Guide to Repairing Focus ST

Maintaining a high-performance automobile requires a deep understanding of its components and systems. This guide aims to provide essential insights and practical advice for enthusiasts and owners alike, enabling them to troubleshoot issues effectively and ensure longevity for their vehicles. Knowledge about the intricate workings of the car can lead to improved performance and a smoother driving experience.

In this section, you will find detailed information designed to assist you in addressing common challenges. From basic upkeep to more complex repairs, the insights shared here will empower you to take control of your automotive needs. With the right approach and resources, you can navigate any situation with confidence.

Understanding the intricacies of your vehicle not only enhances its performance but also fosters a sense of connection between you and your machine. Embracing this journey of knowledge will undoubtedly lead to a more enjoyable driving experience and better management of your automobile.

This section delves into the essential parts of an automobile’s propulsion system. By gaining insight into these elements, one can better appreciate how they work together to ensure optimal performance. Each component plays a vital role in the overall functionality, contributing to the efficiency and power of the vehicle.

Key Components of the Engine

- Engine Block: The core structure housing most of the engine’s components.

- Pistons: Cylindrical pieces that move up and down to convert fuel energy into mechanical power.

- Crankshaft: A rotating shaft that translates linear motion from the pistons into rotational motion.

- Camshaft: Controls the timing of the valve openings and closings, playing a crucial role in the intake and exhaust processes.

- Valves: Allow air and fuel into the combustion chamber and exhaust gases out.

The Importance of Proper Maintenance

Regular upkeep of these components is essential for ensuring the longevity and efficiency of the propulsion system. Neglecting any part can lead to reduced performance and increased wear. Understanding how each piece functions aids in identifying potential issues before they escalate.

- Monitor oil levels to ensure proper lubrication.

- Inspect belts and hoses for wear and tear.

- Keep the cooling system in check to prevent overheating.

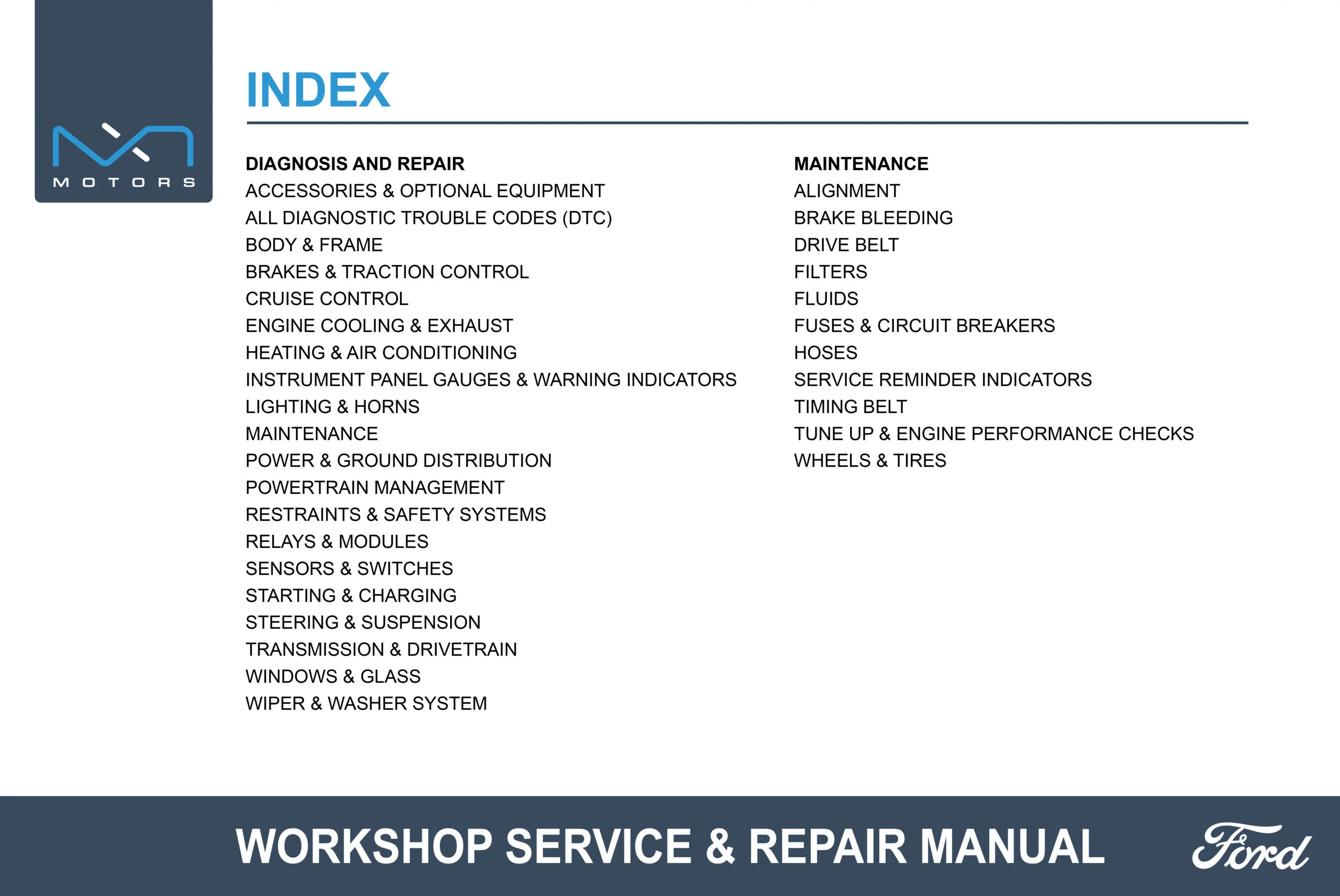

Electrical System Troubleshooting Tips

Tackling issues within the electrical system can be a daunting task, but with a methodical approach, you can identify and resolve many common problems. A thorough understanding of the various components and their functions will assist you in diagnosing issues effectively.

Begin by checking the power source to ensure it is functioning correctly. If electrical components are unresponsive, inspect fuses and circuit breakers, as these can often be the culprits behind a lack of power. Next, examine connections and wiring for signs of wear, corrosion, or loose connections. Poor connectivity can lead to inconsistent performance.

Utilizing a multimeter can significantly aid in your troubleshooting efforts. This device allows you to measure voltage, current, and resistance, helping you pinpoint where the malfunction may be occurring. Additionally, consulting a wiring diagram can provide valuable insights into the correct configurations and help you identify any discrepancies.

Finally, when addressing electronic components, consider their operational integrity. Components such as sensors and relays should be tested for functionality to ensure they are not contributing to the problem. By following these guidelines, you can systematically troubleshoot and restore optimal performance to the electrical system.

Brake System Repair Procedures

This section outlines the essential steps and guidelines for addressing issues within the braking system. Proper attention to this critical component ensures vehicle safety and optimal performance.

General Inspection Steps

- Begin with a visual inspection of the entire braking assembly.

- Check for signs of wear, corrosion, or leakage in brake lines.

- Inspect brake pads and rotors for thickness and surface condition.

- Ensure that the brake fluid level is adequate and free from contamination.

Replacement Procedures

- Lift the vehicle securely and remove the wheel to access the braking components.

- Detach the caliper from the bracket, taking care not to damage the brake line.

- Replace worn brake pads and inspect rotors for any necessary resurfacing.

- Reassemble all components, ensuring that all fasteners are tightened to manufacturer specifications.

- Lower the vehicle and pump the brakes to ensure proper pressure before road testing.

Suspension System Adjustment Guide

This section provides insights into optimizing the performance of your vehicle’s suspension system. Proper alignment and adjustments can significantly enhance handling, comfort, and safety on the road. Understanding the key aspects of this system allows for effective modifications that cater to your driving needs.

Key Adjustment Techniques

When it comes to fine-tuning the suspension, several methods can be employed. These include adjusting the ride height, camber, and toe settings. Each adjustment influences the vehicle’s stability and responsiveness, making it essential to follow guidelines for accurate results.

Importance of Regular Checks

Regular maintenance and assessment of the suspension components are crucial for ensuring optimal performance. By routinely checking for wear and tear, drivers can prevent potential issues that may arise from neglecting these critical parts.

Transmission Maintenance and Repair

Proper upkeep of your vehicle’s transmission system is essential for ensuring smooth operation and longevity. This component plays a crucial role in transferring power from the engine to the wheels, making its maintenance vital for overall performance. Regular checks and timely interventions can prevent major issues and costly fixes down the line.

Regular Inspection

Conducting periodic inspections is a key step in maintaining your transmission. Look for signs of fluid leaks, unusual noises, or changes in shifting behavior. Monitoring fluid levels and condition helps identify potential problems early. Ensuring that the transmission fluid is clean and at the appropriate level can enhance the system’s efficiency and lifespan.

Fluid Changes

Changing the transmission fluid at recommended intervals is crucial for optimal performance. Over time, the fluid can degrade and accumulate contaminants, which may hinder its effectiveness. Fresh fluid not only ensures smoother operation but also protects internal components from wear and tear, contributing to a healthier system overall.

Regular Service Checks and Intervals

Maintaining a vehicle requires consistent attention to various components to ensure optimal performance and longevity. Scheduling regular assessments helps identify potential issues before they escalate, promoting safety and reliability.

It’s essential to adhere to a structured timeline for these evaluations. Here are common intervals for essential checks:

- Engine oil change: every 5,000 to 7,500 miles

- Air filter replacement: every 15,000 to 30,000 miles

- Tire rotation: every 5,000 to 7,500 miles

- Brake inspection: every 10,000 miles

- Fluid levels check: every 3,000 miles

These guidelines can vary based on driving conditions and vehicle usage. It’s advisable to consult the specific recommendations tailored for your model to optimize performance.

In addition to scheduled services, certain signs may indicate the need for immediate attention:

- Unusual noises from the engine

- Warning lights on the dashboard

- Decreased fuel efficiency

- Vibrations while driving

Proactive measures and timely interventions can significantly enhance the overall driving experience and extend the life of your vehicle.