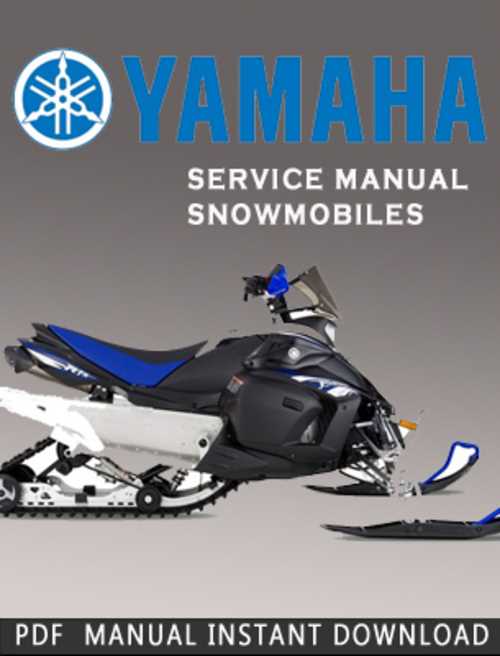

Comprehensive Yamaha Phazer Repair Manual Guide

When it comes to ensuring the longevity and optimal performance of your snow-venturing machine, having a thorough understanding of its components and systems is essential. This section delves into the intricate details of upkeep and troubleshooting, providing enthusiasts with the knowledge they need to tackle common challenges.

Every outdoor enthusiast knows that a well-maintained vehicle can make all the difference on the trails. Whether you’re preparing for a weekend getaway or simply want to keep your ride in peak condition, being equipped with the right information will empower you to handle a variety of issues confidently.

By following a structured approach to maintenance, you can enhance your machine’s reliability and safety. This guide outlines key procedures and offers valuable tips, enabling you to navigate the complexities of your vehicle with ease. Armed with these insights, you’ll be ready to confront any mechanical hiccups that may arise during your adventures.

Overview of Yamaha Phazer

This section provides a comprehensive look at a popular model known for its performance and reliability in the snowmobile market. A blend of innovative design and engineering excellence makes this vehicle a favorite among enthusiasts seeking adventure in winter landscapes.

Key Features

The vehicle is equipped with a powerful engine that ensures smooth acceleration and impressive speed. Its lightweight chassis contributes to excellent maneuverability, making it ideal for both novice riders and experienced enthusiasts. Additionally, the advanced suspension system enhances stability and comfort, allowing for enjoyable rides over various terrains.

Performance and Handling

Notable for its agile handling, this model excels in tight turns and challenging conditions. The balance between power and control is finely tuned, providing riders with confidence as they navigate through snow-covered trails. Overall, this machine embodies a harmonious combination of performance, comfort, and durability, making it a standout choice in its category.

Common Issues with Yamaha Phazer

Every snowmobile has its quirks, and certain models often experience a range of recurring problems. Understanding these frequent complications can help enthusiasts maintain optimal performance and enjoy a smoother ride. Below are some of the most notable issues faced by owners of this specific model.

- Engine Starting Problems:

- Difficulty starting the engine, especially in cold weather.

- Battery drain or failure to hold a charge.

- Fuel System Issues:

- Clogged fuel lines leading to reduced performance.

- Problems with the fuel pump or injectors.

- Electrical Failures:

- Malfunctioning lights or gauges.

- Wiring issues causing intermittent electrical failures.

- Suspension and Handling:

- Worn-out shocks affecting ride quality.

- Alignment problems leading to uneven tire wear.

- Track and Drive System:

- Damage to the track due to debris.

- Drive belt wear causing slippage or poor acceleration.

Addressing these issues promptly can lead to a more enjoyable and safer riding experience. Regular maintenance and inspections can significantly reduce the likelihood of these complications arising.

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance and troubleshooting. This section highlights the fundamental implements that every enthusiast should have on hand to ensure a smooth process. Each tool plays a significant role in diagnosing issues and executing repairs efficiently.

Wrenches and Sockets: A diverse set of wrenches and socket tools is indispensable. These allow for quick and easy loosening or tightening of various components. It’s essential to have both metric and imperial sizes to accommodate different fittings.

Torque Wrench: Precision is key in mechanical work. A torque wrench ensures that bolts are tightened to the manufacturer’s specifications, preventing damage and ensuring safety during operation.

Screwdrivers: A range of screwdrivers, including flathead and Phillips, is necessary for accessing screws in various parts. Consider investing in magnetic or ergonomic options for added convenience.

Multi-tool: A multi-tool can be a lifesaver, offering several functions in one compact design. This versatility allows for quick adjustments and repairs without needing multiple individual tools.

Pliers: Pliers are essential for gripping, twisting, and cutting wires or other materials. Having a variety of pliers, including needle-nose and locking types, will expand your ability to tackle various tasks.

Diagnostic Tools: Utilizing diagnostic equipment, such as multimeters, helps in identifying electrical issues. These tools provide essential data that can guide you in troubleshooting complex problems.

Investing in quality tools not only enhances the efficiency of your work but also contributes to a more enjoyable experience. A well-equipped workspace allows for greater confidence in handling maintenance tasks, ensuring that everything operates smoothly.

Step-by-Step Maintenance Guide

This guide provides a systematic approach to ensuring the longevity and optimal performance of your snow vehicle. By following these essential steps, you can maintain its reliability and prevent potential issues that could arise from neglecting routine care.

Regular Inspection

Begin with a thorough visual examination of your machine. Check for any signs of wear or damage, particularly in the chassis and components. Pay close attention to the following:

- Belts: Inspect for cracks or fraying.

- Fluids: Ensure oil and coolant levels are adequate.

- Battery: Look for corrosion and secure connections.

Essential Upkeep Tasks

Implementing a regular maintenance schedule is crucial. Perform the following tasks periodically:

- Filter Replacement: Change the air and fuel filters as needed to maintain efficiency.

- Lubrication: Apply appropriate lubricants to moving parts to reduce friction.

- Tire Check: Ensure tires are properly inflated and inspect tread depth.

By adhering to these guidelines, you will enhance the performance and durability of your snow vehicle, making every ride more enjoyable.

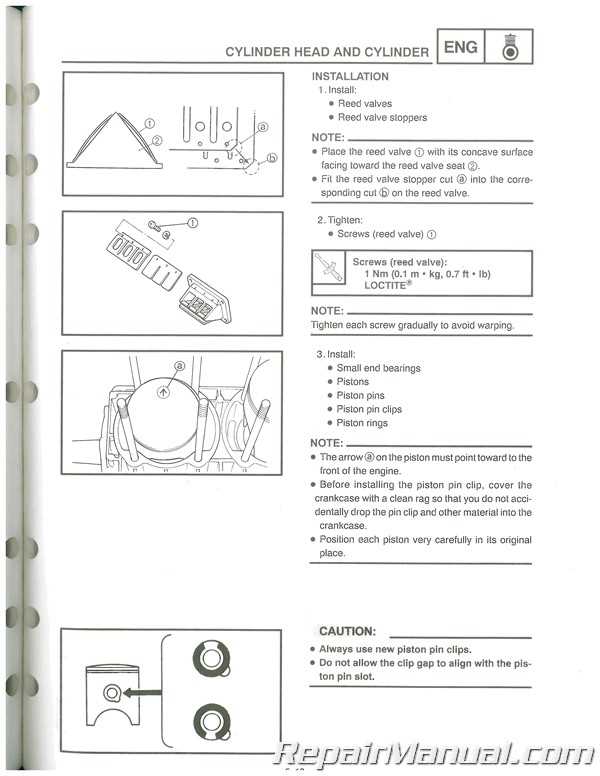

Engine Troubleshooting Techniques

Diagnosing engine issues requires a systematic approach to identify and resolve potential problems effectively. By following a structured method, you can pinpoint malfunctions and restore optimal performance. This section outlines essential strategies for troubleshooting various engine-related concerns.

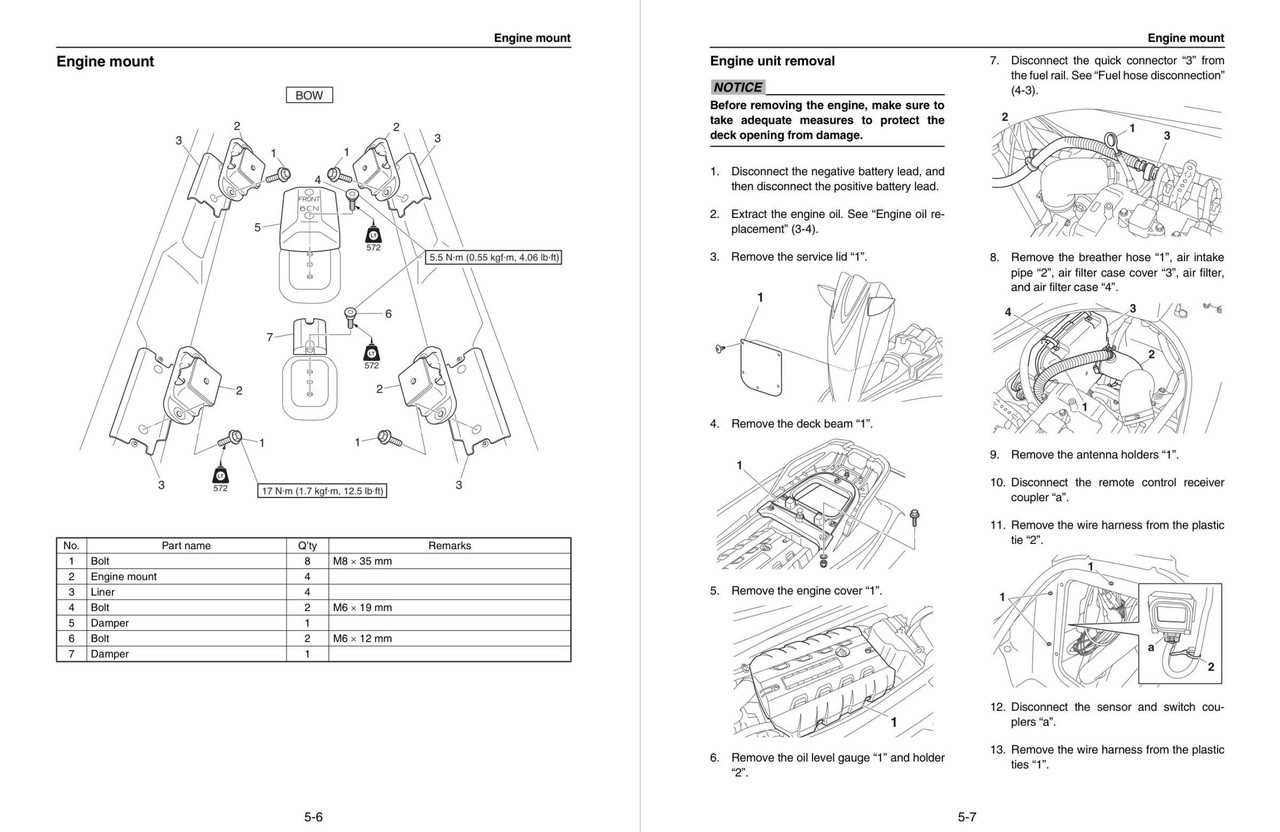

1. Visual Inspection: Begin with a thorough examination of the engine’s external components. Look for signs of wear, damage, or leaks. Pay special attention to hoses, connectors, and mounting points, as these can indicate underlying issues.

2. Check for Error Codes: Utilize diagnostic tools to retrieve error codes from the engine control unit. These codes can provide valuable insight into specific malfunctions, guiding you toward the right area for further investigation.

3. Monitor Performance Metrics: Evaluate performance indicators such as fuel consumption, engine temperature, and exhaust emissions. Significant deviations from normal ranges can signal problems that require attention.

4. Listen for Unusual Noises: Abnormal sounds during operation can indicate mechanical issues. Listen for knocking, tapping, or grinding noises, which may point to failing components or inadequate lubrication.

5. Conduct Compression Tests: Perform compression tests on each cylinder to assess engine health. Low compression readings can suggest problems such as worn piston rings or damaged valves.

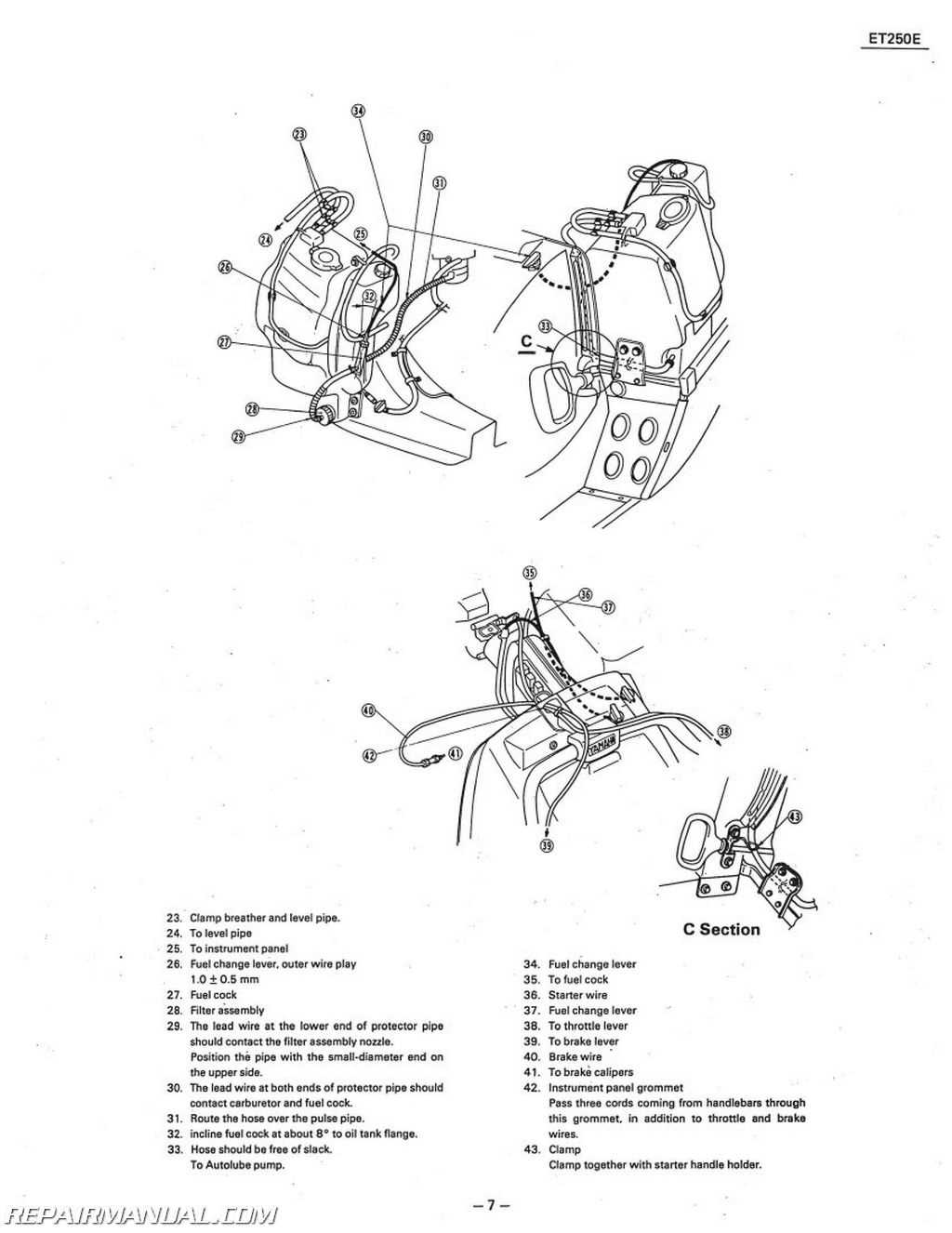

6. Inspect Fuel System: Ensure that the fuel delivery system is functioning correctly. Check the fuel lines, filters, and injectors for clogs or leaks that could affect engine performance.

7. Review Ignition System: Examine the ignition components, including spark plugs, wires, and coils. Faulty ignition parts can lead to misfires and decreased efficiency.

By applying these techniques, you can systematically address engine challenges, leading to a more reliable and efficient operation. Always remember to document your findings and solutions for future reference.

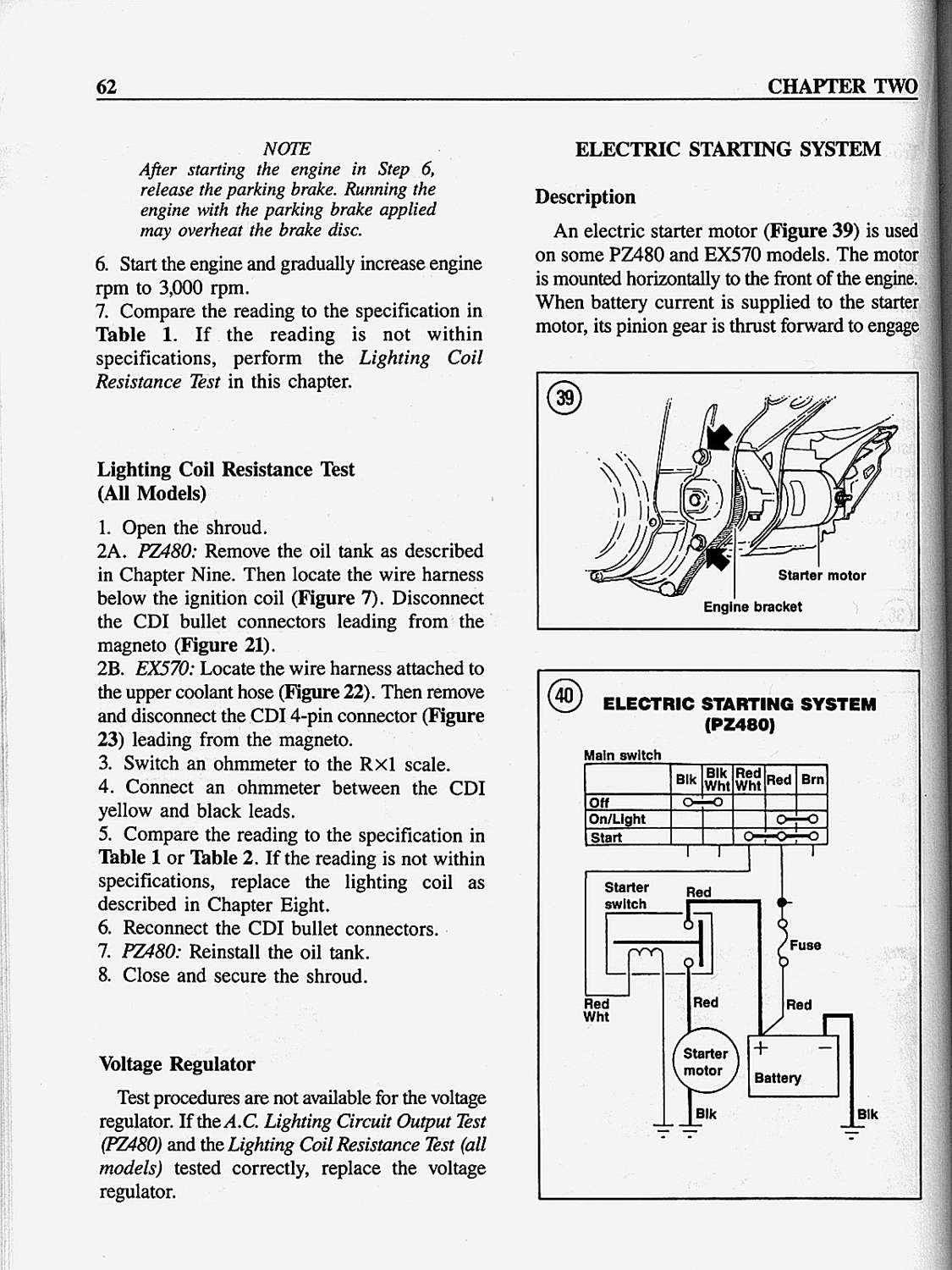

Electrical System Diagnostics

The electrical system of any vehicle is crucial for optimal performance, providing power to essential components and ensuring seamless operation. Diagnosing issues within this system is vital for maintaining functionality and safety. This section outlines the key steps and tools needed for effective troubleshooting of electrical faults.

Identifying Symptoms is the first step in the diagnostic process. Common indicators of electrical issues include dimming lights, erratic behavior of electronic components, or complete power loss. Observing these symptoms can help pinpoint the area requiring attention.

Next, using diagnostic tools such as multimeters and oscilloscopes can greatly enhance the accuracy of the assessment. A multimeter, for example, allows for measuring voltage, current, and resistance, while an oscilloscope can visualize electrical signals over time, revealing underlying issues that may not be immediately apparent.

Additionally, inspecting wiring and connections is crucial. Corrosion, frayed wires, or loose connections can lead to intermittent problems that are often difficult to trace. Ensuring that all electrical connections are secure and clean can prevent many common issues.

Lastly, consulting the circuit diagrams can provide invaluable insight into the system’s layout and function. Understanding how components interact within the electrical network aids in identifying potential faults and devising effective solutions.

By following these diagnostic practices, one can effectively troubleshoot and resolve electrical issues, ensuring reliable performance and safety.

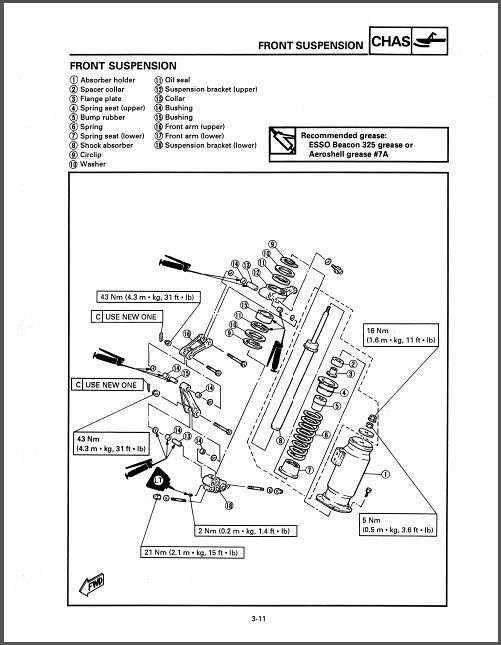

Suspension System Adjustments

Proper tuning of the suspension system is essential for achieving optimal performance and comfort during rides. Adjustments can enhance handling, stability, and responsiveness, allowing for a customized experience tailored to various terrains and riding styles.

When adjusting the suspension, consider the following key factors:

- Compression Settings: This affects how the suspension absorbs bumps and impacts. Stiffer settings provide better control on smooth surfaces, while softer settings improve comfort on rough terrain.

- Rebound Settings: This determines how quickly the suspension returns to its original position after compression. Faster rebound can enhance handling, while slower rebound can provide better stability on uneven surfaces.

- Spring Preload: Adjusting the preload alters the ride height and can affect cornering performance. Increasing preload can help prevent bottoming out during aggressive maneuvers.

- Damping Adjustments: Fine-tuning the damping can improve traction and overall ride quality. Adjust according to weight and riding conditions.

For a successful adjustment process, follow these steps:

- Identify your riding style and the conditions you typically encounter.

- Consult the specifications for the suspension components to understand their adjustment range.

- Make incremental changes, testing the ride after each adjustment to gauge the effects.

- Document your settings for future reference, allowing for quick re-adjustments as needed.

Regular maintenance and adjustment of the suspension system will not only prolong its lifespan but also enhance the overall riding experience. Staying attuned to changes in handling and comfort will guide you in making necessary tweaks to keep your setup performing at its best.

Brake System Repair Procedures

This section outlines essential methods for maintaining and restoring the braking mechanism of your vehicle. Proper functionality of the braking system is crucial for safety and performance, making it imperative to follow systematic approaches for troubleshooting and service.

Before beginning the service, ensure you have the necessary tools and replacement parts. The following steps provide a comprehensive guideline for effective maintenance:

- Inspect the Brake Pads

- Check for wear and tear.

- Ensure they are not glazed or cracked.

- Replace if thickness is below the recommended limit.

- Look for scoring or warping.

- Measure thickness using a caliper.

- Replace or resurface if necessary.

- Ensure the fluid is at the appropriate level.

- Use the recommended type of brake fluid.

- Replace fluid if it appears discolored or contaminated.

- Look for leaks or signs of wear.

- Check for any blockages or kinks.

- Replace damaged lines immediately.

- Press the brake pedal to assess responsiveness.

- Listen for unusual noises while braking.

- Perform a test drive to evaluate performance.

Regular maintenance of the braking system not only enhances safety but also prolongs the lifespan of the components. Following these procedures will help ensure optimal performance and reliability.

Upgrading Yamaha Phazer Components

Enhancing the performance of your snowmobile involves a careful selection of parts that can significantly improve efficiency and overall ride quality. Upgrades can vary from powertrain enhancements to suspension modifications, each aimed at providing a more exhilarating experience on the trails.

Consider the following areas for improvement:

- Engine Performance: Upgrading the engine components can lead to increased horsepower and torque. Consider the following options:

- High-performance exhaust systems

- Aftermarket air filters

- ECU tuning kits

- Suspension System: A well-tuned suspension contributes to better handling and comfort. Possible upgrades include:

- Adjustable shocks

- Stiffer springs

- Improved bushings

- Track and Skis: The right track and ski combinations can drastically affect grip and maneuverability. Look for:

- Performance tracks designed for various snow conditions

- Lightweight skis for enhanced steering

- Braking System: Enhanced stopping power is essential for safety and control. Consider upgrading to:

- High-performance brake pads

- Upgraded calipers

Each component plays a critical role in the overall performance of your snow vehicle. When planning upgrades, always prioritize compatibility and quality to ensure the best results on the trails.

Safety Precautions During Repairs

When undertaking maintenance or troubleshooting tasks, it is essential to prioritize safety. Adhering to specific guidelines helps prevent accidents and ensures a smooth process. Proper preparation and awareness of potential hazards can significantly reduce risks associated with mechanical work.

Essential Safety Measures

Before starting any task, familiarize yourself with the tools and equipment required. Always wear appropriate protective gear, such as gloves and goggles, to safeguard against injuries. Additionally, ensure your workspace is well-ventilated and free of clutter to minimize hazards.

Hazard Awareness

Understanding common risks involved in mechanical tasks is crucial. Here are some key hazards to consider:

| Hazard | Prevention |

|---|---|

| Electrical Shock | Disconnect power sources before beginning work. |

| Sharp Objects | Handle tools carefully and store them properly after use. |

| Falling Components | Secure loose parts and use proper lifting techniques. |

| Chemical Exposure | Use safety equipment and work in well-ventilated areas when handling substances. |

By implementing these precautions, you can create a safer working environment, ultimately leading to more effective and enjoyable maintenance activities.

Where to Find Replacement Parts

Locating suitable components for your vehicle can enhance its performance and extend its lifespan. Various sources provide access to high-quality parts, ensuring you can keep your machine running smoothly.

Online Retailers

One of the most convenient ways to find components is through online platforms. They offer a wide selection, often at competitive prices.

- Official brand websites

- Specialized online marketplaces

- General e-commerce sites

Local Dealers and Shops

Visiting local dealerships and specialty shops can also yield good results. These establishments typically have knowledgeable staff who can assist you in finding the right items.

- Authorized dealerships

- Independent repair shops

- Local automotive parts suppliers

Exploring these options will help ensure you find the necessary components for your vehicle, maintaining its efficiency and reliability.