Comprehensive Guide to Repairing the 1966 Chevy Truck

For enthusiasts and owners of vintage automobiles, having access to a comprehensive guide is essential for ensuring the longevity and performance of their prized possessions. This section provides detailed insights into the intricacies of maintenance and troubleshooting for a specific era of automotive engineering.

Understanding the mechanics and design principles of these classic vehicles can significantly enhance the restoration process. Each component plays a vital role in the overall functionality, and knowledge of their specifications can aid in making informed decisions during refurbishment.

Whether you’re embarking on a complete overhaul or addressing specific issues, having a thorough reference can streamline your efforts. From basic upkeep to complex repairs, this guide aims to empower you with the necessary information to preserve the charm and reliability of your classic ride.

Overview of the 1966 Chevy Truck

This section provides an insight into a classic vehicle renowned for its reliability and performance. It stands out for its robust construction and timeless design, appealing to enthusiasts and collectors alike.

Key features include:

- Durable frame designed for heavy-duty use.

- Variety of engine options to suit different preferences.

- Iconic styling that reflects mid-20th century automotive design.

In terms of functionality, this model is celebrated for:

- Exceptional towing capacity, making it suitable for various tasks.

- Comfortable interior that caters to both work and leisure activities.

- Easy maintenance, contributing to its longevity and usability.

Overall, this vehicle combines practicality with a nostalgic appeal, making it a beloved choice for many. Its rich history and enduring popularity continue to capture the attention of automotive enthusiasts around the world.

Common Issues with Classic Models

Classic vehicles often present a unique set of challenges that enthusiasts and owners must navigate. Over the years, wear and tear can lead to various complications that may affect performance, reliability, and overall enjoyment of these beloved machines.

One prevalent concern is the deterioration of rubber components, which can lead to leaks and compromised functionality. Seals, hoses, and gaskets are particularly vulnerable to age and environmental factors, necessitating regular inspection and replacement.

Additionally, electrical systems in older models may exhibit issues due to outdated wiring or connections. Poor grounding and corroded terminals can cause erratic behavior, making troubleshooting essential for maintaining optimal performance.

Furthermore, fuel delivery problems are common, as older engines rely on carburetors that can become clogged or misadjusted over time. Ensuring proper fuel flow and air mixture is crucial for engine efficiency and longevity.

Lastly, the suspension system often experiences wear, affecting ride quality and handling. Regular checks and necessary adjustments can help restore comfort and safety, making these classic vehicles enjoyable to drive once again.

Essential Tools for Repairs

When it comes to maintaining and restoring classic vehicles, having the right equipment is crucial for efficient work. A well-equipped toolkit not only enhances the repair process but also ensures that tasks are completed safely and effectively. Below are some of the fundamental tools that every enthusiast should consider having on hand.

| Tool | Purpose |

|---|---|

| Wrenches | Used for loosening and tightening nuts and bolts. |

| Screwdrivers | Essential for fastening and unfastening screws in various parts. |

| Pliers | Handy for gripping, twisting, and cutting wires or components. |

| Jack and Stands | Necessary for lifting the vehicle to access the underside safely. |

| Multimeter | Useful for diagnosing electrical issues and measuring voltage. |

| Socket Set | Provides versatility for working with different sizes of fasteners. |

| Torque Wrench | Ensures fasteners are tightened to the correct specifications. |

Engine Maintenance Tips and Tricks

Proper care of your vehicle’s power unit is essential for ensuring its longevity and optimal performance. Regular attention to key components can prevent issues and enhance efficiency, allowing for a smoother driving experience.

1. Regular Oil Changes: Changing the lubricant at recommended intervals is crucial. Fresh oil minimizes friction and helps keep the internal components clean.

2. Monitor Fluid Levels: Keep an eye on all essential fluids, including coolant and transmission fluid. Maintaining appropriate levels ensures the system operates smoothly and reduces the risk of overheating.

3. Inspect Belts and Hoses: Regularly check for signs of wear, such as cracks or fraying. Replacing old components before they fail can save you from unexpected breakdowns.

4. Keep the Air Filter Clean: A clean air intake filter allows for better airflow, which is vital for optimal combustion. Replace it regularly to maintain efficiency.

5. Check Spark Plugs: Worn or dirty spark plugs can lead to poor performance and decreased fuel efficiency. Regular inspection and replacement when necessary are recommended.

6. Battery Maintenance: Ensure your battery terminals are clean and free of corrosion. Testing the battery regularly can prevent starting issues.

Implementing these practices will not only enhance the performance of your vehicle’s engine but also extend its lifespan, ensuring a reliable and enjoyable ride for years to come.

Transmission Care and Adjustments

Maintaining the functionality and longevity of your vehicle’s transmission system is crucial for optimal performance. Regular attention to this component ensures smooth operation and helps prevent more significant issues down the line. This section outlines essential practices for proper upkeep and necessary adjustments.

Regular Maintenance Practices

Routine inspections are vital for identifying potential problems early. Check fluid levels frequently and replace any contaminated fluid as needed. Keeping the transmission cool is also important; ensure that the cooling system is functioning properly. Additionally, pay attention to any unusual noises or shifting issues that may indicate the need for further examination.

Adjustments for Optimal Performance

Fine-tuning the transmission can enhance responsiveness and efficiency. Begin by checking the shift linkage to ensure it is properly aligned. Adjusting the throttle position sensor may also improve shift quality. If your vehicle features a modular transmission, consider recalibrating the electronic controls to match performance specifications.

In conclusion, regular maintenance and timely adjustments are key to ensuring the reliability and efficiency of your vehicle’s transmission system. Following these guidelines will help maintain peak performance and extend the lifespan of this crucial component.

Brake System Troubleshooting Guide

This section provides essential guidance for diagnosing issues within the braking mechanism of your vehicle. Understanding the common problems that can affect braking performance is crucial for maintaining safety and reliability.

Common Symptoms and Causes

Identifying the signs of braking issues can help you pinpoint the underlying causes. Below is a table summarizing typical symptoms and their possible origins:

| Symptom | Possible Cause |

|---|---|

| Poor braking response | Worn brake pads or low fluid level |

| Squeaking or grinding noise | Worn brake pads or damaged rotors |

| Brake pedal feels soft | Air in the brake lines or fluid leaks |

| Vehicle pulls to one side when braking | Uneven brake wear or malfunctioning caliper |

Troubleshooting Steps

To effectively address the identified symptoms, follow these troubleshooting steps:

- Inspect brake fluid levels and top up if necessary.

- Examine brake pads for wear and replace if they are below the recommended thickness.

- Check for any visible leaks in the brake lines or around the master cylinder.

- Test the braking system by pressing the pedal and observing the vehicle’s response.

Electrical System Diagnostics Explained

Understanding the intricacies of a vehicle’s electrical system is essential for effective troubleshooting and maintenance. This section delves into the methodologies employed to identify and resolve issues that may arise within these complex circuits. By recognizing the symptoms and utilizing appropriate diagnostic tools, one can effectively restore functionality and enhance performance.

Common Symptoms of Electrical Issues

Several indicators may suggest problems within the electrical framework. These can range from erratic behavior of components to complete failures. Recognizing these signs early can prevent further complications and costly repairs.

| Symptom | Possible Cause |

|---|---|

| Dim or Flickering Lights | Weak battery or poor connections |

| Electrical Components Not Functioning | Blown fuses or faulty switches |

| Battery Drain | Short circuits or parasitic draws |

Diagnostic Tools and Techniques

Utilizing the right diagnostic instruments is crucial in pinpointing electrical problems. Multimeters, oscilloscopes, and circuit testers are invaluable in assessing voltage levels, current flow, and resistance. Following a systematic approach helps in isolating the fault and implementing effective solutions.

Bodywork Repair Techniques

When it comes to maintaining the exterior of a vehicle, various methods can be employed to ensure a flawless finish and structural integrity. Mastering these techniques can significantly enhance the aesthetic appeal and longevity of any automobile.

Common Techniques

Among the most frequently used approaches are dent removal and panel alignment. Dent removal can be achieved through methods such as heating and cooling, or by using specialized tools to gently massage the metal back into its original shape. For panel alignment, precise adjustments are crucial to achieving uniform gaps and a seamless look.

Finishing Touches

Once the structural work is complete, applying a protective coating is essential. Primers and paints not only enhance the visual appeal but also safeguard against environmental elements. Additionally, regular maintenance of the finish can prevent rust and other forms of degradation, ensuring the vehicle remains in prime condition.

Restoration Process for Vintage Trucks

Restoring classic vehicles is a rewarding endeavor that not only brings old machines back to life but also preserves their history and charm. This process involves various stages that require patience, skill, and attention to detail.

The following steps outline the essential phases of restoration:

- Assessment:

Begin by thoroughly examining the vehicle. Identify areas that need repair and determine the overall condition.

- Planning:

Create a detailed plan that outlines the restoration goals, budget, and timeline. This will serve as a roadmap throughout the project.

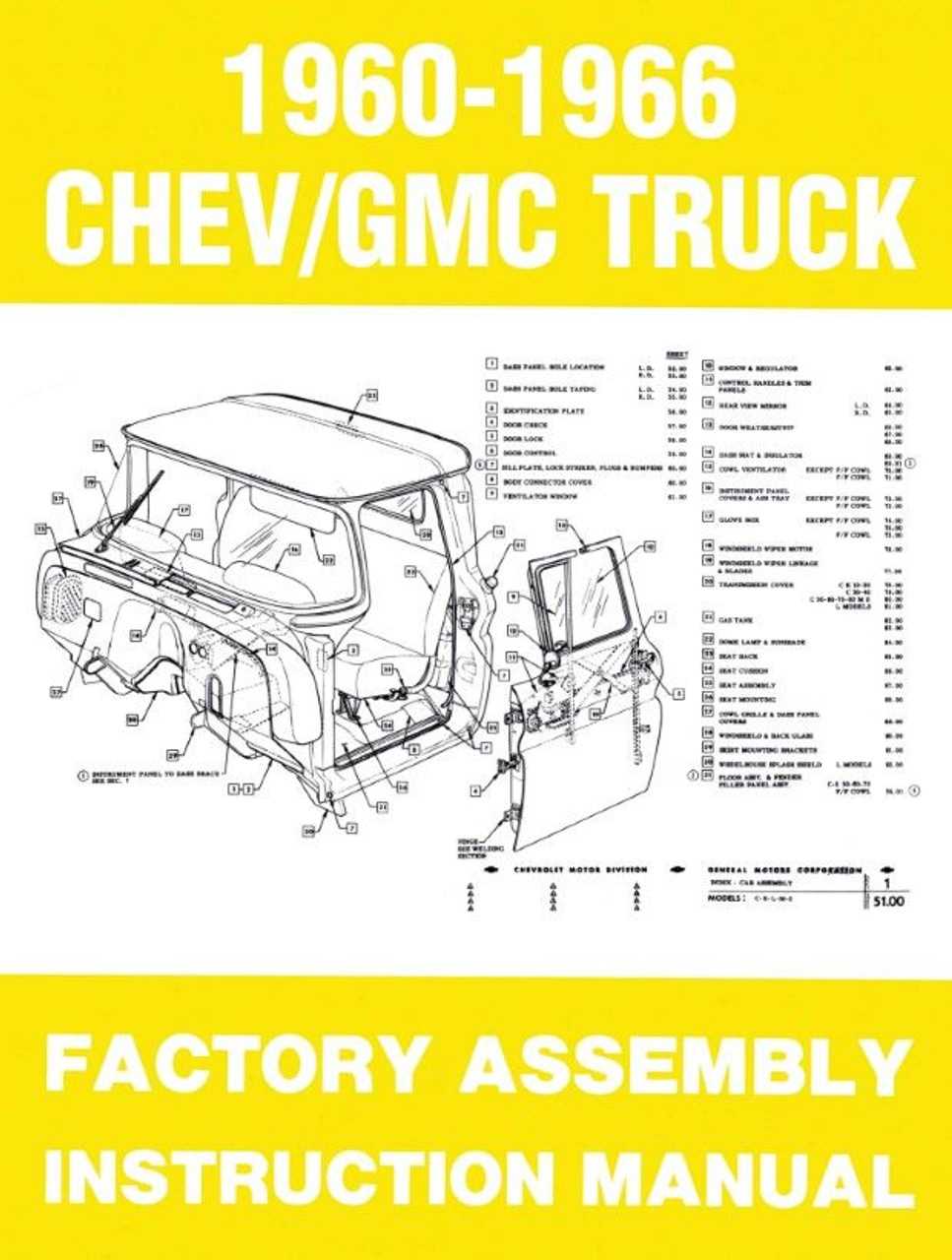

- Disassembly:

Carefully disassemble the vehicle, taking note of how parts are arranged. Documenting this process helps during reassembly.

- Repair and Replacement:

Address any damaged components. This may include welding, bodywork, or replacing parts that are beyond repair.

- Painting:

Once repairs are completed, apply paint. Choose a color that reflects the vehicle’s era or enhances its aesthetic appeal.

- Reassembly:

Put all components back together, following the documentation created during disassembly. Ensure everything is aligned and functions correctly.

- Final Touches:

Inspect the completed restoration for any imperfections. Add finishing touches such as detailing and polishing to enhance the overall look.

With dedication and effort, restoring classic vehicles can lead to a beautiful end product that stands as a testament to craftsmanship and automotive history.

Choosing Replacement Parts Wisely

Selecting suitable components for vehicle maintenance is crucial for ensuring optimal performance and longevity. It is essential to consider factors such as compatibility, quality, and reliability when sourcing alternatives. Making informed choices can significantly impact overall functionality and prevent future issues.

Firstly, verify that the components are compatible with the specific model in question. This can often be determined by checking manufacturer specifications or consulting knowledgeable suppliers. Secondly, prioritize quality over cost. While budget-friendly options may be tempting, investing in high-quality parts typically leads to better performance and durability in the long run.

Additionally, consider sourcing from reputable manufacturers or distributors. This can help guarantee that the parts meet necessary standards and have undergone rigorous testing. Reading customer reviews and seeking recommendations can also provide valuable insights into the reliability of different products.

Lastly, keep in mind the importance of warranty and support services. A reliable warranty can offer peace of mind, ensuring that replacements are covered in case of defects or malfunctions. By following these guidelines, one can make well-informed decisions when selecting components, ultimately enhancing the overall driving experience.

Routine Maintenance Checklist

Regular upkeep is essential for ensuring the longevity and performance of your vehicle. Establishing a systematic approach to monitoring various components can help identify potential issues before they escalate, ultimately enhancing reliability and safety.

Key Areas to Inspect

Fluid Levels: Check engine oil, coolant, brake fluid, and transmission fluid regularly. Maintaining proper levels helps prevent overheating and ensures optimal operation.

Tire Maintenance

Pressure and Tread: Inspect tire pressure monthly and check for uneven wear or damage. Proper inflation and tread depth are crucial for safe handling and fuel efficiency.

By adhering to this checklist, you can significantly contribute to the overall health of your vehicle, ensuring a smoother and safer driving experience.

Improving Fuel Efficiency Strategies

Enhancing fuel economy is essential for maximizing performance and reducing operational costs. By adopting effective practices, individuals can optimize consumption and contribute to a more sustainable environment.

Regular Maintenance: Keeping the vehicle in top condition is crucial. Routine inspections of the engine, air filters, and spark plugs can significantly impact efficiency. Addressing issues promptly helps maintain optimal performance.

Proper Tire Care: Ensuring tires are inflated to the recommended pressure not only improves safety but also enhances fuel economy. Under-inflated tires increase rolling resistance, leading to greater fuel consumption.

Driving Habits: Modifying driving behavior can yield significant benefits. Avoiding rapid acceleration and excessive idling can help conserve fuel. Maintaining a steady speed on highways and utilizing cruise control when appropriate are effective strategies.

Weight Management: Reducing unnecessary cargo can improve efficiency. Carrying excess weight forces the engine to work harder, leading to higher fuel usage. Clearing out any unneeded items can lead to noticeable savings.

Fuel Quality: Using high-quality fuel can enhance performance and efficiency. Investing in premium options may lead to better combustion and overall vehicle operation.

Resources for Classic Truck Enthusiasts

For those passionate about vintage vehicles, a wealth of resources is available to enhance knowledge and skills. From guides to community forums, these tools cater to enthusiasts at all levels, whether they are seasoned restorers or newcomers looking to learn.

Online Communities

- Forums: Join discussions with fellow aficionados to share experiences, ask questions, and exchange tips.

- Social Media Groups: Connect with like-minded individuals on platforms like Facebook and Instagram, where enthusiasts showcase their projects and share advice.

- YouTube Channels: Discover tutorials and restoration projects through visual content that provides step-by-step guidance.

Printed Guides and Literature

- Specialty Books: Look for publications that focus on restoration techniques and vehicle history to deepen your understanding.

- Magazines: Subscribe to periodicals that feature articles on maintenance, upgrades, and classic vehicle events.

- Service Guides: Utilize comprehensive resources that detail troubleshooting and upkeep for specific models.