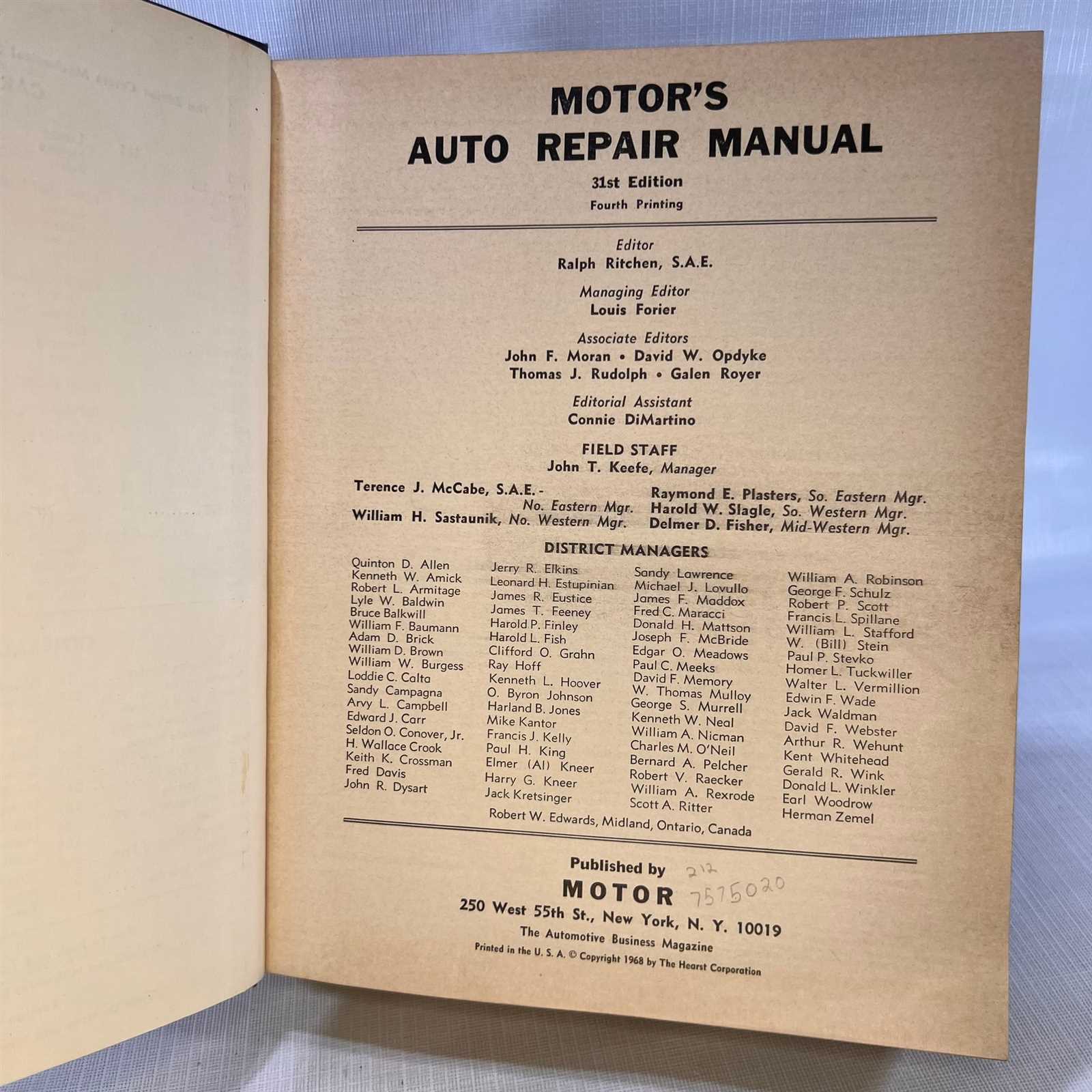

Comprehensive Guide to 1967 Motors Auto Repair Manual

This section serves as an essential resource for enthusiasts and practitioners keen on understanding the intricacies of classic vehicle upkeep. By delving into the specifics of these older models, one can gain valuable insights into their unique characteristics and requirements.

Whether you are a seasoned professional or a curious newcomer, familiarizing yourself with the nuances of these timeless machines can enhance your ability to care for them. From troubleshooting common issues to performing routine tasks, the knowledge contained here will prove invaluable in ensuring longevity and performance.

Explore the various components and systems that define these classic vehicles, equipping yourself with the skills necessary to tackle maintenance tasks confidently. Embrace the journey of preservation, as each effort contributes to the legacy of these remarkable machines.

Overview of 1967 Motors Repair Manuals

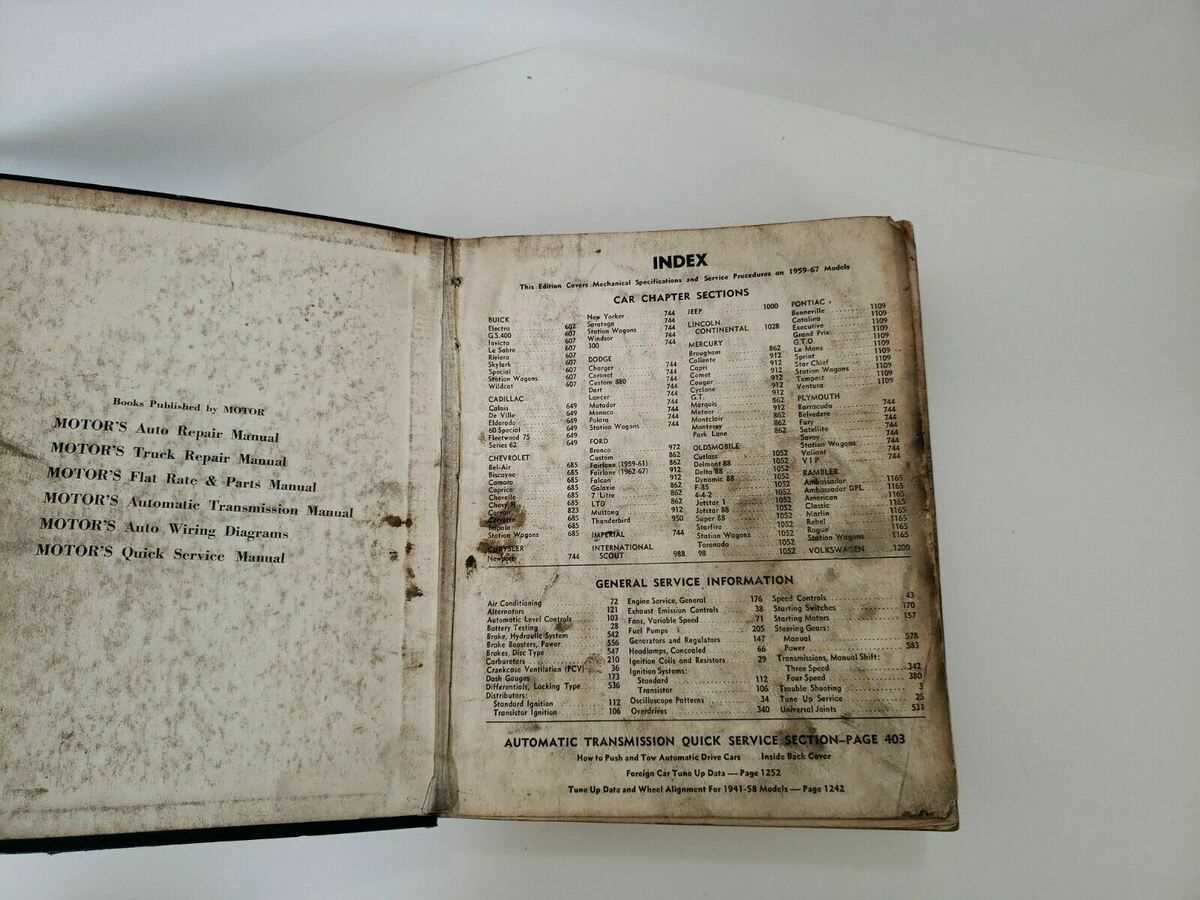

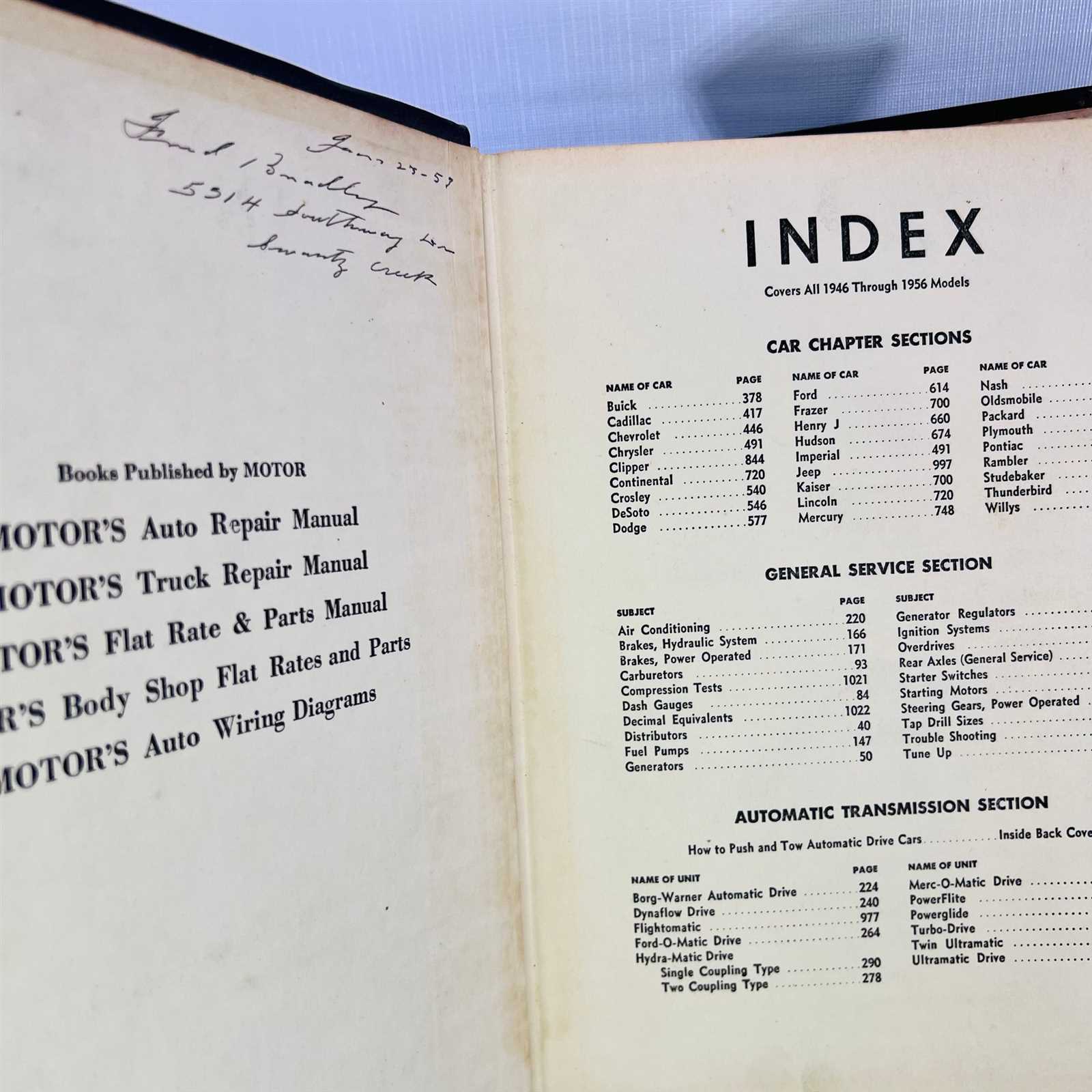

The collection of guides from the late 1960s serves as a crucial resource for enthusiasts and technicians alike. These documents provide detailed insights into vehicle maintenance, focusing on various components and systems essential for optimal performance. They are invaluable for those looking to understand the intricacies of their machines and ensure longevity.

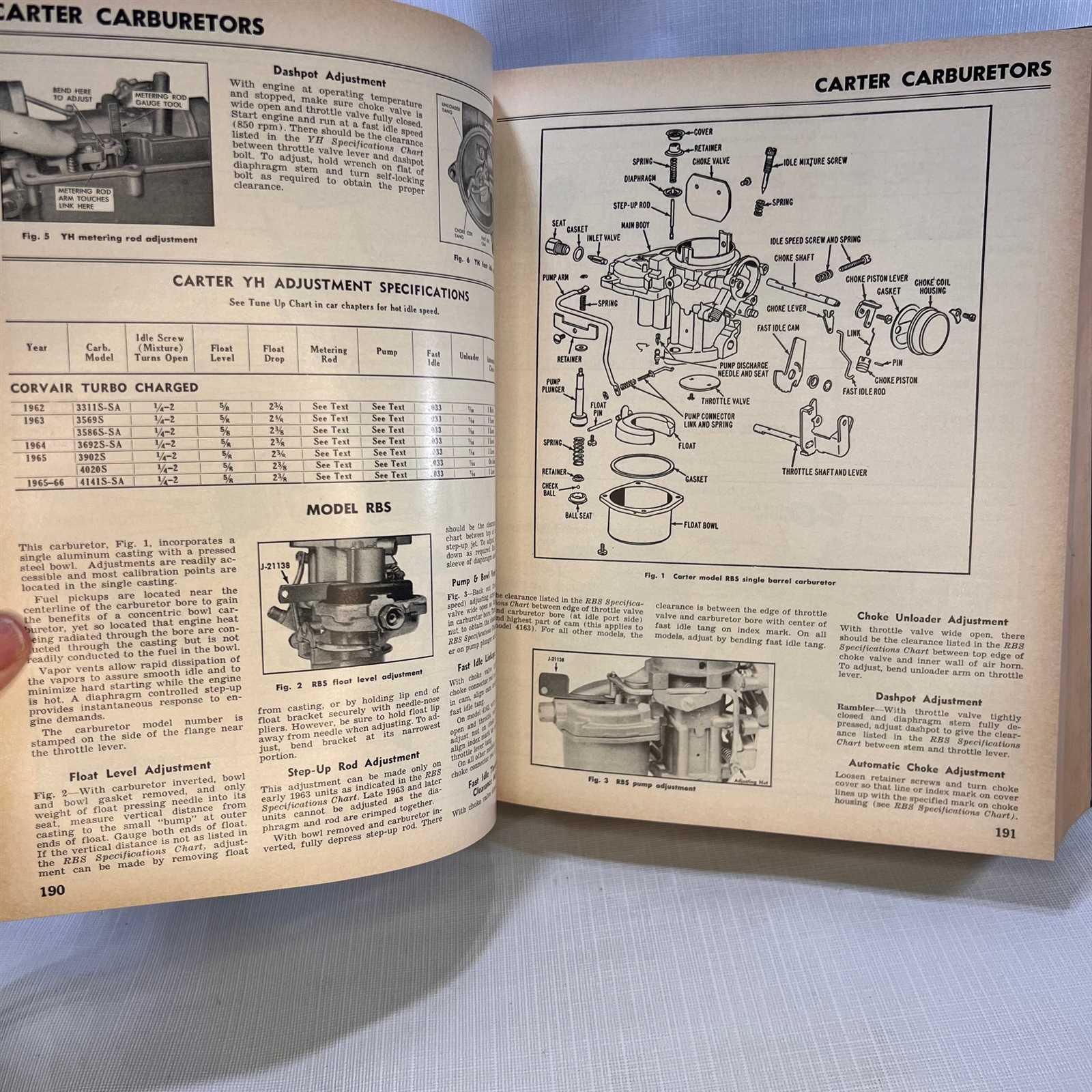

Within these resources, users can find step-by-step procedures and specifications tailored to a range of models. The information encompasses everything from basic upkeep to more complex troubleshooting techniques, allowing users to tackle both simple tasks and intricate challenges with confidence. The clarity of instructions paired with illustrations enhances comprehension, making it easier to follow along.

Moreover, these guides reflect the era’s engineering standards and practices, offering a fascinating glimpse into the automotive landscape of the time. They highlight the evolution of technology and design, demonstrating how vehicles were constructed and serviced, which is of significant interest to historians and collectors.

Common Issues in 1967 Vehicles

The vehicles from this era often exhibit a range of challenges that can affect performance and reliability. Understanding these typical concerns is essential for enthusiasts and owners alike.

- Electrical Problems: Faulty wiring and aging components can lead to issues with lighting and ignition systems.

- Engine Difficulties: Many units face difficulties such as poor fuel efficiency and rough idling due to wear and tear.

- Transmission Issues: Shifting problems, including slipping gears, are frequently reported, impacting drivability.

- Brake System Failures: Deterioration of brake components may result in reduced stopping power and increased stopping distances.

- Cooling System Malfunctions: Overheating can be a common concern, often caused by leaks or malfunctioning thermostats.

Addressing these issues promptly can enhance the longevity and enjoyment of classic vehicles from this period.

Essential Tools for Auto Repairs

Having the right instruments is crucial for anyone looking to fix vehicles effectively. A well-equipped workspace can make the difference between a smooth process and a frustrating experience. Various implements serve unique purposes, ensuring that tasks can be completed efficiently and accurately.

| Tool | Description |

|---|---|

| Wrench Set | Ideal for tightening and loosening nuts and bolts of different sizes. |

| Screwdriver Set | Essential for fastening or removing screws, available in various types such as flathead and Phillips. |

| Pliers | Versatile for gripping, bending, or cutting wires and other materials. |

| Jack | Used to lift the vehicle off the ground for easier access to the underside. |

| Socket Set | Provides a range of sizes for working with fasteners in tight spaces. |

Equipping oneself with these essential implements can enhance the efficiency and effectiveness of vehicle maintenance tasks, leading to successful outcomes and increased satisfaction.

Step-by-Step Engine Overhaul Guide

This section provides a comprehensive approach to rejuvenating your power unit, ensuring it runs smoothly and efficiently. By following these detailed steps, you can enhance the performance and longevity of your machine, while also gaining valuable insight into its mechanics.

Preparation and Disassembly

Begin by gathering all necessary tools and materials, including wrenches, screwdrivers, and cleaning supplies. Ensure you have a clean workspace. Carefully remove components such as the intake manifold and exhaust system, taking note of the order for reassembly. Labeling parts can help prevent confusion later.

Inspection and Replacement

Once disassembled, inspect each part for wear and tear. Pay special attention to gaskets, seals, and bearings. Replace any damaged components to maintain optimal functionality. After replacing parts, clean all surfaces thoroughly to remove dirt and debris. This step is crucial for achieving a tight seal during reassembly.

Transmission Maintenance and Troubleshooting

Ensuring optimal performance of a vehicle’s shifting system is crucial for overall functionality. Regular care and attention can prevent common issues, extending the lifespan of this essential component. Understanding the basic principles of upkeep and diagnostics will empower you to address problems effectively.

Regular Inspections: Routine checks are vital. Look for signs of leaks, unusual noises, or irregular shifting patterns. These indicators can signal underlying issues that require prompt attention.

Fluid Quality: The condition of the shifting fluid plays a significant role in performance. It should be clean and at the proper level. If it appears discolored or has a burnt smell, it may be time for a change.

Troubleshooting Techniques: When encountering difficulties, start with simple solutions. Ensure connections are secure and that no components are worn or damaged. If problems persist, further investigation may be needed, potentially involving professional assistance.

By staying proactive and attentive, you can maintain the efficiency of your vehicle’s shifting system, ensuring a smooth and reliable driving experience.

Electrical System Diagnostics Explained

The analysis of electrical frameworks is a crucial aspect of maintaining vehicle performance. Understanding how to effectively assess these systems ensures that any underlying issues can be identified and addressed promptly. This segment delves into the methodologies used to diagnose electrical components, aiming to provide clarity on the processes involved.

To begin with, it is essential to comprehend the various elements that constitute the electrical architecture. This includes batteries, wiring harnesses, connectors, and fuses. Each component plays a vital role, and any malfunction can lead to significant operational challenges. Utilizing diagnostic tools, technicians can evaluate voltage levels, continuity, and overall system integrity.

Common issues encountered during these assessments may include short circuits, faulty connections, or degraded components. By employing systematic testing techniques, one can isolate problems and determine the necessary corrective actions. This not only enhances reliability but also extends the lifespan of the electrical system.

In conclusion, mastering the techniques for evaluating electrical configurations is invaluable for ensuring optimal functionality. With a methodical approach, one can navigate the complexities of these systems, leading to more efficient resolutions and improved vehicle performance.

Brake System Repair Techniques

This section delves into essential practices for maintaining and enhancing the functionality of braking systems. Effective intervention ensures safety and optimal performance, focusing on identifying issues, selecting appropriate components, and executing repairs with precision.

Identifying Common Issues

Understanding typical problems within the braking apparatus is crucial for timely action. Signs such as unusual noises, decreased responsiveness, or uneven wear can indicate the need for examination. Regular inspections help detect these concerns before they escalate, ensuring the system remains reliable.

Steps for Effective Maintenance

Once issues are identified, the next phase involves systematic procedures to address them. This includes removing the wheels, inspecting brake pads and rotors, and replacing worn components as necessary. Proper installation and adjustment are vital to restore the system’s efficiency and prolong its lifespan.

Suspension and Steering Adjustments

Proper alignment and tuning of the suspension and steering systems are essential for optimal handling and ride quality. These adjustments help ensure that the vehicle responds accurately to driver inputs and maintains stability on various road surfaces. Regular checks can prevent uneven tire wear and enhance overall safety.

Importance of Suspension Tuning

Adjusting the suspension system is crucial for maintaining comfort and control. Key aspects to consider include:

- Spring stiffness

- Shock absorber settings

- Ride height

- Alignment angles

Each of these factors contributes to the vehicle’s ability to absorb road imperfections and provide a smooth driving experience.

Steering System Calibration

Accurate steering adjustments improve response and maneuverability. Important elements include:

- Toe settings

- Camber angles

- Caster adjustments

By ensuring these parameters are within specified ranges, drivers can enjoy a more precise steering feel and enhanced cornering performance.

Restoration Tips for Classic Models

Restoring vintage vehicles can be a rewarding journey, allowing enthusiasts to breathe new life into cherished machines. Each restoration project presents unique challenges, but with the right approach, you can achieve impressive results that honor the original craftsmanship.

Research and Planning

Before diving into the project, take time to gather information about the specific model you are working on. Consult forums, join clubs, and seek out enthusiasts who share your passion. Understanding the history, common issues, and available resources will significantly enhance your restoration experience. Create a detailed plan outlining your goals, budget, and timeline to keep the project on track.

Quality Parts and Materials

Using high-quality components is essential for ensuring longevity and performance. Whether sourcing original parts or opting for reproductions, prioritize authenticity and durability. Consider reaching out to specialty suppliers who cater to vintage vehicle restoration. Investing in superior materials not only improves the finished product but also contributes to the overall value of the restored vehicle.

Safety Precautions During Repairs

When undertaking maintenance tasks, ensuring safety is paramount. Proper precautions not only protect the individual performing the work but also safeguard the surrounding environment. Awareness of potential hazards and preparation to mitigate risks are essential for a successful outcome.

Before starting any task, it’s crucial to wear appropriate personal protective equipment, including gloves, goggles, and sturdy footwear. These items serve as barriers against sharp objects, chemicals, and heavy components that could cause injury. Additionally, working in a well-ventilated area minimizes exposure to harmful fumes and dust.

Organizing tools and materials can greatly enhance safety. Keeping the workspace tidy reduces the risk of accidents caused by tripping or misplaced items. Furthermore, ensuring that all equipment is in good working condition prevents malfunctions that could lead to injuries.

Finally, familiarizing oneself with the specific characteristics of the machinery involved is vital. Understanding how different components operate helps in anticipating potential issues and responding appropriately. Adhering to these safety measures fosters a more secure and efficient working environment.