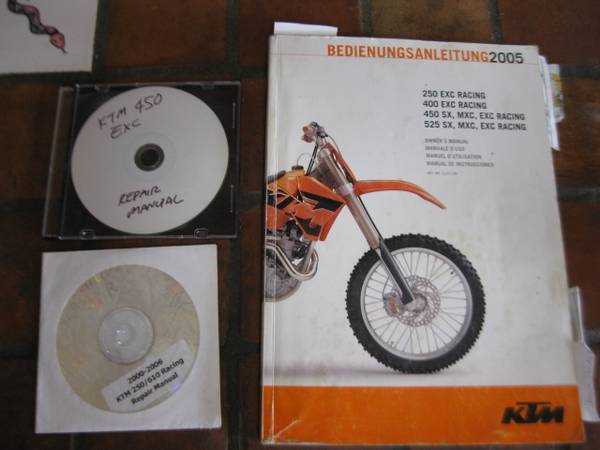

KTM 450 EXC 2004 Repair Manual Guide

When it comes to ensuring optimal performance and longevity of your off-road motorcycle, understanding the intricacies of its upkeep is essential. This guide delves into comprehensive strategies and techniques designed to keep your machine in peak condition, addressing both common challenges and advanced procedures.

Exploring the Essentials of motorcycle maintenance not only enhances your riding experience but also empowers you as an owner. From routine checks to complex adjustments, having a well-structured approach can significantly impact reliability and performance.

By familiarizing yourself with the intricacies of your two-wheeled companion, you can prevent potential issues and enhance its capabilities. This section offers valuable insights and tips to navigate the world of motorcycle maintenance effectively, ensuring that every ride is as thrilling as the last.

Understanding the 2004 KTM 450 EXC

This section delves into the intricacies of a high-performance off-road motorcycle that has garnered attention for its robust capabilities and engineering excellence. This machine is designed for those who seek adventure in challenging terrains, blending power with agility. A comprehensive understanding of its features and maintenance will ensure optimal performance and longevity.

Key Features

- Powerful engine designed for superior torque and responsiveness

- Lightweight frame for enhanced maneuverability

- Advanced suspension system for improved stability on rough paths

- Durable tires suited for various environmental conditions

Maintenance Tips

- Regularly check and change the oil to ensure engine health.

- Inspect the air filter frequently to maintain optimal airflow.

- Examine the brakes and replace components as necessary.

- Keep the chain lubricated and properly tensioned for smooth operation.

Familiarity with these elements will not only enhance riding experience but also extend the lifespan of this remarkable vehicle.

Common Issues with the 2004 Model

When it comes to this specific off-road vehicle, enthusiasts often encounter a range of challenges that can affect performance and reliability. Understanding these common problems is essential for maintaining optimal function and ensuring a smooth riding experience.

Engine Performance Problems

A frequent issue seen in this model is related to engine performance, including difficulties with starting and inconsistent power delivery. Riders have reported instances of stalling, particularly in challenging terrain. Regular maintenance of the fuel system and checking for air leaks can help mitigate these problems.

Suspension and Handling Concerns

Another area where riders may face challenges is the suspension system. Issues such as excessive sag or poor damping can lead to a less than ideal handling experience. It’s advisable to inspect the suspension components regularly and adjust settings according to the rider’s weight and riding style for improved control.

Essential Tools for Repairing Your KTM

Maintaining and fixing your two-wheeled companion requires the right set of instruments to ensure efficiency and precision. Having the proper tools not only facilitates the process but also enhances the quality of the work performed. This section will guide you through the fundamental instruments needed for effective maintenance and troubleshooting.

Basic Hand Tools

Every enthusiast should have a reliable collection of hand tools. These are essential for performing a variety of tasks, from minor adjustments to more extensive work.

| Tool | Purpose |

|---|---|

| Socket Set | For loosening and tightening nuts and bolts. |

| Wrenches | Useful for various fasteners. |

| Torque Wrench | Ensures fasteners are tightened to the correct specifications. |

| Screwdrivers | Essential for a wide range of screws. |

Specialized Instruments

In addition to basic hand tools, specialized equipment can significantly ease specific tasks, enhancing your overall maintenance experience.

| Tool | Purpose |

|---|---|

| Chain Tool | For adjusting and maintaining the drive chain. |

| Oil Filter Wrench | Facilitates easy removal and installation of oil filters. |

| Multimeter | For electrical diagnostics and troubleshooting. |

| Tire Levers | Essential for changing tires. |

Having these tools at your disposal will empower you to tackle a wide range of maintenance tasks, ensuring your ride remains in optimal condition.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to the upkeep of your off-road motorcycle, ensuring optimal performance and longevity. Regular maintenance is crucial for any rider who wishes to enjoy a reliable and safe riding experience. Follow these steps to keep your machine in top condition.

Essential Tools and Supplies

Before you begin, gather the necessary tools and materials:

- Wrench set

- Screwdriver set

- Oil filter wrench

- Grease

- Brake fluid

- Chain lubricant

- Clean rags

- Safety gear (gloves, goggles)

Maintenance Steps

- Check Oil Level: Ensure the oil is at the recommended level. Change the oil if it appears dirty or is below the required mark.

- Inspect Air Filter: Remove the air filter and clean it according to the manufacturer’s instructions. Replace it if damaged.

- Examine the Chain: Check for wear and tension. Clean and lubricate the chain as needed.

- Brake Inspection: Check the brake pads and fluid. Replace worn pads and top off the fluid if necessary.

- Tire Condition: Inspect tires for wear and proper inflation. Replace if the tread is low or damage is visible.

- Inspect Electrical System: Check battery connections and electrical components for any signs of corrosion or damage.

- Visual Inspection: Conduct a thorough visual check of the frame, suspension, and other components for any loose bolts or signs of wear.

Following these maintenance steps regularly will enhance the performance and safety of your vehicle, allowing for enjoyable rides on various terrains.

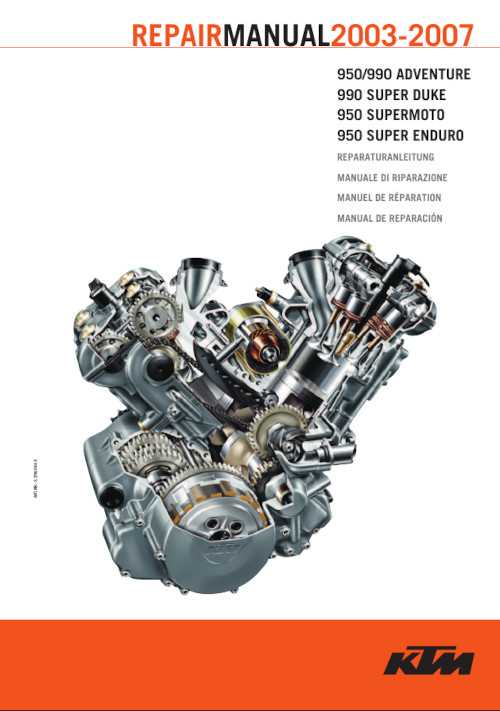

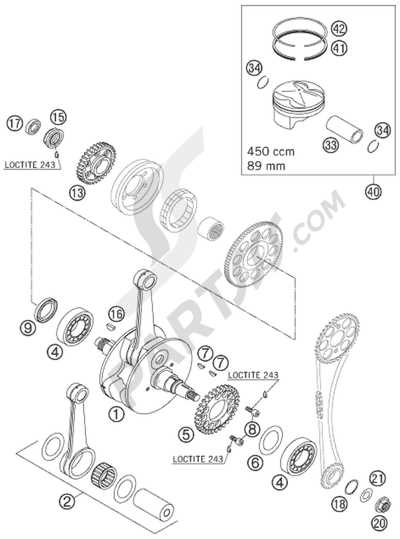

Engine Overhaul Procedures Explained

Performing an engine overhaul is a vital process that enhances performance and extends the lifespan of a power unit. This intricate procedure involves several key steps that ensure the engine operates efficiently and reliably. Understanding the methodology behind these steps is crucial for any technician or enthusiast aiming to maintain or restore engine functionality.

The following outlines the primary stages involved in an engine overhaul:

- Preparation:

- Gather all necessary tools and components.

- Ensure a clean working environment to prevent contamination.

- Review the service manual for specific guidelines and specifications.

- Disassembly:

- Carefully remove external components such as the exhaust and intake systems.

- Document the order of disassembly to facilitate reassembly.

- Take notes on the condition of parts for future reference.

- Inspection:

- Examine each component for wear, damage, or corrosion.

- Use precision tools to measure critical dimensions.

- Identify parts that require replacement or machining.

- Reconditioning:

- Clean all parts thoroughly to remove deposits and debris.

- Perform necessary machining operations such as honing or resurfacing.

- Replace worn components with new or reconditioned parts.

- Reassembly:

- Follow the documented order of assembly.

- Utilize appropriate torque specifications for fasteners.

- Install new gaskets and seals to prevent leaks.

- Testing:

- Conduct a thorough inspection of the reassembled engine.

- Perform a compression test to ensure proper sealing.

- Run the engine at idle to check for unusual noises or leaks.

By adhering to these procedures, individuals can effectively restore an engine’s performance, ensuring longevity and reliability for future use. Proper execution of each stage is essential for achieving optimal results and avoiding potential pitfalls during the overhaul process.

Suspension Tuning for Better Performance

Tuning the suspension is crucial for enhancing the overall performance of any off-road vehicle. Properly adjusted suspension components can significantly improve ride quality, handling, and stability, allowing riders to tackle challenging terrains with confidence. Understanding the dynamics of your suspension system can lead to a more responsive and comfortable experience on the trail.

Understanding Suspension Components

The suspension system consists of various parts, including forks, shock absorbers, and linkage systems. Each component plays a vital role in how the vehicle interacts with the ground. By adjusting settings such as preload, compression, and rebound damping, you can tailor the suspension to suit your riding style and the conditions of the terrain.

Preload Adjustment

Preload refers to the initial tension on the suspension springs. Adjusting the preload can help in achieving the desired ride height and balance. Increasing preload stiffens the suspension, which can be beneficial for aggressive riding on rough trails, while decreasing it allows for more comfort on smoother surfaces.

Compression and Rebound Damping

Compression damping controls how quickly the suspension compresses when encountering bumps, while rebound damping regulates how fast it returns to its original position. Fine-tuning these settings ensures that the wheels stay in contact with the ground, providing better traction and control. Finding the right balance is essential for optimal performance.

Testing and Fine-Tuning

After making adjustments, it is crucial to test the vehicle in various conditions. Pay attention to how it feels during different maneuvers, such as cornering and jumping. Small tweaks can lead to significant improvements in handling. Keep a log of your settings and observations to track changes and refine your setup over time.

Conclusion

Investing time in suspension tuning is rewarding and can transform your riding experience. By understanding and adjusting the key components of your suspension system, you can achieve a setup that maximizes performance and comfort, enabling you to tackle any trail with confidence.

Electrical System Troubleshooting Tips

Addressing issues within an electrical framework can be challenging, yet understanding the core elements can simplify the process. This section aims to provide valuable insights for diagnosing common problems and ensuring optimal performance of your vehicle’s electrical components.

Check Connections: Begin by inspecting all wiring harnesses and connectors. Look for signs of corrosion, looseness, or fraying. A secure and clean connection is essential for proper functionality.

Test Voltage Levels: Utilize a multimeter to measure voltage at various points in the circuit. Ensure that readings match the specifications in your reference guide. Low voltage can indicate issues such as battery drain or faulty wiring.

Inspect Fuses: Examine the fuse box for blown fuses, as they are often the first line of defense against electrical faults. Replace any damaged fuses and observe if the system returns to normal operation.

Battery Health: A well-maintained battery is crucial. Check for signs of wear, such as bulging or leaking, and ensure terminals are clean and tightly connected. If performance issues persist, consider testing or replacing the battery.

Grounding Issues: Poor grounding can lead to erratic behavior of electrical components. Verify that all grounding points are clean and securely fastened to the frame. A solid ground connection minimizes resistance and potential malfunctions.

Component Functionality: Isolate and test individual components, such as the starter motor and relays. Use appropriate tools to confirm their operational status. Replacing malfunctioning parts can restore system integrity.

Consult Documentation: Always refer to your specific technical literature for detailed information on system specifications and troubleshooting guidelines. Accurate knowledge will aid in identifying and resolving issues efficiently.

By following these systematic approaches, you can effectively diagnose and resolve electrical problems, ensuring a reliable and smooth operation of your machine.

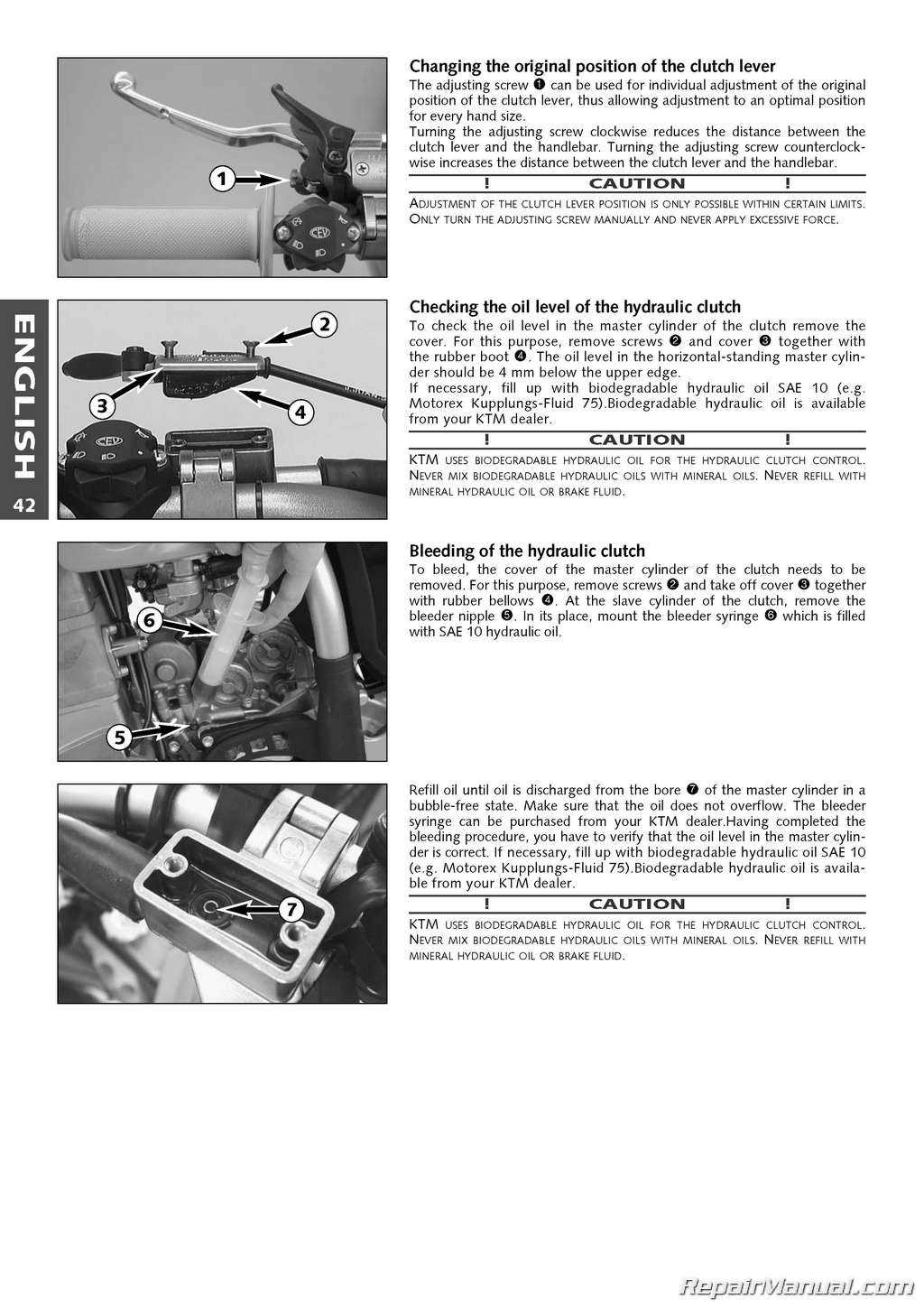

Brake System Inspection and Repair

The braking mechanism is a critical component of any off-road vehicle, ensuring safety and control during operation. Regular evaluation of this system is essential to maintain optimal performance and prevent potential failures. This section focuses on the methods for assessing and addressing issues related to the braking apparatus.

Inspection Procedures

Begin by visually examining the brake components, including the calipers, rotors, and hoses. Look for any signs of wear, corrosion, or fluid leaks. Ensure that the brake pads are not excessively worn; replacing them at the first signs of degradation can prevent further damage. Additionally, check the brake fluid level and its condition, as contaminated fluid can compromise braking effectiveness.

Common Issues and Solutions

If the brakes feel spongy or unresponsive, it may indicate air trapped in the hydraulic lines. Bleeding the system to remove air bubbles is a crucial step in restoring proper functionality. In cases where the braking force is uneven, inspect the calipers for proper alignment and function. Replacing worn components and ensuring all connections are secure will enhance overall performance. Always prioritize safety by following manufacturer guidelines when addressing any issues.

Transmission Maintenance Best Practices

Maintaining the transmission is crucial for ensuring optimal performance and longevity of any vehicle. Regular upkeep not only enhances efficiency but also prevents costly repairs down the line. Understanding and implementing the right practices can lead to a smoother riding experience and extended component life.

1. Regular Fluid Checks: Frequent inspection of transmission fluid levels is essential. Low or dirty fluid can lead to increased wear and tear. Ensure that the fluid is topped off and replaced according to manufacturer recommendations to keep the system functioning properly.

2. Clean Components: Dirt and debris can accumulate in the transmission over time. Regularly cleaning the external parts and checking for contamination can help maintain performance. Use appropriate cleaning agents and tools to avoid damage.

3. Inspect Seals and Gaskets: Worn or damaged seals can lead to leaks, compromising fluid levels. Regularly inspect seals and gaskets for signs of wear, and replace them as necessary to maintain integrity.

4. Monitor Temperature: Transmission overheating can lead to significant damage. Installing a temperature gauge allows for real-time monitoring, enabling timely intervention if temperatures exceed safe limits.

5. Routine Servicing: Following a regular maintenance schedule is vital. This includes changing the fluid, replacing filters, and checking for any signs of wear. Consistency in servicing can prevent unexpected breakdowns.

6. Professional Inspections: Occasionally, having a professional technician evaluate the transmission can uncover issues that may go unnoticed. Their expertise can provide valuable insights into potential problems and recommended solutions.

By adhering to these best practices, owners can ensure that their transmission operates smoothly, thus enhancing overall vehicle reliability and performance.

Upgrading Parts for Enhanced Performance

Improving your off-road machine’s capabilities often involves enhancing specific components. By focusing on key areas such as the engine, suspension, and braking systems, you can significantly boost performance and overall riding experience. Upgrades not only increase power but also enhance handling and safety, making your rides more enjoyable and efficient.

Engine Enhancements: Upgrading the engine components, such as the air filter and exhaust system, can lead to a noticeable increase in horsepower and torque. A high-flow air filter allows for better airflow, while a performance exhaust reduces back pressure and improves exhaust flow, resulting in a more responsive engine.

Suspension Modifications: Investing in high-quality suspension parts can dramatically improve handling. Aftermarket shocks and forks are designed to provide better damping and adjustability, allowing for a more tailored riding experience. This results in improved traction and stability, especially on rough terrains.

Braking System Improvements: Upgrading the braking system is crucial for safety and control. Installing better brake pads, rotors, or even a complete brake kit can enhance stopping power and feel. This ensures you have the confidence to tackle challenging trails and obstacles.

Overall, strategically upgrading parts can transform your machine into a high-performance beast, allowing you to take on any adventure with confidence and ease.

Safety Precautions During Repairs

When engaging in maintenance tasks on any vehicle, it is essential to prioritize safety to prevent accidents and injuries. Proper precautions not only safeguard the individual working on the machine but also protect the equipment itself. Understanding and implementing these measures can lead to a more efficient and secure working environment.

First and foremost, always wear appropriate personal protective equipment (PPE). This includes gloves, safety glasses, and durable footwear to shield against potential hazards. Furthermore, ensure the workspace is well-ventilated, especially when dealing with fumes or chemicals.

Before starting any work, familiarize yourself with the tools and parts you will be using. A clear understanding of each component can reduce the risk of mistakes and enhance safety. Additionally, keep the workspace organized and free from clutter to minimize the chance of accidents.

Another critical aspect is to ensure that the vehicle is stable and secure before performing any tasks. Use stands or blocks as necessary, and never work under a vehicle that is not properly supported. Lastly, always disconnect the battery and follow specific guidelines for the equipment being serviced to avoid electrical hazards.

Finding Quality Replacement Parts

When it comes to maintaining your off-road machine, sourcing top-notch components is essential for optimal performance and longevity. The right parts ensure that your vehicle operates smoothly and reliably, minimizing downtime and enhancing your riding experience.

There are several avenues to explore when searching for reliable replacements. It’s important to consider factors such as compatibility, durability, and overall value. Here are some options to keep in mind:

| Source | Description | Pros | Cons |

|---|---|---|---|

| Authorized Dealers | Official outlets that sell manufacturer-approved parts. | High quality, guaranteed fit. | Often more expensive. |

| Aftermarket Suppliers | Third-party companies that produce compatible parts. | Variety and competitive pricing. | Quality can vary widely. |

| Online Marketplaces | Websites that connect buyers with various sellers. | Convenience and extensive selection. | Need to verify seller reliability. |

| Local Mechanics | Service providers who often have parts on hand. | Expert recommendations, immediate access. | Limited selection compared to larger suppliers. |

By exploring these options and conducting thorough research, you can ensure that you find high-quality replacement components that meet your needs and keep your machine in excellent condition.