Zetor Tractor Repair Guide

Understanding the intricacies of machinery is essential for anyone involved in their upkeep. This section provides insights into the various aspects of servicing and maintaining heavy machinery to ensure optimal performance and longevity. Emphasizing the importance of regular assessments and timely interventions, it serves as a comprehensive resource for enthusiasts and professionals alike.

Proper knowledge of maintenance techniques can greatly enhance the functionality of your equipment. By familiarizing oneself with common issues and their solutions, one can prevent minor problems from escalating into significant challenges. Efficiency and safety are paramount in these undertakings, underscoring the need for diligent practices and informed decision-making.

Furthermore, the process of keeping your machinery in peak condition involves not only routine checks but also an understanding of specific components and their roles. Attention to detail and a proactive approach can lead to improved operational reliability, ultimately benefiting users in various settings. This section aims to equip readers with the necessary tools to navigate the complexities of machinery maintenance effectively.

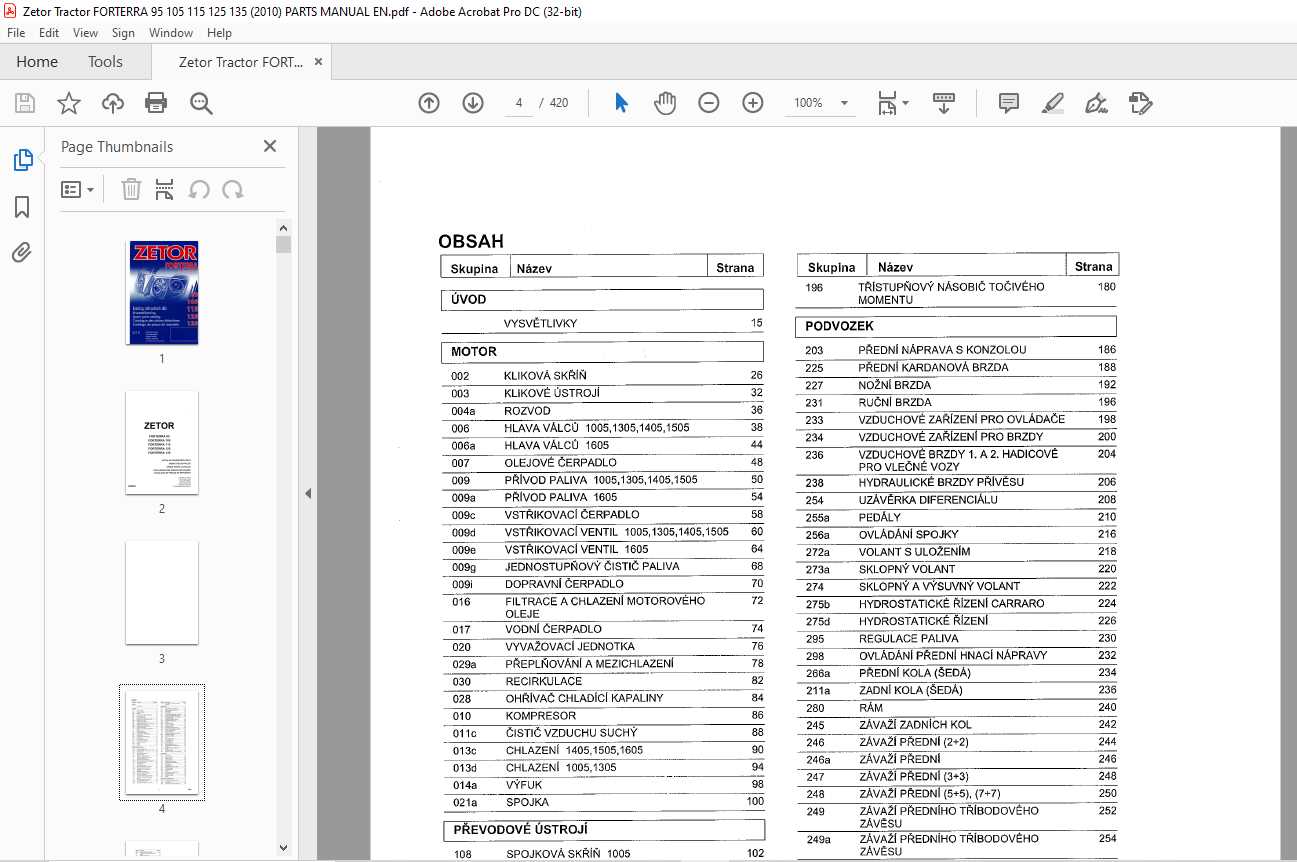

This section presents a structured approach to understanding the intricacies involved in the maintenance and servicing of agricultural machinery. The content will guide readers through various aspects, emphasizing practical knowledge and effective techniques that ensure longevity and optimal performance.

- Introduction to Agricultural Machinery Care

- Importance of regular maintenance

- Overview of essential tools and equipment

- Common Issues and Troubleshooting

- Identifying frequent problems

- Step-by-step troubleshooting procedures

- Maintenance Schedules and Practices

- Routine checks and inspections

- Seasonal maintenance tasks

- Technical Specifications and Modifications

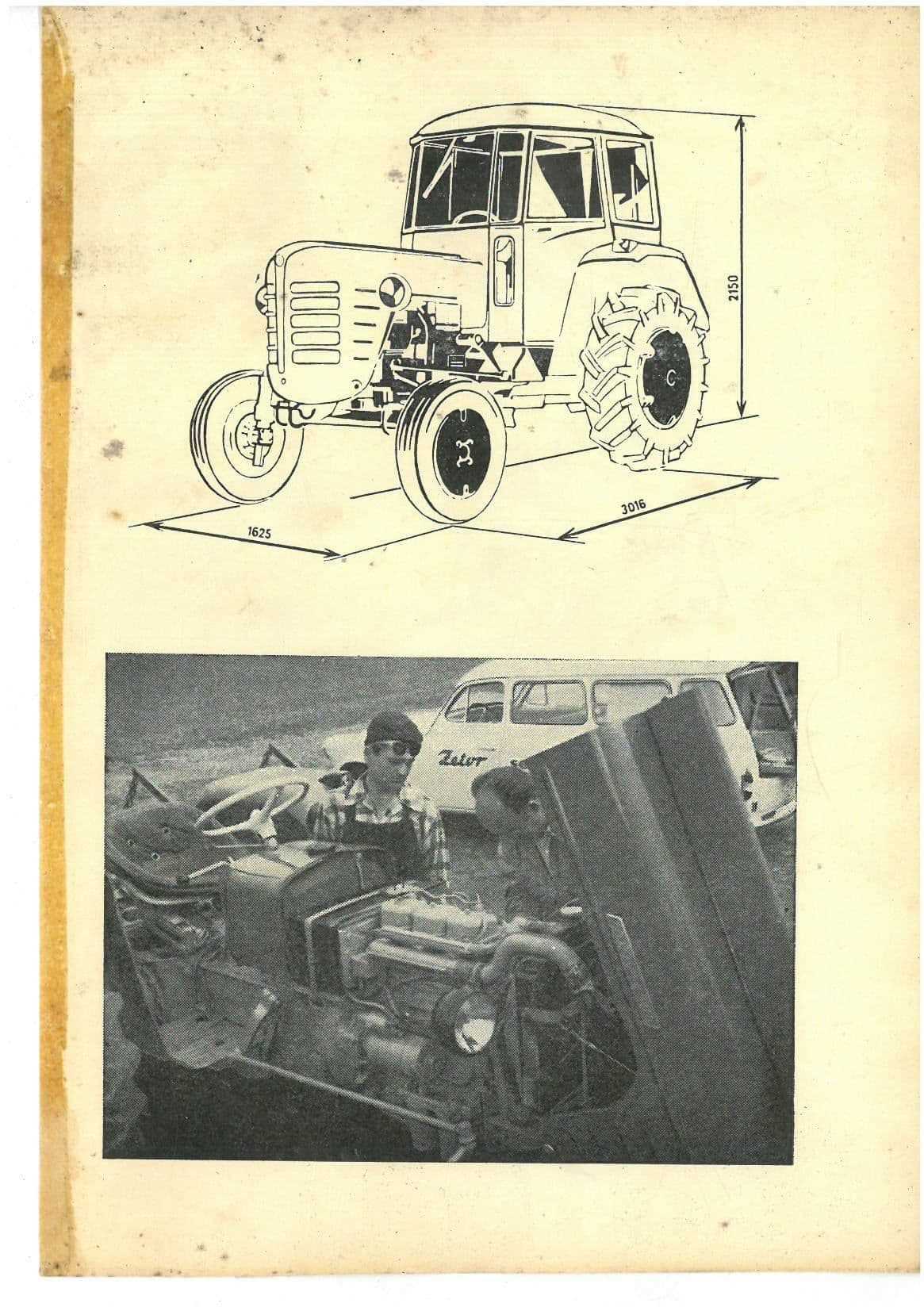

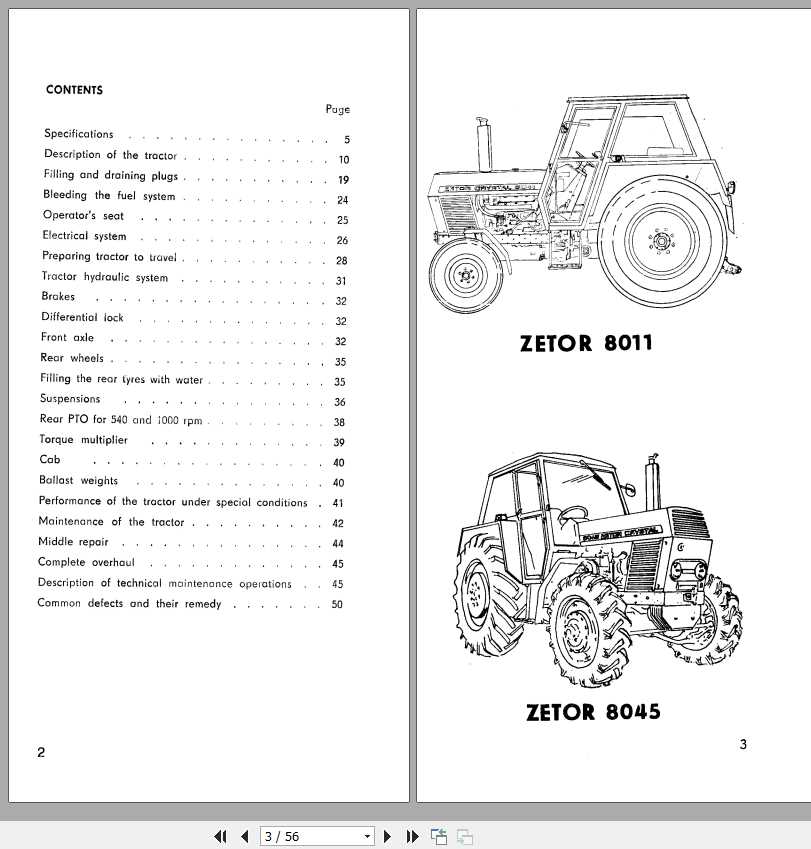

- Understanding machinery features

- Possible upgrades and enhancements

- Resource Management and Safety Tips

- Efficient resource usage

- Safety protocols during servicing

Common Issues with Zetor Tractors

This section addresses typical challenges faced by users of agricultural machinery, focusing on operational inconsistencies and mechanical malfunctions. Understanding these common problems can aid in proactive maintenance and ensure optimal functionality over time.

| Issue | Description | Possible Causes |

|---|---|---|

| Starting Difficulties | Issues related to the engine not turning over or running smoothly. | Weak battery, fuel blockage, or electrical failures. |

| Overheating | Engine temperatures rising above normal operational levels. | Low coolant levels, radiator blockages, or faulty thermostats. |

| Hydraulic Problems | Malfunction in hydraulic systems affecting lift and steering. | Low fluid levels, leaks, or pump failures. |

| Transmission Issues | Challenges related to gear shifting and power transfer. | Low transmission fluid, worn gears, or linkage problems. |

| Electrical Failures | Malfunctions in the electrical system impacting lights and starting. | Corroded connections, blown fuses, or faulty wiring. |

Essential Tools for Tractor Repair

Effective maintenance and troubleshooting of agricultural machinery require a selection of indispensable instruments. These implements not only facilitate straightforward tasks but also ensure safety and efficiency during operations. Understanding which tools to utilize can significantly enhance the overall performance and longevity of the equipment.

Basic Hand Tools

Every workshop should be equipped with fundamental hand tools. Items such as wrenches, screwdrivers, and pliers are crucial for various adjustments and fixes. These tools should be of high quality to withstand regular use. Investing in a reliable toolkit not only saves time but also improves the quality of work.

Diagnostic Equipment

In addition to standard implements, having diagnostic devices is essential for identifying issues efficiently. Equipment like multimeters and pressure gauges can provide valuable insights into the functionality of different components. Using accurate diagnostics can help in quickly addressing problems before they escalate, ensuring the machinery operates smoothly.

Step-by-Step Maintenance Procedures

This section outlines essential practices for ensuring optimal functionality and longevity of agricultural machinery. Regular attention to key components is crucial for preventing malfunctions and enhancing overall performance.

The following procedures provide a structured approach to maintenance tasks, highlighting the importance of systematic inspections and servicing. By adhering to these steps, operators can effectively manage upkeep and address potential issues before they escalate.

| Task | Frequency | Description |

|---|---|---|

| Check fluid levels | Weekly | Inspect engine oil, coolant, and hydraulic fluids to ensure they are at appropriate levels. |

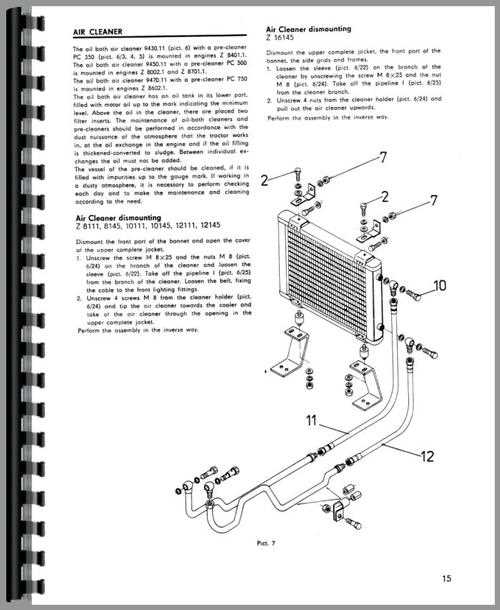

| Inspect filters | Monthly | Examine air and fuel filters for clogs or dirt accumulation, replacing them if necessary. |

| Examine belts and hoses | Every 100 hours | Look for signs of wear, cracks, or fraying and replace damaged components to avoid breakdowns. |

| Clean exterior | As needed | Remove dirt and debris from the exterior surfaces to prevent corrosion and ensure proper operation. |

| Grease moving parts | Every 50 hours | Apply grease to pivot points and joints to minimize friction and wear. |

Implementing these maintenance tasks will contribute to a reliable operation, ultimately leading to increased productivity and reduced downtime.

Troubleshooting Electrical System Problems

Identifying issues within the electrical framework of machinery can be challenging yet essential for optimal performance. Recognizing common symptoms and understanding the potential causes are crucial steps in resolving malfunctions effectively.

Begin by observing the symptoms displayed by the equipment. Issues such as dimming lights, intermittent functionality, or complete power loss may indicate underlying electrical faults. A systematic approach to diagnosing these problems can save time and resources.

Check the battery condition first, ensuring it is fully charged and free of corrosion. Connections should be tight and clean, as loose or dirty terminals can disrupt electrical flow. Next, inspect wiring for signs of wear or damage, which can lead to shorts or open circuits. Testing fuses and relays can help isolate defective components.

If the issue persists, utilize a multimeter to measure voltage and continuity throughout the system. This tool can provide valuable insights into where the fault may lie. Always follow safety protocols while handling electrical components to prevent accidents or further damage.

By following these steps, you can systematically identify and address electrical problems, ensuring reliable operation of your equipment.

Engine Care and Maintenance Tips

Proper upkeep of the power unit is crucial for optimal performance and longevity. Regular attention to its components ensures efficient operation and reduces the risk of unexpected failures. Here are some essential practices to keep in mind for maintaining the engine.

- Check and replace the oil regularly to ensure smooth functioning.

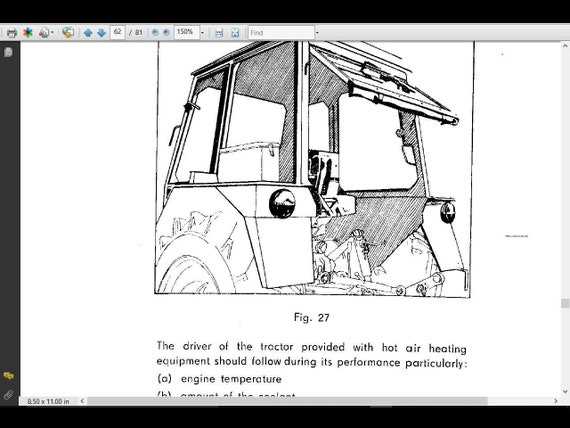

- Monitor coolant levels and keep the cooling system free of debris.

- Inspect air filters and clean or replace them as needed to maintain airflow.

- Examine fuel filters periodically to prevent clogging and ensure proper fuel delivery.

- Look for any leaks or signs of wear and tear in hoses and belts.

Additionally, regular inspections can help identify potential issues early. Keeping a maintenance log can aid in tracking the condition of various components and scheduling necessary service.

- Follow the manufacturer’s guidelines for maintenance intervals.

- Utilize high-quality fluids and filters that meet specified standards.

- Maintain cleanliness around the engine area to prevent dirt accumulation.

By implementing these practices, you can enhance the reliability and efficiency of the power unit, ultimately ensuring its optimal performance over time.

Transmission Repair Techniques Explained

This section delves into various methods employed for restoring functionality in gear systems. Understanding these techniques is essential for ensuring optimal performance and longevity of the equipment. Proper maintenance practices can significantly enhance the efficiency of power transfer mechanisms.

Common Issues and Diagnosis

Identifying prevalent problems within the transmission system is the first step towards effective resolution. Common issues may include unusual noises, difficulty in shifting gears, or fluid leaks. A systematic approach to diagnosis often involves visual inspections and testing fluid levels to pinpoint the root cause of the malfunction.

Techniques for Restoration

Once the issue is identified, various techniques can be applied to restore functionality. Disassembly of components allows for a thorough inspection and cleaning, while replacing worn-out parts ensures that the system operates smoothly. Additionally, regular fluid changes contribute to maintaining optimal performance and preventing future complications.

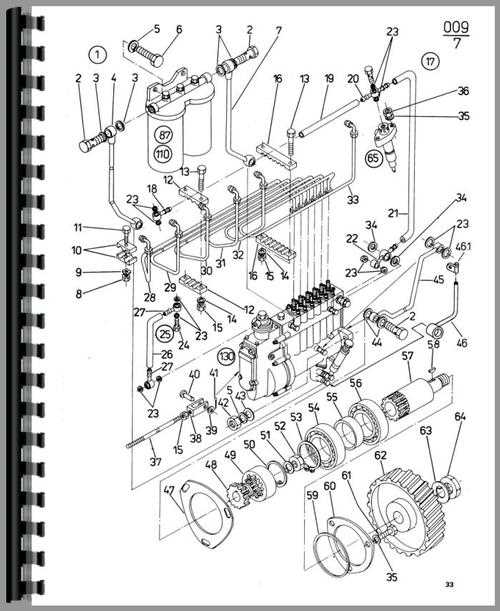

Hydraulic System Functionality Insights

The hydraulic system plays a crucial role in enhancing the operational efficiency of machinery, ensuring the effective transfer of power through fluid mechanics. This system is designed to manage various tasks, from lifting and lowering implements to facilitating precise control of attachments. Understanding its functionality is essential for optimal performance and maintenance.

Key components of the hydraulic system include:

- Hydraulic pump

- Hydraulic cylinders

- Valves

- Hoses and fittings

- Fluid reservoir

The hydraulic pump is responsible for generating flow, which moves the hydraulic fluid through the system. This movement creates pressure that activates cylinders, enabling lifting or lowering actions. Valves regulate this flow, directing it as needed to various parts of the system. Proper maintenance of hoses and fittings is essential to prevent leaks and ensure efficiency.

Additionally, the fluid reservoir stores hydraulic fluid, which must be regularly checked and maintained at appropriate levels to prevent system failure. Over time, hydraulic fluid can degrade, making it vital to replace it according to the manufacturer’s guidelines.

Overall, a thorough understanding of the hydraulic system’s functionality and regular maintenance practices contribute significantly to the longevity and reliability of the equipment.

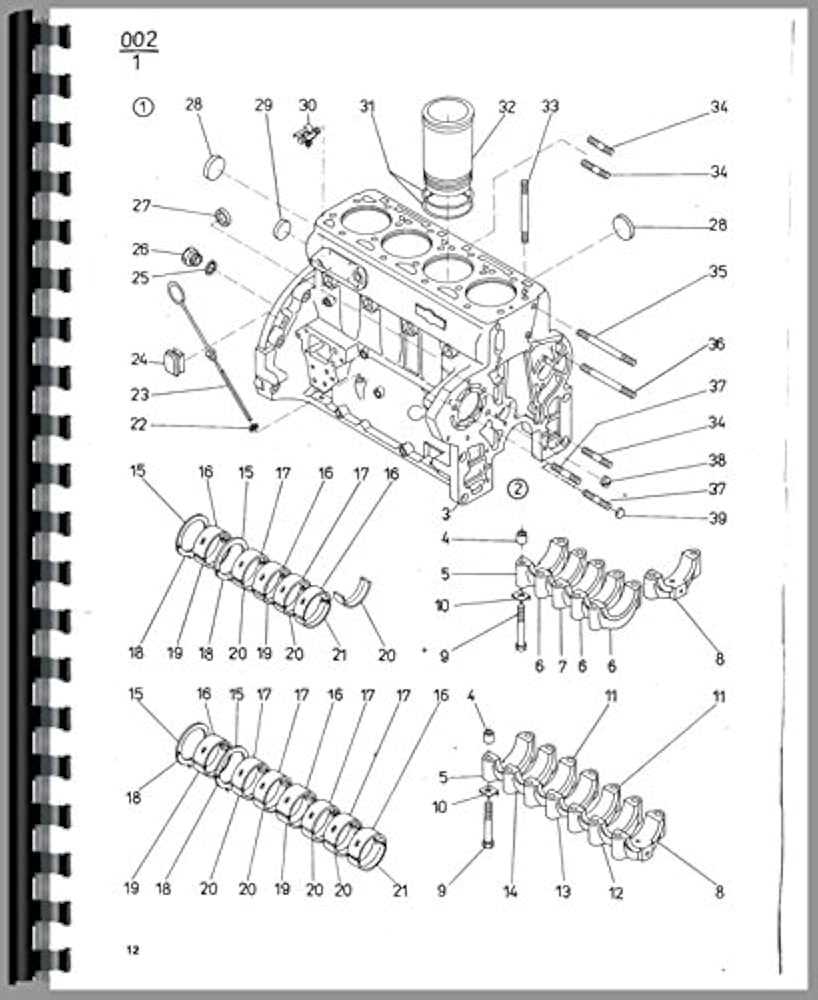

How to Replace Key Components

Replacing essential parts of machinery is a crucial task that ensures optimal performance and longevity. Understanding the steps involved in this process can greatly enhance efficiency and prevent potential issues. This section outlines the general procedures for swapping out vital components, focusing on common practices and considerations.

Before starting the replacement, it is important to gather all necessary tools and new parts. Ensure the workspace is clean and organized to facilitate smooth operations. It is advisable to consult relevant documentation to familiarize yourself with the specific requirements for each component.

To begin, disconnect any power sources to prevent accidents. Carefully remove the old part by loosening bolts or fasteners as needed. Take note of how the part is installed, as this will aid in correctly positioning the new component.

Once the old part is removed, install the new one by aligning it properly and securing it with the appropriate fasteners. Be sure to tighten all connections according to manufacturer specifications to avoid future malfunctions. After installation, reconnect power sources and perform a thorough check to ensure everything is functioning as intended.

Maintaining regular inspections and addressing issues promptly can significantly extend the lifespan of your equipment. By mastering the replacement of key components, you contribute to the overall efficiency and reliability of your machinery.

Safety Precautions During Repairs

Ensuring a secure environment while conducting maintenance tasks is essential for both the individual performing the work and the equipment being handled. Adhering to specific guidelines can significantly reduce the risk of accidents and injuries.

Here are key measures to consider:

- Always wear appropriate personal protective equipment, including gloves, goggles, and sturdy footwear.

- Keep the workspace well-ventilated to avoid inhaling harmful fumes and ensure proper air circulation.

- Use tools that are in good condition and appropriate for the task to prevent mishaps.

- Maintain a clean workspace to minimize clutter and the potential for accidents.

- Disconnect power sources before beginning any disassembly or maintenance work.

By following these safety measures, one can create a secure atmosphere conducive to efficient and safe maintenance practices.

Resources for Further Learning

For those seeking to deepen their understanding and skills related to agricultural machinery, a wealth of materials is available. Engaging with various resources can enhance knowledge and provide practical insights into the maintenance and functioning of these essential tools.

Online Courses: Numerous platforms offer structured courses that cover different aspects of machinery operation and maintenance. These programs often include video tutorials, quizzes, and community forums for discussion and support.

Books and Publications: There is an extensive array of literature focusing on machinery handling and upkeep. Books written by experts in the field provide valuable theoretical knowledge and practical advice, making them indispensable for both novices and seasoned operators.

Forums and Communities: Participating in online forums dedicated to machinery enthusiasts can be incredibly beneficial. These platforms allow individuals to share experiences, ask questions, and obtain tips from others who have faced similar challenges.

Workshops and Seminars: Attending hands-on workshops or seminars can significantly improve practical skills. These events often feature experienced instructors who can provide direct guidance and answer specific queries related to machinery operation.

Utilizing these resources can empower individuals to become more proficient in handling and caring for agricultural equipment, ultimately leading to better performance and longevity of the machinery.