Essential Guide to John Deere 4400 Tractor Repair Manual

In the world of farming and heavy machinery, understanding the intricacies of equipment maintenance is essential for optimal performance and longevity. This guide delves into the various aspects of upkeep and troubleshooting for specific models, ensuring that operators can effectively manage their assets.

Every piece of equipment requires attention to detail, from routine inspections to more complex interventions. By familiarizing oneself with the specifics of these machines, owners can prevent minor issues from escalating into costly repairs. This resource aims to empower users with the knowledge needed to keep their machinery running smoothly.

Whether you are a seasoned operator or new to the field, having access to detailed information can significantly enhance your ability to maintain and operate agricultural equipment. The following sections provide insights into essential procedures and best practices that contribute to the efficiency and reliability of these vital tools.

Understanding the John Deere 4400 Tractor

This section delves into the essential features and operational aspects of a specific model known for its versatility and efficiency in agricultural tasks. It provides insights into its design, performance, and the key components that contribute to its functionality.

Key Features

- Powerful engine designed for optimal performance.

- Durable construction ensuring longevity and reliability.

- User-friendly controls for easy operation.

- Versatile attachment options for various farming needs.

Maintenance Considerations

- Regular oil changes to maintain engine health.

- Routine inspection of belts and hoses for wear.

- Cleaning air filters to ensure optimal airflow.

- Checking fluid levels and topping off as necessary.

Understanding these aspects can enhance the longevity and efficiency of the machine, making it an invaluable asset for any farming operation.

Common Issues with the 4400 Model

Every machine has its quirks, and this particular model is no exception. Users often encounter a range of typical problems that can impact performance and efficiency. Understanding these common challenges is essential for effective troubleshooting and maintenance.

Engine Performance: One of the frequent complaints involves engine inefficiency. Owners may notice issues such as rough idling or stalling, which can stem from various factors including fuel contamination or ignition system failures.

Hydraulic System Troubles: The hydraulic system is crucial for operation, and leaks or pressure loss can hinder functionality. Common signs include slower response times or unexpected drops in power when engaging implements.

Electrical Failures: Electrical components may also pose challenges, with issues ranging from battery drain to faulty wiring connections. Regular checks on the electrical system can help identify potential problems before they escalate.

Transmission Concerns: Shifting difficulties are another notable issue. Users might experience hard shifts or slipping gears, often due to low fluid levels or worn components within the transmission system.

By being aware of these prevalent issues, operators can take proactive measures to ensure their machinery remains in optimal working condition, minimizing downtime and enhancing productivity.

Essential Tools for Tractor Repair

When it comes to maintaining and fixing agricultural machinery, having the right equipment is crucial. Proper tools not only streamline the process but also enhance safety and efficiency during maintenance tasks. Understanding the various implements available can make a significant difference in ensuring optimal performance.

Wrenches are fundamental for loosening and tightening bolts and nuts. A set of adjustable and socket wrenches will cover most requirements. Additionally, screwdrivers in various sizes and types are indispensable for assembling and disassembling components.

Pliers, especially needle-nose varieties, are useful for gripping and manipulating small parts. Meanwhile, a reliable hammer can assist in driving fasteners and providing force where needed. For electrical work, a multimeter is essential to diagnose issues and ensure proper function.

Lastly, investing in a good-quality jack and stands is vital for safe lifting of heavy machinery. Ensuring that you have the right assortment of tools will facilitate a smoother and more efficient maintenance experience.

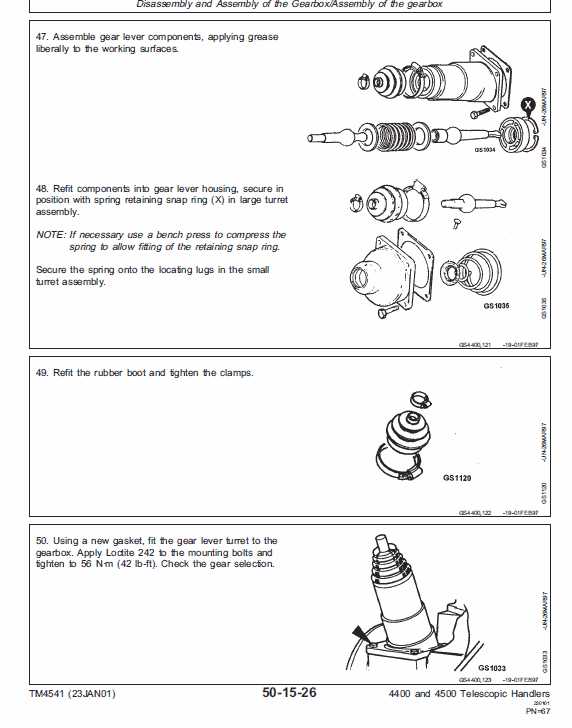

Step-by-Step Repair Procedures

This section outlines a systematic approach to troubleshooting and fixing various issues that may arise with your equipment. By following a structured method, you can ensure that each problem is addressed thoroughly and effectively.

Preparation Phase

- Gather necessary tools and equipment.

- Review relevant technical documents for guidance.

- Ensure a clean and organized workspace.

Diagnosis Steps

- Identify the symptoms of the malfunction.

- Perform a visual inspection for obvious damage.

- Utilize diagnostic tools to assess functionality.

- Record findings for reference.

Following these steps will lead to a more efficient resolution of the issues, ensuring your machinery remains in optimal condition.

Maintenance Tips for Longevity

Proper upkeep is essential for enhancing the lifespan of any agricultural machinery. By adhering to specific guidelines, operators can ensure optimal performance and reduce the likelihood of unexpected failures. This section outlines key practices that contribute to the durability of equipment.

| Tip | Description |

|---|---|

| Regular Inspections | Conduct frequent checks on all components to identify wear and tear early. |

| Fluid Changes | Replace oils and fluids according to the manufacturer’s recommendations to maintain lubrication and prevent damage. |

| Cleanliness | Keep the machinery clean to prevent dirt buildup, which can lead to corrosion and mechanical issues. |

| Tire Maintenance | Ensure proper inflation and tread condition to enhance traction and prevent uneven wear. |

| Storage Conditions | Store the equipment in a dry, sheltered location to protect it from the elements. |

Implementing these practices will not only extend the operational life of the machinery but also improve efficiency and reliability during usage.

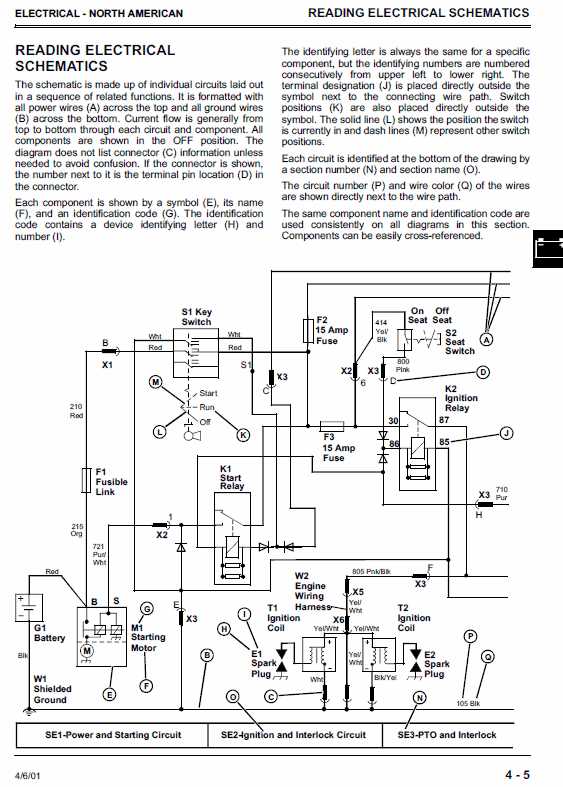

Electrical System Troubleshooting Guide

This section provides a comprehensive approach to diagnosing issues within the electrical framework of your equipment. Proper understanding and systematic evaluation of electrical components are essential for effective maintenance and repair. By following this guide, you can identify common faults and implement corrective actions to restore functionality.

Begin by checking the battery condition. Ensure it is fully charged and connections are clean and tight. A weak or poorly connected battery can lead to a range of electrical malfunctions. If the battery appears functional, proceed to inspect the fuses. A blown fuse may interrupt power to critical systems.

Next, examine wiring and connectors for signs of wear or corrosion. Damaged wires can lead to shorts or open circuits, impacting performance. Use a multimeter to test voltage at key points, ensuring that power is being delivered where needed. If voltage is absent, trace the circuit to locate the source of the problem.

Consider the starter and ignition system as potential trouble spots. If the engine does not crank, the starter motor or solenoid may be at fault. Verify operation by testing these components directly. Additionally, inspect the ignition switch for functionality, as a faulty switch can prevent the system from engaging.

Finally, if issues persist after these checks, investigate the electronic control unit and sensors. Modern equipment often relies on these components for optimal operation. Ensure they are receiving proper inputs and functioning correctly. By systematically addressing these areas, you can effectively resolve electrical issues and enhance the overall performance of your machinery.

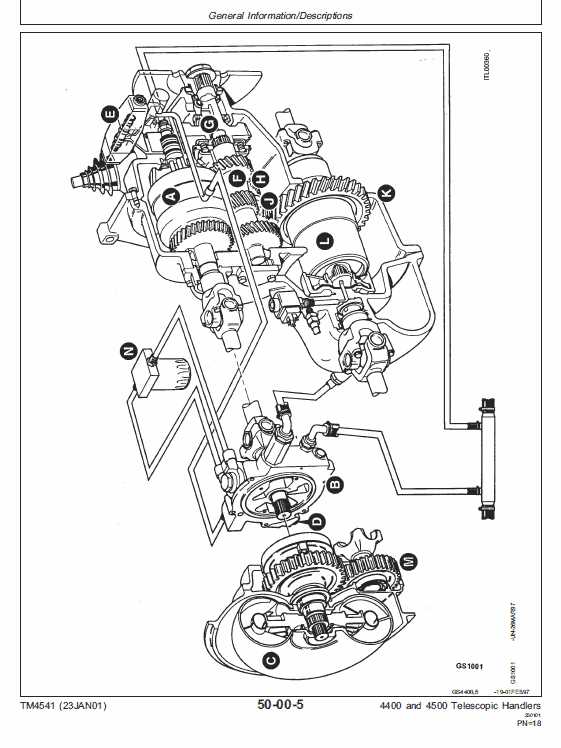

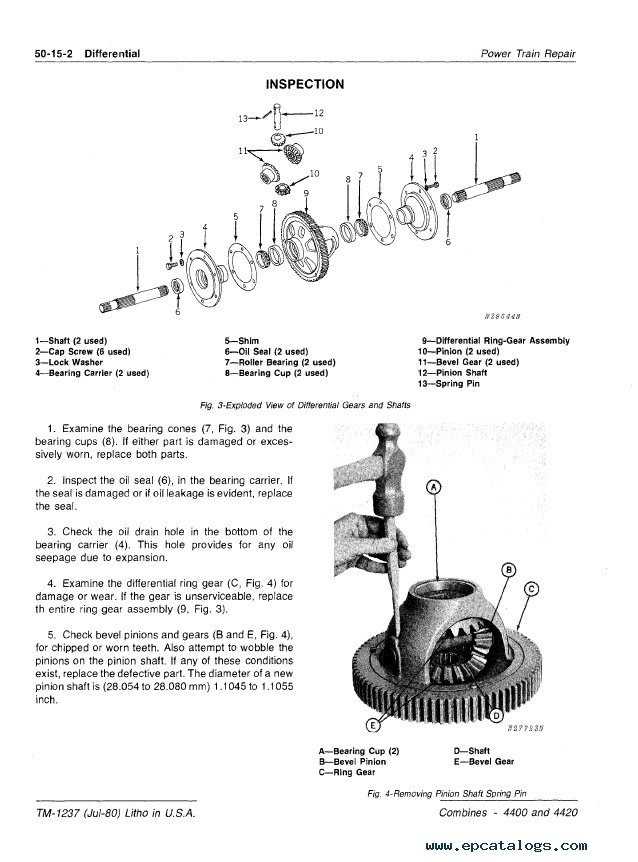

Engine Overhaul Process Explained

An engine overhaul is a comprehensive procedure aimed at restoring an engine’s performance and reliability. This process involves meticulous examination and replacement of critical components, ensuring that the engine operates at its optimal capacity.

Steps Involved in Overhauling an Engine

The engine overhaul process generally includes several key stages:

| Step | Description |

|---|---|

| Disassembly | Carefully removing engine components to access internal parts. |

| Inspection | Thorough examination of all parts for wear and damage. |

| Cleaning | Removing debris and buildup from engine components. |

| Replacement | Substituting worn or damaged parts with new or refurbished ones. |

| Reassembly | Putting the engine back together following the manufacturer’s specifications. |

| Testing | Running the engine to ensure proper function and performance. |

Key Considerations

During the overhaul, it’s crucial to adhere to proper techniques and utilize high-quality parts. This not only enhances performance but also extends the engine’s lifespan, ultimately delivering better efficiency and reliability.

Hydraulic System Maintenance Techniques

Effective upkeep of hydraulic systems is crucial for optimal performance and longevity. Regular attention to various components ensures that the system operates smoothly, minimizes wear and tear, and prevents costly breakdowns. Implementing systematic maintenance practices can significantly enhance efficiency and reliability.

Start by routinely inspecting hoses and connections for any signs of leaks or damage. Worn or cracked hoses can lead to fluid loss and reduced pressure, adversely affecting performance. Ensure that all connections are tight and free from corrosion, as this can compromise system integrity.

Regular fluid checks are essential. Hydraulic fluid should be clean and at the proper level. Contaminated or low fluid can result in inadequate lubrication, leading to component failure. When changing the fluid, use a high-quality product that meets the specifications of the system.

Filters play a vital role in maintaining fluid cleanliness. Check and replace filters according to the manufacturer’s guidelines to prevent contaminants from circulating through the system. This simple step can prolong the life of hydraulic components and maintain system efficiency.

Pay attention to the actuators and cylinders. Ensure they are functioning smoothly and are free from any obstructions. Lubricate moving parts as recommended to reduce friction and wear, which can lead to premature failure.

Finally, keep an eye on system pressure. Monitoring gauges regularly will help identify any anomalies that may indicate underlying issues. Addressing these promptly can prevent more significant problems down the line, ensuring that the hydraulic system remains reliable and efficient.

Parts Replacement for Optimal Performance

Maintaining peak functionality of heavy machinery relies significantly on the timely replacement of various components. Regular assessments and proactive management of parts ensure not only the longevity of the equipment but also its efficiency during operation. Proper attention to this aspect can mitigate the risk of unexpected failures and enhance productivity.

Key Components to Monitor

- Engine oil filters

- Fuel filters

- Hydraulic fluid

- Belts and hoses

- Brake components

Each of these elements plays a critical role in overall machine health. Ignoring any can lead to diminished performance and costly repairs in the future.

Replacement Guidelines

- Schedule routine inspections to identify worn or damaged parts.

- Refer to the manufacturer’s specifications for replacement intervals.

- Use high-quality parts to ensure compatibility and reliability.

- Document all replacements to maintain an accurate service history.

By adhering to these guidelines, operators can foster a reliable working environment, ultimately maximizing the utility and performance of their equipment.

Finding the Right Repair Manual

When it comes to maintaining heavy machinery, having access to a comprehensive guide is essential. Whether you’re troubleshooting issues or performing routine maintenance, a well-structured reference can significantly enhance your efficiency. The key is to locate the appropriate document that covers the specific model you are working with.

First, consider the source of the material. Official publications from the manufacturer often provide the most accurate and detailed information. These documents typically include diagrams, specifications, and step-by-step instructions tailored to the equipment. However, there are also alternative resources available, such as aftermarket guides and online forums, which may offer valuable insights from other users’ experiences.

Next, pay attention to the publication date. Machinery evolves over time, and newer versions of guides may reflect the latest updates and modifications. It’s beneficial to choose the most recent documentation available to ensure that you are following the latest procedures and safety standards.

Lastly, ensure that the manual you select matches your specific needs. Look for features such as troubleshooting tips, maintenance schedules, and parts lists that align with the tasks you plan to undertake. By carefully evaluating these factors, you can ensure that you have the best possible resource at your disposal for effective equipment management.