Putzmeister Concrete Pump Repair Guide

The longevity and efficiency of heavy machinery are crucial for any construction project. Regular upkeep ensures that these vital tools operate at their best, minimizing downtime and enhancing productivity. This section aims to explore essential techniques and insights to maintain complex machinery effectively.

Understanding the intricate mechanisms involved in these devices is key to achieving optimal functionality. With the right approach, users can enhance performance and extend the lifespan of their equipment. This guide provides step-by-step instructions and valuable tips to address common issues that may arise.

Ultimately, gaining familiarity with these maintenance processes empowers operators to tackle challenges confidently. By delving into this topic, individuals can not only preserve their equipment but also ensure safety and reliability on site.

Putzmeister Concrete Pump Overview

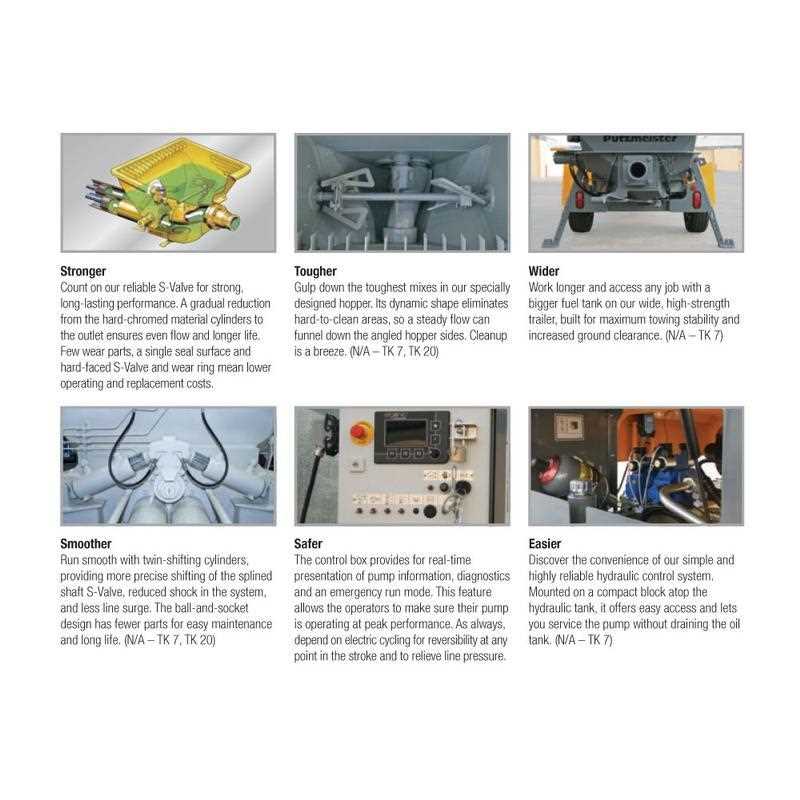

This section provides a comprehensive insight into a leading brand known for its advanced machinery designed for transporting heavy materials. The equipment is engineered to ensure efficiency and reliability in various construction tasks, making it a preferred choice among industry professionals.

Recognized for its robust construction and innovative technology, this equipment offers superior performance in demanding environments. With a focus on durability, it incorporates high-quality components that enhance longevity and reduce downtime.

The versatile design allows for a range of applications, catering to both small-scale projects and large construction sites. Features such as adjustable output and user-friendly controls contribute to its popularity, enabling operators to achieve optimal results with minimal effort.

Regular maintenance is crucial to ensure the longevity and effectiveness of these machines. Understanding their operational mechanics and potential issues can significantly enhance productivity and reduce the likelihood of malfunctions during critical operations.

Common Issues in Concrete Pumps

In the realm of fluid transportation systems, several challenges can arise that affect performance and efficiency. Understanding these common problems is essential for maintaining optimal functionality and prolonging the lifespan of equipment.

1. Blockages and Clogs

One of the most frequent complications encountered involves blockages within the delivery system. These can lead to significant operational downtime. Common causes include:

- Improper mix consistency

- Debris or foreign objects in the mixture

- Inadequate cleaning after use

2. Hydraulic System Failures

Hydraulic components are crucial for effective operation. Failures in this system can manifest as:

- Loss of pressure

- Leaking fluid

- Overheating due to excessive load

Regular inspection and maintenance of hydraulic lines and seals can mitigate these issues.

Understanding Pump Components

Grasping the essential elements of a delivery system is crucial for ensuring efficient operation and longevity. Each part plays a specific role in the overall functionality, and understanding these roles can lead to better maintenance practices and enhanced performance. This section explores the primary components that comprise a typical system, highlighting their functions and interconnections.

Main Components

The primary elements of a delivery mechanism include the following:

| Component | Function |

|---|---|

| Motor | Drives the entire system, providing necessary power for operation. |

| Hopper | Serves as the initial chamber where materials are collected before being moved. |

| Delivery Cylinder | Facilitates the movement of materials through pressure application. |

| Valves | Control the flow and direction of materials within the system. |

| Pipes | Transport the material from one location to another, maintaining integrity under pressure. |

Importance of Each Component

Understanding the role of each part is essential for troubleshooting and effective operation. Each element not only contributes to the efficiency of the system but also impacts overall reliability. Regular inspections and maintenance of these components can prevent unexpected breakdowns and extend the lifespan of the equipment.

Step-by-Step Repair Process

This section outlines a systematic approach to restoring equipment functionality, ensuring optimal performance and longevity. By following these detailed steps, you can effectively troubleshoot issues and execute necessary interventions.

Preparation Phase

Before starting the intervention, gather all required tools and materials. Ensure you have access to the appropriate protective gear to maintain safety throughout the process. Review any relevant documentation that provides insights into potential issues and solutions.

Execution of Repairs

Begin by isolating the unit from its power source to prevent any accidents. Inspect all components for visible wear or damage, making notes of any irregularities. Replace or repair parts as needed, ensuring that each replacement matches the specifications outlined in the equipment’s guidelines. Once all necessary actions have been taken, conduct a thorough test to verify that functionality has been restored.

Essential Tools for Repairs

Proper maintenance and troubleshooting of machinery require specific instruments to ensure efficiency and effectiveness. Having the right set of tools not only simplifies the process but also enhances the quality of work. Below are the crucial items that every technician should have at their disposal for successful interventions.

Basic Hand Tools

Fundamental hand tools are indispensable for any maintenance task. These instruments enable detailed work and adjustments, making them essential in the toolkit.

| Tool | Purpose |

|---|---|

| Wrenches | Used for tightening and loosening fasteners. |

| Screwdrivers | Essential for driving screws and making adjustments. |

| Pliers | Useful for gripping and bending various components. |

| Socket Set | Allows for easy access to hard-to-reach nuts and bolts. |

Specialized Instruments

In addition to basic tools, certain specialized instruments can greatly enhance the repair process. These are designed for more intricate tasks and can save time during complex interventions.

| Tool | Purpose |

|---|---|

| Torque Wrench | Ensures that fasteners are tightened to the correct specifications. |

| Multimeter | Measures electrical properties, useful for troubleshooting electrical issues. |

| Inspection Camera | Provides a visual of hard-to-reach areas for thorough inspections. |

| Hydraulic Jack | Facilitates lifting heavy components safely and efficiently. |

Preventative Maintenance Tips

Regular upkeep is essential for ensuring optimal performance and longevity of machinery. By implementing systematic practices, operators can minimize the risk of unexpected failures and enhance the efficiency of their equipment.

Here are some effective strategies to consider:

| Task | Frequency | Description |

|---|---|---|

| Visual Inspection | Daily | Check for leaks, cracks, or signs of wear in components. |

| Fluid Levels Check | Weekly | Ensure that all necessary fluids are at appropriate levels to prevent overheating and ensure proper lubrication. |

| Filter Replacement | Monthly | Replace filters to maintain cleanliness and avoid contamination. |

| Hoses and Connections Inspection | Monthly | Examine hoses for signs of wear and ensure connections are secure. |

| Calibrate Equipment | Quarterly | Adjust settings to ensure the machinery operates within specified parameters. |

| Comprehensive Service | Annually | Conduct a thorough review and service of all critical components to identify potential issues before they arise. |

By adhering to these maintenance practices, users can significantly reduce downtime and extend the life of their equipment. Consistency in these efforts leads to greater reliability and performance.

Troubleshooting Hydraulic System Problems

Hydraulic systems are vital for the smooth operation of various machinery. Identifying and resolving issues within these systems is essential to maintain performance and prevent downtime. This section provides insights into common challenges and their potential solutions.

Common Symptoms and Their Causes

- Low Pressure:

- Check for leaks in hoses and connections.

- Inspect the fluid level and top up if necessary.

- Examine filters for clogs that may restrict flow.

- Unusual Noises:

- Listen for grinding or whining sounds indicating component wear.

- Identify any air in the system that may cause cavitation.

- Ensure that all fittings are securely tightened.

- Overheating:

- Verify that the cooling system is functioning properly.

- Monitor fluid levels to prevent excessive temperature rise.

- Assess the condition of the fluid; replace if degraded.

Steps for Effective Troubleshooting

- Begin with a thorough visual inspection of the entire system.

- Utilize diagnostic tools to measure pressure and flow rates.

- Refer to technical specifications for operational parameters.

- Document all findings and actions taken for future reference.

- Consult with experts if problems persist after initial troubleshooting.

Replacing Wear Parts Effectively

Ensuring the longevity and efficiency of machinery requires timely attention to components that experience frequent degradation. This section focuses on the best practices for replacing these essential elements, emphasizing the importance of precision and technique to maintain optimal performance.

Identify the Right Components

Before beginning the replacement process, it’s crucial to accurately identify the worn parts. Utilizing a comprehensive inventory list can facilitate this step, ensuring that only necessary components are ordered and replaced. This helps in avoiding unnecessary downtime and costs associated with incorrect parts.

Preparation and Safety

Prior to the replacement, ensure that the work area is safe and organized. Disconnect power sources and use appropriate personal protective equipment (PPE) to safeguard against potential hazards. A clean workspace not only enhances safety but also promotes efficiency during the replacement process.

Follow Manufacturer Guidelines

Refer to the specifications provided by the manufacturer when replacing parts. Adhering to these instructions ensures that components are installed correctly and function as intended. Proper alignment and torque settings are critical for achieving the desired performance and avoiding future issues.

Regular Maintenance

Establishing a routine maintenance schedule can significantly extend the lifespan of wear components. Regular inspections allow for early detection of wear, enabling timely replacements and reducing the risk of unexpected breakdowns. This proactive approach not only preserves functionality but also enhances operational efficiency.

Document the Process

Keeping a detailed record of all replacements and maintenance activities is beneficial for future reference. Documenting each step provides insight into the machinery’s history, assisting in troubleshooting and planning for future replacements. This practice contributes to a more streamlined maintenance approach over time.

Safety Precautions During Repairs

Ensuring a safe working environment is crucial when undertaking maintenance tasks. Adhering to specific guidelines not only protects the individual performing the work but also safeguards others in the vicinity. By prioritizing safety measures, potential accidents can be minimized, creating a more efficient and secure atmosphere.

Personal Protective Equipment (PPE)

Using appropriate protective gear is essential. Consider the following items:

- Hard hats to protect against falling objects.

- Safety goggles to shield the eyes from debris.

- Gloves to prevent cuts and abrasions.

- Steel-toed boots for foot protection.

- High-visibility vests to ensure visibility in busy areas.

Work Area Safety

Maintaining a clean and organized workspace is vital. Implement these practices:

- Keep the area free of clutter to avoid tripping hazards.

- Ensure all tools and equipment are in good condition before use.

- Label hazardous materials clearly and store them properly.

- Use barriers or cones to mark off dangerous zones.

Best Practices for Pump Storage

Ensuring the longevity and efficiency of equipment requires careful consideration during storage. Proper techniques can mitigate wear and tear, safeguard components, and maintain operational readiness. This section outlines essential practices that can enhance the preservation of machinery, ensuring optimal performance when it’s time to use them again.

Climate Control and Environment

Storing machinery in a controlled environment is crucial. Extreme temperatures, humidity, and exposure to the elements can lead to rust, corrosion, and other forms of degradation. Ideally, equipment should be kept in a dry, temperature-regulated facility. If outdoor storage is necessary, protective covers can shield against moisture and harmful UV rays.

Regular Maintenance and Inspection

Even when not in use, routine checks are vital. Regular inspections help identify potential issues before they escalate. Cleaning components and ensuring that seals and joints are intact can prevent damage. Keeping a log of maintenance activities will assist in tracking the condition of the equipment and planning for necessary servicing.

Finding Genuine Replacement Parts

When maintaining heavy machinery, sourcing authentic components is crucial for ensuring optimal performance and longevity. Using high-quality parts not only enhances efficiency but also minimizes the risk of malfunctions. It is essential to navigate the market carefully to identify trustworthy suppliers and avoid counterfeit items that can compromise functionality.

Identifying Authorized Suppliers

One of the most effective ways to find genuine components is to work with authorized distributors. These suppliers have established relationships with manufacturers and adhere to strict quality standards. They often provide warranties and support, giving you peace of mind with your purchase. Always verify the credibility of the supplier by checking for customer reviews and certification.

Understanding Part Specifications

Familiarizing yourself with part specifications is equally important. Each component is designed with particular dimensions and materials to meet performance criteria. Consulting the original specifications can help you identify suitable replacements. Ensure that the parts you select match the necessary criteria to avoid compatibility issues.

In summary, sourcing authentic components involves working with reputable suppliers and understanding the specific requirements of each part. Taking these steps will help maintain the efficiency and reliability of your machinery.

Expert Resources and Support

Accessing reliable assistance and in-depth knowledge is crucial for ensuring optimal functionality of specialized machinery. Whether you are seeking troubleshooting tips, maintenance guidelines, or expert insights, various resources are available to support your endeavors and enhance performance.

Online Forums and Communities

Engaging with online platforms dedicated to industry professionals can provide invaluable information and shared experiences. These communities often host discussions on common challenges, best practices, and innovative solutions, allowing users to learn from one another and stay updated on the latest developments.

Manufacturer Support Services

Many manufacturers offer dedicated support teams ready to assist with inquiries related to equipment usage and maintenance. These professionals possess extensive knowledge and can provide tailored advice, ensuring you receive the most accurate and effective assistance for your specific needs.

Enhancing Pump Performance After Repairs

Improving the functionality of equipment after maintenance is crucial for achieving optimal efficiency and longevity. This section focuses on actionable strategies that can be employed to maximize the operational capabilities of machinery once restoration tasks have been completed.

Regular Maintenance Checks: Implementing a routine inspection schedule can identify potential issues before they escalate. Regular assessments of components ensure that everything is functioning smoothly, contributing to sustained performance.

Quality Lubrication: Utilizing high-quality lubricants is essential for reducing friction and wear on moving parts. Ensuring that all necessary areas are adequately lubricated can significantly enhance the overall efficiency and lifespan of the machine.

System Calibration: After any significant adjustments, recalibrating the equipment is vital. This process ensures that all settings align with operational requirements, optimizing performance and preventing unnecessary strain on the machinery.

Operator Training: Investing in training for operators can lead to better handling of equipment. Well-informed personnel are more likely to utilize the machinery effectively, reducing the risk of misuse and enhancing productivity.

Utilizing Upgraded Parts: When replacing components, opting for advanced or more durable alternatives can boost performance. Upgraded parts may offer enhanced efficiency, reliability, and lower maintenance needs over time.

By implementing these strategies, users can significantly enhance the performance of their machinery, ensuring that it operates at its best even after undergoing maintenance or restoration efforts.