Comprehensive Guide to David Brown 990 Repair

In the realm of agricultural machinery, understanding the intricacies of equipment operation and upkeep is essential for ensuring optimal performance. This section delves into the critical aspects of managing a specific model, offering insights that can enhance efficiency and longevity.

Essential knowledge regarding the mechanisms and functionalities can significantly aid operators in navigating common issues that arise during usage. With the right approach, even the most challenging problems can be resolved with relative ease.

Moreover, this guide provides practical advice on conducting routine checks and implementing necessary adjustments. By prioritizing these maintenance strategies, users can maintain their machinery in peak condition, ultimately leading to improved productivity in their agricultural endeavors.

Overview of David Brown 990

The subject of this section revolves around a notable agricultural machinery model renowned for its robust performance and reliability in various farming tasks. Designed with efficiency in mind, this machine caters to both small and large-scale operations, making it a versatile choice for many users.

Features of this equipment include an innovative engine design that ensures optimal power output while maintaining fuel efficiency. Additionally, its ergonomic layout provides ease of use, allowing operators to manage operations comfortably.

Furthermore, maintenance considerations play a crucial role in extending the lifespan of the equipment. Regular checks and upkeep are essential to ensure that all components function smoothly, thereby enhancing overall productivity on the field.

Common Issues with David Brown 990

This section highlights frequently encountered challenges associated with a popular agricultural machinery model. Understanding these common problems can assist users in identifying and addressing potential malfunctions effectively.

| Issue | Description | Possible Solutions |

|---|---|---|

| Hydraulic System Failure | Inconsistent performance or complete loss of hydraulic power. | Check fluid levels and inspect for leaks; replace faulty seals or pumps. |

| Engine Overheating | Excessive temperature readings leading to performance issues. | Ensure proper coolant levels; clean radiator and check for blockages. |

| Transmission Problems | Difficulties in shifting gears or unusual noises while operating. | Inspect for fluid leaks; replace worn gears or bearings as needed. |

| Electrical Failures | Issues with starting or electrical components not functioning. | Examine battery connections and wiring; replace faulty fuses. |

Tools Required for Repairs

When undertaking maintenance tasks, having the right equipment is essential for achieving effective outcomes. The necessary instruments not only enhance efficiency but also ensure safety during the process. Below is an overview of key implements that will facilitate various maintenance activities.

Wrenches: A variety of wrenches, including adjustable and socket types, are crucial for loosening and tightening fasteners. These tools enable precise adjustments and can accommodate different sizes of nuts and bolts.

Screwdrivers: Both flathead and Phillips screwdrivers are indispensable for accessing and securing components. The proper selection of screwdriver is vital for avoiding damage to screws and surfaces.

Pliers: These versatile tools are useful for gripping, bending, and cutting wires. Pliers come in several styles, including needle-nose and slip-joint, each suited for specific tasks.

Torque Wrench: To ensure that fasteners are tightened to the manufacturer’s specifications, a torque wrench is essential. This tool helps prevent over-tightening, which can lead to damage.

Diagnostic Tools: For troubleshooting issues, diagnostic equipment such as multimeters and pressure gauges can provide valuable insights into the performance of various systems.

Having these tools at hand will greatly enhance your ability to carry out necessary adjustments and maintain optimal functioning of the machinery. Proper preparation is key to a successful maintenance experience.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to keeping your agricultural machinery in optimal condition. Regular upkeep is essential for ensuring longevity and efficient performance. By following a systematic process, you can prevent issues and enhance the functionality of your equipment.

Routine Checks

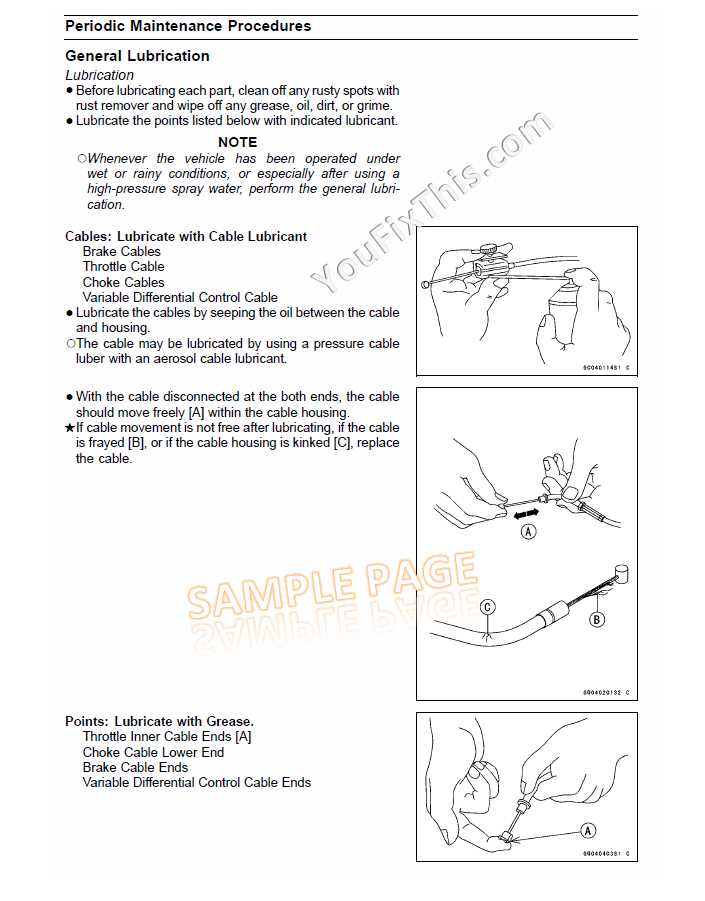

Begin with frequent inspections of vital components. Examine fluid levels, including engine oil, coolant, and hydraulic fluids. Regularly check for any signs of wear or damage in belts and hoses. Maintaining proper tire pressure is crucial for stability and efficiency.

Scheduled Servicing

Adhere to a defined service schedule for tasks such as oil changes and filter replacements. Utilize high-quality products to ensure the best results. Cleaning and lubricating moving parts will minimize friction and extend the lifespan of your machinery. Always refer to guidelines for specific intervals and recommendations based on usage.

Engine Troubleshooting Techniques

Identifying and resolving issues within an engine can significantly enhance its performance and longevity. Effective troubleshooting requires a systematic approach, allowing operators to pinpoint problems based on symptoms observed during operation. Understanding common signs of malfunction and the underlying mechanics is crucial for efficient diagnostics.

Begin by listening for unusual noises, which may indicate internal damage or component wear. Visual inspections can reveal leaks, corrosion, or loose connections that affect performance. Monitoring performance metrics, such as power output and fuel consumption, provides further insights into engine health.

Utilizing diagnostic tools can streamline the troubleshooting process. Scanners and gauges help in detecting errors and assessing various engine parameters. Regular maintenance checks, including fluid levels and filter conditions, contribute to preventing future issues and ensuring optimal functionality.

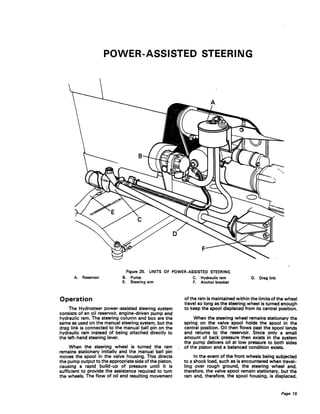

Hydraulic System Repair Insights

The hydraulic system plays a crucial role in the overall functionality of agricultural machinery. Understanding its components and common issues is essential for effective maintenance and troubleshooting. This section delves into key considerations for enhancing the performance and longevity of hydraulic systems.

Common Issues and Solutions

Hydraulic systems can encounter various problems, such as fluid leaks, pressure drops, and overheating. Identifying the root causes of these issues is vital for ensuring optimal operation. Below are some typical challenges and their potential resolutions:

| Issue | Possible Cause | Recommended Action |

|---|---|---|

| Fluid Leak | Worn seals or damaged hoses | Inspect and replace damaged components |

| Pressure Drop | Clogged filters or malfunctioning pump | Clean or replace filters and check pump operation |

| Overheating | Low fluid levels or inefficient cooling | Check fluid levels and ensure proper ventilation |

Maintenance Tips

Regular maintenance is critical for preventing issues within the hydraulic system. Recommended practices include routine fluid checks, filter replacements, and inspections of hoses and fittings. Keeping an eye on these factors can significantly enhance the reliability and efficiency of the machinery.

Transmission Problems and Solutions

This section addresses common issues related to gear mechanisms in agricultural machinery, providing insights into typical challenges and their resolutions. Understanding these problems can significantly enhance the performance and longevity of the equipment.

Common Issues

- Slipping Gears

- Difficulty in Shifting

- Unusual Noises

- Fluid Leaks

Troubleshooting Steps

- Check Fluid Levels: Ensure that the transmission fluid is at the appropriate level to prevent gear slippage.

- Inspect for Leaks: Look for any signs of fluid leakage, which can indicate a seal or gasket failure.

- Examine Linkages: Inspect the shifting linkages for wear or damage that may impede proper gear engagement.

- Replace Worn Components: Identify and replace any worn-out parts to restore functionality.

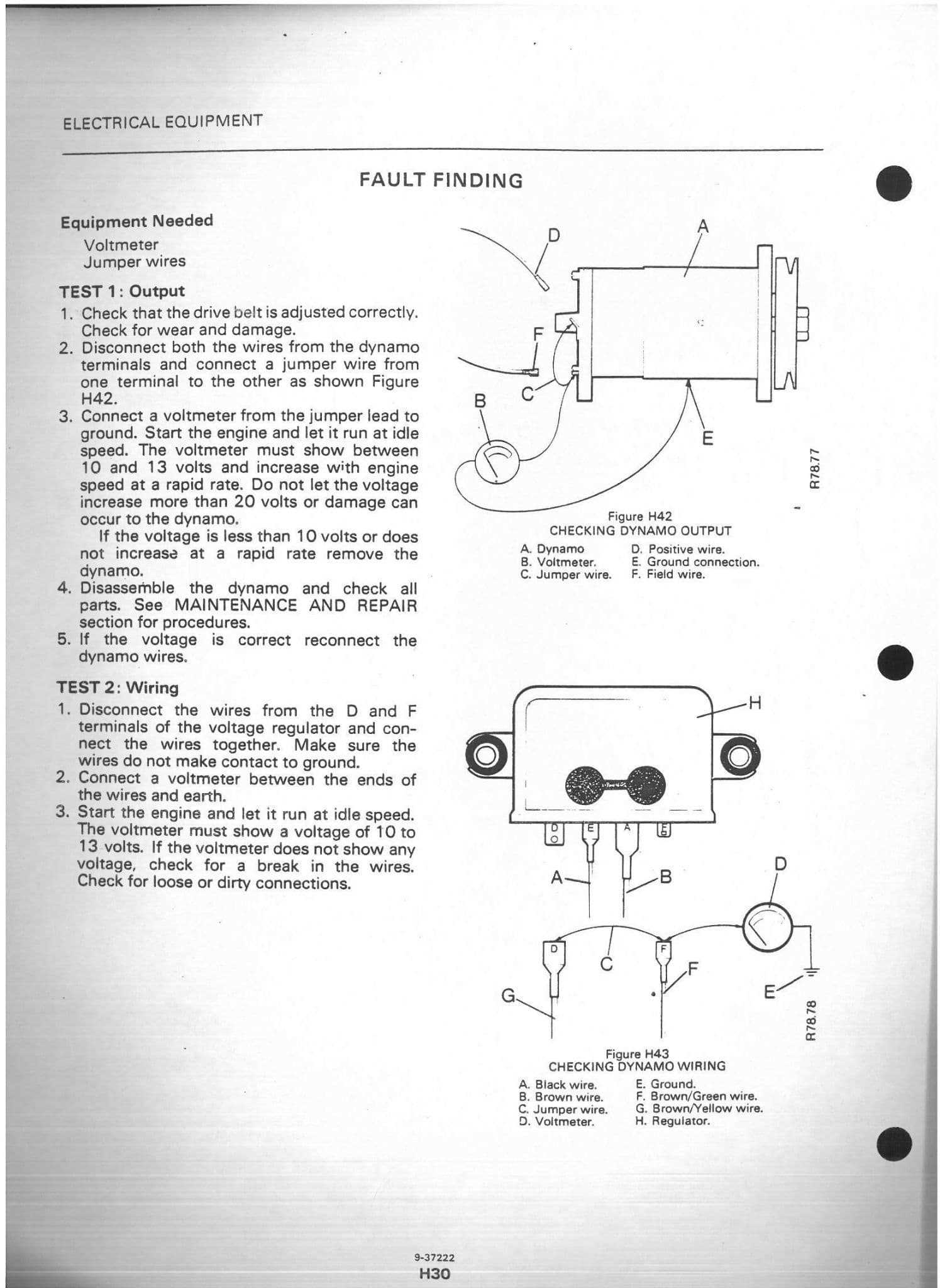

Electrical System Diagnostics

This section focuses on the procedures and methods for assessing and troubleshooting the electrical components of agricultural machinery. Understanding the intricacies of the electrical framework is essential for maintaining optimal performance and ensuring longevity.

Common Electrical Issues

- Battery failures

- Faulty wiring connections

- Malfunctioning switches

- Defective sensors

Diagnostic Steps

- Inspect the battery and ensure proper voltage levels.

- Check all wiring for signs of wear or damage.

- Test switches for functionality and continuity.

- Examine sensors to confirm they are operating within specified parameters.

By systematically evaluating these components, one can effectively identify and rectify issues that may hinder the electrical system’s performance.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is crucial for both the individual and the equipment involved. Following appropriate guidelines can significantly reduce the risk of accidents and injuries.

First and foremost, always wear suitable personal protective equipment (PPE). This includes gloves, goggles, and sturdy footwear to shield against potential hazards. Adequate clothing is also essential to prevent injuries from sharp objects or hot surfaces.

Additionally, it is vital to work in a well-ventilated area to avoid inhaling harmful fumes or dust. Keeping the workspace organized helps prevent slips, trips, and falls, which are common during maintenance activities.

Before beginning any task, disconnecting the power source is essential to ensure that the machinery does not operate unexpectedly. Proper locking and tagging methods should be employed to indicate that maintenance is underway.

By adhering to these precautions, individuals can create a safer environment, leading to more efficient and effective service on equipment.

Parts Replacement Recommendations

Ensuring the longevity and efficiency of machinery requires timely and appropriate component replacements. Regularly assessing the condition of various parts can prevent significant issues and extend the operational lifespan of the equipment.

Key Components for Monitoring

It is crucial to focus on specific elements that are prone to wear and tear. Regular inspections can help identify when these parts need to be changed to maintain optimal performance.

Replacement Schedule

Establishing a systematic approach to part replacement based on usage and environmental conditions is beneficial. The following table outlines common components along with suggested intervals for replacement:

| Component | Recommended Replacement Interval |

|---|---|

| Oil Filter | Every 100 hours of operation |

| Air Filter | Every 200 hours of operation |

| Fuel Filter | Every 300 hours of operation |

| Belts and Hoses | Annually or as needed |

| Battery | Every 2-3 years |

Frequently Asked Questions

This section addresses common inquiries that users may have regarding maintenance and troubleshooting procedures for their agricultural machinery. By providing clear answers to these questions, we aim to assist operators in maximizing the efficiency and longevity of their equipment.

1. What should I do if my machine won’t start?

2. How often should I check the fluid levels?

3. Are there any specific maintenance routines I should follow regularly?

4. What are the signs that indicate a need for servicing?

5. Where can I find replacement parts for my equipment?