Comprehensive Guide to Repairing the Stihl 020 AV

When it comes to ensuring the longevity and efficiency of your cutting tool, a thorough understanding of its components and upkeep practices is essential. This guide aims to provide invaluable insights into the intricacies of servicing your equipment, empowering users to tackle common issues and enhance performance.

By delving into the various aspects of maintenance, from engine tuning to chain adjustment, you will equip yourself with the knowledge necessary to keep your device running smoothly. This resource will cover essential techniques, troubleshooting tips, and preventative measures, ensuring that your machine remains in peak condition throughout its lifespan.

Whether you’re a seasoned professional or a novice user, understanding the inner workings of your tool can lead to significant improvements in efficiency and safety. Embracing regular maintenance routines not only enhances performance but also promotes a deeper appreciation for your equipment and its capabilities.

Understanding the Stihl 020 AV

This section delves into the intricacies of a renowned cutting tool, focusing on its features, mechanics, and performance. With a blend of power and efficiency, this device is designed to meet the needs of both casual users and professionals.

Key characteristics of this model include:

- Lightweight design for ease of handling

- Advanced vibration dampening system for user comfort

- Powerful engine that ensures robust performance

- Simple starting mechanism for quick usability

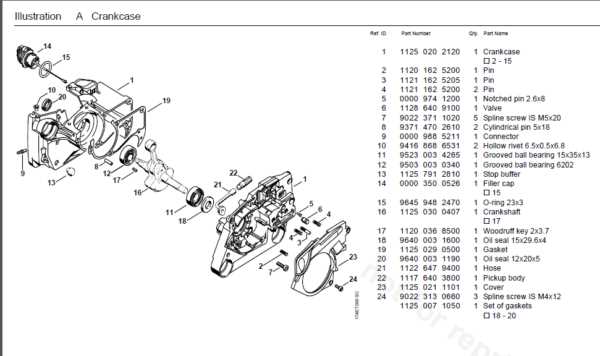

Understanding the operational components is crucial for maximizing performance:

- Engine: A high-efficiency power unit that balances output and fuel consumption.

- Chain System: A precision-engineered cutting chain that provides superior cutting ability.

- Safety Features: Essential mechanisms designed to enhance user safety during operation.

- Maintenance Needs: Regular upkeep is vital for longevity and reliable functioning.

By exploring these aspects, users can appreciate the quality and functionality of this equipment, making informed decisions regarding its use and maintenance.

Common Issues with Stihl 020 AV

This section explores frequent problems encountered with this specific model of chainsaw. Users often report various malfunctions that can hinder performance, and understanding these issues can help in troubleshooting effectively.

| Issue | Description | Possible Solutions |

|---|---|---|

| Starting Difficulties | Owners may find it hard to start the engine, often due to fuel or ignition problems. | Check fuel quality and ensure the spark plug is functioning properly. |

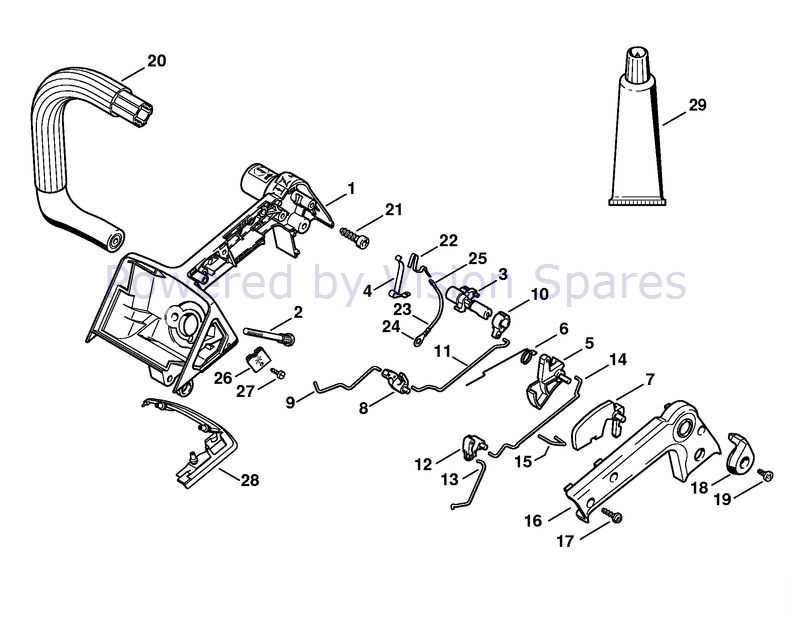

| Chain Brake Problems | The chain brake may not engage or disengage correctly, posing safety risks. | Inspect the brake mechanism for wear and lubricate if necessary. |

| Overheating | Excessive heat can lead to engine damage and decreased efficiency. | Ensure proper airflow and check for clogged air filters. |

| Fuel Leaks | Leaks can occur from various parts, leading to performance issues and hazards. | Inspect fuel lines and seals for cracks and replace them as needed. |

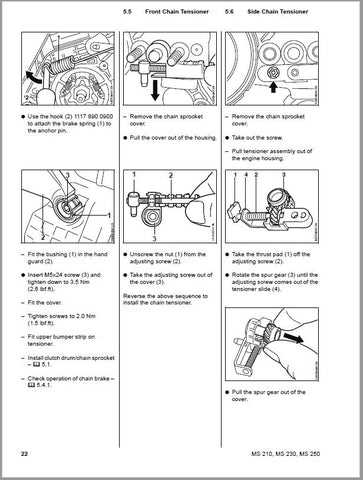

| Chain Tension Issues | Improper chain tension can result in poor cutting performance and safety concerns. | Regularly check and adjust the chain tension according to specifications. |

Essential Tools for Repairs

When tackling maintenance tasks, having the right instruments at hand can significantly enhance efficiency and effectiveness. This section highlights the crucial items that every enthusiast should consider for successful troubleshooting and upkeep of their equipment.

| Tool | Purpose |

|---|---|

| Wrench Set | Used for loosening and tightening bolts and nuts. |

| Screwdriver Set | Essential for removing and installing screws of various types. |

| Pliers | Helpful for gripping, twisting, and cutting wires or small parts. |

| Torque Wrench | Ensures that fasteners are tightened to the manufacturer’s specifications. |

| File Set | Ideal for smoothing rough edges and surfaces. |

| Cleaning Brushes | Used for clearing debris and dirt from hard-to-reach areas. |

| Multimeter | Essential for diagnosing electrical issues and measuring voltage. |

Equipping yourself with these fundamental tools will facilitate smoother procedures and ensure your equipment remains in top condition for years to come.

Step-by-Step Disassembly Guide

This section provides a comprehensive approach to safely taking apart a specific type of power tool. Following these guidelines will ensure that all components are handled correctly, minimizing the risk of damage and facilitating efficient reassembly.

Tools Required

Before starting the disassembly process, gather the necessary tools. Below is a list of items you will need:

| Tool | Purpose |

|---|---|

| Screwdriver Set | For removing screws |

| Wrench | To loosen nuts and bolts |

| Pliers | For gripping and twisting components |

| Clean Cloth | To wipe surfaces and parts |

| Container | For storing small parts |

Disassembly Steps

Follow these steps to carefully disassemble the tool:

- Ensure the tool is unplugged and cool to the touch.

- Begin by removing any protective covers or casings.

- Carefully detach the handle by unscrewing the fasteners.

- Proceed to disconnect the motor assembly by loosening the securing bolts.

- Remove any additional components, such as the air filter and spark plug, as needed.

- Organize the parts in the container to keep track of everything.

Replacing the Fuel System Components

Maintaining the integrity of the fuel system is crucial for optimal performance and longevity of your equipment. Over time, components such as filters, lines, and pumps can wear out or become clogged, leading to inefficiencies or operational failures. This section will guide you through the necessary steps to replace these vital elements effectively.

Identifying Components: Start by familiarizing yourself with the key elements of the fuel system. The fuel filter, which removes impurities, and the fuel lines, which transport the mixture, are essential for smooth operation. Recognizing when these parts need attention is the first step in ensuring proper functionality.

Gathering Tools and Parts: Before beginning the replacement process, gather the required tools such as screwdrivers, wrenches, and replacement components. Ensure that the new parts are compatible and of high quality to guarantee reliable performance.

Removing Old Components: Carefully detach the old components. Take care to avoid damaging surrounding parts during removal. It is often helpful to take pictures or make notes to remember how everything is assembled.

Installing New Parts: Once the old components are removed, install the new parts in reverse order. Ensure that all connections are secure and that there are no leaks in the fuel lines. Proper installation is essential for the safe operation of your machinery.

Testing the System: After installation, test the system to ensure that everything is functioning correctly. Check for leaks and monitor performance during initial use. This will help confirm that the replacements were successful and that the equipment is ready for operation.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your outdoor equipment requires regular attention and care. Adopting a systematic approach to maintenance not only enhances functionality but also extends the lifespan of your tools. Below are essential practices to keep your equipment running smoothly.

- Regular Cleaning: After each use, clean the exterior to remove dirt and debris. Pay special attention to air filters and cooling fins to prevent overheating.

- Lubrication: Apply appropriate lubricants to moving parts as specified in the guidelines. This reduces friction and wear, contributing to smoother operation.

- Inspection: Frequently check for signs of wear or damage. Look for frayed cables, loose screws, or cracks in the casing.

- Fuel Maintenance: Use fresh fuel and appropriate oil mixtures. Old or contaminated fuel can lead to starting issues and engine problems.

- Blade Care: Regularly sharpen and inspect blades for wear. Dull blades can strain the engine and produce uneven cuts.

- Storage Practices: Store equipment in a dry, sheltered area. Use covers to protect from dust and moisture when not in use.

By following these maintenance tips, you can ensure your tools remain in excellent condition, ready for any task ahead. Regular upkeep is a small investment that pays off in performance and longevity.

Troubleshooting Engine Performance Problems

When dealing with engine performance issues, identifying the root cause is crucial for restoring optimal function. Various factors can contribute to decreased efficiency, from fuel quality to mechanical wear. This section outlines common symptoms and corresponding solutions to help diagnose and rectify the problems effectively.

Common Symptoms and Causes

| Symptom | Possible Cause | Suggested Action |

|---|---|---|

| Poor Acceleration | Clogged air filter | Inspect and clean or replace the air filter. |

| Excessive Smoke | Incorrect fuel mixture | Check and adjust the fuel mixture to specifications. |

| Engine Stalling | Fuel line obstruction | Examine and clear any blockages in the fuel line. |

| Rough Idle | Worn spark plug | Replace the spark plug if necessary. |

| Overheating | Low oil levels | Check oil levels and top up if needed. |

Diagnostic Steps

To effectively troubleshoot, start with a thorough visual inspection of the engine components. Ensure that all connections are secure and that there are no visible signs of damage. Proceed to test each potential cause systematically, focusing on one issue at a time. Utilizing proper tools can greatly enhance the accuracy of your diagnostics, leading to timely and efficient repairs.

Reassembly Process Explained

The process of putting components back together is crucial for ensuring the proper functioning of the equipment. Attention to detail during reassembly can significantly affect performance and longevity. This section outlines the essential steps and considerations to achieve a successful reconstruction.

Preparation Steps

Before starting the assembly, gather all necessary tools and components. Ensure that all parts are clean and free from debris. It is advisable to review any documentation or guides related to the initial disassembly. This preparatory phase sets the stage for a smoother reassembly process.

Step-by-Step Assembly

Begin by placing the base component securely. Gradually add other parts in the correct order, ensuring alignment with their designated slots. Pay close attention to any fasteners or clips; they must be tightened adequately to prevent future issues. After each stage, conduct a quick check to confirm that everything fits snugly. Finally, perform a thorough inspection once reassembly is complete to guarantee that no parts are left out and that everything operates as intended. Following these steps will help ensure a successful reconstruction.

Aftermarket Parts: Pros and Cons

Exploring the realm of alternative components can offer users a range of choices, often at more appealing prices. However, the decision to utilize these substitutes involves weighing benefits against potential drawbacks, making it essential to understand both sides of the equation.

Advantages of Aftermarket Components

One significant advantage is cost-effectiveness; these parts are often cheaper than original variants, enabling budget-conscious users to maintain their equipment without overspending. Additionally, the variety of options can lead to improved performance or enhanced features, catering to specific user needs.

Disadvantages of Aftermarket Components

On the flip side, quality can be inconsistent, leading to reliability issues that may result in frequent replacements. Moreover, using non-original parts might void warranties or lead to compatibility challenges, affecting overall functionality and user satisfaction.

Safety Precautions During Repairs

Ensuring a safe environment while working on equipment is essential for both the individual and the machinery involved. Adhering to specific guidelines not only minimizes the risk of accidents but also enhances the overall efficiency of the maintenance process. Proper preparation and awareness can prevent injuries and prolong the lifespan of tools.

Before initiating any work, it is crucial to wear appropriate personal protective equipment (PPE). This includes items such as gloves, safety goggles, and sturdy footwear. Additionally, maintaining a tidy workspace can significantly reduce hazards.

| Safety Gear | Purpose |

|---|---|

| Gloves | Protects hands from cuts and abrasions |

| Safety Goggles | Shields eyes from debris and dust |

| Sturdy Footwear | Prevents foot injuries from heavy objects |

| Ear Protection | Reduces noise exposure from machinery |

Additionally, it is advisable to familiarize oneself with the specific equipment being serviced. Understanding its components and operation can prevent misuse and potential accidents. Always ensure that the machinery is powered off and disconnected from any power sources before beginning work.

In conclusion, prioritizing safety during maintenance activities is vital. By following these precautions and remaining vigilant, individuals can effectively reduce risks and contribute to a safer working environment.