Comprehensive Guide to John Deere 318 Repair Manual

When it comes to the upkeep of agricultural machinery, understanding the intricacies of your equipment is vital. This section serves as a comprehensive resource for enthusiasts and professionals alike, offering insights into the proper care and troubleshooting techniques for specific models. Whether you’re dealing with routine checks or addressing more complex issues, having access to reliable information can significantly enhance your operational efficiency.

Effective maintenance not only extends the lifespan of your machinery but also ensures optimal performance during critical tasks. Familiarizing yourself with the various components and systems is crucial, as it empowers you to tackle potential challenges with confidence. This guide will delve into essential practices, providing step-by-step instructions and practical tips to help you navigate the nuances of your tractor.

Moreover, understanding the common pitfalls and how to avoid them is key to minimizing downtime and maximizing productivity. By utilizing this resource, you will equip yourself with the knowledge needed to maintain your equipment in peak condition, allowing you to focus on what truly matters–successful farming and land management.

Overview of John Deere 318

This section provides a comprehensive look at a popular model known for its reliability and versatility in various tasks. With a robust design and innovative features, it serves as an essential tool for both residential and commercial applications.

Key Features

- Powerful engine with efficient performance

- Durable chassis suitable for tough conditions

- Versatile attachments for multiple functionalities

- User-friendly controls for ease of operation

Applications

- Lawn care and maintenance

- Snow removal during winter

- Landscaping projects

- Garden cultivation and tilling

Understanding the characteristics and applications of this model helps users maximize its potential, ensuring effective operation in diverse environments.

Common Issues with John Deere 318

This section addresses frequent challenges encountered with a popular model of garden tractors. Owners often face a variety of mechanical and operational problems that can impact performance and usability. Understanding these common issues is crucial for effective troubleshooting and maintenance.

Mechanical Problems

- Engine Start Issues: Difficulty in starting the engine may stem from fuel delivery problems, battery failures, or ignition system malfunctions.

- Transmission Difficulties: Slipping gears or an inability to change speeds can indicate transmission fluid issues or internal wear.

- Hydraulic System Failures: Leaks or poor lifting capacity often arise from worn hoses or malfunctioning pumps.

Operational Challenges

- Uneven Cutting: This can result from dull blades, incorrect deck height settings, or uneven tire pressure.

- Overheating: Blocked air filters or insufficient coolant levels may lead to engine overheating.

- Electrical Failures: Problems such as blown fuses or faulty switches can disrupt electrical components.

Addressing these common issues promptly can enhance the longevity and efficiency of this reliable garden tractor. Regular maintenance and inspections are essential to prevent minor problems from escalating into major repairs.

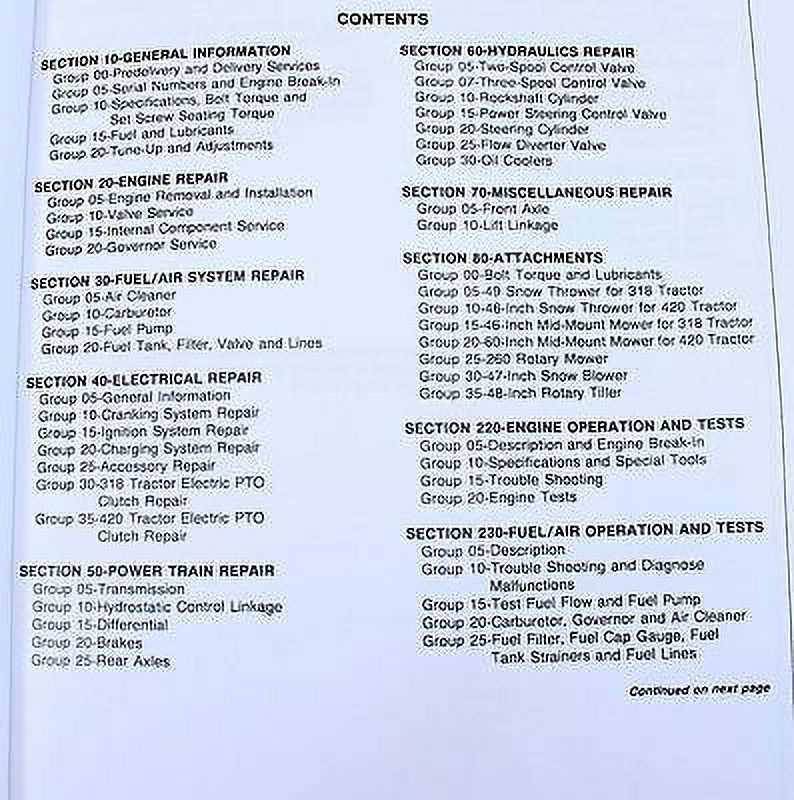

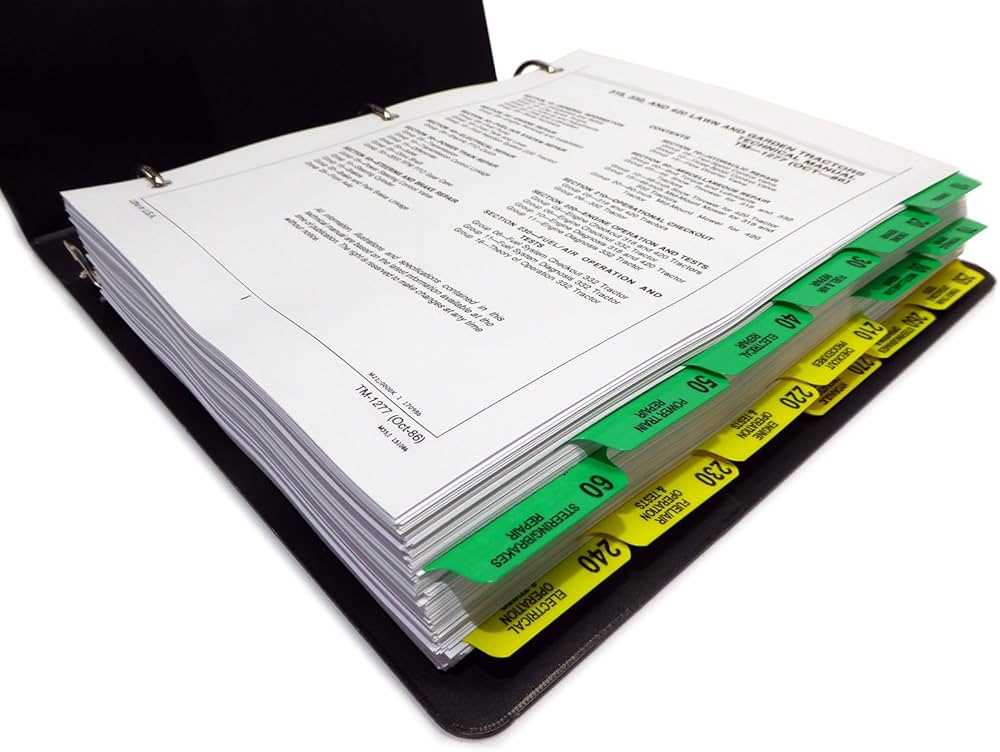

Importance of Repair Manuals

Documentation that provides detailed guidance on maintenance and troubleshooting plays a crucial role in the longevity and efficiency of machinery. Such resources empower users to understand their equipment better, enabling them to perform necessary tasks effectively and safely.

Having access to thorough instructions allows individuals to address issues promptly, minimizing downtime and repair costs. These references often contain diagrams, specifications, and step-by-step procedures that simplify complex tasks, making them manageable even for those with limited experience.

Moreover, comprehensive guides foster a deeper knowledge of the equipment, encouraging users to engage in regular upkeep. This proactive approach not only enhances performance but also extends the lifespan of the machinery, ultimately leading to greater satisfaction and reliability.

In summary, well-structured documentation serves as an invaluable asset, ensuring that operators can maintain their equipment with confidence and precision.

Tools Needed for Repair

When undertaking maintenance tasks on your equipment, having the right instruments is essential for achieving efficient and effective results. A well-equipped workspace can significantly enhance the repair process, allowing for smoother execution and reducing the likelihood of complications. Familiarity with the necessary tools ensures that you are prepared to address various issues that may arise during servicing.

Essential Hand Tools

Basic hand tools form the foundation of any maintenance kit. A set of wrenches, screwdrivers, and pliers is crucial for disassembly and reassembly tasks. Additionally, having a reliable socket set can greatly simplify the process of removing fasteners. Don’t forget to include a good-quality hammer and a pry bar, as they can assist in overcoming stubborn parts that need adjustment or replacement.

Specialized Equipment

In some cases, more specialized equipment may be required. Items such as torque wrenches are essential for ensuring that fasteners are tightened to the manufacturer’s specifications. A multimeter can be invaluable for diagnosing electrical issues, while a compression tester can help evaluate engine performance. Investing in these specialized tools can lead to a more thorough and accurate servicing experience.

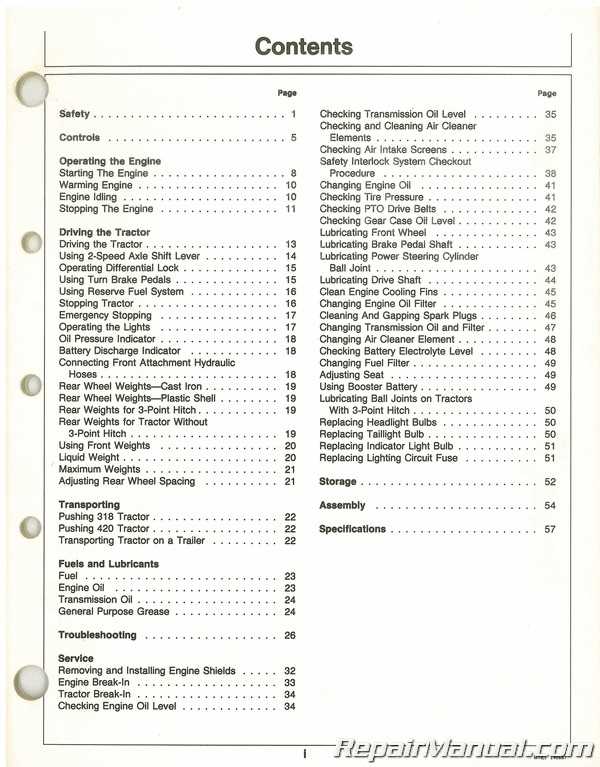

Step-by-Step Maintenance Guide

Regular upkeep is essential for optimal performance and longevity of your equipment. This guide provides a structured approach to ensure all critical aspects are covered, helping you to maintain your machine in top condition. Following these steps will not only enhance functionality but also prevent potential issues that could arise from neglect.

Essential Maintenance Tasks

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 50 hours | Replace engine oil and filter to ensure proper lubrication. |

| Air Filter Check | Every 25 hours | Inspect and clean or replace air filter to maintain airflow. |

| Battery Inspection | Monthly | Check battery terminals for corrosion and ensure proper charge. |

| Tire Pressure | Weekly | Verify and adjust tire pressure for optimal traction and efficiency. |

Detailed Procedures

For each task listed, follow the specific procedures to ensure accuracy and safety. Refer to your specific guidelines for detailed instructions on performing these tasks. Regular checks and timely actions can significantly enhance the lifespan and reliability of your machinery.

Replacing the Engine Components

Maintaining the integrity of a machine’s power unit is crucial for optimal performance. When certain parts become worn or damaged, replacing them ensures the engine operates efficiently and reliably. This section outlines the steps and considerations involved in swapping out essential components of the engine.

Key Components to Replace

Understanding which parts require attention is vital for successful maintenance. Here are some of the primary components that may need replacing:

| Component | Function | Signs of Wear |

|---|---|---|

| Piston Rings | Seal combustion chamber | Loss of power, increased oil consumption |

| Oil Filter | Filter impurities from oil | Reduced engine performance, dirty oil |

| Fuel Injector | Deliver fuel to the combustion chamber | Misfiring, poor fuel efficiency |

Steps for Replacement

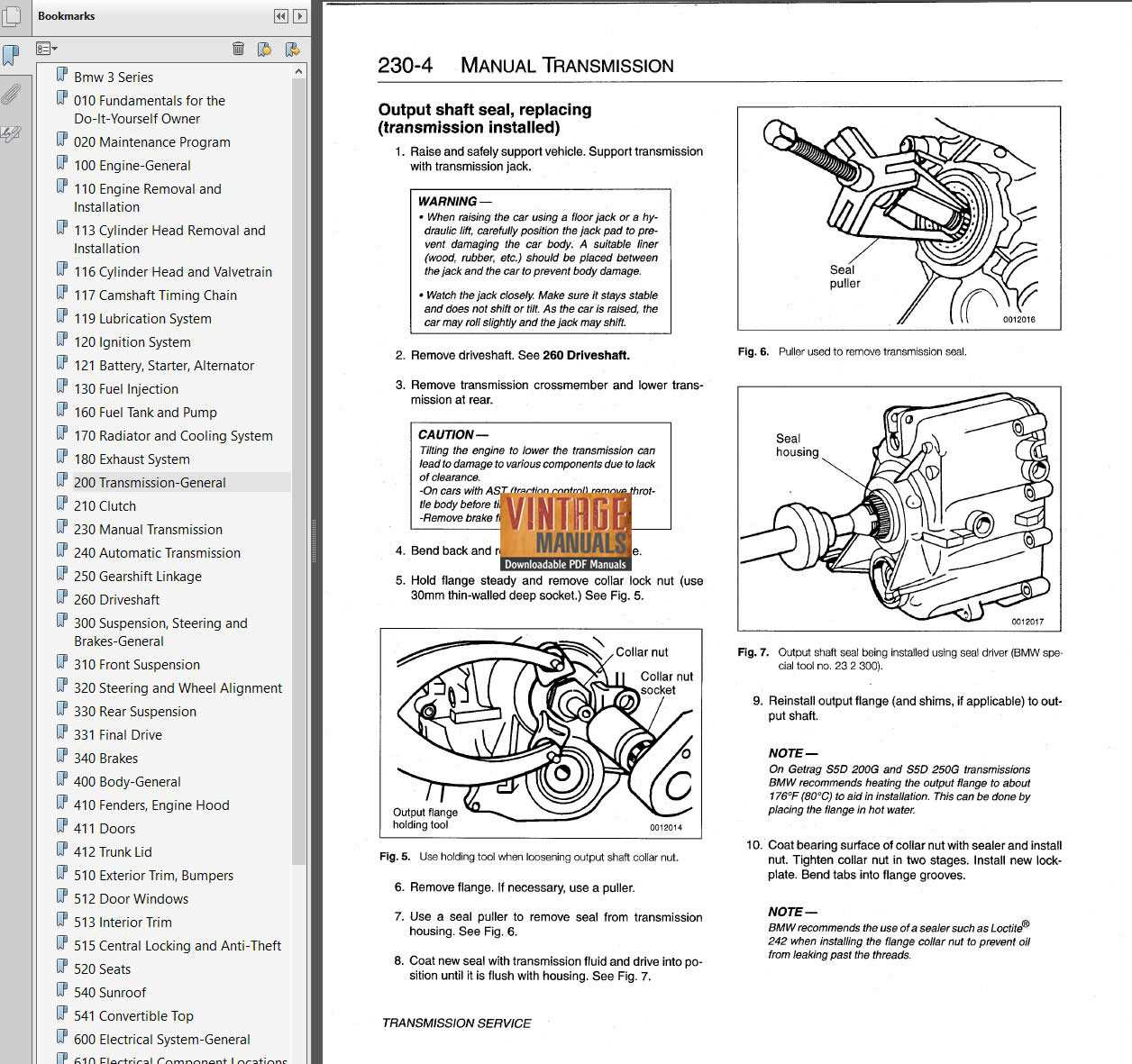

Replacing engine components involves a series of systematic steps. First, ensure that the engine is cool and disconnect the battery. Then, carefully remove the damaged part, taking note of any connected wiring or hoses. Install the new component, making sure all connections are secure. Finally, reconnect the battery and perform a thorough check to confirm the engine is running smoothly.

Electrical System Troubleshooting

Identifying and resolving issues within the electrical system of machinery can be crucial for maintaining optimal performance. A systematic approach to troubleshooting can help pinpoint malfunctions, ensuring that all components function properly. This guide provides essential steps to diagnose common electrical problems and offers solutions for effective maintenance.

Common Issues and Symptoms

Various symptoms may indicate an electrical fault, including failure to start, dim lights, or irregular operation of electronic components. Inspecting connections and checking for signs of corrosion or wear can reveal underlying problems. Additionally, a thorough examination of the fuses and circuit breakers is necessary, as these elements often play a key role in the electrical circuit.

Troubleshooting Steps

Begin by checking the battery voltage with a multimeter to ensure it is within the specified range. If the voltage is low, recharge or replace the battery as needed. Next, inspect wiring for any visible damage or loose connections. It’s essential to trace the wiring harness and ensure all grounds are secure. If these checks do not resolve the issue, further investigation into the starter motor and alternator may be required, as these components can significantly impact electrical performance.

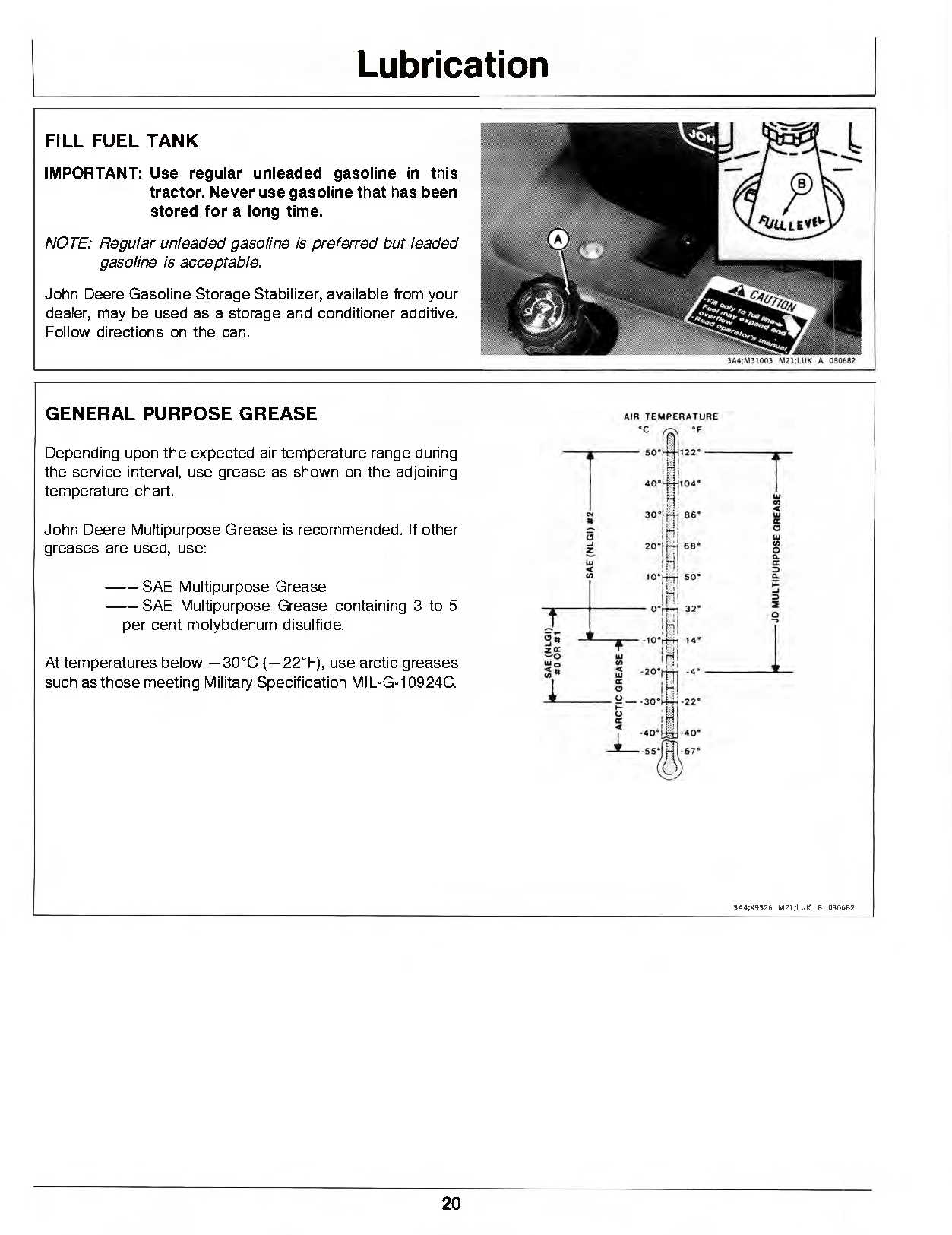

Hydraulic System Maintenance Tips

Proper upkeep of the hydraulic system is essential for ensuring optimal performance and longevity of machinery. Regular attention to this system can prevent costly failures and enhance overall efficiency. Below are some key practices to consider for maintaining hydraulic components effectively.

1. Regular Fluid Checks: Ensure the hydraulic fluid is at the recommended level. Low fluid levels can lead to air entering the system, causing inefficiency. Use the manufacturer’s guidelines to determine the appropriate type and grade of fluid.

2. Inspect for Leaks: Frequently examine hoses, fittings, and seals for any signs of leakage. Even minor leaks can lead to significant problems over time. Address any leaks immediately to maintain system integrity.

3. Clean Filters: Hydraulic filters play a crucial role in keeping the fluid clean. Regularly inspect and replace filters as necessary to prevent contamination that can damage components.

4. Monitor Temperature: Keep an eye on the operating temperature of the hydraulic fluid. Elevated temperatures can indicate issues such as overloading or insufficient fluid, leading to premature wear. Ensure proper cooling systems are in place and functioning effectively.

5. Check Hose Condition: Inspect hoses for signs of wear, cracking, or bulging. Damaged hoses can result in pressure loss and system failures. Replace any compromised hoses to maintain safe and efficient operation.

6. System Flush: Periodically flushing the hydraulic system can help remove contaminants and prevent buildup. Follow the recommended flushing procedures to ensure thorough cleaning without causing damage.

7. Professional Inspections: Schedule regular inspections with a qualified technician. They can identify potential issues that may not be evident during routine checks, ensuring the system remains in peak condition.

Seasonal Preparation Checklist

Ensuring that your equipment is ready for the changing seasons is crucial for maintaining optimal performance and longevity. A comprehensive checklist can help you address potential issues before they arise, allowing for a smoother operational experience throughout the year.

| Task | Description | Frequency |

|---|---|---|

| Fluid Levels | Check and top off all essential fluids, including oil, coolant, and hydraulic fluids. | Seasonally |

| Battery Maintenance | Inspect battery terminals for corrosion and ensure a full charge. | Monthly |

| Tire Condition | Examine tires for wear and proper inflation; replace if necessary. | Before Heavy Use |

| Belts and Cables | Inspect belts and cables for fraying or damage; replace if needed. | Seasonally |

| Filters | Change air and fuel filters to ensure optimal performance. | Every 50 Hours of Use |

| Safety Equipment | Verify that all safety features and equipment are functioning properly. | Before Use |

By following this checklist, you can enhance the reliability and efficiency of your machinery, ensuring it remains in peak condition for all seasonal challenges.

Resources for Parts and Support

When maintaining or troubleshooting your equipment, having access to reliable resources is crucial. This section provides valuable information on where to find components and support services to ensure optimal performance and longevity of your machinery.

Official Dealers: One of the best options for sourcing authentic parts is through certified dealers. They not only supply high-quality components but also offer expert guidance on installation and compatibility, ensuring that you receive the right items for your specific needs.

Online Marketplaces: Various online platforms specialize in machinery parts. These websites often feature user reviews, detailed descriptions, and competitive pricing. Be sure to verify the seller’s reputation to avoid counterfeit products.

Community Forums: Engaging with other users through community forums can provide insights and recommendations for both parts and support. These platforms often have members who share their experiences, troubleshooting tips, and reliable suppliers.

Local Repair Shops: In addition to official dealers, local repair shops can be an excellent resource for both parts and expert advice. Many technicians are familiar with a wide range of equipment and can assist in finding the right components or performing necessary repairs.

Manufacturer’s Website: The manufacturer’s website is a valuable hub for resources, including downloadable guides, part catalogs, and customer service contacts. Regularly checking this site can keep you informed about new products and updates.

Utilizing these resources will help ensure that your equipment remains functional and efficient, allowing you to tackle any tasks with confidence.