Comprehensive Guide to Toyota T50 Gearbox Repair

Understanding the intricacies of automotive systems is essential for any enthusiast or professional in the field. This guide delves into the essential processes involved in maintaining and overhauling a specific type of transmission, providing insights into the mechanisms that allow vehicles to operate smoothly. With a focus on practical steps and detailed information, this resource aims to equip readers with the knowledge needed to tackle challenges effectively.

In the realm of automotive maintenance, mastering the intricacies of transmission systems can lead to significant improvements in vehicle performance. Each component plays a crucial role in the overall functionality, and recognizing the importance of proper maintenance is key. By exploring various aspects of these systems, this guide empowers readers to enhance their skills and confidence when addressing issues that may arise.

Furthermore, a thorough understanding of transmission assemblies not only facilitates better repairs but also promotes longevity and reliability in vehicle operation. This resource is designed to break down complex concepts into manageable sections, allowing for a clear understanding of each step in the process. Whether you are a novice or a seasoned expert, this comprehensive overview will serve as a valuable tool in your automotive endeavors.

Toyota T50 Gearbox Overview

This section provides a comprehensive examination of a specific type of transmission widely recognized for its performance and reliability. Understanding its components and functionalities is essential for enthusiasts and mechanics alike. This assembly plays a crucial role in the powertrain, facilitating effective torque transfer and enhancing driving experience.

Key Features

- Durable construction designed for longevity

- Precision engineering for smooth shifting

- Multiple gear ratios for optimal performance

- Compatibility with various engine types

Common Applications

- Sports cars, providing enhanced acceleration

- Classic vehicles, maintaining authenticity

- Off-road trucks, ensuring robust performance

Understanding these aspects can greatly assist in maintenance and troubleshooting, ensuring optimal operation over time.

Common Issues with T50 Gearbox

Understanding the frequent problems that can arise in this type of transmission system is essential for effective maintenance. Drivers and enthusiasts alike should be aware of potential faults that may affect performance and longevity. Below are some prevalent concerns that may arise, along with insights into their causes and potential solutions.

Typical Symptoms

- Difficulty in shifting gears

- Unusual noises during operation

- Leaking fluid

- Overheating issues

Potential Causes

- Worn Synchronizers: These components may degrade over time, leading to challenging gear changes.

- Fluid Contamination: Debris or old fluid can impact performance, causing slipping or harsh engagement.

- Sealing Failures: Deteriorated seals can result in fluid leaks, which compromise lubrication and cooling.

- Gear Wear: Continuous use can lead to wear on gears, affecting their ability to engage properly.

Tools Needed for Repairs

Undertaking maintenance on mechanical components requires a specific set of instruments to ensure precision and efficiency. Proper preparation not only facilitates a smoother process but also enhances the likelihood of achieving successful outcomes. Below is a detailed overview of the essential tools you will need to tackle any task effectively.

Basic Hand Tools

Starting with the fundamentals, a reliable collection of hand tools is vital. These typically include a variety of wrenches, screwdrivers, and pliers. Socket sets are especially useful for loosening and tightening fasteners in tight spaces. Additionally, having a torque wrench on hand ensures that components are secured to the manufacturer’s specifications, which is crucial for maintaining integrity.

Specialized Equipment

For more complex tasks, specialized equipment can make a significant difference. A hydraulic press is invaluable for removing and installing components with ease. Furthermore, an engine hoist can assist in handling heavier assemblies safely. Lastly, a comprehensive diagnostic tool will help in troubleshooting issues and confirming the success of your efforts.

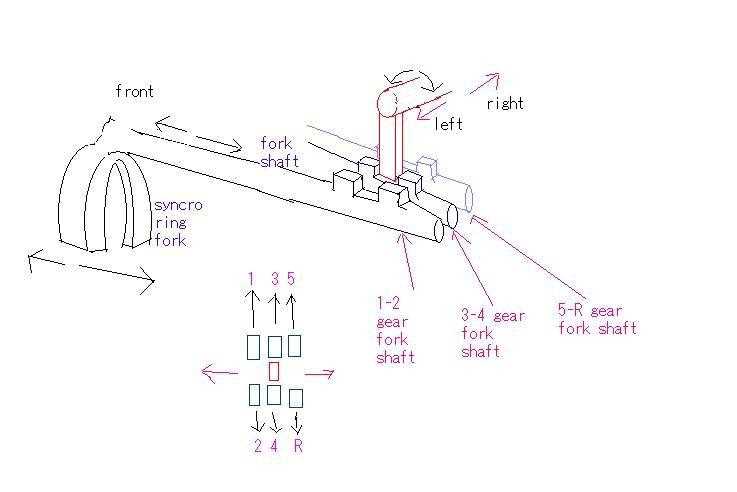

Step-by-Step Disassembly Process

The process of dismantling a complex mechanical assembly requires precision and attention to detail. Understanding the sequence of steps involved is crucial for a successful reassembly. This section will guide you through the systematic breakdown of components, ensuring that each part is handled with care and documented appropriately.

Preparation and Initial Steps

Before beginning the disassembly, gather all necessary tools and create a clean workspace. Start by disconnecting any power sources and removing external attachments. This initial stage ensures safety and prevents damage to interconnected elements. Label each component as it is removed to streamline reassembly.

Component Removal

With the assembly secure and labeled, proceed to detach individual parts. Begin with larger components, working your way down to smaller ones. Use appropriate tools to avoid stripping screws or damaging surfaces. Pay special attention to any fasteners or clips that may be unique to the design, and consider taking photographs at each step for future reference.

Inspecting Gearbox Components

Regular examination of transmission parts is crucial for maintaining optimal performance and longevity of the entire system. This process involves a detailed assessment of various elements to identify wear, damage, or potential failure points. Understanding how to properly evaluate these components can prevent costly repairs and ensure smoother operation.

Key Components to Check

Focus on inspecting the input and output shafts, synchronizers, and bearings. Look for signs of excessive wear, such as scoring or pitting on surfaces. Ensure that all components fit snugly without any unusual play. Additionally, check for any signs of corrosion or contamination that could impact functionality.

Assessment Techniques

Utilize visual inspections combined with tools such as micrometers and calipers for precise measurements. Performing a thorough cleaning of parts can also reveal hidden issues. When in doubt, consulting technical specifications can provide guidance on acceptable tolerances and operational standards.

Replacing Worn-Out Parts

Maintaining optimal performance in mechanical systems often requires the replacement of aging components. Over time, parts can suffer from wear and tear, leading to decreased efficiency and potential failures. Identifying these worn-out elements and addressing them promptly is crucial for ensuring the longevity and functionality of the assembly.

Identifying Worn Components

Regular inspection plays a vital role in spotting parts that may need replacement. Look for signs such as unusual noises, vibrations, or fluid leaks. Additionally, visual checks for discoloration, cracks, or surface damage can help pinpoint problematic areas. Understanding the typical lifespan of components can also aid in anticipating necessary changes.

Replacement Process

Once worn parts are identified, the next step is the removal and replacement process. Begin by ensuring the system is de-energized and properly secured. Carefully detach the affected components, taking note of the order and orientation for reassembly. Installing new parts should be done with precision, and it is essential to follow the manufacturer’s specifications to maintain integrity. After replacement, conduct a thorough test to confirm that everything operates smoothly.

In conclusion, proactive management of worn components is essential for maintaining system performance. Regular inspections and timely replacements can prevent larger issues and enhance overall reliability.

Reassembly Techniques for T50

Reassembling a transmission unit requires careful attention to detail and a systematic approach to ensure optimal functionality. Each component plays a critical role, and understanding the interactions between parts is essential for a successful rebuild. This section outlines effective strategies for reassembling the unit to achieve reliable performance.

Preparation and Organization

Before beginning the assembly process, it’s crucial to organize all components meticulously. Create a clean workspace and use labeled containers to keep small parts sorted. Reviewing the disassembly steps and having a clear reference guide can help in understanding the sequence of assembly. Additionally, inspecting all components for wear and damage before reassembly will prevent future issues.

Step-by-Step Assembly Process

Start the assembly by installing the largest components first, gradually working your way down to the smaller parts. Apply appropriate lubricants to moving surfaces as specified in the reference guide, ensuring all seals and gaskets are correctly positioned. Utilize torque specifications to avoid over-tightening, which can lead to damage. Once the major components are in place, double-check the alignment and secure connections to ensure a smooth operation.

Fluid Types and Maintenance Tips

Maintaining optimal performance of your transmission system requires understanding the various lubricants and their role in ensuring smooth operation. The right fluids not only protect components from wear but also enhance shifting efficiency and prolong the lifespan of the entire assembly.

Types of Fluids: It’s crucial to select the appropriate lubricant for your specific system. Common options include synthetic, semi-synthetic, and mineral oils, each offering distinct properties. Synthetic fluids provide superior thermal stability and resistance to breakdown, making them ideal for high-performance applications. In contrast, mineral oils are often more affordable but may require more frequent changes due to their lower resistance to heat and oxidation.

Maintenance Tips: Regular checks and timely changes of the lubricant are essential. Monitor the fluid level and quality; if the fluid appears dark or contains debris, it may be time for a replacement. Additionally, consider flushing the system periodically to remove accumulated contaminants. Using a funnel during fluid changes can help prevent spills and ensure precise application.

Always consult your manufacturer’s guidelines for specifications regarding fluid types and change intervals to maintain the integrity and functionality of your transmission system.

Common Modifications and Upgrades

When enhancing the performance and reliability of a particular transmission system, enthusiasts often explore various modifications and upgrades. These alterations can significantly improve functionality, durability, and driving experience. Below are some popular options that are frequently considered.

- Short Shifter Kit: This upgrade reduces the distance the shifter needs to travel between gears, allowing for quicker gear changes and a sportier feel.

- High-Performance Clutch: Installing a stronger clutch can handle increased power and torque, ensuring smoother engagement and improved responsiveness.

- Synchro Upgrade: Enhanced synchronizers can provide smoother shifts and extend the lifespan of the transmission components.

- Cooling Solutions: Adding an external cooler helps maintain optimal operating temperatures, preventing overheating during intensive use.

- Reinforced Housing: Strengthening the transmission casing can prevent flex and potential failures under high-stress conditions.

These enhancements not only improve performance but can also provide a more enjoyable driving experience. It is essential to choose modifications that align with individual driving needs and vehicle specifications.

Troubleshooting Gearbox Performance Issues

Addressing performance challenges within a transmission system requires a methodical approach to identify the root causes. Various symptoms can manifest, and understanding these signs is crucial for effective diagnosis and resolution.

1. Slipping Engagement: If the system fails to engage smoothly, it may indicate worn components or insufficient fluid levels. Begin by checking the fluid condition and levels; dirty or low fluid can severely impact operation.

2. Unusual Noises: Grinding or whining sounds often signal mechanical issues. These may arise from misalignment, damaged gears, or insufficient lubrication. Inspecting the components for wear can help pinpoint the source of the noise.

3. Delayed Shifting: A lag in changing gears can be a symptom of hydraulic problems or electronic malfunctions. Testing the system’s pressure can reveal if there are issues with the pump or solenoids.

4. Fluid Leaks: External leaks are a clear indicator of potential failure. Identifying the location of the leak is essential for determining whether seals or gaskets need replacement. Regular inspection can prevent more significant issues down the line.

By systematically evaluating these performance indicators, one can effectively diagnose and address issues, ensuring smooth operation and longevity of the transmission system.

Safety Precautions During Repairs

Ensuring a secure environment while working on mechanical components is essential to prevent accidents and injuries. Adopting appropriate safety measures not only safeguards the individual but also contributes to the longevity of the equipment being serviced.

Wear Protective Gear: Always don safety glasses, gloves, and sturdy footwear. This minimizes the risk of injuries from flying debris or heavy objects.

Maintain a Clean Workspace: A tidy area reduces hazards. Keep tools organized and remove any unnecessary items that could cause tripping.

Disconnect Power Sources: Before beginning any work, ensure all power sources are disconnected. This prevents accidental starts that could lead to serious harm.

Use Proper Tools: Employ the correct tools for the task at hand. Using inappropriate equipment can lead to damage or personal injury.

Stay Informed: Familiarize yourself with the specific components and procedures before starting. Understanding the mechanics will help mitigate risks during the process.

Resources for Further Learning

Expanding your knowledge in automotive maintenance and systems can significantly enhance your skills and confidence. Whether you are a novice or an experienced enthusiast, exploring various resources can provide valuable insights and practical techniques essential for mastering complex machinery.

Online platforms, such as forums and video tutorials, offer a wealth of information where enthusiasts share their experiences and solutions to common challenges. Engaging with these communities can foster a deeper understanding of specific components and their functions.

Additionally, instructional books and technical literature serve as excellent references for detailed procedures and theoretical concepts. Many publications focus on specific models or systems, providing comprehensive guidance that can aid in troubleshooting and assembly processes.

Workshops and hands-on training sessions can also be beneficial, allowing individuals to gain real-world experience under the supervision of seasoned professionals. Participating in local car clubs or attending automotive shows can further enhance your learning through networking and shared experiences.

Utilizing these diverse resources can greatly improve your proficiency and appreciation for automotive mechanics, empowering you to tackle more advanced projects with ease.