Comprehensive Guide to Iseki Tractor Repair Manuals

In the world of agricultural equipment, understanding the intricacies of machinery is essential for optimal performance and longevity. Every operator knows that even the most reliable machines can encounter challenges that require skilled intervention. This section delves into the resources available for troubleshooting and enhancing the functionality of various vehicles designed for farming tasks.

These invaluable resources offer detailed insights into common issues and their resolutions, empowering users to take charge of maintenance and care. By equipping oneself with the right knowledge, operators can ensure that their equipment remains in peak condition, ultimately enhancing productivity and reducing downtime.

Moreover, the availability of these comprehensive guides encourages a proactive approach to machinery care. With a thorough understanding of the systems at play, users can implement effective solutions and make informed decisions, fostering a deeper connection with their equipment and promoting its efficiency.

Iseki Tractor Repair Manuals Overview

This section provides a comprehensive look at the essential resources for maintaining and troubleshooting agricultural machinery. These guides are invaluable for operators and technicians alike, offering detailed insights into the workings and upkeep of these vital machines.

Understanding the Importance

Having access to thorough documentation ensures that users can effectively manage their equipment. Such resources typically cover various aspects, from routine maintenance to complex problem-solving techniques, thereby enhancing operational efficiency.

Contents and Features

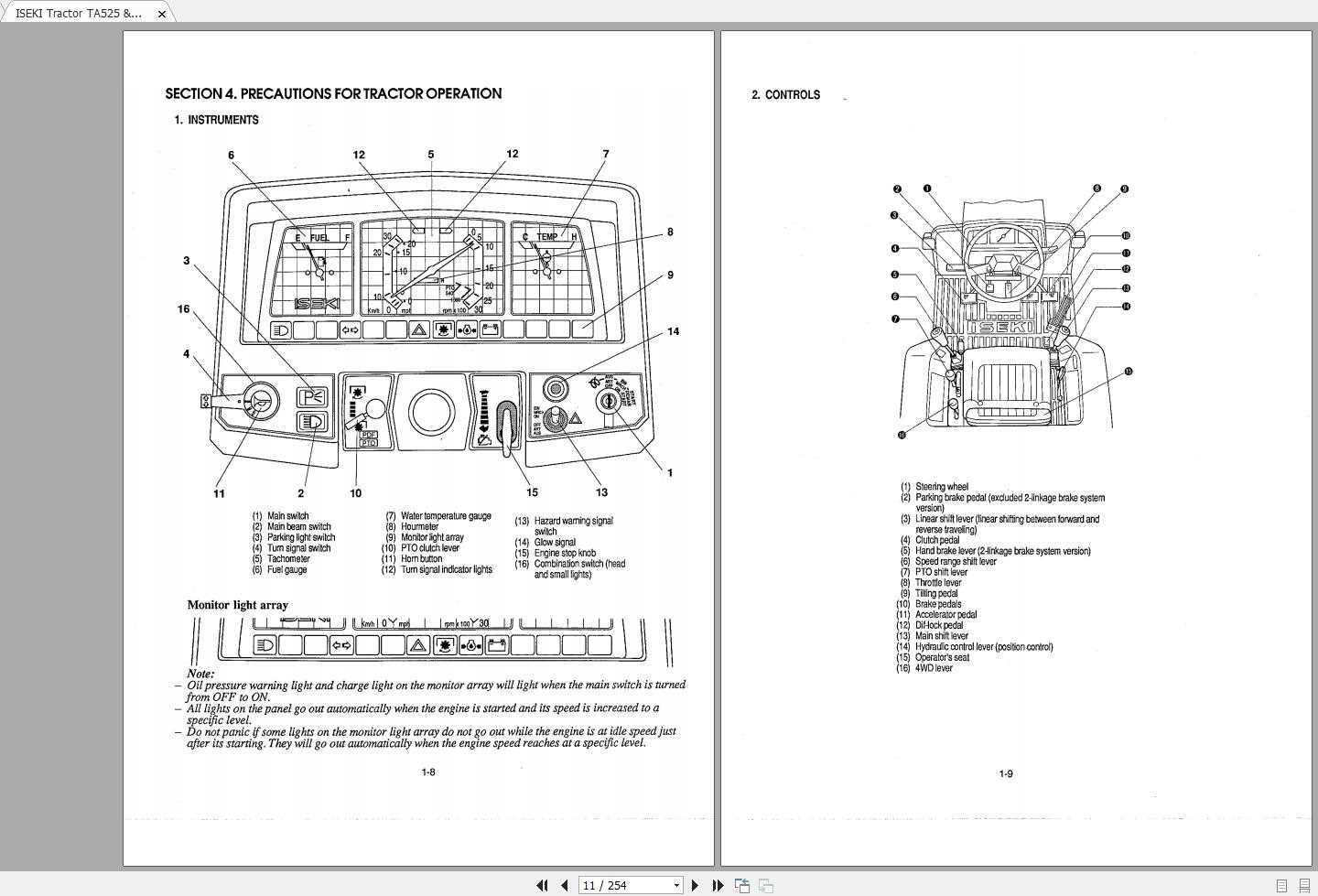

These resources often include schematics, parts lists, and step-by-step instructions. Users can find information on everything from engine specifications to hydraulic systems, facilitating a deeper understanding of the machinery and its components.

Benefits of Using These Resources

Utilizing these guides can significantly reduce downtime and repair costs. Knowledgeable operators can quickly identify issues and perform necessary actions, promoting better performance and longevity of the equipment.

In conclusion, investing time in familiarizing oneself with these essential documents can lead to more productive and efficient use of agricultural machinery.

Understanding Iseki Tractor Models

When exploring various agricultural machinery, it’s essential to recognize the unique features and specifications of each model. Different variants are designed to meet specific operational needs, providing a range of functionalities that cater to diverse farming practices. Grasping the distinctions among these machines can significantly enhance efficiency and productivity on the field.

Each model boasts its own set of characteristics, including engine capacity, horsepower, and size, which influence performance. Some units are engineered for compact spaces, while others excel in larger agricultural environments. Familiarizing oneself with these attributes allows operators to select the most suitable machine for their tasks, ultimately improving the overall workflow.

Moreover, understanding the lineage of these machines can provide insights into their evolution and technological advancements. This knowledge not only aids in making informed decisions but also enhances maintenance practices, ensuring longevity and optimal functionality. Thus, a thorough comprehension of the various models can lead to better resource management and operational success.

Importance of Repair Manuals

Understanding the significance of instructional resources is crucial for maintaining and servicing machinery effectively. These resources provide detailed guidance that ensures proper functionality and longevity of equipment.

- Comprehensive Guidance: Detailed instructions help users navigate complex procedures with ease.

- Preventive Maintenance: Regular reference to these documents aids in identifying potential issues before they escalate.

- Cost Efficiency: By following expert recommendations, users can minimize repair costs and avoid unnecessary expenditures.

- Safety Protocols: Instructions often include essential safety measures, protecting users from potential hazards during operation.

Utilizing these resources empowers individuals to undertake tasks with confidence, fostering a deeper understanding of their equipment and enhancing overall performance.

- Increased Lifespan: Proper upkeep based on expert insights can significantly extend the working life of machinery.

- Skill Development: Familiarity with these documents improves technical skills and problem-solving abilities.

In conclusion, having access to reliable instructional materials is vital for anyone involved in the upkeep of machinery, ensuring optimal operation and reliability over time.

Common Issues with Iseki Tractors

When it comes to agricultural machinery, operators often encounter a variety of challenges that can impact performance and efficiency. Understanding these common problems is crucial for effective management and longevity of the equipment.

Engine Performance: One of the frequent concerns relates to engine functionality. Issues such as poor starting, stalling, or reduced power output can stem from fuel contamination or air filter blockages. Regular checks and maintenance can mitigate these problems.

Hydraulic System Failures: The hydraulic system is essential for various operations. Common issues include leaks or unresponsive controls, which can result from worn seals or low fluid levels. Timely inspection and fluid replacement are key to maintaining optimal performance.

Electrical Problems: Electrical components may malfunction, leading to issues like failure to start or inconsistent lighting. This often arises from corroded connections or a weak battery. Ensuring clean and secure connections can prevent these disruptions.

Transmission Troubles: Operators might experience difficulties with gear shifting or unusual noises. These issues could be caused by low transmission fluid or worn gears. Regular fluid checks and timely servicing are important for smooth operation.

By being aware of these prevalent challenges, operators can take proactive measures to ensure the smooth functioning of their machinery, ultimately enhancing productivity in their agricultural endeavors.

How to Obtain Repair Manuals

Accessing essential documentation for machinery maintenance can significantly enhance operational efficiency. These resources often contain vital information for troubleshooting and servicing equipment effectively.

Online Resources

- Official Manufacturer Websites

- Online Marketplaces

- Specialized Forums

Local Options

- Dealerships

- Repair Shops

- Library Archives

Utilizing a combination of these sources can ensure you find comprehensive guides tailored to your needs.

Step-by-Step Repair Procedures

This section provides a detailed approach to addressing issues in agricultural machinery. By following a systematic method, users can effectively troubleshoot and resolve problems, ensuring optimal functionality and longevity of their equipment. Each phase is designed to simplify the process and enhance understanding.

Initial Assessment

Begin by conducting a thorough examination of the machinery. Identify any visible signs of wear or damage, such as leaks or unusual noises. Gather necessary tools and safety equipment before proceeding to avoid any accidents during the process.

Detailed Repair Process

Once the assessment is complete, move on to the specific steps needed for fixing the identified issues. Refer to appropriate resources for guidance on disassembly and reassembly. Always document each stage of the process to ensure nothing is overlooked. Regular maintenance checks can prevent future complications.

Tools Needed for Repairs

When tackling maintenance tasks on agricultural machinery, having the right equipment is essential for efficiency and effectiveness. The right tools can make complex jobs simpler, ensuring that everything runs smoothly and reliably.

Essential Tools

To begin with, it’s important to gather the fundamental instruments that will help you with various tasks. Here are some of the key items you should have in your toolkit:

| Tool | Purpose |

|---|---|

| Wrenches | For loosening or tightening bolts and nuts. |

| Screwdrivers | To drive screws into or out of components. |

| Pliers | For gripping, twisting, and cutting wire. |

| Socket Set | For accessing hard-to-reach fasteners. |

| Jack Stands | To support the machine safely while working underneath. |

Specialized Instruments

In addition to the basic tools, certain specialized instruments can enhance your ability to perform specific tasks. These might include:

| Tool | Purpose |

|---|---|

| Torque Wrench | To ensure fasteners are tightened to the correct specification. |

| Multimeter | For diagnosing electrical issues. |

| Compression Tester | To evaluate engine performance. |

| Diagnostic Scanner | For reading error codes and troubleshooting electronic systems. |

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended lifespan and optimal performance of any machinery. Regular attention to key components not only enhances efficiency but also minimizes the risk of unexpected failures. Implementing a structured maintenance routine can lead to significant savings and improved functionality over time.

Regular Inspections

Conducting frequent evaluations of all essential parts is crucial. Look for signs of wear, corrosion, or leaks that may indicate underlying issues. Pay special attention to hydraulic systems, belts, and filters, as these elements are vital for smooth operation. Catching problems early can prevent costly repairs in the future.

Fluid Checks and Changes

Maintaining proper fluid levels is vital for optimal performance. Regularly check engine oil, hydraulic fluid, and coolant levels, and replace them according to the manufacturer’s recommendations. Using high-quality fluids can greatly enhance reliability and performance, providing necessary lubrication and cooling during operation.

Parts Replacement Guidelines

Replacing components in machinery is essential for maintaining optimal performance and longevity. Following a systematic approach can enhance efficiency and minimize the risk of errors during the process. This section provides essential steps and considerations to ensure successful part exchanges.

- Identify the Component: Clearly ascertain which part requires replacement. Review any visible signs of wear or damage.

- Obtain the Correct Replacement: Use reputable suppliers to source parts that match specifications. Verify compatibility with your equipment.

- Prepare the Workspace: Organize your tools and ensure a clean area to facilitate a smooth replacement process. Safety gear should be worn at all times.

When executing the replacement, follow these key steps:

- Power Down: Ensure the machinery is powered off and secure to prevent accidental operation.

- Disassemble: Carefully remove the damaged component, taking note of how it is connected to avoid mistakes when reassembling.

- Install the New Part: Position the new component accurately, ensuring all connections align properly.

- Test Functionality: Once installed, run a thorough check to confirm that the new part operates as expected.

Regular maintenance and timely replacement of worn parts can significantly extend the life of your machinery. Keep records of all replacements for future reference and optimal operational planning.

Safety Precautions During Repairs

Ensuring safety is paramount when working on machinery. Proper precautions not only protect the individual performing maintenance but also contribute to the longevity of the equipment. Following a few essential guidelines can significantly reduce the risk of accidents and injuries.

Personal Protective Equipment (PPE) is essential. Always wear appropriate gear, such as gloves, goggles, and steel-toed boots. This equipment serves as a barrier against potential hazards, including sharp objects, chemical exposure, and heavy components.

Before starting any work, disconnect power sources. Ensure that all energy sources, including batteries and fuel lines, are turned off or disconnected. This step prevents accidental activation, which could lead to severe injuries.

Work in a well-ventilated area. Adequate airflow is crucial, especially when dealing with chemicals or solvents that may emit harmful fumes. Proper ventilation helps minimize inhalation risks and ensures a safer working environment.

Maintain a clean workspace. Clutter can lead to trips and falls, which are common causes of injuries. Keeping tools organized and the area tidy enhances focus and reduces the likelihood of accidents.

Lastly, always have a first aid kit on hand. Being prepared for emergencies is vital. Regularly check the kit to ensure all supplies are available and in good condition.

Troubleshooting Electrical Systems

Diagnosing issues within electrical systems can be a complex task that requires a systematic approach. Understanding the components involved and the typical symptoms of failure is crucial for effective resolution. This section will guide you through common problems and solutions, ensuring reliable functionality in your machinery.

Common Symptoms and Causes

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| No power | Dead battery | Check battery charge and connections |

| Flickering lights | Loose wiring | Inspect and secure all connections |

| Starter not engaging | Faulty solenoid | Test solenoid and replace if necessary |

| Blown fuses | Short circuit | Identify and repair short before replacing fuses |

Testing Procedures

Utilizing the right tools is essential for diagnosing electrical faults. Multimeters, test lights, and circuit testers are invaluable for measuring voltage, continuity, and resistance. Begin by checking the voltage at the battery terminals, then follow the circuit path to locate the source of the issue. Ensure all connections are clean and secure, as corrosion can lead to unreliable performance.

FAQs About Iseki Repair Manuals

This section addresses common inquiries regarding maintenance guides for various agricultural machinery. Understanding these documents can enhance performance and longevity, ultimately leading to efficient operation.

What types of information are included?

Typically, these guides encompass troubleshooting steps, parts lists, and detailed instructions for upkeep. Comprehensive insights are crucial for ensuring that machinery operates smoothly and effectively.

How can I obtain a copy?

Copies are often available through authorized distributors or online platforms. It’s essential to ensure you have the correct version for your specific model to delve into accurate details.

Resources for Further Learning

Expanding your knowledge in machinery maintenance and troubleshooting can greatly enhance your skills and efficiency. A variety of resources are available to help you deepen your understanding and improve your hands-on capabilities.

- Online Courses: Numerous platforms offer structured programs focusing on mechanical systems and maintenance techniques. These can provide both theoretical and practical insights.

- Workshops and Seminars: Attending local workshops or seminars can offer hands-on experience and direct interaction with experts in the field.

- Books and Publications: A range of literature is available, covering various aspects of equipment maintenance, troubleshooting techniques, and innovations in machinery.

- Forums and Online Communities: Engaging with online groups can facilitate knowledge exchange, where enthusiasts and professionals share tips and solutions.

- Manufacturer Resources: Many companies provide resources such as videos, articles, and FAQs that can help you understand specific models and systems.

Utilizing these resources can empower you to become more proficient in machinery upkeep and enhance your overall expertise.