Complete Guide to Repairing Ronson Crown Lighters

In the world of collectible accessories, the allure of vintage flame devices remains unmatched. These unique items not only serve a practical purpose but also carry a rich history and craftsmanship that enthusiasts cherish. Restoring such treasures requires a keen eye for detail and an understanding of their intricate mechanisms.

Whether you are a seasoned collector or a novice with a newfound interest, knowing how to maintain and rejuvenate these devices can greatly enhance your experience. This guide aims to provide valuable insights and techniques for bringing these artifacts back to life, ensuring they continue to function beautifully for years to come.

With the right tools and knowledge, you can tackle common issues that may arise, allowing you to enjoy the charm of these classic pieces. Embrace the challenge of restoring a beloved item and discover the satisfaction that comes from breathing new life into a cherished relic.

Overview of Ronson Crown Lighters

This section provides insights into a unique category of portable flame-producing devices that have captured the attention of enthusiasts and collectors alike. Known for their distinctive design and functionality, these tools have become iconic over the years, serving both practical purposes and aesthetic appeal.

Historical Significance

The development of these devices dates back to the early 20th century, marking a significant advancement in personal ignition methods. With a blend of innovation and style, they became popular accessories, reflecting the cultural trends of their time. Collectors often seek these items not just for their utility but for their historical context and craftsmanship.

Design and Features

Characterized by a sleek and sophisticated aesthetic, these ignition devices often feature intricate detailing and a variety of finishes. Many models incorporate user-friendly mechanisms that enhance their functionality while maintaining an elegant appearance. Collectors appreciate the diversity of styles, with some pieces showcasing artistic designs that elevate them to the status of functional art.

In summary, this category of ignition tools represents a fascinating blend of history, design, and practicality, making them cherished items for both users and collectors.

Common Issues with Ronson Crown

Many users encounter various challenges with their ignition devices, often stemming from wear and tear or improper handling. Understanding these frequent problems can facilitate timely solutions and enhance the longevity of the item.

Fuel Leakage is a prevalent concern. It may arise from worn seals or damaged components, leading to inefficiency and potential hazards. Regular inspections can help identify any signs of leakage early on.

Flame Adjustment issues can occur when the flame is too high or too low, impacting usability. This can often be attributed to a malfunctioning adjustment mechanism, which may require recalibration or replacement for optimal performance.

Ignition Failure is another common dilemma, often caused by a depleted ignition source or an obstructed mechanism. Cleaning the ignition area and ensuring sufficient power can resolve this issue in many cases.

Physical Damage to the exterior can also hinder functionality. Scratches, dents, or cracks can not only affect the appearance but may also compromise the integrity of the device. Careful handling and storage are essential to prevent such damage.

By addressing these issues promptly and performing regular maintenance, users can enjoy a reliable and efficient experience with their ignition tools for years to come.

Tools Required for Repair

When undertaking the restoration of a classic ignition device, having the right equipment is essential for a successful outcome. A well-prepared toolkit not only streamlines the process but also enhances the quality of the work performed. Below is a comprehensive list of instruments that will facilitate effective handling and maintenance tasks.

Essential Instruments

- Precision Screwdriver Set

- Small Pliers

- Needle-Nose Pliers

- Wire Cutters

- Soft Cloth or Towel

- Cleaning Solution

Additional Supplies

- Replacement Parts

- Lubricant

- Multimeter for Electrical Testing

- Heat Source for Component Adjustment

- Magnifying Glass for Detailed Inspection

Having these tools at your disposal will ensure that the process is efficient and effective, allowing for thorough inspection and restoration of the device’s functionality.

Step-by-Step Disassembly Guide

This section provides a comprehensive approach to taking apart a classic ignition device, ensuring a careful process that preserves all components. Following these instructions will help you navigate through the intricacies of the assembly while minimizing the risk of damage.

Tools Required

- Screwdriver set (flat and Phillips)

- Pliers

- Small container for screws

- Tweezers

Disassembly Steps

- Start by removing any external decorative parts, such as the casing. Use the appropriate screwdriver to avoid stripping the screws.

- Once the outer shell is off, identify the internal components. Take care to note their arrangement for reassembly.

- Detach the ignition mechanism by carefully unscrewing any securing elements. Keep all screws in a designated container.

- Next, remove the fuel reservoir. Be cautious of any residual fuel; it’s advisable to let it air out in a well-ventilated area.

- Finally, inspect and remove any additional internal components, such as springs or flints. Use tweezers for delicate parts.

Ensure that you document each step with photographs or notes to aid in the reassembly process. Taking your time during disassembly will pay off when it’s time to put everything back together.

Identifying Fuel Leaks

Detecting fuel leaks is crucial for ensuring the safe and efficient operation of portable igniters. Proper identification of any signs of leakage can prevent accidents and prolong the lifespan of the device. This section focuses on various methods and indicators that can help users spot potential issues.

Visual Inspection: Begin by examining the exterior of the igniter for any visible signs of damage or wear. Look for cracks, holes, or any irregularities in the material that could indicate a breach. Pay close attention to joints and seams, as these are common points of failure.

Smell Test: A distinct odor often accompanies fuel leaks. If you notice a strong smell of fuel, it may be an indicator that leakage is occurring. This should be taken seriously, as inhalation of such fumes can be hazardous.

Check for Residue: Inspect the area around the igniter for any oily or sticky residues. Accumulation of fuel around the base or on surfaces nearby can suggest a leak. Use a cloth to wipe the area and observe if any fluid is present.

Functional Testing: Carefully operate the igniter to assess its performance. If you notice irregularities in ignition or persistent issues with fuel delivery, these could point to an underlying leakage problem that requires further investigation.

Sound Indicators: Listen for unusual sounds while the device is in use. Hissing or whistling noises may indicate escaping fuel, necessitating immediate attention to ensure safety.

By following these guidelines, users can effectively identify and address fuel leaks, maintaining the reliability and safety of their igniting devices.

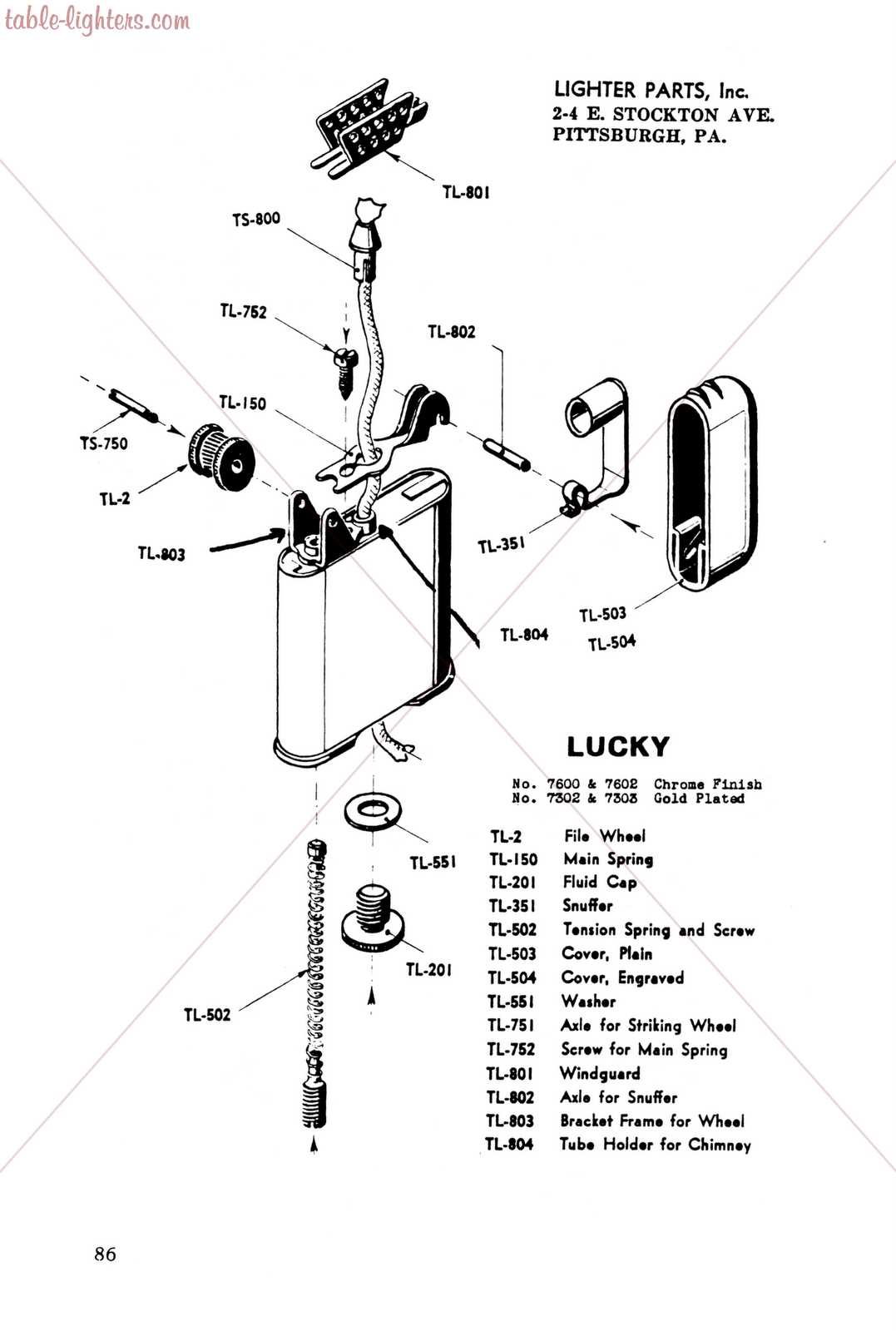

Replacing the Flint Mechanism

When a flame-producing device fails to ignite, one common issue is the flint component. This crucial part is responsible for generating the spark necessary for combustion. Over time, wear and tear can diminish its effectiveness, necessitating a replacement to restore functionality.

To begin the replacement process, ensure you have the appropriate tools at hand, including a screwdriver and a new flint. Start by disassembling the device carefully, paying close attention to the positioning of each part. Remove the old flint from its housing, ensuring no remnants are left behind, as these can obstruct the new component.

Once the old flint is removed, insert the new one, making sure it fits snugly within its designated space. Reassemble the device by following the steps in reverse order, securing all components properly to prevent any malfunctions. After reassembly, test the device to ensure that the new flint is functioning correctly, producing a reliable spark for ignition.

Cleaning the Lighter Components

Maintaining the internal parts of a portable flame source is essential for optimal performance and longevity. Regular cleaning prevents buildup of residue and ensures that all mechanisms operate smoothly. This section outlines effective methods for cleansing various elements of the device, enhancing both functionality and appearance.

Begin by disassembling the unit carefully, taking note of each component’s placement. Use a soft cloth or cotton swab to gently wipe away any dust or debris from the surfaces. For intricate areas, a small brush can help dislodge stubborn particles without causing damage.

Next, consider a suitable cleaning solution. Isopropyl alcohol is often recommended due to its evaporative properties and effectiveness against oils. Dampen a cloth with the solution and meticulously clean each part, ensuring no residue is left behind. Rinse with a clean, dry cloth afterward to avoid moisture accumulation.

Pay special attention to the ignition mechanism, as it is critical for reliable operation. Ensure that the spark area is free of any obstructions. A thorough cleaning here can significantly improve ignition efficiency.

Finally, after reassembly, perform a test to confirm that everything functions correctly. Regular maintenance, including cleaning, will keep your device in excellent condition for years to come.

Refilling the Fuel Tank

Maintaining an adequate supply of fuel is essential for the efficient operation of portable igniters. Regular refilling not only ensures optimal performance but also prolongs the lifespan of the device. This section will guide you through the process of replenishing the fuel reservoir safely and effectively.

Preparation Steps

Before you begin the refilling process, it is crucial to follow certain precautions:

- Choose a well-ventilated area to prevent the accumulation of fumes.

- Keep away from open flames or sources of heat.

- Ensure the device is turned off and completely cool to the touch.

Refilling Process

Follow these steps to refill the fuel compartment:

- Locate the refill opening, typically situated at the base of the unit.

- Carefully remove the cap or cover, ensuring not to lose any small components.

- Using an appropriate fuel type, slowly pour or inject the liquid into the tank. Avoid overfilling.

- Replace the cap securely to prevent leakage.

- Allow a few moments for any excess fumes to dissipate before using the device.

Following these guidelines will help maintain the functionality and safety of your portable igniter. Regular checks and refills can enhance your experience and ensure readiness whenever you need it.

Troubleshooting Ignition Problems

When dealing with issues related to the ignition mechanism of a portable flame device, it’s essential to identify the underlying causes of failure to ignite. This section provides a systematic approach to diagnosing and addressing common challenges that may arise during operation.

Common Causes of Ignition Failure

- Insufficient Fuel: Ensure that there is enough fluid in the reservoir for proper function.

- Blockage in the Nozzle: Check for any debris or residue that might obstruct the flow of fuel.

- Faulty Ignition Mechanism: Investigate the striking mechanism to confirm it is functioning correctly.

- Worn Out Parts: Examine components for signs of wear or damage that may affect performance.

Troubleshooting Steps

- Check Fuel Level: Verify the amount of fluid present and refill if necessary.

- Inspect for Blockages: Clean the nozzle and surrounding areas to eliminate any obstructions.

- Test the Ignition Mechanism: Engage the ignition system several times to see if it creates a spark.

- Examine Components: Look for cracks, bends, or other signs of deterioration that might impede function.

- Consult a Professional: If issues persist, consider seeking assistance from an experienced technician.

Maintaining Your Ronson Crown

Proper care is essential for the longevity and optimal performance of your flame-generating device. Regular attention to maintenance not only enhances functionality but also preserves its aesthetic appeal. By following a few simple guidelines, you can ensure your item remains in excellent condition for years to come.

Routine Cleaning

Cleaning your apparatus regularly is vital. Use a soft, lint-free cloth to wipe down the exterior and remove any residue or dirt. For deeper cleaning, a gentle solution of warm water and mild soap can be employed. Avoid abrasive materials, as they may damage the finish.

Refilling and Adjustment

Ensure that the fuel reservoir is adequately filled with the appropriate fluid. Overfilling can lead to leakage, while underfilling may result in inadequate performance. Additionally, check and adjust the flame height as necessary to suit your preferences, ensuring a consistent and reliable output.

By adhering to these simple maintenance practices, you can prolong the life of your cherished item and enjoy its reliable performance whenever needed.

Where to Find Replacement Parts

Locating components for your vintage device can be a rewarding experience, allowing enthusiasts to maintain and restore their treasured possessions. Understanding where to source these parts can greatly enhance your chances of a successful refurbishment.

Online Marketplaces

Numerous online platforms specialize in vintage accessories. Websites such as eBay and Etsy often feature sellers who list individual components, kits, or even entire models. Using specific keywords related to your item can help narrow down the search effectively.

Specialty Shops and Collectors

Consider visiting local antique stores or specialty shops that focus on retro items. These establishments may carry unique parts or have connections with collectors who are willing to sell. Additionally, joining forums or groups dedicated to enthusiasts can provide insights into where to find elusive components.

Networking with fellow hobbyists can also yield valuable recommendations and lead to discovering hidden gems in the market.

Safety Tips for Lighter Repair

Ensuring safety during the maintenance of ignition devices is paramount. Adhering to specific precautions can prevent accidents and enhance the overall experience. Here are essential guidelines to follow when handling these items.

General Precautions

- Always work in a well-ventilated area to avoid inhaling harmful fumes.

- Wear safety goggles to protect your eyes from any potential splashes or debris.

- Keep a fire extinguisher nearby in case of unexpected flames.

- Handle flammable materials with care, and store them in a safe location away from direct heat sources.

Tool and Material Safety

- Use appropriate tools for the task to minimize the risk of injury.

- Inspect tools before use to ensure they are in good condition.

- Be cautious when using any solvents or chemicals; read labels and follow instructions carefully.

- Dispose of any waste materials properly to prevent accidents or environmental harm.