Comprehensive Guide to Farmall H Repair Manual

In the realm of agricultural machinery, understanding the intricacies of machinery upkeep is vital for optimal performance and longevity. A well-structured approach to addressing mechanical issues can enhance efficiency and minimize downtime. This resource aims to provide essential insights for owners and operators to navigate common challenges associated with their equipment.

Equipping oneself with the right knowledge not only facilitates smoother operation but also fosters a deeper connection with the machinery. By learning about key components and potential malfunctions, users can proactively manage their machines and ensure they remain in peak condition. This guide serves as a valuable tool for those seeking to delve into the fundamentals of maintenance.

From troubleshooting typical problems to conducting routine checks, mastering these techniques will empower individuals to take charge of their equipment. Whether you are a seasoned operator or a newcomer, this collection of information is designed to aid in understanding and effectively managing the complexities of agricultural machinery.

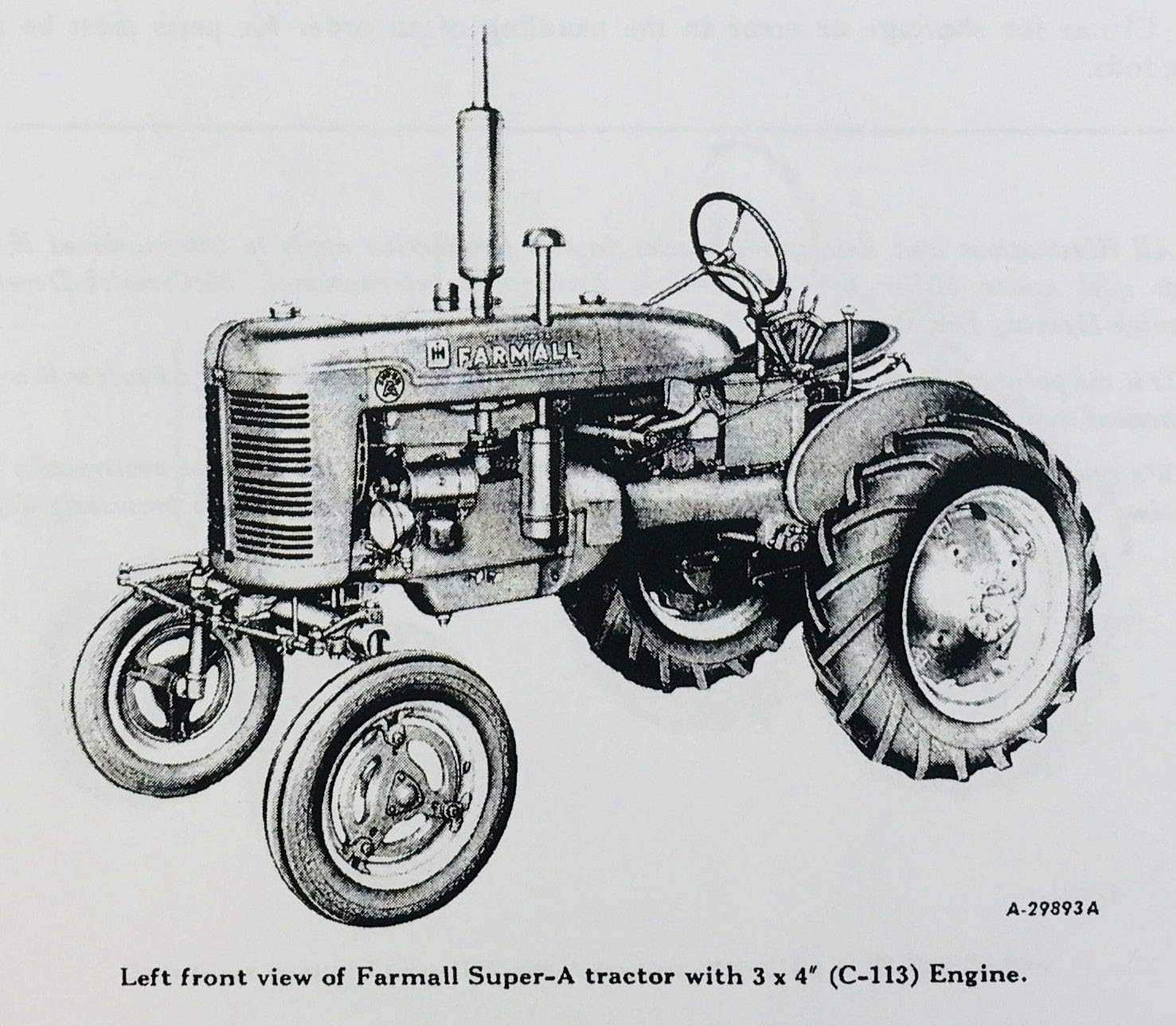

Understanding the Farmall H Tractor

The iconic agricultural machine embodies a blend of durability and efficiency, essential for various farming tasks. Its design caters to both small-scale operations and larger agricultural enterprises, making it a versatile choice for many enthusiasts and professionals alike.

Key Features

One of the standout characteristics of this tractor is its robust engine, which offers reliable performance across diverse conditions. The transmission system is designed for smooth gear shifts, ensuring ease of use for operators. Additionally, the model’s ergonomic layout enhances comfort during prolonged work periods, allowing for increased productivity.

Maintenance and Care

Regular upkeep is crucial for optimal functionality. Simple checks on fluid levels, tire pressure, and general wear can significantly extend the lifespan of the equipment. Understanding the specific needs of this machine can help owners maintain peak performance and avoid costly repairs.

In summary, this agricultural powerhouse combines traditional craftsmanship with modern technology, making it a valuable asset for anyone in the farming community. Emphasizing care and understanding will ensure it continues to serve its purpose effectively for years to come.

Common Issues Faced by Owners

Operating vintage agricultural machinery can present a variety of challenges that users must navigate. Many owners encounter similar problems that can hinder performance and efficiency. Understanding these common difficulties can aid in maintaining optimal functionality and extending the lifespan of the equipment.

Mechanical Failures

One of the primary concerns for operators is mechanical breakdowns. These issues can stem from wear and tear, outdated components, or insufficient maintenance. Common mechanical failures include:

| Issue | Symptoms | Potential Solutions |

|---|---|---|

| Engine Overheating | Excessive temperature readings, steam from engine | Check coolant levels, inspect radiator for blockages |

| Transmission Problems | Difficulty shifting gears, unusual noises | Inspect fluid levels, check for leaks |

| Electrical Failures | Inconsistent starting, dim lights | Examine battery connections, test alternator output |

Operational Inefficiencies

In addition to mechanical issues, users may experience operational inefficiencies that affect productivity. These can often be attributed to poor calibration, incorrect settings, or lack of proper adjustments. Some prevalent operational problems include:

| Issue | Symptoms | Potential Solutions |

|---|---|---|

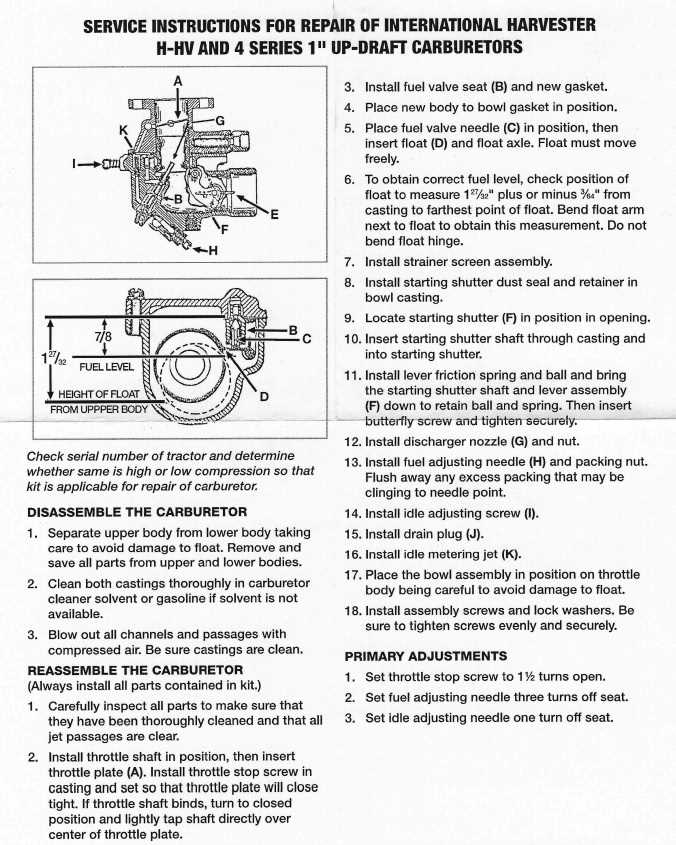

| Poor Fuel Efficiency | Frequent refueling, excessive exhaust emissions | Adjust carburetor settings, clean fuel filters |

| Ineffective Hydraulics | Slow response time, inconsistent lifting | Check hydraulic fluid levels, inspect for leaks |

| Steering Issues | Unresponsive steering, excessive play | Lubricate steering components, adjust linkage |

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance tasks. A well-equipped toolkit not only enhances efficiency but also ensures that every job is performed safely and correctly. Understanding which instruments are necessary can significantly simplify the upkeep process.

Basic Hand Tools

At the core of any toolkit are basic hand tools. These include wrenches, screwdrivers, and pliers. Each plays a vital role in loosening, tightening, or manipulating components, making them indispensable for any restoration project.

Specialized Equipment

Beyond the basics, some specialized instruments are essential for more intricate tasks. Items like torque wrenches and diagnostic tools can provide the precision needed for specific adjustments, ensuring optimal performance and longevity of your machinery.

Step-by-Step Engine Overhaul Guide

Undertaking an engine overhaul is a rewarding yet challenging task that can breathe new life into your machinery. This comprehensive guide will lead you through each crucial phase, ensuring that you understand the process and achieve the best possible results.

1. Preparation: Gather all necessary tools and parts before starting. A clean, organized workspace will enhance your efficiency and safety.

2. Disassembly: Carefully remove the engine from its housing. Document each step and take photos to assist with reassembly.

3. Cleaning: Thoroughly clean all components to remove grime and old lubricants. Use appropriate solvents for effective results.

4. Inspection: Examine each part for wear or damage. Pay close attention to gaskets, seals, and bearings.

5. Replacement: Replace any worn or damaged components with high-quality parts to ensure longevity and performance.

6. Reassembly: Follow your documentation and photos closely to reassemble the engine. Ensure all fasteners are torqued to specifications.

7. Testing: Once reassembled, conduct a series of tests to verify proper function and identify any potential issues.

8. Final Touches: After successful testing, perform a final inspection and make any necessary adjustments before placing the engine back into service.

By following this systematic approach, you can effectively delve into the intricacies of engine refurbishment, achieving the ultimate outcome for your machine.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your machinery requires regular attention and proactive measures. By following a systematic approach to upkeep, you can enhance performance and reduce the likelihood of unexpected breakdowns. Here are essential strategies to keep your equipment running smoothly for years to come.

Regular Inspections

Routine evaluations are crucial for identifying potential issues before they escalate. Consider these steps:

- Check fluid levels frequently to maintain optimal operation.

- Inspect belts and hoses for wear and tear, replacing them as needed.

- Examine electrical connections to ensure they are secure and free from corrosion.

Proper Lubrication

Lubrication plays a vital role in minimizing friction and wear. Follow these guidelines:

- Use the recommended type of lubricant for various components.

- Apply lubricant regularly, adhering to the manufacturer’s schedule.

- Clean surfaces before applying grease to prevent contamination.

Implementing these practices will significantly contribute to the reliability and efficiency of your equipment, helping you achieve optimal performance over time.

Transmission Troubleshooting Techniques

When faced with issues in the power transfer system, it’s essential to approach the situation methodically. Identifying the root cause of malfunctions requires careful observation and systematic analysis of symptoms. By following a structured troubleshooting process, operators can effectively isolate problems and implement appropriate solutions.

Common Symptoms and Initial Checks

Start by noting any unusual sounds, shifting difficulties, or fluid leaks. Check the fluid level and condition, as low or contaminated fluid can lead to performance issues. Ensure that the linkage and connections are intact, as misalignments can hinder proper operation. Observing these basic elements can provide crucial insights into the underlying issue.

Advanced Diagnostic Techniques

If initial checks do not reveal the problem, consider utilizing diagnostic tools. Pressure gauges can help assess system performance, while specialized equipment may identify internal wear or damage. Engage in a thorough inspection of gears and bearings, as wear can often manifest as shifting irregularities. Documenting findings will aid in tracking progress and determining if further intervention is necessary.

Electrical System Diagnosis and Fixes

Understanding the intricacies of a vehicle’s electrical framework is crucial for ensuring optimal performance. This section provides insights into common issues, diagnostic techniques, and effective solutions for maintaining a reliable electrical system.

Common Electrical Issues

- Dead battery: A frequent problem often resulting from age or lack of use.

- Faulty wiring: Damaged or corroded wires can disrupt the flow of electricity.

- Defective alternator: This component is essential for charging the battery while the engine runs.

- Malfunctioning starter: A key part in initiating the engine, a faulty starter can prevent operation.

Diagnostic Techniques

- Visual Inspection: Check for obvious signs of damage, corrosion, or loose connections.

- Multimeter Testing: Use a multimeter to measure voltage and continuity throughout the system.

- Battery Load Test: Assess the battery’s ability to hold charge under load.

- Check Fuses: Ensure that all fuses are intact and functioning correctly.

By methodically addressing these areas, one can effectively troubleshoot and rectify electrical complications, leading to a more dependable operation.

Hydraulic System Maintenance Procedures

The hydraulic system is a critical component that requires regular attention to ensure optimal performance and longevity. Proper maintenance practices can prevent potential issues and enhance the efficiency of your machinery. By understanding the key procedures involved, operators can safeguard the hydraulic system against wear and tear.

Start by regularly checking the fluid levels in the reservoir. Ensure that the hydraulic fluid is at the recommended level to avoid overheating and inadequate lubrication. If the fluid appears contaminated, it may be necessary to replace it, as impurities can lead to system failure.

Inspect hoses and connections for signs of leaks or wear. Cracks or fraying can compromise the integrity of the system, leading to reduced pressure and performance. Replace any damaged components promptly to maintain a secure and efficient hydraulic circuit.

Additionally, clean or replace filters as specified in the equipment guidelines. Clogged filters can restrict fluid flow and increase the risk of overheating, which may ultimately harm the system. Maintaining clean filters is essential for ensuring the hydraulic fluid circulates freely.

Finally, periodic testing of the hydraulic system’s pressure can identify any irregularities that may indicate underlying problems. Monitoring pressure levels allows for early detection of issues, helping to prevent costly repairs and downtime in the future.

Finding Replacement Parts Effectively

Locating suitable components for machinery can be a daunting task, especially when considering the variety of options available. Understanding where to search and how to evaluate your choices will streamline the process significantly, ensuring that you get the right items without unnecessary hassle.

One effective approach is to categorize potential sources of parts. This can help you focus your search and make informed decisions. Below is a table summarizing various options for sourcing components along with their benefits:

| Source | Benefits |

|---|---|

| Local Dealerships | Direct access to genuine parts; expert advice available. |

| Online Retailers | Wide selection; often competitive prices; convenient shopping. |

| Salvage Yards | Cost-effective solutions; possibility of finding rare items. |

| Manufacturer Websites | Assurance of quality; official product information. |

| Online Marketplaces | Diverse offerings; user reviews can guide choices. |

By utilizing these avenues, you can enhance your chances of finding the necessary components. Additionally, always consider reaching out to fellow enthusiasts or joining online forums for recommendations and tips, which can further aid your search.

Safety Precautions During Repairs

Ensuring a safe environment while conducting maintenance tasks is essential for both personal well-being and the longevity of equipment. By following specific guidelines, one can minimize risks and create a more efficient workspace.

Personal Protective Equipment

- Always wear safety goggles to protect your eyes from debris.

- Use gloves to shield your hands from sharp edges and chemicals.

- Wear steel-toed boots to prevent foot injuries from heavy components.

- Consider ear protection when working with loud machinery.

Workspace Safety

- Keep your workspace organized to avoid accidents.

- Ensure adequate ventilation when handling chemicals.

- Disconnect power sources before starting any maintenance work.

- Have a first aid kit accessible in case of emergencies.

Resources for Farmall H Enthusiasts

For those passionate about vintage agricultural machinery, finding the right materials and connections can enhance both knowledge and enjoyment. This section offers a collection of valuable resources to support enthusiasts in their journey, whether for maintenance, restoration, or simply to connect with fellow aficionados.

- Online Forums: Engaging with a community can provide insights and tips from experienced users. Consider joining platforms like:

- TractorByNet

- Red Power Magazine Forum

- Yesterdays Tractors Forum

- Books and Publications: Numerous books delve into the history and mechanics of these iconic machines. Some recommended titles include:

- “The Complete Guide to Antique Tractors”

- “Tractor Restoration: A Comprehensive Guide”

- “Understanding Vintage Engines”

- Video Tutorials: Visual aids can be particularly helpful. Platforms like YouTube offer a wealth of instructional content, including:

- Step-by-step restoration projects

- Maintenance tips and tricks

- Historic documentaries

- Local Clubs and Events: Joining a local group can provide camaraderie and shared knowledge. Look for:

- Vintage machinery shows

- Local tractor clubs

- Farm machinery expos

lessCopy code

Utilizing these resources can enhance understanding and appreciation, ensuring that enthusiasts remain connected and informed about their passion.