Comprehensive Guide to Repairing the 1999 Ford F350

Maintaining a robust and durable vehicle is essential for ensuring its longevity and optimal performance. This section aims to provide valuable insights into the upkeep of powerful trucks, focusing on various techniques and procedures that can enhance reliability and efficiency.

In this guide, readers will discover essential information on troubleshooting common issues, performing routine inspections, and executing necessary adjustments. Whether you are a seasoned mechanic or a vehicle owner, understanding the nuances of heavy-duty maintenance can empower you to make informed decisions.

Expert tips and practical advice will be shared to help streamline the maintenance process, ensuring that your vehicle remains in peak condition for years to come. Embracing proactive care can lead to significant savings and improved functionality, making this guide a vital resource for any dedicated truck enthusiast.

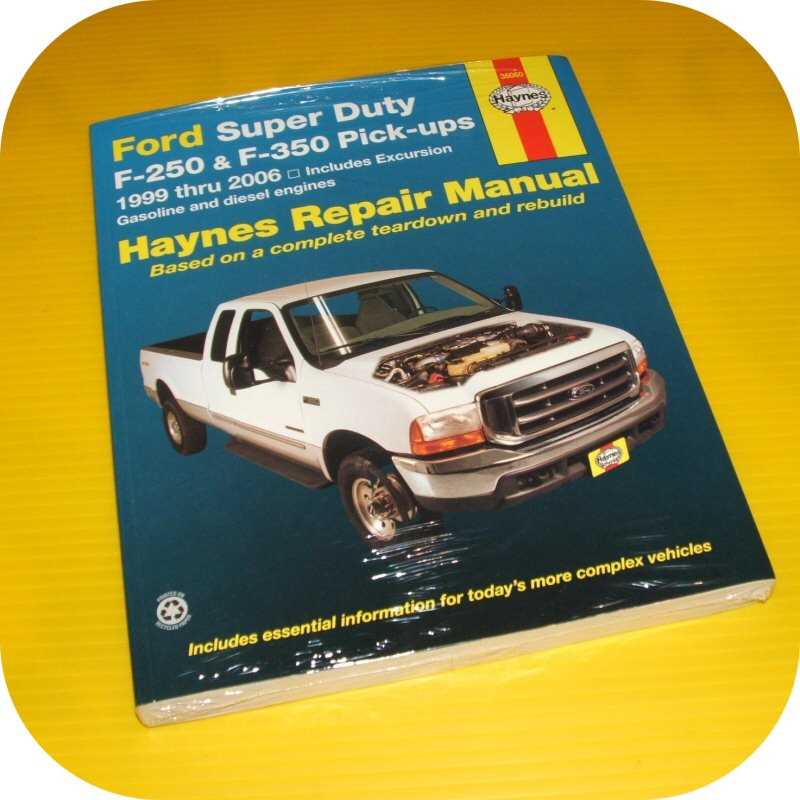

1999 Ford F350 Repair Manual Overview

This section provides a comprehensive look at the guidelines and resources available for maintaining and troubleshooting a heavy-duty vehicle from a specific model year. It serves as a crucial reference for owners and mechanics alike, ensuring that all necessary procedures are followed for optimal performance and longevity.

Key features of this resource include:

- Detailed Instructions: Step-by-step guidance on various maintenance tasks.

- Specifications: Essential technical details that support repairs and upgrades.

- Troubleshooting Tips: Effective solutions for common issues encountered.

- Illustrations: Visual aids to assist in understanding complex processes.

Utilizing this guide effectively can lead to improved reliability and safety for your vehicle.

Common Issues and Solutions

Vehicle maintenance often reveals recurring problems that require attention. Understanding these frequent challenges can help owners address them effectively, ensuring optimal performance and longevity of their automobiles.

Electrical System Failures: A prevalent issue involves electrical components malfunctioning, which may stem from worn-out batteries or faulty connections. Regular inspections and timely replacements can mitigate these problems.

Transmission Problems: Shifting difficulties or unusual noises during gear changes are common. Checking fluid levels and addressing leaks can often resolve these concerns, while comprehensive diagnostics might be necessary for persistent issues.

Cooling System Overheating: Overheating can occur due to a malfunctioning radiator or thermostat. Routine checks of the coolant levels and hoses, along with periodic flushes, help prevent overheating incidents.

Suspension Wear: Deterioration of suspension components can lead to a rough ride and handling issues. Regular inspections and timely replacements of worn parts, such as bushings and shocks, will maintain comfort and safety.

Engine Maintenance Guidelines

Proper upkeep of your vehicle’s powertrain is crucial for optimal performance and longevity. Following systematic procedures can help prevent costly repairs and ensure smooth operation over time.

Routine Inspections

Conduct regular assessments of engine components to identify wear or damage. Check the oil level and quality frequently, and replace filters as needed to maintain cleanliness. Inspect belts and hoses for cracks or leaks, ensuring they are in good condition to prevent breakdowns.

Fluid Management

Keep an eye on all essential fluids, including coolant, transmission fluid, and brake fluid. Regularly topping off and replacing these fluids according to manufacturer recommendations will help sustain engine efficiency and reduce the risk of overheating or other mechanical failures.

Transmission Troubleshooting Techniques

Addressing issues with vehicle gear systems requires a systematic approach. Identifying symptoms accurately is crucial for effective diagnostics. By observing specific behaviors, one can narrow down the potential causes of transmission malfunctions.

Common Symptoms and Their Implications

Unusual noises, slipping gears, or erratic shifting patterns can indicate various underlying problems. For instance, grinding sounds may suggest worn components, while hesitation during acceleration could point to fluid deficiencies or filter blockages.

Diagnostic Steps to Follow

Start by checking the fluid level and condition, as insufficient or contaminated fluid can severely affect performance. If the fluid appears dark or has a burnt smell, a replacement is necessary. Additionally, scanning for error codes using a diagnostic tool can provide insights into electronic issues within the system.

Electrical System Diagnostics

This section focuses on the evaluation and troubleshooting of the electrical system within a vehicle. Proper diagnostics are essential to ensure all components operate efficiently and to identify any underlying issues that may lead to malfunctions.

Common steps in the diagnostic process include:

- Visual Inspection: Examine wiring, connectors, and components for signs of wear, corrosion, or damage.

- Check Power Supply: Use a multimeter to measure voltage at various points in the system, ensuring adequate power is reaching components.

- Test Ground Connections: Verify that ground connections are secure and free of corrosion, as poor grounding can lead to electrical issues.

- Component Testing: Evaluate individual components such as relays, switches, and sensors to determine their functionality.

By following these procedures, technicians can systematically identify and address problems within the electrical system, enhancing vehicle performance and reliability.

Brake System Repair Procedures

This section outlines essential techniques and steps for maintaining and fixing the braking mechanism of heavy-duty vehicles. Proper attention to these procedures ensures safety and optimal performance on the road.

Inspection and Diagnosis

Begin by examining the entire braking system, including pads, rotors, and lines. Look for signs of wear, leaks, or damage. Utilize appropriate tools to assess the condition of components, ensuring they meet manufacturer specifications.

Component Replacement

When replacing worn parts, ensure the new components are compatible with the vehicle’s specifications. Follow the manufacturer’s guidelines for installation, paying close attention to torque settings and alignment. After replacement, bleed the braking system to remove air, which can compromise performance.

Suspension and Steering Insights

This section provides an overview of the key aspects related to the suspension and steering systems in heavy-duty vehicles. Understanding these components is essential for maintaining optimal performance and safety during operation. Properly functioning suspension and steering mechanisms contribute significantly to ride comfort and handling stability.

Regular inspection and maintenance of these systems can prevent costly repairs and enhance vehicle longevity. Below are some vital considerations:

| Component | Function | Maintenance Tips |

|---|---|---|

| Shock Absorbers | Dampen road bumps for a smoother ride. | Check for leaks and replace if worn out. |

| Control Arms | Connect the wheel assembly to the frame. | Inspect for cracks and ensure proper alignment. |

| Steering Rack | Translates steering wheel motion to wheel movement. | Ensure fluid levels are adequate and check for leaks. |

| Ball Joints | Allow for pivoting of the suspension system. | Lubricate regularly and replace if there is play. |

Cooling System Maintenance Tips

Proper upkeep of the cooling system is essential for ensuring optimal engine performance and longevity. Regular maintenance can prevent overheating and costly repairs, ultimately enhancing the vehicle’s efficiency.

Routine Inspections

- Check coolant levels frequently and top off as necessary.

- Inspect hoses for wear, leaks, or cracks, replacing them if needed.

- Examine the radiator for debris and clear any obstructions.

Fluid Management

- Replace coolant according to the manufacturer’s recommended schedule.

- Use the appropriate coolant type to prevent corrosion.

- Flush the cooling system periodically to remove contaminants.

Fuel System Inspection Methods

Evaluating the integrity and functionality of the fuel system is crucial for ensuring optimal performance. Proper inspection methods allow for the identification of potential issues before they escalate, contributing to the overall reliability of the vehicle.

Visual Inspection

A thorough visual assessment can reveal signs of wear, leaks, or damage in fuel lines, filters, and injectors. Look for cracks, corrosion, or any unusual staining around connections that may indicate fuel seepage.

Pressure Testing

Conducting a pressure test is essential to ascertain the system’s ability to maintain the required pressure levels. Utilize a gauge to measure pressure at various points, ensuring that it aligns with manufacturer specifications. Abnormal readings may signify blockages or failing components.

Bodywork and Paint Repairs

Maintaining the exterior of a vehicle is essential for both aesthetics and longevity. Addressing issues such as dents, scratches, and corrosion can enhance the overall appearance while preventing further damage. This section provides an overview of techniques and materials used in restoring body panels and applying finishes.

Assessing Damage

Begin by evaluating the extent of the damage. Look for surface imperfections and structural issues. Minor scratches may only require polishing, while deeper dents might necessitate more extensive intervention. Documenting the condition helps in planning the repair process effectively.

Tools and Materials

Gather essential tools such as sanders, fillers, and paint sprayers. Quality materials are crucial; using the right primer, paint, and clear coat ensures a durable finish. Always choose products compatible with the vehicle’s existing paint to achieve a seamless look.

Repair Techniques

For small dents, consider using a heat source and a plunger to pull the dent out. Larger damages might require cutting and welding new metal. After preparing the surface by sanding and applying filler, smooth it out before applying primer. Follow up with paint, ensuring even layers for optimal coverage.

Final Touches

Once the paint has dried, apply a clear coat to protect the finish. Buffing and polishing will help achieve a glossy appearance. Regular maintenance, including washing and waxing, will prolong the life of the repairs and keep the vehicle looking new.

Wiring Diagrams and Schematics

Understanding the electrical layout of a vehicle is essential for effective troubleshooting and repair. This section delves into the various wiring diagrams and schematics that illustrate the connections and components within the electrical system. These visual guides provide critical insights for anyone looking to diagnose issues or perform modifications.

Importance of Accurate Diagrams

Accurate wiring diagrams are crucial for identifying the specific locations of wires, connectors, and electrical components. By following these diagrams, technicians can ensure that repairs are conducted correctly, minimizing the risk of errors that could lead to further complications.

Types of Schematics

There are several types of schematics used in automotive applications, including block diagrams, circuit diagrams, and wiring layouts. Each type serves a different purpose, offering varying levels of detail. Block diagrams provide a high-level overview, while circuit diagrams detail individual components and their connections. Understanding these distinctions can enhance the effectiveness of repair and maintenance efforts.

Owner’s Experience and Recommendations

This section provides insights from individuals who have extensive interaction with a specific heavy-duty vehicle model. Their experiences encompass maintenance routines, performance insights, and essential tips for prospective owners. Sharing these anecdotes can greatly enhance understanding and facilitate better ownership experiences.

Common Issues and Solutions

Owners often encounter similar challenges with their vehicles. Addressing these concerns promptly can prolong the lifespan and improve functionality. Here are some frequent issues along with practical solutions:

| Issue | Recommended Solution |

|---|---|

| Engine Overheating | Regularly check coolant levels and inspect hoses for leaks. |

| Brake Wear | Monitor brake pads frequently and replace them when necessary. |

| Electrical Problems | Ensure connections are tight and inspect for corroded terminals. |

Maintenance Tips

Regular upkeep is crucial for optimal performance. Here are some recommended practices:

- Perform oil changes every 5,000 miles to maintain engine health.

- Rotate tires regularly to ensure even wear.

- Keep the exterior clean to prevent rust and corrosion.