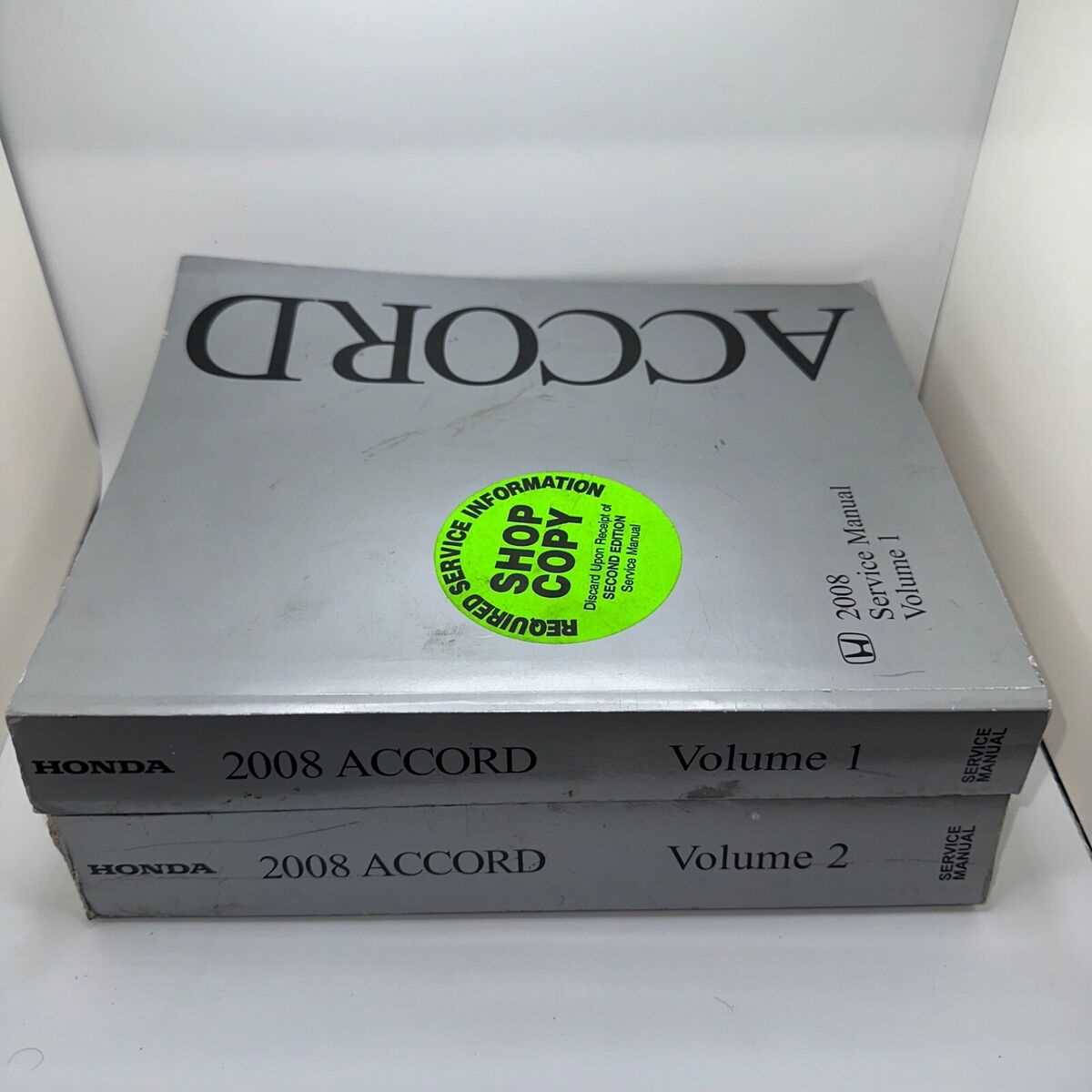

Comprehensive Guide for 2008 Honda Accord Repairs

Understanding the intricacies of automotive upkeep is essential for any car owner. This section delves into the critical aspects of ensuring a vehicle operates at its best. From routine check-ups to more complex procedures, having the right information can make all the difference in prolonging the life of your automobile.

Regular maintenance is not just a recommendation; it is a necessity. By familiarizing yourself with essential practices, you can prevent potential issues and save on costly repairs. Moreover, being proactive in car care enhances both safety and performance, allowing for a smoother driving experience.

Equipped with the appropriate resources, you can navigate through various tasks with confidence. Whether you are performing simple inspections or tackling more detailed projects, knowledge is your greatest ally. This section aims to empower you with the expertise needed to maintain your vehicle effectively.

This section highlights key aspects necessary for the optimal functioning of a vehicle from a specific model year. Proper upkeep not only enhances performance but also extends the lifespan of essential components.

Key Maintenance Tasks

- Regular oil changes

- Checking and replacing air filters

- Inspecting tire pressure and tread depth

- Fluid level assessments

- Brake system evaluations

Scheduled Service Intervals

Establishing a timeline for routine check-ups ensures that potential issues are addressed promptly, promoting reliability.

DIY Maintenance Tips

- Learn basic tools required for minor repairs.

- Consult resources for step-by-step guidance.

- Stay informed about common issues for your model.

Importance of Professional Inspections

Engaging certified technicians for thorough evaluations can prevent major malfunctions and ensure safety.

Common Issues and Solutions

- Engine performance problems

- Electrical system failures

- Suspension issues

Aftermarket Parts Considerations

Using non-original components can affect the vehicle’s performance. Research before making a purchase.

Resources for Further Assistance

- Online forums and communities

- Automotive books and publications

- Manufacturer websites

Tools and Equipment Needed

A well-equipped garage enhances the ability to perform maintenance tasks efficiently and safely.

Understanding Vehicle Systems

- Engine and drivetrain

- Electrical and ignition

- Cooling and heating systems

Conclusion and Next Steps

Implementing these practices ensures a reliable driving experience and peace of mind for owners.

Troubleshooting Common Issues

Addressing frequent problems in vehicles is essential for maintaining optimal performance and safety. Understanding the common signs and symptoms can help owners identify issues early, preventing further complications and costly repairs.

Engine Performance Problems

When experiencing a lack of power or rough idling, it is crucial to check the fuel system, ignition components, and air intake. These areas often contribute to engine inefficiencies, leading to decreased performance.

Electrical System Failures

If the electrical components are malfunctioning, such as lights flickering or the battery draining unexpectedly, inspecting the wiring and connections is vital. Ensuring that the battery and alternator are functioning correctly can prevent many electrical-related issues.

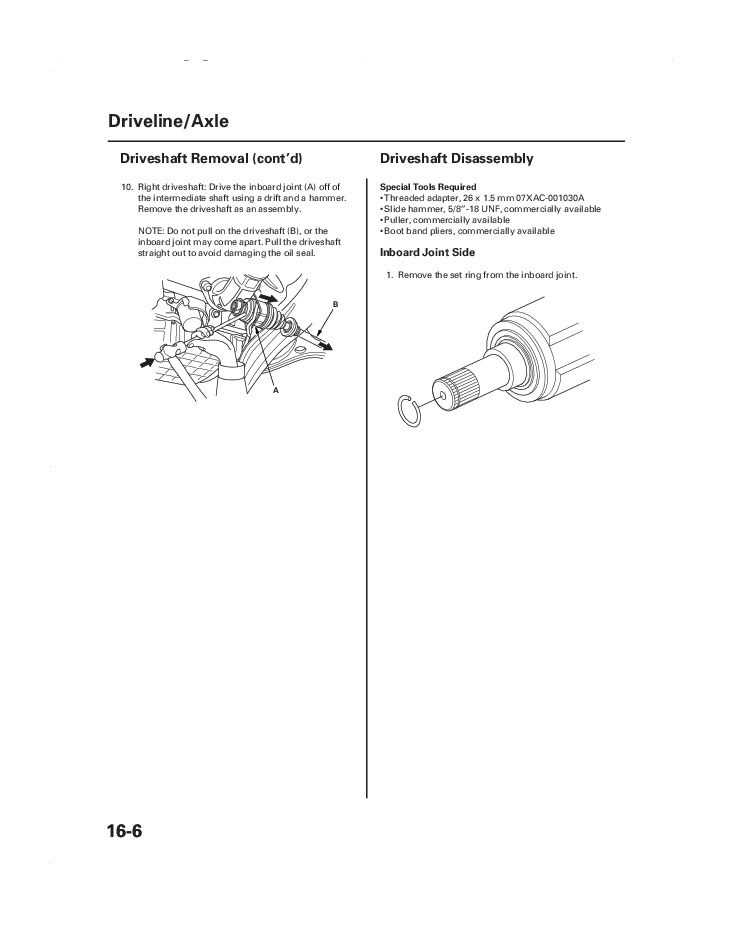

Step-by-Step Repair Procedures

This section provides a comprehensive guide to the systematic approach for addressing various mechanical issues. Each procedure is designed to ensure clarity and effectiveness in tackling common tasks, making it easier for individuals to achieve successful outcomes.

Essential Tools Required

- Socket set

- Wrench set

- Jack and jack stands

- Diagnostic scanner

- Screwdrivers (flathead and Phillips)

Procedure Overview

- Identify the issue by conducting a thorough inspection.

- Gather all necessary tools and parts before starting the task.

- Follow the outlined steps in a sequential manner to ensure proper execution.

- Test the system after repairs to confirm that the problem has been resolved.

- Document any changes made for future reference.

Tools Required for Repairs

When undertaking maintenance tasks on your vehicle, having the right equipment is crucial for achieving effective results. This section outlines the essential instruments that facilitate various procedures, ensuring that the process is efficient and safe.

Essential Hand Tools

A selection of hand tools is necessary for performing most tasks on your automobile. These instruments allow for precise adjustments and repairs, contributing to the overall efficiency of the work.

| Tool Type | Purpose |

|---|---|

| Wrench Set | For tightening and loosening nuts and bolts. |

| Screwdriver Set | To drive screws and remove panels. |

| Pliers | Useful for gripping, twisting, and cutting wires. |

Specialized Equipment

In addition to hand tools, certain specialized equipment may be necessary for specific repairs. This equipment helps address complex issues that require a more technical approach.

| Equipment Type | Function |

|---|---|

| Diagnostic Scanner | To read error codes and assess system functionality. |

| Torque Wrench | Ensures bolts are tightened to specified levels. |

| Jack and Stands | For lifting the vehicle safely for undercarriage access. |

Understanding the Engine Specifications

This section delves into the critical aspects of engine specifications, providing a comprehensive overview of performance metrics and technical details that are essential for effective maintenance and optimization. Understanding these parameters is vital for ensuring the longevity and efficiency of the vehicle.

Key Performance Metrics

- Displacement: The total volume of all the cylinders in the engine, influencing power output and efficiency.

- Horsepower: A measurement of the engine’s power, indicating how much work it can perform over time.

- Torque: The rotational force produced by the engine, crucial for acceleration and towing capacity.

Engine Types

- Inline Engines: Characterized by a straight layout, these engines are commonly found in many vehicles due to their compact design.

- V-Engines: Featuring a ‘V’ configuration, these engines often provide more power in a smaller space.

- Hybrid Engines: Combining traditional combustion with electric power, these systems enhance fuel efficiency and reduce emissions.

Electrical System Diagnostics

This section focuses on the processes and techniques used to identify issues within a vehicle’s electrical framework. Proper diagnostics are essential for ensuring that all electronic components function efficiently, providing reliability and safety for the driver.

Common Issues and Symptoms

Electrical malfunctions can manifest in various ways, such as dimming lights, erratic instrument readings, or unresponsive electronic features. Recognizing these symptoms early can help in pinpointing the root cause and preventing further complications.

Diagnostic Tools and Techniques

Utilizing specialized tools like multimeters and diagnostic scanners is crucial for effective troubleshooting. These devices aid in measuring voltage, continuity, and resistance, allowing technicians to evaluate the condition of wiring and components systematically.

Fluid Replacement Guidelines

Maintaining optimal performance in any vehicle requires regular fluid changes. This section outlines the key recommendations for replacing essential fluids, ensuring longevity and efficiency.

Here are the primary fluids that should be monitored and replaced periodically:

- Engine Oil: Replace every 5,000 to 7,500 miles to ensure proper lubrication.

- Transmission Fluid: Change every 30,000 to 60,000 miles to maintain smooth shifting.

- Coolant: Inspect and replace every 2 to 3 years to prevent overheating.

- Brake Fluid: Change every 2 years or as needed to ensure braking efficiency.

- Power Steering Fluid: Check regularly and replace if contaminated or low.

Always consult the vehicle’s specifications for precise intervals and procedures tailored to specific models. Regular checks and timely replacements are crucial for overall vehicle health.

Braking System Maintenance Tips

Ensuring the optimal performance of your vehicle’s stopping mechanism is crucial for safety and efficiency. Regular attention to this essential system can prevent costly repairs and enhance driving confidence.

1. Regular Inspection: Check brake pads, rotors, and fluid levels periodically. Look for signs of wear or leaks that may indicate the need for immediate attention.

2. Fluid Replacement: Brake fluid should be changed according to the manufacturer’s recommendations. Old fluid can absorb moisture, reducing braking efficiency.

3. Listen for Unusual Noises: Pay attention to any grinding or squeaking sounds when braking. These noises often signal that components need servicing.

4. Maintain Cleanliness: Keep the brake components clean from dust and debris to avoid performance issues. Regular cleaning can prolong the lifespan of the system.

5. Professional Check-ups: Schedule periodic professional evaluations to ensure all components function properly and safely. Experts can provide insights that may not be obvious during a personal inspection.

Suspension and Steering Adjustments

Proper alignment and tuning of the suspension and steering systems are essential for optimal vehicle handling and comfort. Adjustments in these areas can significantly enhance driving stability and overall performance.

Key components that may require attention include:

- Shock absorbers and struts

- Control arms

- Steering rack

- Wheel bearings

- Suspension bushings

Regular checks and modifications can prevent uneven tire wear and improve responsiveness. Consider the following adjustment procedures:

- Check the alignment settings using appropriate measuring equipment.

- Inspect suspension components for wear and replace as needed.

- Adjust the ride height to achieve optimal clearance and handling.

- Calibrate the steering system to ensure accurate steering response.

By maintaining these systems, drivers can enjoy a safer and more enjoyable experience on the road.

Bodywork and Interior Repairs

Maintaining the aesthetics and functionality of your vehicle’s exterior and interior is essential for preserving its value and ensuring a pleasant driving experience. This section will explore various techniques and considerations involved in restoring the body and cabin of your automobile.

Exterior Considerations

The exterior of your vehicle is constantly exposed to environmental elements. Addressing damage promptly can prevent further issues. Here are some common concerns:

- Minor dents and scratches

- Corrosion and rust prevention

- Paint touch-ups and refinishing

Interior Restoration

The interior space should provide comfort and functionality. Regular maintenance can enhance the driving experience. Key areas to focus on include:

- Upholstery cleaning and repair

- Dashboard and control panel upkeep

- Floor mat replacement and care

Safety Precautions During Repairs

Ensuring safety is paramount when undertaking any maintenance task. Proper precautions can prevent accidents and injuries, creating a secure environment for both the technician and the vehicle. It is essential to be aware of potential hazards and to adopt measures that mitigate risks.

Always wear appropriate personal protective equipment. This includes gloves, goggles, and sturdy footwear to protect against chemicals, debris, and heavy components. In addition, ensure that the workspace is well-lit and organized to minimize hazards.

Before beginning any task, disconnect the battery to avoid electrical shocks and other complications. If lifting the vehicle, utilize reliable jacks and stands to ensure stability. Regularly inspect tools and equipment for damage to prevent malfunctions during use.

By adhering to these safety guidelines, the process becomes not only more efficient but also significantly safer, reducing the likelihood of accidents and ensuring a successful maintenance experience.