Comprehensive Guide to Repairing the Stihl FS 90

In the world of outdoor power equipment, ensuring optimal performance and longevity is essential. A well-maintained tool not only enhances efficiency but also provides a safer experience for the user. This section focuses on the intricacies of upkeep and common issues faced by enthusiasts and professionals alike.

Understanding the functionality and components of your equipment is crucial for effective management. With various models and configurations, knowing the specifics can help in diagnosing problems and implementing solutions promptly. This guide aims to provide clear insights and practical advice, empowering users to tackle challenges with confidence.

Whether you are dealing with minor adjustments or more complex complications, having access to detailed instructions can make a significant difference. By exploring troubleshooting techniques and maintenance practices, you can ensure that your equipment remains in peak condition, ready to handle any task at hand.

Understanding the Stihl FS 90

The FS 90 is a versatile piece of equipment designed for various outdoor tasks. Its robust construction and innovative features make it a preferred choice for both professionals and enthusiasts. Understanding its components and functionality is essential for optimal use and maintenance.

Key Features

This model is equipped with a powerful engine that ensures efficiency and reliability. Its ergonomic design allows for comfortable handling, reducing fatigue during prolonged use. Additionally, the adjustable cutting head enhances versatility, making it suitable for tackling different types of vegetation.

Maintenance Tips

Regular upkeep is crucial for the longevity of this tool. Ensuring that the air filter and spark plug are clean will enhance performance significantly. Furthermore, periodically checking the fuel system and lubrication points will help prevent potential issues, keeping the equipment in prime condition for any task.

Common Issues with Stihl FS 90

When operating outdoor power equipment, users may encounter a variety of challenges that can hinder performance. Identifying these frequent problems is crucial for maintaining efficiency and extending the lifespan of the machine. Below are some of the most common issues faced by users of this particular model.

1. Engine Starting Difficulties

One of the most prevalent issues is trouble with starting the engine. This can be attributed to several factors:

- Poor fuel quality or incorrect fuel mixture.

- Clogged air filters restricting airflow.

- Faulty spark plug causing ignition failure.

- Blocked fuel lines preventing proper fuel delivery.

2. Loss of Power During Operation

Users often report a significant decrease in power while the equipment is in use. Common causes include:

- Worn or damaged cutting heads affecting performance.

- Improperly adjusted throttle settings.

- Debris buildup around the engine or exhaust.

- Insufficient lubrication leading to friction issues.

Regular maintenance and troubleshooting can help address these common challenges, ensuring smoother operation and enhanced productivity.

Essential Tools for Repairs

Having the right instruments is crucial for effective maintenance tasks. Proper equipment ensures that you can tackle any issue efficiently, prolonging the life of your machinery and enhancing performance. Below is a list of indispensable tools that every technician should have on hand.

- Wrenches: Adjustable and fixed wrenches are essential for loosening or tightening various fasteners.

- Screwdrivers: A set of both flathead and Phillips screwdrivers will cover most screw types found in equipment.

- Pliers: Needle-nose and regular pliers are useful for gripping, twisting, and cutting wires or small components.

- Socket Set: A comprehensive socket set allows for efficient work on bolts in tight spaces.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications, preventing damage.

In addition to the basic tools, consider adding the following specialized equipment:

- Feeler Gauges: Useful for measuring gaps and ensuring precise adjustments.

- Multimeter: Essential for diagnosing electrical issues by measuring voltage, current, and resistance.

- Cleaning Brushes: Keep components free of debris and improve functionality.

- Lubricants: Essential for reducing friction and wear on moving parts.

By equipping yourself with these tools, you can approach maintenance tasks with confidence and effectiveness, ensuring that your equipment runs smoothly for years to come.

Step-by-Step Repair Procedures

This section outlines a comprehensive approach to addressing common issues encountered with outdoor power equipment. Following a systematic method ensures effective troubleshooting and resolution, minimizing downtime and enhancing performance.

Identifying the Issue

The first step involves careful observation of the equipment’s symptoms. Listen for unusual sounds, check for fluid leaks, and assess the overall functionality. Making detailed notes will assist in pinpointing the root cause and aid in subsequent steps.

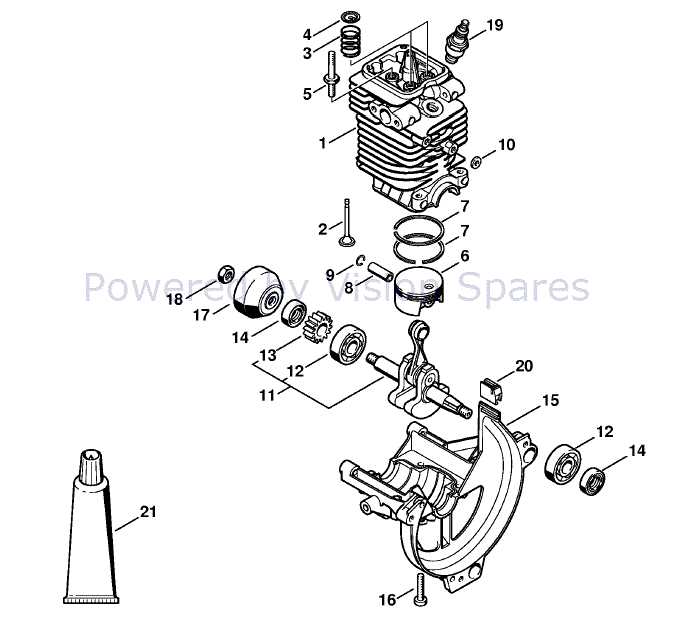

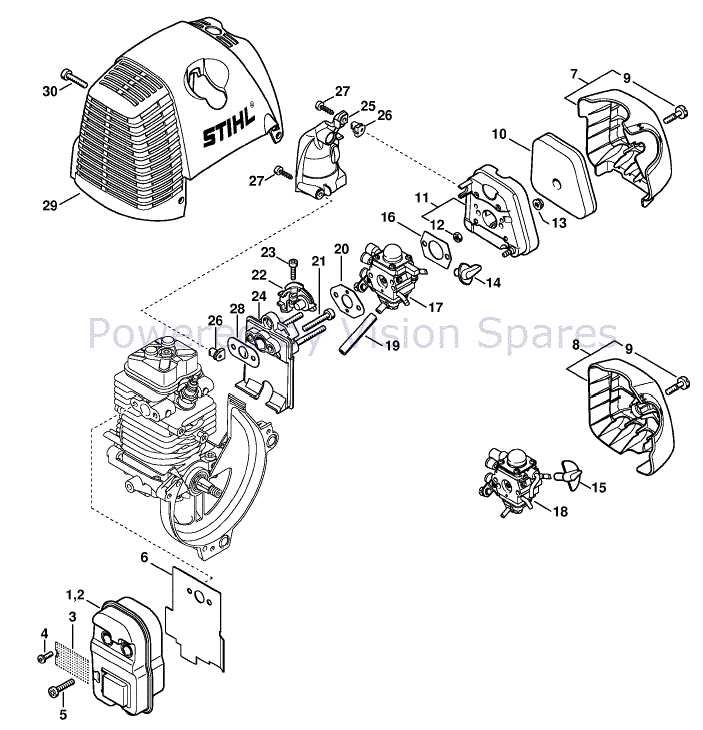

Disassembly and Inspection

Once the problem is identified, begin disassembling the necessary components. Use appropriate tools to avoid damage, and keep track of all parts for reassembly. Inspect each component for wear, cracks, or other signs of malfunction. Replace any damaged parts with quality replacements, ensuring compatibility with your model.

After inspection and necessary replacements, reassemble the unit meticulously, adhering to the original layout. Perform a final test to confirm that the equipment operates smoothly and efficiently.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential for ensuring the extended lifespan of your outdoor power equipment. By following a few simple practices, you can enhance performance and reliability, minimizing the need for frequent repairs. This section outlines key strategies to maintain your equipment effectively.

Regular Cleaning

Keeping the exterior and components free of dirt and debris is crucial. After each use, take a moment to clean the unit, removing any grass clippings or soil that may have accumulated. This not only prevents corrosion but also allows for better air circulation, which is vital for optimal operation.

Inspect and Replace Parts

Routine inspections are key to identifying wear and tear before it becomes a significant issue. Pay attention to the cutting attachments, spark plugs, and fuel filters. Replace any worn-out parts promptly to ensure your equipment continues to function at its best. Additionally, keeping the fuel system clean and using high-quality fuel can prevent issues down the line.

Replacing the Cutting Head

Changing the cutting attachment on your equipment is essential for maintaining optimal performance and ensuring safety during operation. This process can be straightforward if done with attention to detail and proper technique.

Follow these steps to effectively replace the cutting head:

- Gather Necessary Tools:

- Socket wrench or appropriate tool for the nut

- Protective gloves

- Safety glasses

- Ensure Safety:

- Disconnect the power source to prevent accidental starts.

- Clear the workspace of any obstructions.

- Remove the Old Cutting Head:

- Locate the securing nut on the cutting head.

- Use the socket wrench to loosen and remove the nut.

- Carefully detach the old head from the shaft.

- Install the New Cutting Head:

- Align the new head with the shaft.

- Secure it in place by tightening the nut with the socket wrench.

- Final Checks:

- Ensure everything is tightly secured.

- Reconnect the power source and conduct a test run to confirm functionality.

Regularly replacing the cutting attachment not only enhances efficiency but also prolongs the lifespan of your equipment. Make this maintenance routine part of your care strategy.

Troubleshooting Engine Problems

Engine issues can significantly impact the performance and reliability of your outdoor equipment. Identifying and resolving these problems requires a systematic approach to diagnose the underlying causes effectively. This section provides insights into common symptoms and solutions to help restore optimal function.

Common Symptoms

There are several indicators that your engine may be experiencing difficulties. These include irregular starting, stalling during operation, and unusual noises. Additionally, a decrease in power or excessive vibrations can signal underlying issues. Recognizing these signs early can prevent further complications.

Diagnostic Steps

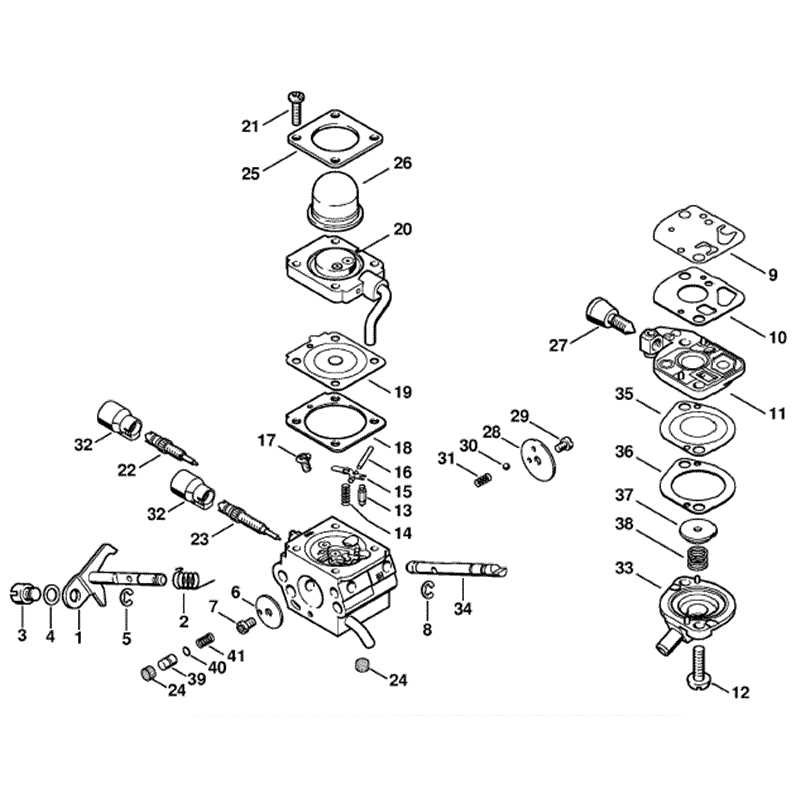

To address engine malfunctions, start by checking the fuel system. Ensure that the fuel is fresh and properly mixed, as stale or incorrect fuel can lead to performance problems. Next, inspect the air filter for dirt or blockages that may restrict airflow. A clean filter is essential for efficient combustion. Finally, examine the ignition system, including the spark plug, for wear or damage. Replacing faulty components can often resolve the issue and enhance overall performance.

Regular maintenance is crucial to preventing engine issues. Following a consistent schedule for cleaning and inspecting components will help ensure that your equipment runs smoothly for years to come.

Fuel System Care and Maintenance

Proper upkeep of the fuel system is crucial for ensuring optimal performance and longevity of your equipment. Regular attention to this component not only enhances efficiency but also minimizes the risk of potential issues that can arise from neglect. Understanding the key aspects of fuel system maintenance will help you keep your machinery running smoothly.

Regular Inspection

Consistent examination of the fuel system is essential. Check for any signs of leaks or wear in the fuel lines, as these can lead to inefficiencies and dangerous situations. Ensure that all connections are secure and that filters are free from debris. Timely replacement of filters can prevent blockages that may hinder fuel flow.

Fuel Quality and Storage

The quality of fuel used plays a significant role in the overall function of your equipment. Always use fresh fuel, as old or contaminated fuel can cause damage and reduce performance. Store fuel in clean, approved containers, and avoid mixing different fuel types. Proper storage methods will help maintain the integrity of the fuel and prolong the lifespan of the system.

Understanding Electrical Components

Electrical components play a crucial role in the functionality of various outdoor power equipment. Their proper operation ensures that the machinery runs efficiently and reliably. This section delves into the primary elements that make up the electrical system, highlighting their functions and significance.

Key Electrical Parts

- Ignition System: Responsible for starting the engine, it ignites the fuel mixture.

- Battery: Stores energy and provides power to the electrical system when needed.

- Wiring Harness: Connects various components, facilitating the flow of electricity.

- Switches: Control the operation of the equipment, allowing for on/off functions.

- Sensors: Monitor different parameters, ensuring optimal performance.

Importance of Maintenance

Regular maintenance of electrical components is essential for preventing malfunctions and prolonging the life of the equipment. Neglecting these parts can lead to serious performance issues or even complete failure. Here are some tips for keeping electrical systems in top shape:

- Inspect connections for corrosion and damage.

- Ensure proper wiring to avoid shorts or disconnections.

- Test batteries periodically for charge and performance.

- Replace worn-out components promptly.

By understanding and maintaining the electrical components, users can enhance the reliability and efficiency of their equipment, ensuring it operates smoothly for years to come.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is crucial to prevent accidents and injuries. This section highlights essential measures to adopt before and during any servicing activities. Adhering to these guidelines will help maintain a secure working environment.

Personal Protective Equipment

- Always wear safety goggles to protect your eyes from debris.

- Use gloves to safeguard your hands from sharp objects and chemicals.

- Consider wearing ear protection to minimize noise exposure.

- Ensure sturdy footwear is worn to prevent slips and injuries.

Work Area Safety

- Keep the workspace clean and organized to reduce hazards.

- Avoid clutter that may obstruct your movements or create tripping risks.

- Ensure adequate lighting is available to see details clearly.

- Store tools and materials in designated areas to prevent accidents.

By implementing these safety measures, individuals can significantly reduce the likelihood of mishaps while handling machinery or tools. Prioritizing safety not only protects the individual but also contributes to a more efficient and effective service process.