiency, reducing the risk of unexpected breakdowns. Here are some essential practices to keep in mind.

- Regular Oil Changes: Change the engine oil as recommended in the specifications to keep it clean and efficient.

- Check Air Filter: Inspect and replace the air filter periodically to ensure proper airflow and engine breathing.

- Inspect Spark Plugs: Regularly check and replace spark plugs to maintain effective combustion.

- Coolant Levels: Monitor and maintain appropriate coolant levels to prevent overheating.

- Fuel Quality: Use high-quality fuel and consider adding fuel stabilizers if storing for extended periods.

Additionally, always refer to the manufacturer’s guidelines for specific maintenance intervals and recommendations.

- Clean the engine exterior to prevent dirt buildup.

- Inspect belts and hoses for wear and replace them as necessary.

- Check battery terminals for corrosion and ensure a secure connection.

By following these tips, you can ensure that your engine operates smoothly and efficiently for years to come.

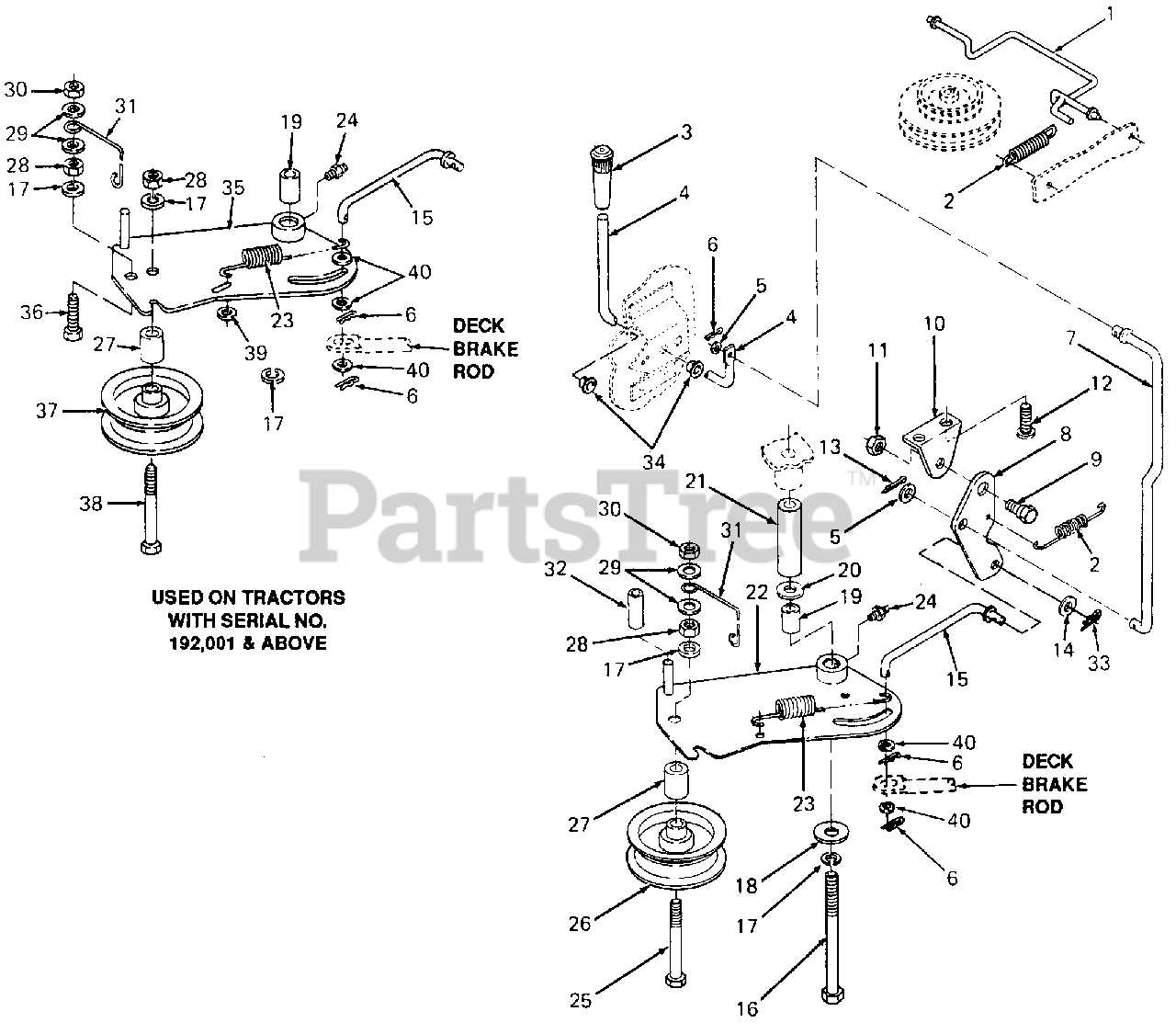

Replacing the Drive Belt

Maintaining the functionality of your lawn equipment often requires periodic replacement of essential components, such as the drive belt. This task is crucial for ensuring optimal performance and preventing potential damage to the machinery. Below is a step-by-step guide to assist you in executing this replacement effectively.

| Step | Description |

|---|---|

| 1 | Disconnect the power source to ensure safety during the procedure. |

| 2 | Remove any covers or guards that obstruct access to the drive belt. |

| 3 | Carefully release tension from the existing belt by adjusting the tensioner. |

| 4 | Take out the old belt, noting its routing for the installation of the new one. |

| 5 | Install the new belt by following the same routing path, ensuring it is seated properly on all pulleys. |

| 6 | Reapply tension to the new belt and check for proper alignment. |

| 7 | Reattach any covers or guards that were removed earlier. |

| 8 | Reconnect the power source and perform a brief test to confirm functionality. |

Following these steps will help ensure a smooth and efficient replacement of the drive belt, allowing your equipment to function at its best.

Carburetor Cleaning Procedures

Maintaining the optimal performance of a small engine often involves ensuring that the fuel delivery system remains clean and efficient. One of the key components of this system is the carburetor, which requires regular cleaning to prevent clogs and ensure smooth operation. Proper cleaning not only enhances performance but also extends the lifespan of the engine.

Preparation for Cleaning

Before beginning the cleaning process, gather the necessary tools, including a socket set, screwdrivers, and a cleaning solution designed for carburetors. Ensure the engine is cool and disconnect the spark plug to prevent accidental starts. Remove any fuel lines and linkages connected to the carburetor, taking care to document their positions for reassembly.

Cleaning Process

Once the carburetor is removed, disassemble it carefully, noting the order of components. Immerse the parts in a cleaning solution for a specified duration to dissolve any deposits. Use a soft brush to gently scrub areas that require extra attention. Pay special attention to jets and passages, as these are prone to clogging. After thorough cleaning, rinse with fresh fuel or solvent, ensuring all residues are eliminated before reassembling the unit.

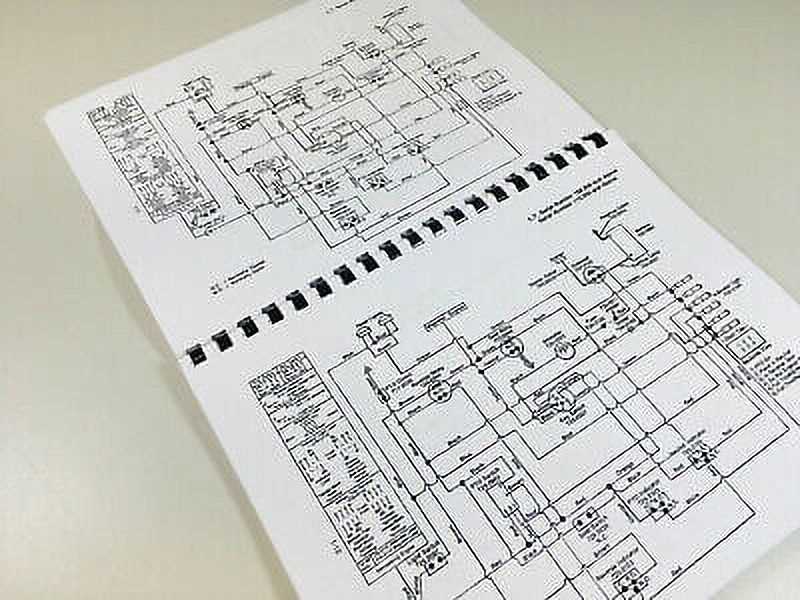

Electrical System Troubleshooting

Diagnosing issues within the electrical framework of your equipment is crucial for ensuring optimal performance. Problems can arise from various components, and understanding how to systematically approach these issues can save time and prevent further complications.

Common Symptoms of Electrical Failures

When dealing with electrical malfunctions, certain signs can indicate specific problems. Here are some frequent symptoms:

- Equipment fails to start.

- Inconsistent power supply.

- Warning lights illuminate on the dashboard.

- Unusual noises from the electrical components.

Troubleshooting Steps

Follow these steps to identify and resolve electrical issues effectively:

- Check the battery voltage using a multimeter.

- Inspect all wiring for damage or loose connections.

- Examine fuses and relays for integrity.

- Test individual components, such as the starter and alternator.

- Refer to circuit diagrams for further analysis if necessary.

By methodically addressing each potential issue, you can restore functionality and ensure reliable operation.

Maintaining the Fuel System

Ensuring the optimal performance of any engine requires attention to its fuel system. Regular maintenance can prevent issues such as clogged filters and fuel line obstructions, which ultimately enhance efficiency and longevity. This section outlines essential practices for keeping the fuel delivery system in prime condition.

Routine Checks

Performing frequent inspections is crucial. Look for signs of leaks, corrosion, or damage in the fuel lines and connectors. Verify that the fuel filter is clean and replace it according to the manufacturer’s recommendations.

Cleaning and Flushing

Periodically flushing the fuel system can remove accumulated deposits. Use a quality fuel system cleaner to help maintain flow and improve combustion efficiency.

| Task | Frequency | Notes |

|---|---|---|

| Inspect fuel lines | Every 10 hours of use | Look for leaks or wear |

| Replace fuel filter | Every 25 hours of use | Follow specific model guidelines |

| Flush fuel system | Every 50 hours of use | Use approved cleaners |

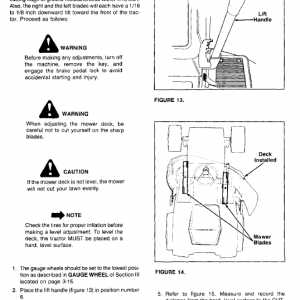

Deck and Blade Adjustments

Ensuring optimal performance of your lawn equipment involves regular maintenance, particularly focusing on the height and angle of the cutting apparatus. Proper adjustments not only enhance the effectiveness of the machine but also contribute to the longevity of the blades and the overall health of your lawn.

Height Adjustment: The cutting height should be tailored to the type of grass and the desired lawn aesthetics. Generally, a higher setting is beneficial during warmer months, promoting deeper root growth and healthier turf. To adjust the height, locate the appropriate levers or knobs on the deck, and modify them according to your requirements.

Blade Angle: The angle at which the blades are positioned can significantly impact the quality of the cut. Ensure that the blades are parallel to the ground when set at the desired height. Any deviation can lead to uneven cuts and potential damage to the grass. Adjusting the angle may require loosening certain bolts or screws, followed by careful repositioning and retightening.

Regular checks and adjustments will keep your equipment functioning efficiently and help achieve a clean, uniform cut. Always consult the specific guidelines for your model to ensure you are making the correct modifications.

Tire Replacement and Care

Proper maintenance and timely replacement of wheels are essential for optimal performance and safety. Understanding the key aspects of tire management can significantly enhance the longevity and efficiency of your vehicle. This section will guide you through the necessary steps and considerations for maintaining your tires effectively.

Signs It’s Time for Replacement

- Visible tread wear indicators

- Cracks or cuts in the rubber

- Uneven wear patterns

- Punctures that cannot be repaired

- Loss of air pressure that cannot be fixed

Steps for Replacing Tires

- Gather necessary tools: jack, lug wrench, and replacement tires.

- Ensure the vehicle is on a flat, stable surface.

- Loosen the lug nuts slightly before lifting the vehicle with a jack.

- Lift the vehicle until the tires are off the ground.

- Completely remove the loosened lug nuts and take off the old tire.

- Mount the new tire onto the wheel hub.

- Hand-tighten the lug nuts before lowering the vehicle back down.

- Once the vehicle is on the ground, fully tighten the lug nuts in a crisscross pattern.

Tire Care Tips

- Regularly check tire pressure and adjust as needed.

- Inspect for any signs of damage or wear periodically.

- Rotate tires according to the manufacturer’s recommendations.

- Ensure proper alignment and balancing to prevent uneven wear.

- Store seasonal tires in a cool, dry place away from direct sunlight.

By following these guidelines, you can ensure your wheels remain in good condition, ultimately enhancing your vehicle’s performance and safety on the road.

Winterization Steps for Longevity

Preparing your equipment for the cold season is essential to ensure its durability and optimal performance. By following a few simple steps, you can protect your machinery from the harsh winter elements and extend its lifespan. Proper winterization not only safeguards against damage but also promotes efficient operation when the warmer months return.

-

Clean Thoroughly:

- Remove any debris, dirt, and grass clippings from the exterior.

- Inspect and clean the undercarriage and any hard-to-reach areas.

-

Fuel System Maintenance:

- Drain the fuel tank or add a fuel stabilizer to prevent degradation.

- Run the engine briefly to ensure the stabilizer circulates through the system.

-

Oil Change:

- Replace the oil to prevent contamination and maintain engine health.

- Check and change the oil filter if necessary.

-

Batteries:

- Disconnect the battery and store it in a cool, dry place.

- Consider using a trickle charger to maintain charge during storage.

-

Tires and Wheels:

- Inflate tires to the recommended pressure to avoid flat spots.

- Store equipment on wooden planks or blocks to reduce ground contact.

-

Cover and Store:

- Use a breathable cover to protect against moisture accumulation.

- Store in a sheltered, dry area to prevent exposure to the elements.

By implementing these essential winterization steps, you can ensure that your equipment remains in peak condition and ready for use when spring arrives. Investing time in proper care now will pay off with reliable performance in the future.

Safety Guidelines for Repairs

When undertaking maintenance tasks on machinery, adhering to safety protocols is crucial to prevent accidents and ensure a secure working environment. This section outlines essential practices that should be followed to protect both the individual performing the work and the equipment itself.

| Guideline | Description |

|---|---|

| Personal Protective Equipment | Always wear appropriate gear, including gloves, goggles, and sturdy footwear, to minimize the risk of injury. |

| Work Area Organization | Maintain a clean and organized workspace to avoid tripping hazards and to ensure that tools and parts are easily accessible. |

| Tool Inspection | Regularly check tools for damage or wear. Do not use defective equipment, as it may lead to accidents. |

| Proper Handling of Fluids | Be cautious when working with oils or other fluids. Store them securely and clean any spills immediately. |

| Follow Manufacturer Instructions | Always refer to specific guidelines provided by the manufacturer to ensure safe and effective procedures. |

| Electrical Safety | Disconnect power sources before performing any work on electrical components to prevent shocks or short circuits. |

By following these guidelines, individuals can create a safer atmosphere while performing necessary tasks, ensuring both personal safety and the longevity of the equipment involved.

Finding Replacement Parts Easily

Locating suitable components for your equipment can often feel overwhelming, but it doesn’t have to be. With the right approach and resources, you can streamline the process and ensure that your machinery runs smoothly. Whether you’re looking for a specific piece or just browsing for spares, knowing where to look is key.

Utilizing Online Resources

The internet is an invaluable tool for sourcing parts. Numerous websites specialize in equipment components, offering extensive catalogs that can help you find exactly what you need. Utilize search engines effectively by entering specific terms related to your model, and consider checking manufacturer websites for direct access to their inventory.

Local Dealers and Salvage Yards

Don’t overlook local options. Authorized dealers often have parts readily available, and visiting a salvage yard can yield unexpected finds at a fraction of the cost. Building relationships with local suppliers can also lead to valuable insights and recommendations for reliable sources.