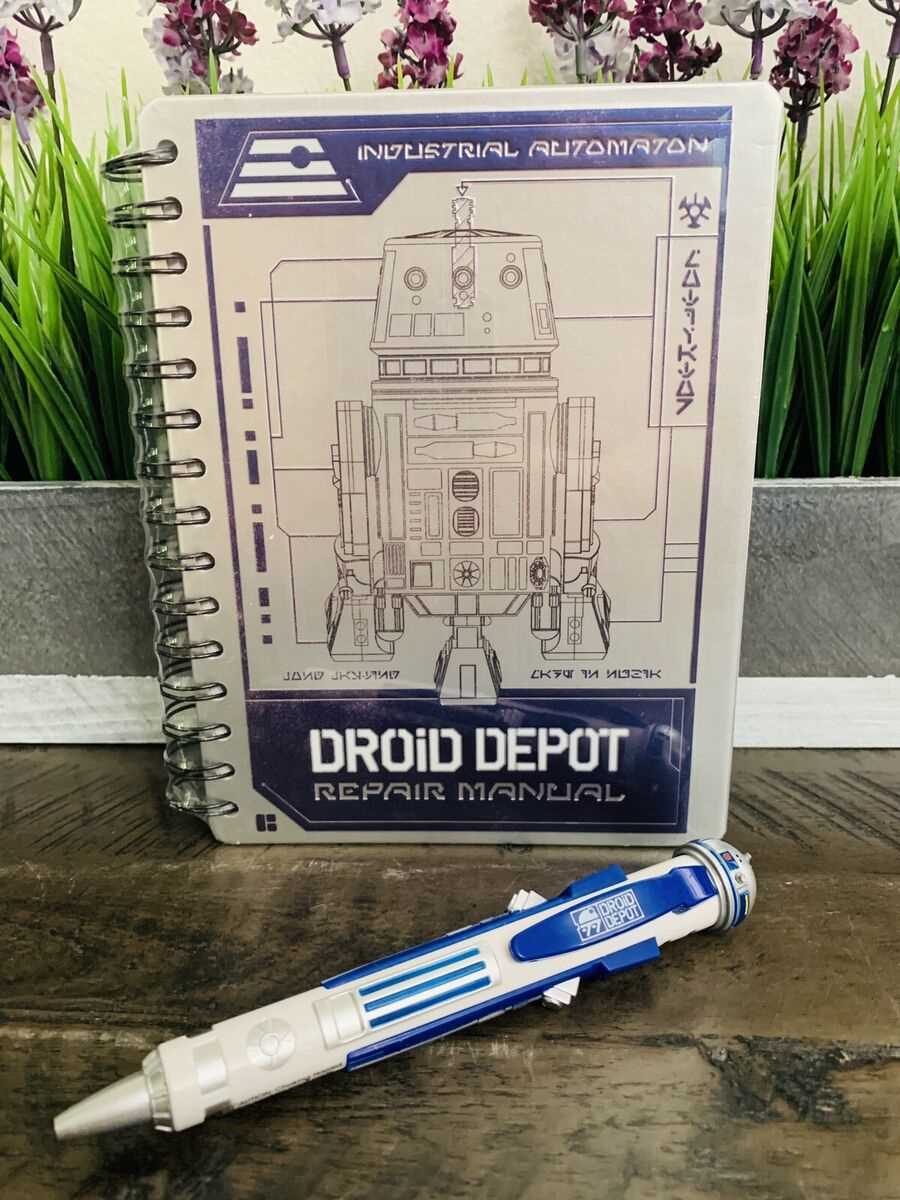

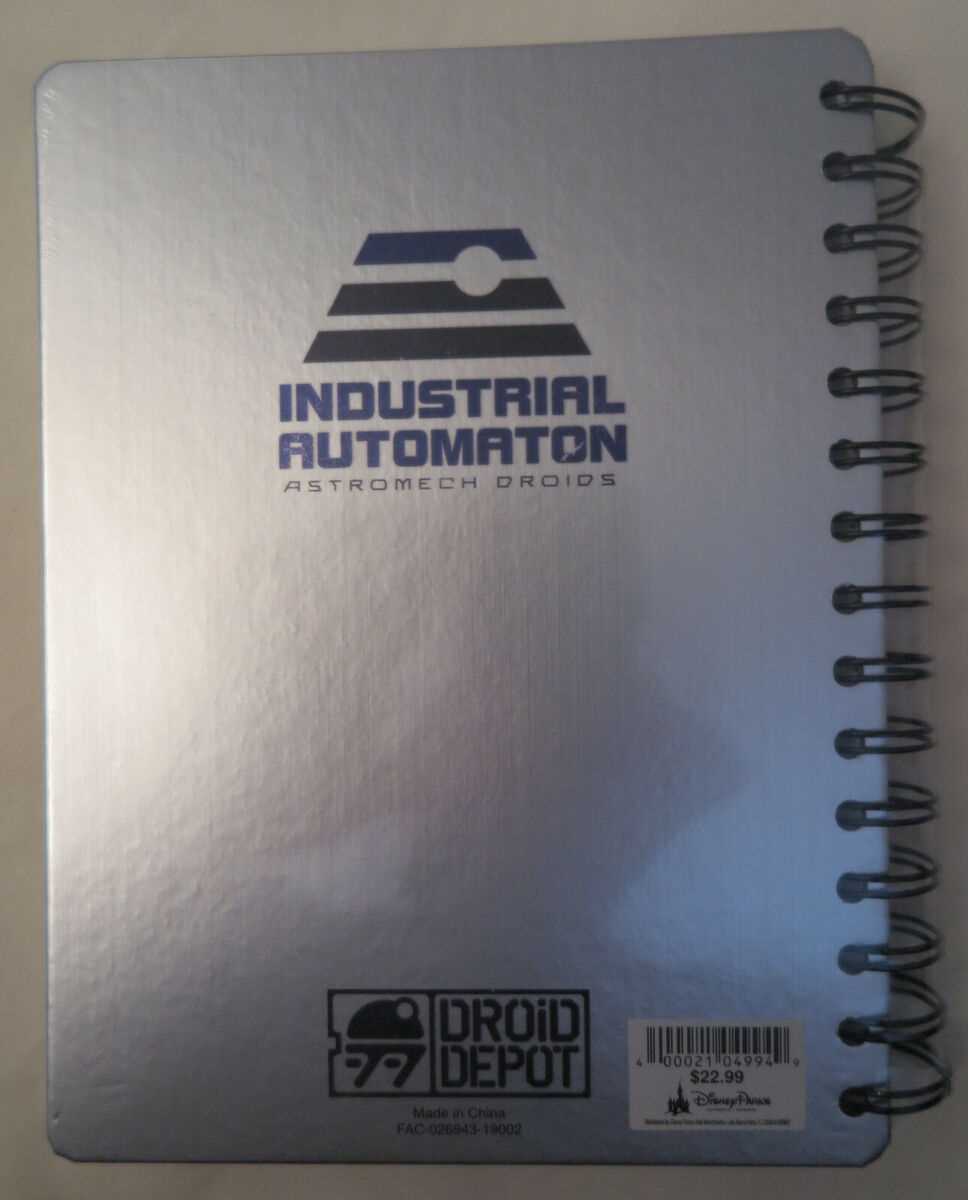

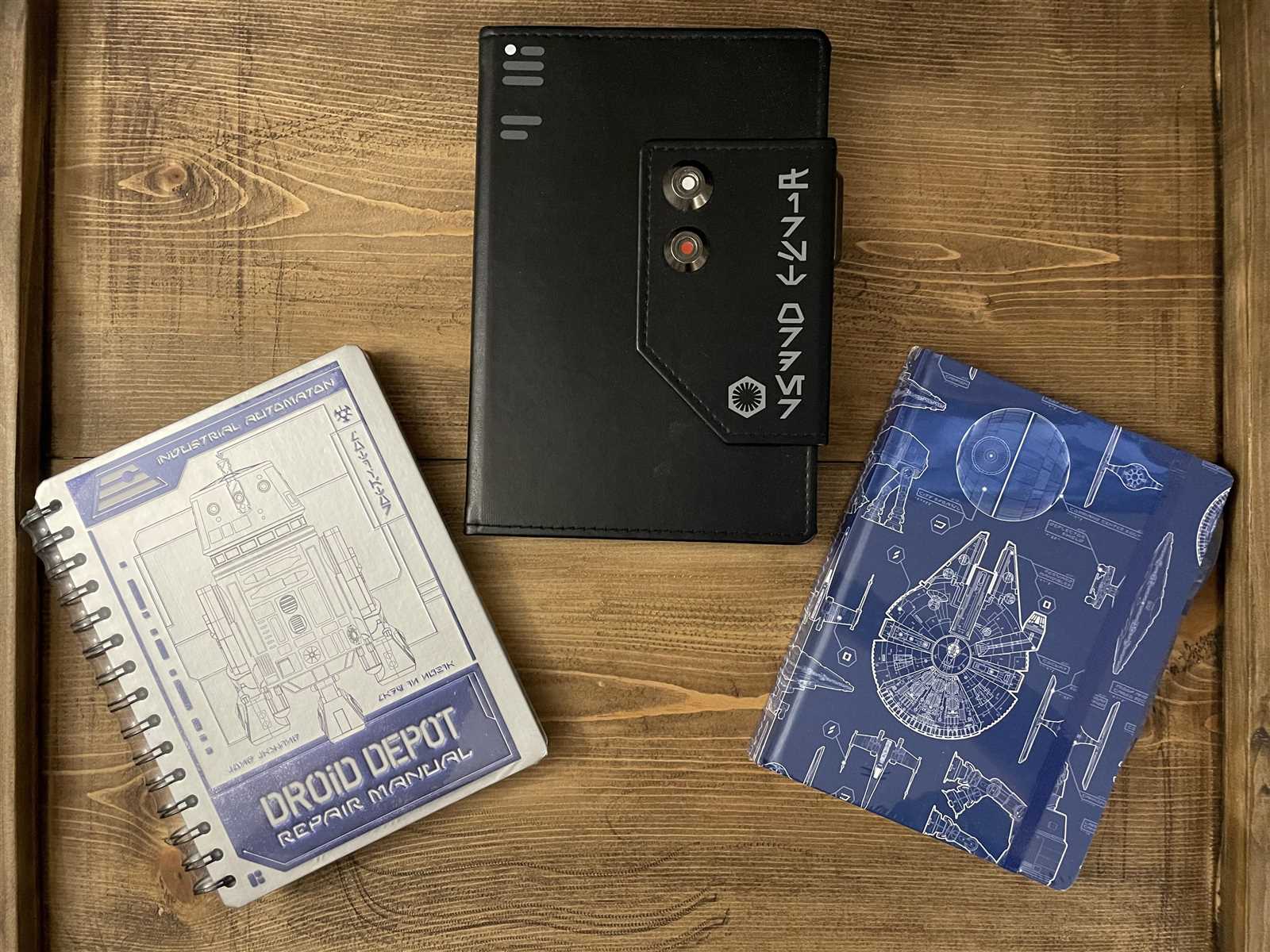

Comprehensive Guide to Droid Depot Repair Manual

In today’s technological landscape, understanding the intricacies of your personal unit can greatly enhance its performance and longevity. This section provides essential insights and procedures that can help you address common issues, ensuring that your device remains in optimal condition. Whether you’re troubleshooting a minor glitch or looking to enhance its capabilities, having a clear set of guidelines is invaluable.

With a focus on practical solutions, this resource aims to equip you with the knowledge needed to navigate various challenges. You’ll discover step-by-step instructions, tips for effective upkeep, and strategies for resolving typical problems. By following these suggestions, you can maintain the functionality of your unit and extend its lifespan.

As you delve into the various sections, you’ll gain a deeper understanding of the components and systems that make your device unique. Emphasizing hands-on approaches and proactive care, this guide encourages you to engage with your technology confidently, fostering a more satisfying experience.

Robot Facility Service Guide Overview

This section provides a comprehensive look at the essential guide for the upkeep and troubleshooting of robotic units. Designed for both enthusiasts and professionals, this resource equips users with the knowledge to effectively manage issues, enhance functionality, and ensure optimal performance of these sophisticated machines.

Key Components and Structure

The document outlines various segments that cover crucial aspects, including diagnostic procedures, component replacements, and maintenance routines. Each section is crafted to facilitate a better understanding of the mechanisms involved, allowing users to navigate the complexities of their robotic devices.

Utilizing the Guide for Optimal Performance

By leveraging the information presented, users can address common challenges encountered with robotic units. Practical insights and detailed instructions enable individuals to undertake necessary actions with confidence, ultimately leading to enhanced longevity and efficiency of their technology.

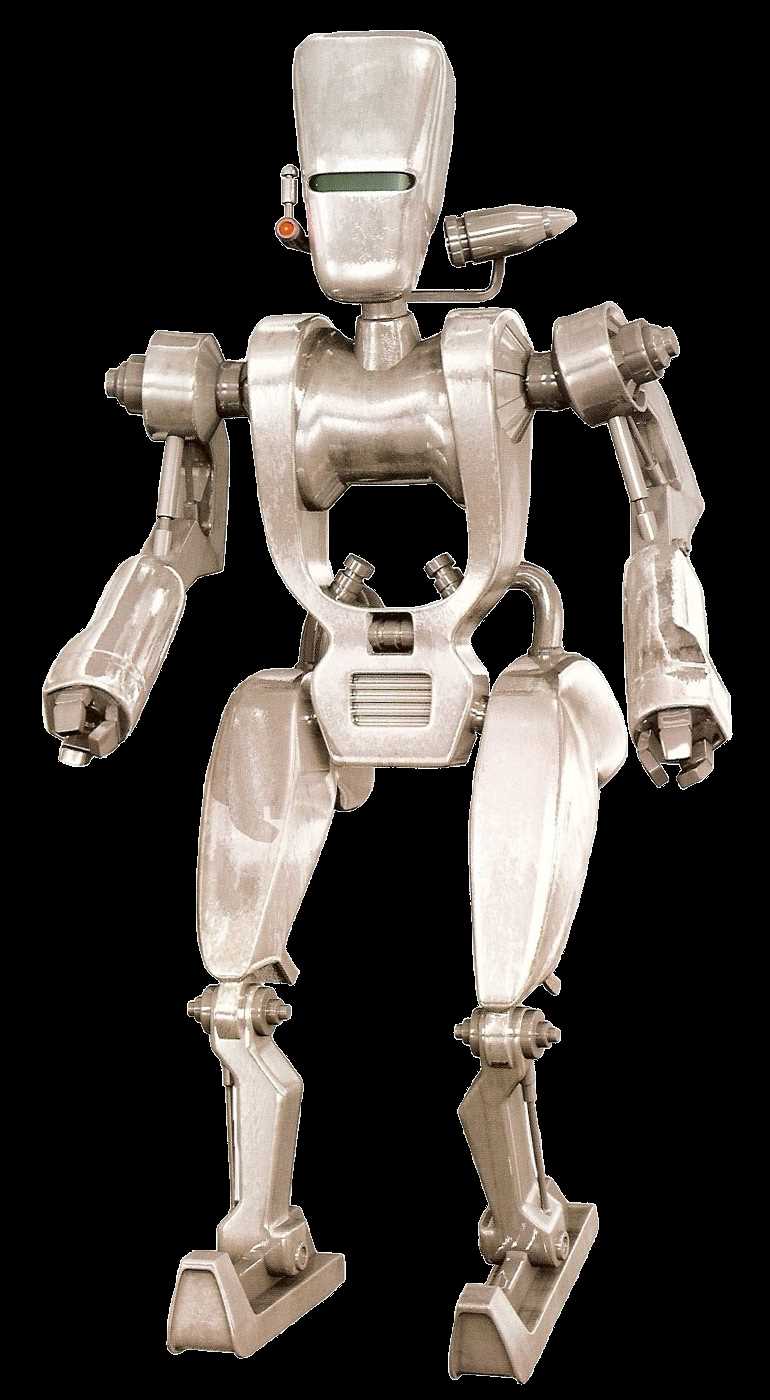

Understanding Droid Depot Components

This section aims to explore the various elements that contribute to the functionality and design of robotic creations. Each component plays a crucial role in the overall operation, ensuring that these machines perform as intended while providing an engaging experience for users. By examining these parts, we can gain insights into how they interact and contribute to the success of the assembly process.

Core Elements of Robotics

The essential elements of robotic systems include sensors, actuators, and control units. Sensors are responsible for gathering information from the environment, allowing the machine to respond effectively to external stimuli. In contrast, actuators translate commands from the control unit into physical movements, enabling the robot to interact with its surroundings. The control unit, often referred to as the “brain” of the robot, processes data from sensors and orchestrates the actions of the actuators.

Customization and Aesthetic Features

Beyond functionality, aesthetic components contribute to the visual appeal of robotic assemblies. Users can personalize their creations with various decorative elements, enhancing the overall experience. The integration of unique colors, shapes, and designs allows for endless possibilities, fostering creativity and individual expression.

Common Issues and Troubleshooting Tips

When working with complex electronic devices, users may encounter a variety of challenges that hinder optimal performance. Understanding these typical problems and knowing effective solutions can significantly enhance the user experience. This section aims to provide insights into frequent obstacles and practical advice for resolving them.

1. Power Malfunctions: One of the most common issues involves the device not powering on. Ensure that the power source is functional and connections are secure. If the problem persists, consider replacing the power supply unit.

2. Connectivity Problems: Users may face difficulties with wireless connections. Verify that the device is within range of the network and that any necessary credentials are entered correctly. Restarting the device and the router can also help restore connectivity.

3. Software Glitches: Unresponsive applications can be frustrating. Regularly updating the software can prevent bugs. If an application freezes, try force closing it and restarting the device.

4. Sensor Calibration Issues: Inaccurate readings from sensors can impact functionality. Calibrate the sensors according to the manufacturer’s guidelines. If errors continue, inspect for physical obstructions or damage.

5. Display Errors: Visual problems such as flickering or dead pixels can diminish the user experience. Check for loose connections, and if the issue persists, a screen replacement may be necessary.

By recognizing these frequent challenges and implementing the suggested solutions, users can maintain the functionality of their devices effectively.

Essential Tools for Repairs

Having the right equipment ensures precise adjustments and smoother restoration tasks. With a carefully selected toolkit, it’s possible to handle a range of adjustments, upgrades, and maintenance routines more efficiently. Below is a list of must-have tools for successful restoration work and adjustments.

- Precision Screwdrivers: These allow for detailed work on various components, especially in small or delicate areas.

- Needle-Nose Pliers: Ideal for accessing tight spaces, these pliers provide grip and control when working with intricate parts and wiring.

- Multimeter: Useful for diagnosing electrical issues, this device helps assess voltage, current, and continuity in circuits.

- Heat Gun: Essential for tasks involving adhesives or shrink tubing, a heat gun can soften materials for easy adjustments or secure wiring.

- Cleaning Brushes and Compressed Air: Dust and debris can interfere with performance, so these tools help keep parts clean and functional.

- Lubricants and Cleaners: Regular application of safe cleaners and lubricants prevents wear and keeps mechanisms running smoothly.

Using these tools as part of your regular work routine can enhance efficiency, ensure accuracy, and extend the longevity of components. With proper maintenance and the right equipment, even complex adjustments can become manageable tasks.

Step-by-Step Repair Procedures

In this section, we’ll explore a structured approach for restoring functionality to your unit, guiding you through each essential phase. Following these procedures will enable you to address and resolve operational challenges effectively, ensuring your device continues to perform at its best.

Preparation: Start by gathering all necessary tools and checking the workspace for cleanliness and organization. Proper preparation minimizes errors and ensures a smooth process.

Inspection: Begin with a thorough inspection of the device to identify visible signs of wear, disconnected components, or other irregularities. Use this step to document issues and prioritize tasks.

Disassembly: Carefully detach outer panels and casing elements, keeping screws and small parts organized. Always follow a systematic approach to avoid unnecessary damage and maintain alignment for reassembly.

Component Assessment: Inspect each internal component to determine functionality. For electrical parts, testing connections and voltage levels can help identify faults that may not be visible.

Replacement or Adjustment: Based on the assessment, replace or adjust faulty components as necessary. Ensure each part is compatible and correctly positioned to prevent further issues.

Reassembly: Reattach panels and casing elements in the reverse order of disassembly. Double-check each connection to ensure it is secure and aligned correctly.

Testing: Power on the unit and conduct functionality tests. Confirm that each component operates as expected, and troubleshoot any issues that arise.

Following these structured procedures will help maintain your unit’s functionality and longevity, ensuring it remains operational in various environments and conditions.

Upgrading Droid Depot Features

Enhancing the capabilities of interactive units brings new dimensions to their functionality and performance. By introducing additional modifications, users can access a broader range of actions, increase responsiveness, and fine-tune behaviors. The process involves careful selection and integration of compatible components that work seamlessly within existing systems, offering an enriched experience for both builders and users.

Choosing the Right Enhancements

When selecting new features, compatibility with the unit’s core framework is essential. Prioritizing parts designed to integrate smoothly helps maintain operational stability while providing upgraded functionality. From extended range sensors to improved audio output, choosing the right additions can make a significant difference in interaction quality.

Installation Guide

Each component upgrade requires specific installation steps, which may involve adjustments to the base structure or wiring. It’s advisable to follow guidelines and test each upgrade individually before proceeding to additional modifications. This method minimizes operational issues and ensures each enhancement performs as expected.

| Feature | Function | Installation Complexity |

|---|---|---|

| Enhanced Sound Module | Provides richer audio quality and greater volume control | Medium |

| Advanced Proximity Sensors | Increases responsiveness to nearby objects | High |

| LED Light Customization | Allows unique lighting effects and colors | Low |

Preventive Maintenance Best Practices

Effective care routines can extend the operational lifespan of complex machinery by ensuring that all components function optimally. Regular assessments and proactive servicing reduce the likelihood of unexpected malfunctions, allowing for smoother, uninterrupted operation over time.

- Schedule Regular Inspections: Establish a consistent inspection schedule to check for signs of wear, irregularities, or potential issues that may need attention. Early detection is key to preventing larger problems.

- Keep Components Clean: Dust and debris can interfere with performance. Ensure that all parts are kept clean, paying special attention to areas prone to buildup or blockage.

- Lubricate Moving Parts: Proper lubrication minimizes friction, reducing strain on parts that are in constant motion. Be sure to use the correct type and amount for each component.

- Update Software and Firmware: Regular updates can improve functionality and security. Make sure to check for and apply any necessary updates to avoid compatibility issues and enhance performance.

- Check for Loose Connections: Connections may loosen over time due to vibrations and regular use. Periodically verify that all connections are secure to prevent potential faults.

- Inspect power sources and ensure they meet the recommended voltage levels.

- Test sensory systems periodically to verify accuracy in response and detection.

- Evaluate performance metrics regularly to gauge the effectiveness of the maintenance routine.

Safety Precautions During Repairs

Understanding the importance of safety measures is essential when working with mechanical components and intricate circuitry. Ensuring a secure and controlled environment reduces risks and helps maintain both the quality of the components and personal safety.

Before beginning, ensure that all power sources are disconnected, and that the workspace is free from any conductive materials that could cause unexpected reactions. Use appropriate protective gear, including gloves and eye protection, to prevent accidental contact with sharp or heated elements.

Maintain a well-organized workspace to easily access tools and parts without creating clutter, as this reduces the risk of slips and accidental damage. Regularly inspect tools for wear to ensure they function correctly, and replace any that appear compromised. Following these precautions contributes to a more effective and hazard-free maintenance experience.

Identifying Component Malfunctions

Effective maintenance begins with accurately recognizing issues within various parts of the system. Detecting signs of wear or failure in individual components can prevent larger disruptions and ensure continued smooth performance. This section provides insights into recognizing early indicators of malfunction to address them promptly.

Visual Inspection: A thorough visual assessment is often the first step. Look for signs such as discoloration, unusual wear, or deformation on the surfaces. These symptoms may point to a component experiencing stress or heat beyond normal operational levels.

Performance Testing: Testing functionality under controlled conditions can reveal inconsistencies in performance. Unstable operation, fluctuations in response time, or reduced efficiency may indicate underlying issues that need closer examination.

Sound Analysis: Unusual sounds, such as clicking, grinding, or buzzing, often suggest internal misalignments or foreign objects interfering with the mechanism. Regularly listening for any changes in the usual operation sounds can help in early detection of potential problems.

Heat Monitoring: Some parts may exhibit excessive warmth, a sign of overworking or improper cooling. Periodically check temperatures, as overheating can accelerate wear and lead to complete failure if not managed.

Using these techniques, you can systematically evaluate each part, identify early signs of malfunction, and apply corrective measures before they escalate, enhancing the overall reliability of the system.

Replacing Parts: A Guide

This section provides a comprehensive overview of how to effectively replace various components to ensure optimal functionality. By understanding how to identify, remove, and replace worn or faulty elements, you can extend the operational lifespan of your unit and maintain peak performance.

Identifying Necessary Replacements

Before starting, it’s essential to recognize which components require attention. Regular inspection helps pinpoint wear, damage, or any inconsistencies that might affect performance. Keep a checklist to track specific parts that need frequent monitoring.

- Visual inspection: Check for any signs of physical wear, such as cracks or rust.

- Functional tests: Evaluate each component to confirm if it operates as expected.

- Documentation: Review any guidelines for recommended replacement intervals.

Steps to Replace a Component

- Preparation: Power down and disconnect all power sources to ensure a safe replacement process.

- Removal: Carefully detach the component using the appropriate tools, taking care not to damage surrounding parts.

- Installation: Align the new part properly, ensuring a secure fit before reassembling any additional elements.

- Testing: Once installed, test the new component to verify that it integrates smoothly with the system and performs as intended.

By following these steps, you’ll be able to handle replacements confidently, ensuring both reliability and longevity of each part you work with.

Cleaning and Maintenance Techniques

Regular upkeep and care are essential for ensuring long-lasting functionality and peak performance. Through systematic cleaning and thorough maintenance, devices retain their efficiency and operational safety, preventing potential issues caused by dust buildup or material wear.

Basic Cleaning Process

To begin, use a soft, lint-free cloth to remove surface dust and prevent scratches on external parts. For harder-to-reach areas, a gentle brush or compressed air can be effective in clearing out small particles that may accumulate over time. It’s crucial to avoid liquid cleaners on any sensitive parts, as moisture can compromise internal components.

Preventive Maintenance Tips

Conducting routine checks and component adjustments ensures uninterrupted function. Inspecting moving parts for signs of wear and applying a light lubricant when necessary can reduce friction and prolong service life. Additionally, periodic recalibration may be required for devices that experience frequent use, ensuring accuracy and reliability in operations.

Resources for Advanced Repairs

For those who possess a deeper understanding of complex systems, specialized resources offer valuable insights and guidance. From intricate diagnostics to customized modifications, these resources are tailored for enthusiasts and professionals looking to address unique challenges in maintaining sophisticated devices.

In this section, we explore various materials, including technical guides and in-depth tutorials, that delve into advanced components and configurations. Access to such resources empowers users to overcome complex issues effectively, ensuring long-term performance and durability.

Key resources include comprehensive documentation, interactive support communities, and online libraries featuring expert contributions. Each of these resources provides tools for precise adjustments, enhancing both functionality and adaptability.

Community Support and Forums

Online communities and specialized forums offer invaluable resources where enthusiasts and professionals gather to share insights, ask questions, and solve problems together. These virtual spaces provide a collaborative environment for exchanging experiences, offering guidance, and addressing technical challenges.

Finding Active Online Communities

Several online platforms host groups dedicated to troubleshooting, customizing, and enhancing projects similar to yours. Participating in these groups allows you to access a wealth of knowledge from experienced users and industry experts alike.

- Forums: Dedicated discussion boards are often organized by topic, making it easy to locate advice or post queries related to specific areas.

- Social Media Groups: Many platforms feature public and private groups where users can share updates, tips, and technical support.

- Q&A Platforms: Websites focused on question-and-answer formats allow you to post specific problems and receive responses from the community.

Getting the Most from Community Interactions

Engaging thoughtfully with these communities can improve your experience and help you quickly find the solutions you need. Here are some tips:

- Search Before Asking: Use the forum’s search function to see if your question has already been addressed. This can save you time and provide immediate answers.

- Be Clear and Specific: When posting questions, describe your issue in detail. Clear explanations increase the chances of receiving helpful responses.

- Contribute Back: Share your own experiences and solutions to help others. Active participation enhances the community’s knowledge base and supports continuous learning.

By leveraging these communities, users can foster meaningful connections, gain practical advice, and develop a deeper understanding through shared experiences.