Comprehensive Guide to 42RLE Transmission Repair Manual

In the intricate world of automotive technology, the upkeep and enhancement of core vehicle components play a pivotal role in ensuring smooth operation and longevity. One of these essential systems, responsible for shifting and adapting speed, is often complex and requires specialized attention. A well-structured approach to this component’s care not only improves its function but also contributes to the overall performance of the vehicle.

Understanding the inner workings and common challenges of such mechanisms can provide valuable insights for enthusiasts and professionals alike. By familiarizing oneself with potential issues and effective maintenance techniques, it’s possible to extend the lifespan of key parts and enhance driving efficiency. Additionally, learning about proper adjustments and preventive steps can significantly reduce the need for costly replacements.

In this section, we delve into essential techniques, strategies for fine-tuning, and practical solutions for optimal operation. Whether addressing specific challenges or improving overall performance, this guide serves as a valuable resource for those looking to master the intricacies of vehicular system management.

42RLE Transmission Repair Manual

This guide is designed to offer valuable insights into the maintenance and revitalization of vehicle shifting systems. Through clear and concise steps, this section helps drivers and mechanics understand the essentials of restoring smooth function and reliability.

In the following paragraphs, you’ll find structured recommendations for troubleshooting various challenges that can arise over time. By adhering to these expert tips, owners and technicians can ensure optimal operation and prevent potential future issues.

The focus here is on identifying key symptoms of wear and providing step-by-step solutions. Through this approach, even complex adjustments become manageable, aiding both novices and professionals in keeping components in top condition.

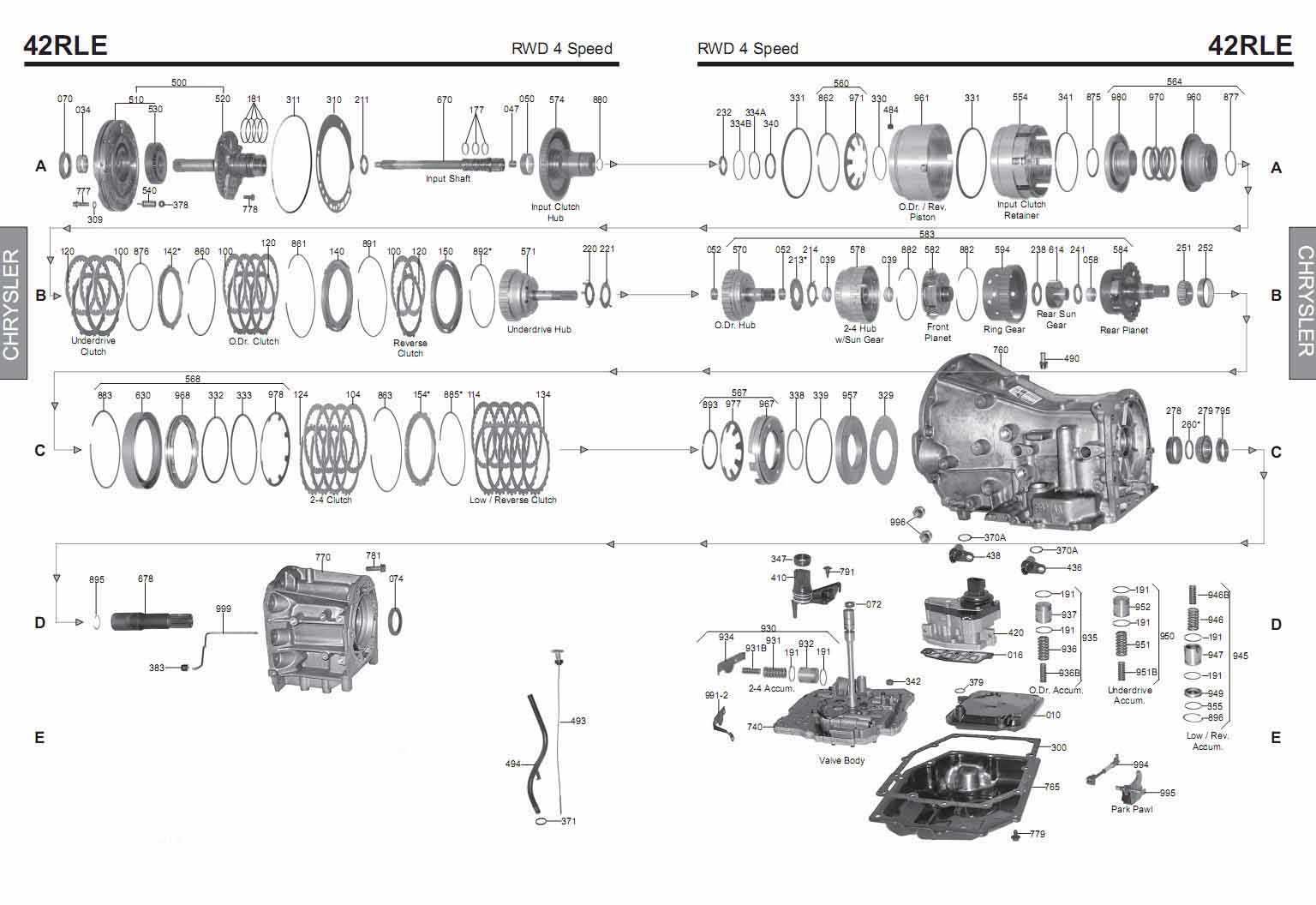

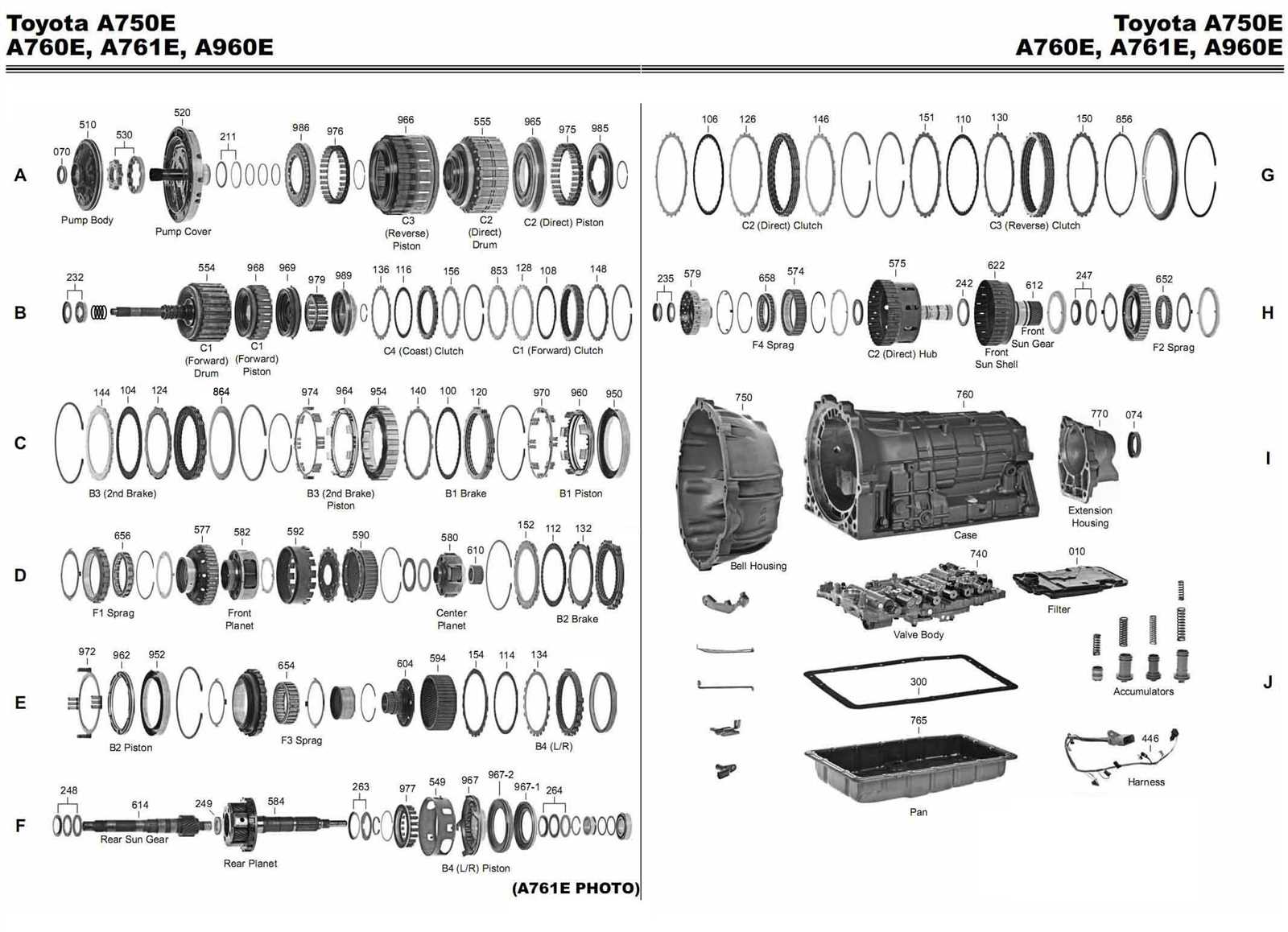

Key Components of the 42RLE Transmission

Understanding the primary mechanisms that enable this system to function effectively is essential for maintaining its longevity and performance. These core elements work together, each playing a specific role to ensure smooth operation, efficient power transfer, and reliable performance on the road.

| Component | Role |

|---|---|

| Clutch Packs | Regulate the engagement and disengagement of gears, allowing for seamless shifting under varying loads and speeds. |

| Planetary Gear Set | Provides multiple gear ratios, facilitating smooth changes in speed and torque, critical for efficient acceleration and deceleration. |

| Valve Body | Directs hydraulic fluid flow to manage gear transitions and modulate the pressure within the system for precise control. |

| Torque Converter | Acts as a bridge between the engine and the system, enabling the vehicle to idle without stalling and providing torque multiplication during acceleration. |

| Oil Pump | Maintains the necessary hydraulic pressure, ensuring fluid circulation and consistent lubrication across all components. |

Common Issues and Their Causes

Understanding the frequent problems that can affect this type of system is essential for keeping it in optimal condition. Various symptoms often signal internal wear or misalignments that can lead to more significant issues over time. Early identification of these signs allows for timely maintenance and prevents costly breakdowns.

Overheating

One of the most prevalent issues involves the system heating up beyond normal levels. Excessive heat often results from prolonged usage, inadequate cooling, or blockages within the fluid passages. This heat buildup can compromise the system’s components, causing a noticeable drop in performance and efficiency.

Fluid Leaks

Leaks are another common concern, typically occurring due to deteriorated seals, loose connections, or cracks in the housing. Fluid loss reduces the system’s ability to operate smoothly and can lead to increased friction and internal wear. Identifying and addressing leaks promptly is crucial to avoid further damage.

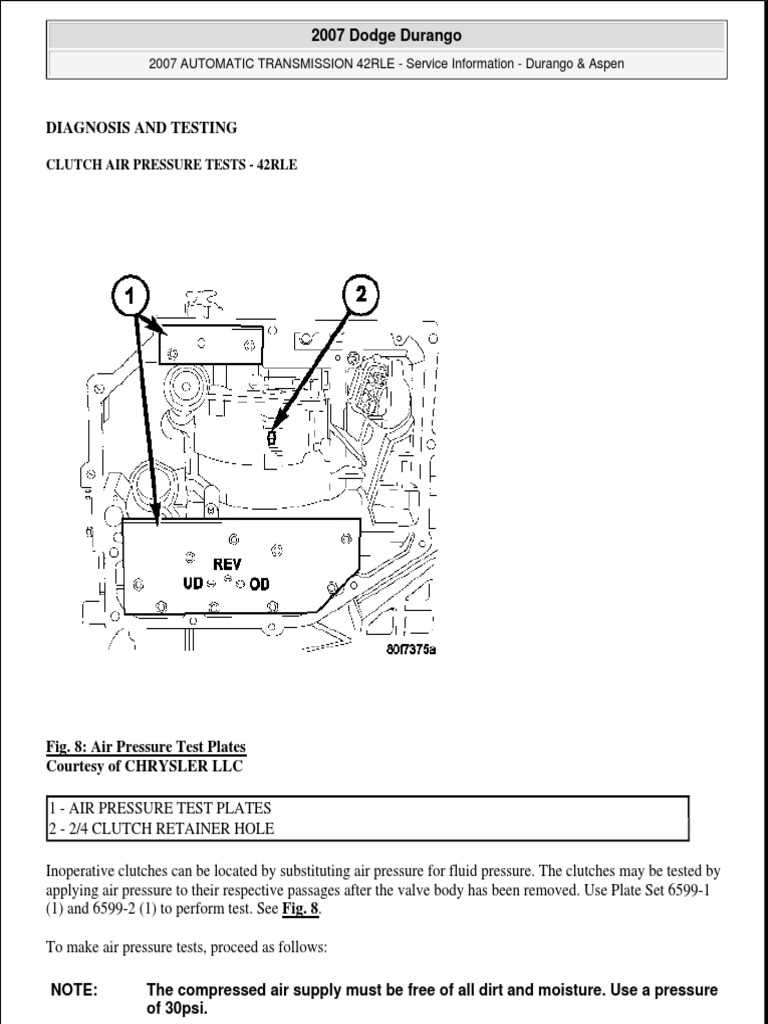

Diagnostic Techniques for Accurate Assessment

Identifying the root causes of mechanical issues requires a systematic and thorough approach to ensure precise evaluations. This section covers effective techniques that can help pinpoint potential problems within a system, using advanced tools and meticulous observation. Proper diagnostic methods not only reveal immediate issues but also help in foreseeing areas that may need attention in the future.

Step-by-Step Visual Inspection

Beginning with a visual inspection is crucial for any assessment. Observing key components for signs of wear, corrosion, or misalignment can reveal essential clues about the system’s condition. A careful examination of all visible areas provides a foundation for more detailed diagnostic steps, setting the stage for identifying both minor and major concerns early.

Electronic Testing for Precision

Utilizing electronic diagnostic tools allows for a deeper analysis of the system’s performance and efficiency. These tools measure various parameters, such as temperature, pressure, and fluid levels, offering valuable data that may not be apparent through visual checks alone. By combining electronic diagnostics with physical inspection, it becomes possible to develop a comprehensive picture of the system’s operational health.

Effective assessment techniques, when applied consistently, enable the identification of potential issues with high accuracy. A detailed diagnostic process minimizes the risk of overlooking critical aspects, ensuring a well-rounded evaluation and facilitating smoother maintenance procedures.

Required Tools for Effective Repair

Efficiently restoring mechanical components to their optimal state demands specific equipment that ensures both precision and safety. The right set of tools is crucial for facilitating each stage of the work, minimizing errors, and enhancing overall workflow. Here, we outline essential instruments that streamline complex processes and maintain the highest standards of quality.

Basic Hand Tools

Basic hand tools are indispensable for almost any maintenance task. A quality socket set and wrench collection allow for precise adjustments and secure handling of various fasteners. In addition, screwdrivers of different sizes and types support both minor and intricate tasks, ensuring a stable and reliable approach to assembly and disassembly.

Specialized Equipment

While standard tools handle general tasks, specialized equipment provides added support for delicate adjustments and inspections. Tools like torque wrenches are essential for setting accurate force levels, preventing component strain. Meanwhile, diagnostic devices assist in identifying any underlying issues, streamlining troubleshooting, and confirming successful adjustments.

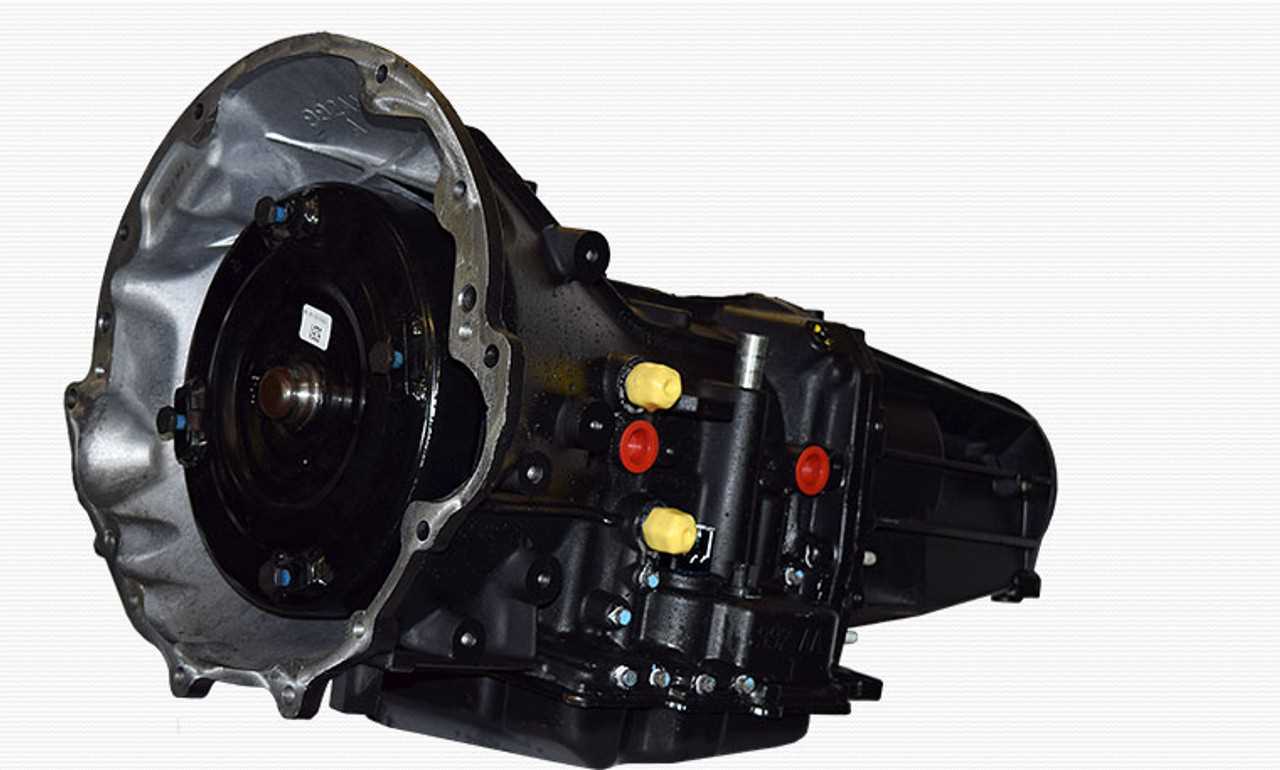

Removing the Transmission Step-by-Step

To successfully detach the powertrain component from the vehicle, a systematic approach is essential. This section outlines the necessary steps to ensure a smooth disassembly process, minimizing the risk of damage and promoting efficiency. Following this guide will aid in achieving a seamless extraction.

1. Preparation: Begin by ensuring the vehicle is on a level surface and securely elevated using jack stands. Disconnect the battery to prevent any electrical mishaps during the procedure.

2. Fluid Drainage: Remove the drain plug and allow the fluid to fully empty from the system into a suitable container. This step is crucial to avoid spills and ensure safety.

3. Disconnecting Components: Detach all necessary components linked to the powertrain, including electrical connections, linkages, and any supporting brackets. Make sure to label each part to facilitate reassembly.

4. Crossmember Removal: Take out the crossmember that supports the assembly. This may require removing bolts or fasteners that secure it in place. Use proper tools to avoid stripping threads.

5. Detachment: Carefully unbolt the assembly from the engine. Ensure that all fasteners are accounted for and removed completely to prevent any obstruction during the lift.

6. Extraction: With assistance, slowly lower the assembly while ensuring it clears any remaining components. Maintain a steady lift to prevent twisting or damage to surrounding parts.

Following these steps will help ensure a safe and efficient extraction process, paving the way for further work on the vehicle.

Inspecting Internal Parts for Wear

Evaluating the internal components of a system is essential for maintaining optimal performance and longevity. Regular assessments can help identify signs of degradation, ensuring timely interventions and preventing further damage. Understanding how to effectively examine these elements is key to achieving reliable operation.

Common Signs of Wear

When inspecting internal components, certain indicators can signal potential issues:

- Visible scratches or scoring on surfaces

- Abnormal discoloration, often indicating overheating

- Loose or misaligned parts

- Excessive play or movement in assemblies

Inspection Process

The following steps outline a systematic approach to evaluating internal elements:

- Begin by disassembling the unit to access the internal parts.

- Carefully clean all components to remove debris and contaminants.

- Examine each piece for signs of wear, focusing on critical areas.

- Measure tolerances with appropriate tools to ensure specifications are met.

- Document findings for future reference and potential follow-up actions.

Cleaning and Reassembling Procedures

This section outlines the essential steps for maintaining the integrity and functionality of the mechanical assembly. Proper cleaning and reassembly are crucial for ensuring optimal performance and longevity of the components involved. Following the outlined procedures will help eliminate contaminants and restore the system to a reliable state.

Begin the process by carefully disassembling the unit, ensuring that all parts are organized systematically. Use suitable cleaning agents to remove grease, dirt, and any residues from the various components. It is important to inspect each part for wear and damage during this stage, as this will determine if replacement is necessary.

| Step | Description |

|---|---|

| 1 | Disassemble the assembly and lay out all parts in an organized manner. |

| 2 | Use appropriate solvents and brushes to clean each component thoroughly. |

| 3 | Inspect parts for signs of damage or wear and replace as needed. |

| 4 | Apply lubricants to necessary surfaces before reassembly. |

| 5 | Reassemble the unit, ensuring all components fit together snugly. |

Final inspection is essential after reassembly to confirm that all parts are functioning correctly. Proper alignment and secure fittings should be checked to prevent future issues. Following these procedures will contribute to the overall efficiency and reliability of the assembly.

Reinstalling the Transmission Correctly

Properly reinstating the powertrain component is crucial for optimal vehicle performance. This process requires careful attention to detail to ensure that all connections and alignments are accurately made. Here are the essential steps to follow for a successful reinstallation:

- Preparation: Before beginning, gather all necessary tools and parts. Ensure that the workspace is clean and organized.

- Alignment: Align the component with the engine. Check that the mounting points are properly positioned.

- Connection: Reconnect all electrical and fluid lines, making sure they are secure and undamaged.

- Fastening: Use the correct torque specifications for bolts and screws to ensure everything is tightened properly.

- Inspection: After the component is in place, inspect all connections again to confirm they are secure.

- Testing: Once reinstallation is complete, start the engine and monitor for any unusual noises or leaks.

Following these steps meticulously will help ensure that the unit functions effectively, contributing to the overall reliability of the vehicle.

Tips for Avoiding Future Problems

To ensure the longevity and optimal performance of your vehicle’s components, it’s crucial to implement preventive measures. Regular maintenance and attention to specific details can significantly reduce the likelihood of encountering issues down the line.

One effective strategy is to establish a consistent maintenance schedule. This practice helps in identifying potential problems before they escalate. Additionally, paying close attention to the signs of wear or irregularities can aid in timely interventions.

| Tip | Description |

|---|---|

| Regular Fluid Checks | Monitor fluid levels regularly to ensure they are within recommended ranges, replacing or topping up as necessary. |

| Routine Inspections | Conduct routine inspections of the system for any visible leaks or damage, addressing issues promptly. |

| Use Quality Components | Opt for high-quality parts and fluids to enhance reliability and performance, minimizing the risk of failures. |

| Professional Servicing | Engage with qualified technicians for servicing to ensure that all procedures are performed correctly and efficiently. |

Maintenance Guide for Longevity

Proper upkeep is essential for ensuring the durability and efficiency of your vehicle’s powertrain components. By following a systematic approach to maintenance, you can significantly extend the lifespan of these crucial systems.

Here are some key practices to maintain optimal performance:

- Regular Fluid Checks: Monitor and replace fluids at recommended intervals to prevent wear and overheating.

- Inspection of Components: Routinely inspect all parts for signs of damage or excessive wear.

- Cleanliness: Keep the surrounding area clean to avoid contamination of vital systems.

- Driving Habits: Adopt smooth driving techniques to reduce stress on mechanical components.

- Timely Repairs: Address any issues immediately to prevent further damage.

Implementing these guidelines can lead to improved performance and a longer operational life for your vehicle’s essential systems.

Testing and Final Adjustments

This section focuses on evaluating the performance of the assembly and ensuring optimal operation. Proper diagnostics and fine-tuning are crucial steps in the overall process, as they help identify any potential issues that may affect functionality.

To achieve reliable performance, follow these key steps:

- Initial Diagnostics: Conduct thorough checks to identify any irregularities.

- Fluid Levels: Ensure that the fluid levels are within the specified range for proper lubrication.

- Pressure Testing: Use a pressure gauge to confirm that the system maintains appropriate pressure during operation.

- Functional Testing: Perform a series of tests to assess shifting quality and responsiveness.

- Final Adjustments: Make necessary calibrations based on diagnostic results to enhance performance.

By diligently following these procedures, one can ensure that the assembly operates smoothly and effectively, minimizing the risk of future complications.