Comprehensive Guide to Repairing Your Singer Sewing Machine

Maintaining and reviving your cherished crafting instrument can seem daunting, yet it is a rewarding endeavor. Understanding the intricacies of your device is essential for ensuring its longevity and optimal performance. This guide is designed to equip you with the knowledge necessary to tackle common challenges and enhance your expertise.

Throughout this section, you will discover valuable insights into the mechanics of your device. From troubleshooting minor issues to comprehending the assembly of various components, each aspect will be explored in detail. Whether you are a novice or an experienced user, the information presented here will empower you to achieve success in your restoration journey.

With a combination of practical tips and detailed instructions, this guide aims to foster confidence and skill. Embrace the process of getting to know your tool better, and take pride in the improvements you make along the way. Your crafting companion deserves the best care, and with the right approach, it can serve you faithfully for many years to come.

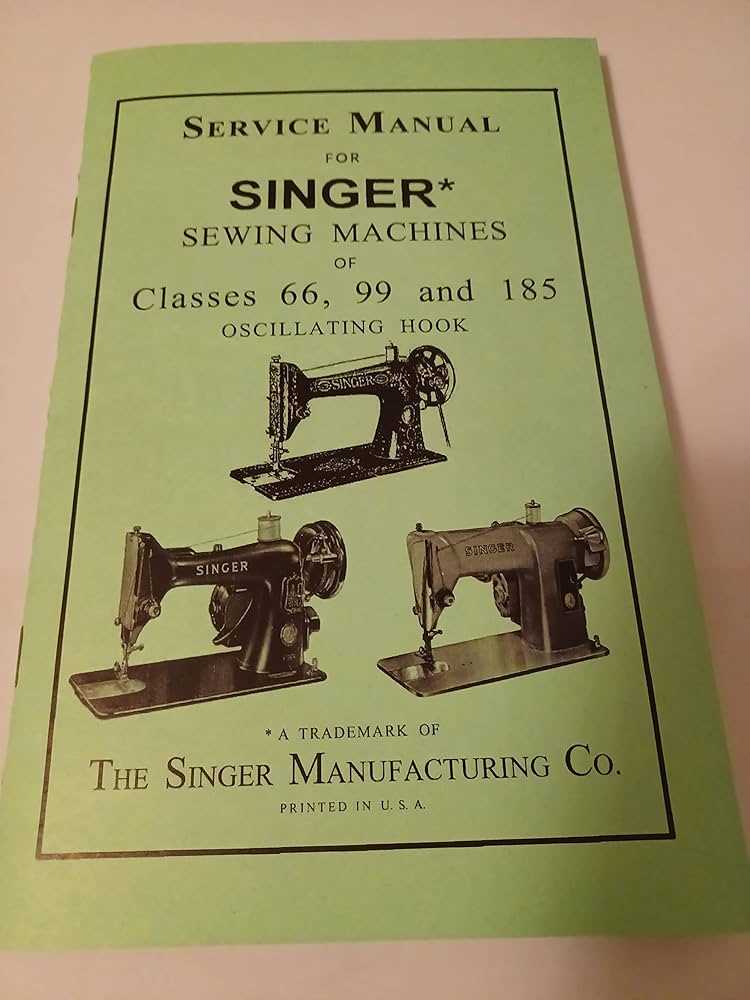

Singer Sewing Machine Repair Manual

This section provides essential guidance for maintaining and troubleshooting your textile creation device. Whether you’re encountering operational issues or simply seeking to enhance its longevity, a structured approach will ensure optimal performance. Familiarity with the components and their functions is key to effective management.

Common Issues and Solutions

Many users face typical challenges such as thread jams, inconsistent stitching, or tension discrepancies. To address these, first, check the threading path and ensure it is correctly configured. Regular cleaning of the interior parts can prevent buildup that leads to malfunction. Additionally, adjusting the tension settings can resolve issues related to uneven stitches.

Maintenance Tips

To prolong the life of your device, implement routine maintenance practices. Always clean the feed dogs and needle plate to eliminate lint accumulation. Lubrication of moving parts is also crucial; refer to the specific recommendations for oil types and application points. Regular inspections can catch minor problems before they escalate into major repairs, ensuring smooth operation.

Understanding Your Singer Sewing Machine

Gaining familiarity with your equipment is essential for effective usage and maintenance. Knowing the components and their functions will enhance your experience and ensure optimal performance. This section will guide you through the fundamental aspects, enabling you to work confidently and efficiently.

Key Components

The primary parts include the needle, thread, and tension settings. Each element plays a crucial role in the stitching process. The needle’s size and type can significantly affect the quality of your project, while proper threading is vital for smooth operation. Additionally, understanding how to adjust the tension can prevent common issues such as puckering or thread breakage.

Basic Operation

Familiarizing yourself with the basic functions will empower you to handle various tasks. Start by learning how to load the thread and set up the fabric correctly. Practice is key; try out different stitch types and lengths to see how they influence your outcomes. Remember, patience is essential as you develop your skills.

Common Issues with Singer Machines

When working with textile creation tools, users may encounter various challenges that can affect performance and functionality. Understanding these frequent problems can help in maintaining optimal usage and prolonging the life of your equipment. Below are some typical concerns along with their potential causes.

| Issue | Possible Causes |

|---|---|

| Thread Bunching | Poor tension settings, incorrect threading, or using incompatible thread. |

| Skipping Stitches | Worn or damaged needle, improper needle type, or issues with the feed mechanism. |

| Fabric Jamming | Incorrect presser foot, tangled thread, or insufficient tension. |

| Noise During Operation | Lack of lubrication, loose parts, or foreign objects obstructing movement. |

| Uneven Stitching | Incorrect foot pressure, improper thread installation, or an unlevel surface. |

Being aware of these common issues allows for timely intervention and enhances the overall experience of using these valuable tools.

Basic Tools for Repairing Sewing Machines

When it comes to maintaining and fixing textile devices, having the right instruments is crucial for achieving optimal results. A well-equipped toolkit not only facilitates efficient work but also enhances the quality of repairs. Understanding the essential tools can empower users to troubleshoot issues effectively and prolong the life of their equipment.

Essential Instruments

Among the most important items in a toolkit are precision screwdrivers, which come in various sizes to accommodate different fasteners. A good pair of scissors is equally vital, allowing for accurate cutting of threads and fabric. Additionally, a seam ripper can be invaluable for correcting mistakes without damaging the surrounding material.

Maintenance Supplies

To ensure smooth operation, lubricants designed specifically for textile devices are necessary. These oils help reduce friction and prevent wear. Moreover, a cleaning brush aids in removing lint and debris, which can accumulate in the nooks and crannies, affecting performance. Having these basic tools on hand can make the difference between a quick fix and a lengthy process.

Step-by-Step Troubleshooting Guide

This section provides a comprehensive approach to identifying and resolving common issues that may arise during the use of your crafting apparatus. By following the outlined steps, you can systematically diagnose problems and implement effective solutions, ensuring smooth operation and longevity of your device.

Common Issues and Solutions

| Problem | Possible Cause | Solution |

|---|---|---|

| Thread Bunching | Incorrect threading or tension settings | Re-thread the device and adjust tension to recommended levels. |

| Skipped Stitches | Worn needle or incorrect needle type | Replace with a new needle suitable for the fabric. |

| Fabric Not Feeding | Dirty feed dogs or incorrect presser foot pressure | Clean the feed dogs and adjust the presser foot pressure. |

| Bobbin Issues | Improper bobbin winding or insertion | Ensure bobbin is wound correctly and inserted properly. |

Final Checks

After addressing the identified issues, perform a series of test runs to verify that everything functions as expected. Regular maintenance and careful handling can prevent many of these problems from recurring, ensuring that your crafting experience remains enjoyable and efficient.

Cleaning and Maintaining Your Machine

Regular upkeep is essential for ensuring the longevity and efficiency of your equipment. By incorporating a few simple practices into your routine, you can enhance performance and prevent issues before they arise. This section outlines effective techniques for keeping your device in optimal condition.

First and foremost, it is vital to keep the workspace tidy. Dust and debris can accumulate in various areas, potentially causing obstructions. Make it a habit to wipe down surfaces with a soft cloth and remove any threads or lint that may gather around moving parts.

Next, periodic lubrication is necessary to ensure smooth operation. Use a suitable oil specifically designed for such devices, applying it sparingly to the designated areas as indicated in your guide. This will minimize friction and wear, prolonging the life of components.

Additionally, always inspect the tension settings and alignment. Regular checks help maintain consistent performance and prevent uneven outcomes. If you notice any discrepancies, adjustments should be made promptly to avoid further complications.

Finally, store your equipment in a safe, dry place when not in use. Protecting it from extreme temperatures and moisture will greatly reduce the risk of damage, ensuring it remains ready for action whenever needed.

Replacing the Needle and Bobbin

Ensuring optimal performance of your device involves regular maintenance, particularly the replacement of key components such as the needle and bobbin. These elements are crucial for achieving precise and high-quality results in your projects. Understanding how to correctly change them is essential for anyone looking to enhance their crafting experience.

Follow these steps for a smooth replacement process:

- Gather Necessary Tools:

- New needle

- Replacement bobbin

- Screwdriver (if applicable)

- Fabric or paper for testing

- Remove the Current Needle:

- Ensure the device is powered off.

- Locate the needle holder and loosen the set screw.

- Carefully slide the old needle out and discard it.

- Insert the New Needle:

- Position the new needle in the holder with the flat side facing the correct direction.

- Secure it by tightening the set screw firmly.

- Replace the Bobbin:

- Open the bobbin case and remove the empty bobbin.

- Insert the new bobbin, ensuring it is wound correctly.

- Thread the bobbin according to the specified path.

- Test the Setup:

- Power on the device and select a test fabric.

- Run a few stitches to ensure everything is functioning smoothly.

By following these straightforward steps, you can maintain the efficiency of your equipment and ensure quality in your creative endeavors. Regularly checking and replacing these components will lead to improved performance and better results.

Fixing Tension Problems Effectively

Tension issues can significantly affect the quality of your projects, leading to frustration and unsatisfactory results. Understanding how to address these challenges is essential for achieving smooth and professional outcomes. This section will guide you through the common causes of tension discrepancies and provide practical solutions.

- Identifying the Symptoms:

- Uneven stitches

- Fabric puckering

- Thread breakage

- Common Causes:

- Incorrect thread type or quality

- Improperly threaded components

- Worn or damaged tension discs

- Adjusting Tension:

- Check the upper and lower settings separately.

- Make small adjustments incrementally.

- Test with scrap fabric before continuing.

- Preventive Measures:

- Regular maintenance checks

- Use quality threads compatible with your project

- Store materials properly to avoid damage

By following these guidelines, you can effectively troubleshoot and resolve tension problems, leading to improved outcomes in your creative endeavors.

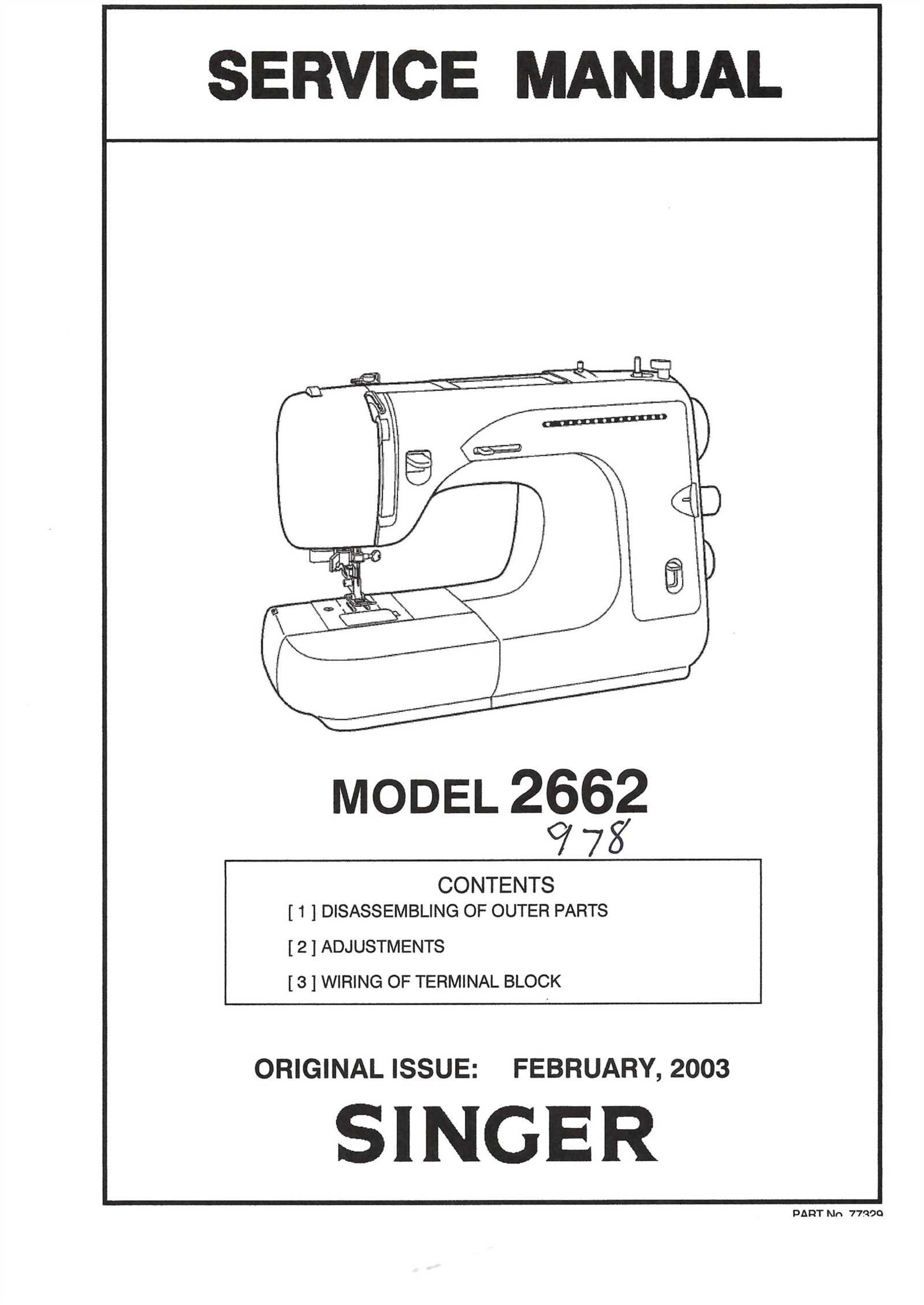

Repairing Electrical Components Safely

Ensuring the safety of your electrical devices is paramount when addressing issues within their systems. Understanding proper protocols can significantly reduce the risk of accidents or further damage. This section outlines essential practices to follow when working with electrical parts, promoting a secure environment for both the technician and the equipment.

Before commencing any work, it is crucial to familiarize yourself with the specific characteristics of the electrical components involved. Always disconnect power sources and utilize protective gear to prevent electrical shock. Proper handling techniques will not only safeguard your well-being but also preserve the integrity of the components you are addressing.

| Safety Practice | Description |

|---|---|

| Power Disconnection | Always unplug the device before beginning any maintenance work to eliminate the risk of electric shock. |

| Use of Insulated Tools | Employ tools with insulated handles to prevent accidental contact with live circuits. |

| Proper Grounding | Ensure that all equipment is properly grounded to prevent electrical surges and short circuits. |

| Wear Protective Gear | Utilize gloves and safety glasses to shield against potential hazards during maintenance tasks. |

| Follow Manufacturer Guidelines | Refer to the manufacturer’s instructions for specific troubleshooting and safety recommendations. |

Adhering to these guidelines will facilitate a safer environment when addressing electrical issues, allowing for effective troubleshooting and enhancement of device longevity. By prioritizing safety, you can confidently tackle any challenges that arise within electrical components.

Identifying Mechanical Failures

Recognizing issues within textile apparatus can significantly enhance performance and longevity. A thorough understanding of potential faults allows users to address concerns before they escalate into major problems. This section provides insights into identifying common mechanical discrepancies.

Listen for Unusual Noises: Pay attention to any irregular sounds during operation. Clicking, grinding, or rattling can indicate misalignment or wear in components.

Examine Movement: Observe the motion of parts. Sticking or sluggish operation often points to lubrication deficiencies or blockages that need addressing.

Check Threading: Inconsistent tension or difficulty in feeding fabric may suggest improper threading. Ensure all guides and tension mechanisms are correctly aligned.

Inspect Components: Regularly inspect gears, belts, and other critical elements for signs of wear or damage. Cracks, fraying, or breaks can severely impact functionality.

Monitor Performance: If the performance diminishes or the results become unsatisfactory, it may be time to investigate further. Documenting changes can help in pinpointing specific issues over time.

By being vigilant and proactive, users can effectively identify and resolve mechanical issues, ensuring smooth operation for years to come.

Upgrading Parts for Better Performance

Enhancing the functionality of your equipment can lead to improved efficiency and a more satisfying experience. By replacing certain components with higher-quality alternatives, you can achieve a significant boost in performance, durability, and user comfort. This approach not only prolongs the lifespan of your tool but also ensures it operates at its best, allowing you to tackle various tasks with ease.

Key Components to Consider

When looking to upgrade parts, focus on the following elements that can have a major impact on overall performance:

| Component | Benefits of Upgrading |

|---|---|

| Needles | Improved precision and reduced friction, leading to cleaner results. |

| Belts | Enhanced power transfer and less wear, resulting in smoother operation. |

| Presser Feet | Increased versatility for various fabric types and projects. |

| Bobbin Cases | Better tension control and reduced thread jamming issues. |

Choosing the Right Upgrades

Selecting the appropriate components for enhancement is crucial. Research compatible options that suit your specific requirements. Prioritize high-quality materials that promise longevity and superior performance. Investing in these upgrades not only maximizes efficiency but also transforms your experience into one that is enjoyable and productive.

When to Seek Professional Help

Understanding when to enlist the expertise of a professional can significantly enhance the longevity and functionality of your equipment. While many issues can be resolved independently, certain situations necessitate specialized knowledge and skills.

Consider the following scenarios where professional assistance is advisable:

- Complex Malfunctions: If your device exhibits multiple or intricate problems, it may be best to consult an expert.

- Unusual Noises: Persistent or strange sounds during operation often indicate underlying issues that require a trained ear to diagnose.

- Electrical Problems: Any issues involving wiring or electrical components should be addressed by a qualified technician to prevent safety hazards.

- Parts Replacement: If you’re unsure about how to replace critical components, seeking help can prevent damage to your equipment.

- Frequent Breakdowns: Regularly recurring issues suggest a deeper problem that requires professional insight for a lasting solution.

- Insufficient Knowledge: If you feel overwhelmed by a specific issue or lack the necessary skills, it’s wise to reach out to an expert.

Taking proactive steps by identifying when to seek help can save time, resources, and ensure your device remains in optimal working condition.

Resources for Further Learning

Exploring additional resources can greatly enhance your understanding and skills in maintaining and troubleshooting textile crafting tools. A variety of platforms and materials are available to support enthusiasts at all levels, providing insights into both basic techniques and advanced methods.

Online Platforms

Numerous websites and forums offer valuable information, tutorials, and community support. Engaging with these platforms can help you stay updated on best practices and innovative solutions.

| Resource Name | Description | Link |

|---|---|---|

| Craft Forums | Community discussions and advice on various topics related to tool upkeep. | craftforums.com |

| Video Tutorials | Visual guides that demonstrate techniques and troubleshooting steps. | youtube.com |

| Instructional Blogs | Articles and step-by-step guides from experienced crafters. | craftblog.com |

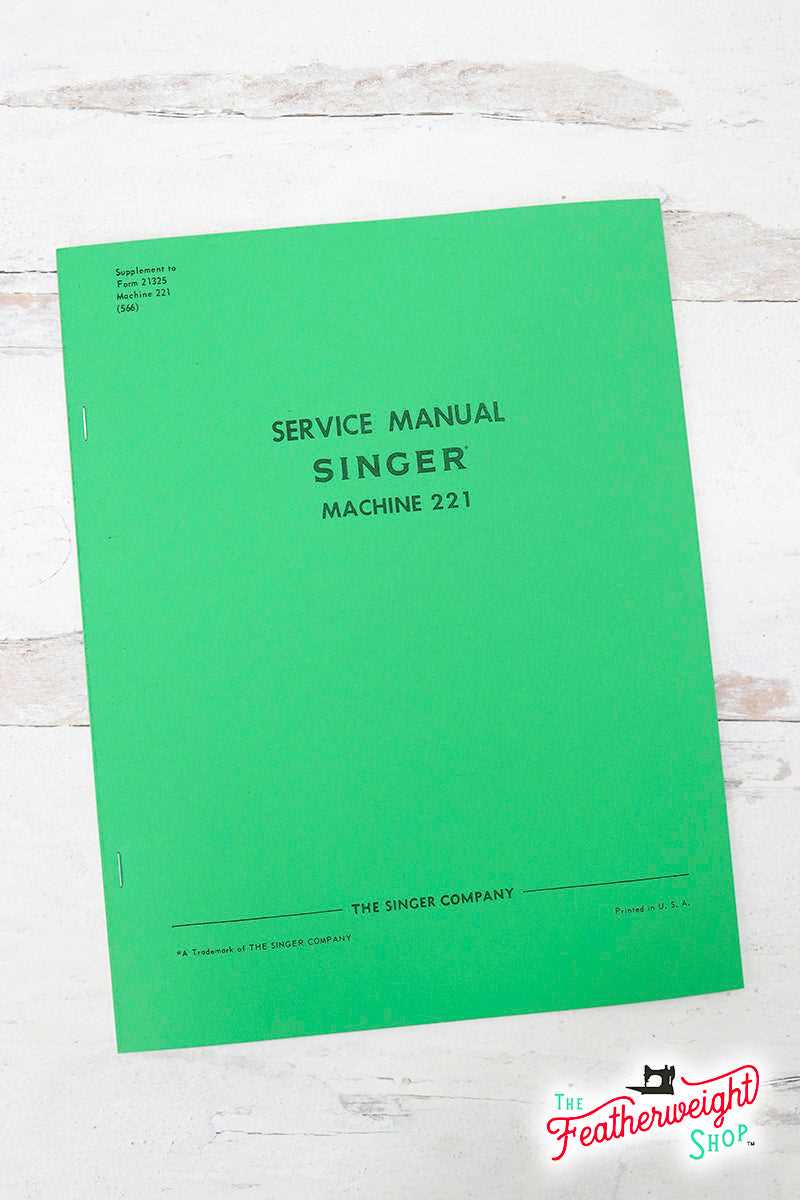

Books and Guides

Books authored by experts provide in-depth knowledge and can serve as comprehensive references. Look for titles that cover various aspects of maintenance and troubleshooting.