Comprehensive Guide to 2008 Suzuki Forenza Repair

Ensuring the longevity and optimal performance of your vehicle requires access to detailed guidance on servicing and troubleshooting. This section aims to equip readers with essential information that facilitates the understanding of various components and systems within the vehicle. By following structured instructions and recommendations, users can navigate through common issues effectively.

From routine checks to more intricate repairs, having a solid resource at hand simplifies the process of vehicle maintenance. With step-by-step procedures and practical insights, enthusiasts and everyday drivers alike can enhance their mechanical skills. Engaging with this knowledge not only fosters confidence but also promotes a deeper appreciation for automotive technology.

Understanding the specifics of vehicle upkeep is crucial for anyone looking to save time and resources. This section serves as a reliable reference point, enabling individuals to tackle challenges head-on. With a focus on clarity and precision, the information provided here is designed to empower users, ensuring they feel equipped to handle a variety of automotive tasks.

This section provides an insight into the essential aspects of a particular vehicle model, highlighting its key features, functionalities, and maintenance tips. Understanding these components is crucial for owners looking to enhance their experience and ensure longevity.

The following points outline significant elements related to this vehicle:

- Design and Features: The model is characterized by its sleek exterior and spacious interior, catering to comfort and style.

- Engine Performance: The vehicle is equipped with a robust engine that balances power and fuel efficiency, making it suitable for various driving conditions.

- Safety Standards: It incorporates several safety features designed to protect passengers, including advanced airbag systems and stability control.

- Maintenance Tips: Regular checks and routine servicing are recommended to keep the vehicle in optimal condition, ensuring reliability and performance.

Familiarity with these aspects not only aids in effective operation but also contributes to informed decision-making regarding upkeep and potential upgrades.

Common Issues and Solutions

This section addresses frequent complications that vehicle owners may encounter, along with effective remedies to ensure optimal performance and reliability. Understanding these common pitfalls can aid in proactive maintenance and enhance the overall driving experience.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Engine Overheating | Temperature gauge reading high, steam from the hood | Check coolant level, inspect radiator for leaks, replace thermostat |

| Transmission Slipping | Unresponsive shifting, delayed engagement | Inspect transmission fluid level, replace fluid and filter, check for leaks |

| Electrical Issues | Dashboard warning lights, flickering headlights | Test battery and alternator, check for loose connections, replace faulty components |

| Brake Problems | Squeaking noise, reduced stopping power | Inspect brake pads and rotors, replace worn components, check brake fluid level |

Maintenance Schedule and Guidelines

A well-structured maintenance routine is essential for ensuring optimal performance and longevity of any vehicle. Following a systematic schedule not only enhances safety but also helps in identifying potential issues before they escalate into major problems. Adhering to recommended practices fosters reliability and efficiency, allowing drivers to enjoy a smooth driving experience.

Here are some key recommendations for maintaining your vehicle:

- Regular Oil Changes: Change the engine oil every 5,000 to 7,500 miles to keep the engine components lubricated and functioning efficiently.

- Filter Replacement: Replace the air and oil filters at the same interval as oil changes to ensure clean airflow and effective filtration.

- Tire Inspection: Check tire pressure monthly and rotate tires every 5,000 to 7,500 miles to promote even wear and extend tire life.

- Brake System Checks: Inspect brake pads and fluid regularly, replacing components as needed for optimal stopping power.

- Fluid Levels: Regularly check and top off essential fluids, including coolant, transmission fluid, and brake fluid.

To further enhance your maintenance approach, consider the following guidelines:

- Document all maintenance activities to keep track of services performed.

- Consult the manufacturer’s recommendations for specific service intervals and tasks.

- Utilize quality parts and fluids that meet or exceed manufacturer specifications.

- Be proactive about scheduling appointments with a qualified technician for complex tasks.

By following these maintenance schedules and guidelines, vehicle owners can ensure their vehicle remains reliable and efficient for years to come.

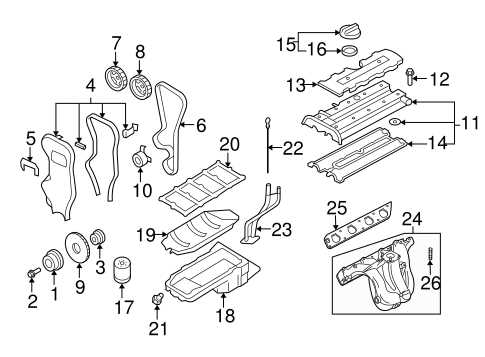

Engine Specifications and Diagnostics

This section provides essential information regarding the performance characteristics and troubleshooting methodologies for the powertrain. Understanding these elements is crucial for maintaining optimal functionality and addressing potential issues effectively.

Performance Characteristics

The engine is designed with a specific displacement and configuration that ensures efficient power output and fuel consumption. Key specifications include the maximum horsepower and torque ratings, as well as the operational range of RPMs. These parameters play a vital role in determining the overall driving experience and responsiveness.

Diagnostic Approaches

Accurate diagnostics are fundamental in identifying malfunctions within the engine system. Utilizing onboard diagnostic tools can reveal error codes that correspond to specific issues. Regular monitoring of fluid levels and inspecting for unusual noises or vibrations are also important practices. Implementing these strategies can enhance longevity and performance.

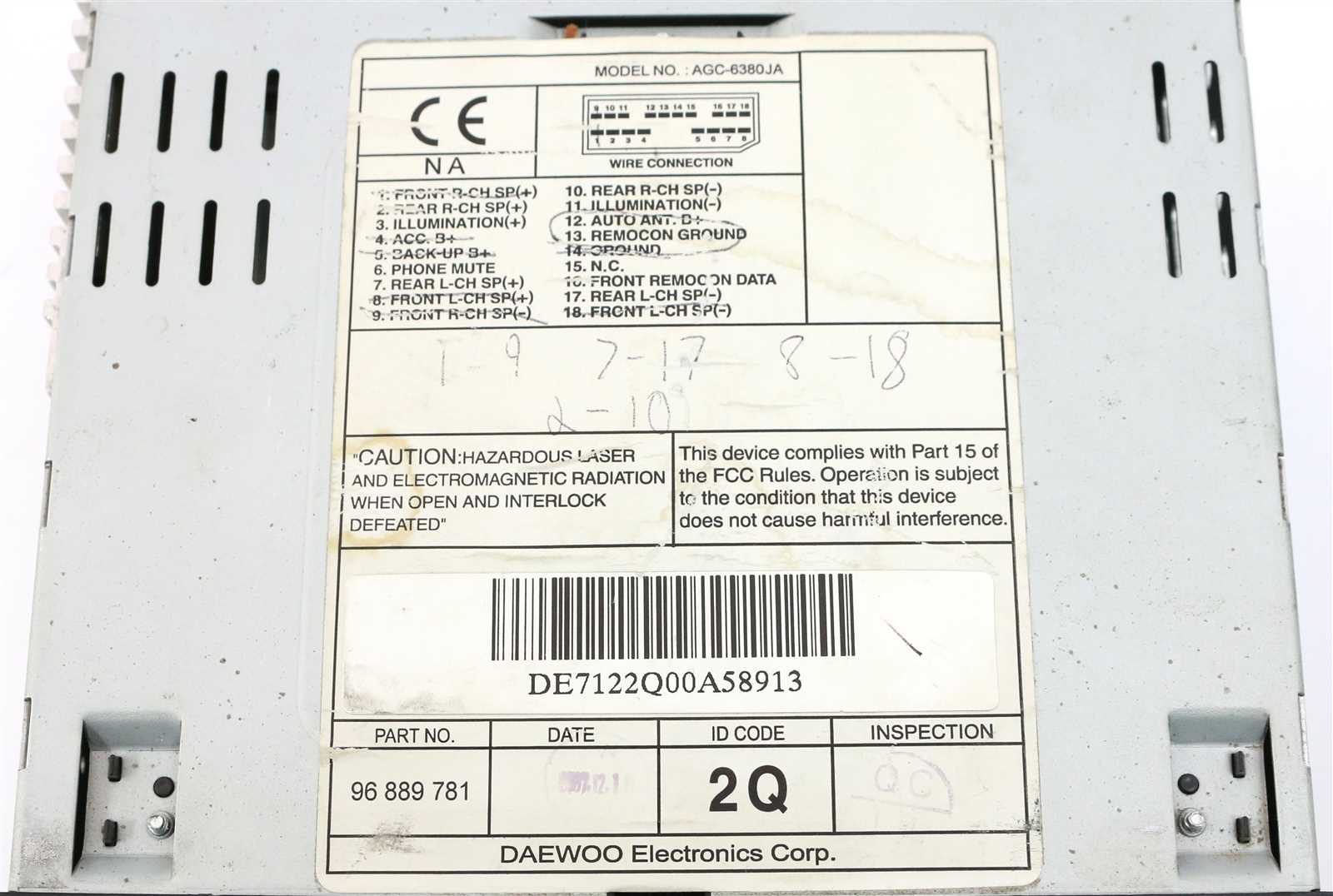

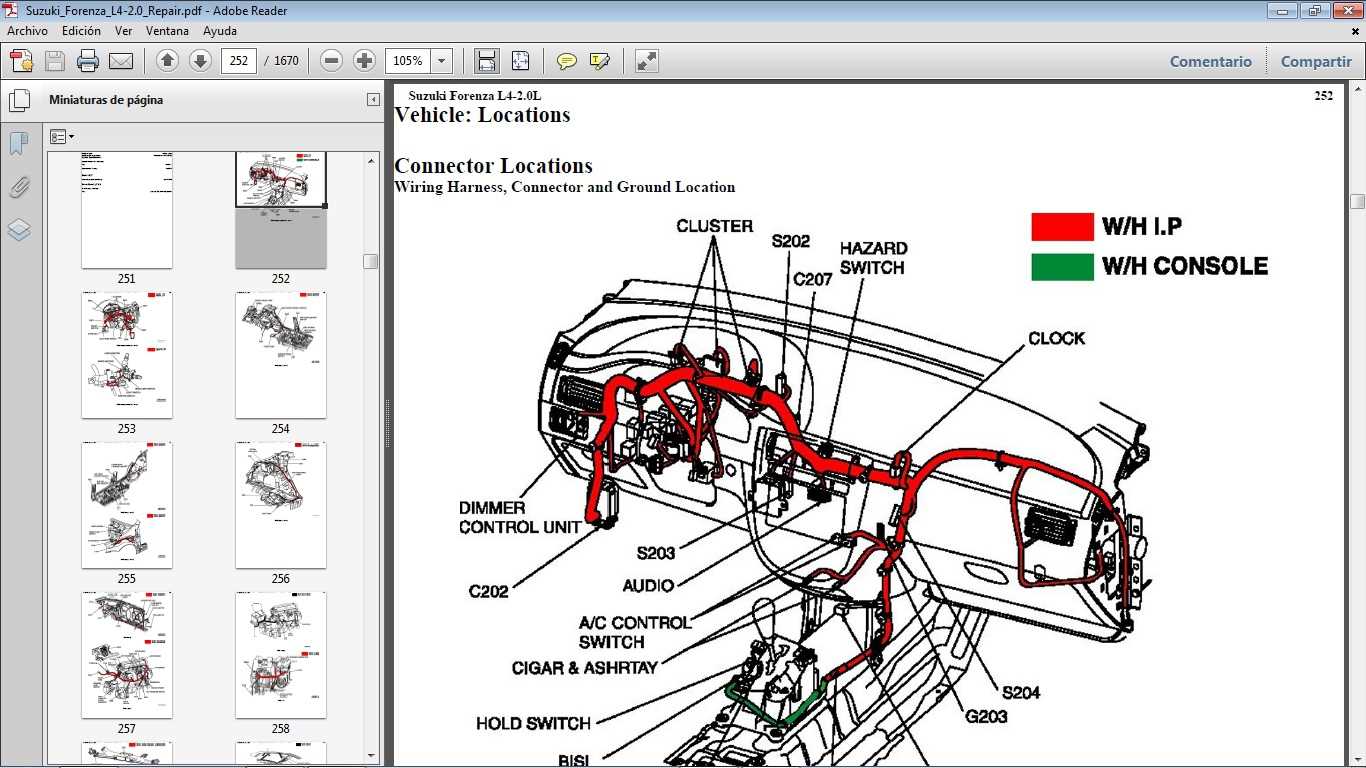

Electrical System Troubleshooting

Troubleshooting electrical systems involves systematic identification and resolution of issues that may arise within the circuitry of a vehicle. This process ensures that all components function optimally, leading to reliable performance and safety.

Common Symptoms: Symptoms of electrical malfunctions can vary widely, including intermittent power loss, malfunctioning accessories, or warning lights illuminating on the dashboard. Recognizing these signs early can prevent more significant complications.

Diagnostic Techniques: Begin by checking the battery and its connections. A weak battery or corroded terminals can lead to erratic behavior. Utilize a multimeter to assess voltage levels and continuity across various components. Inspecting fuses and relays is also crucial, as these protect the electrical system from overloads.

Final Steps: After identifying the faulty component, ensure proper replacement and secure connections to restore functionality. Regular maintenance checks can greatly reduce the likelihood of electrical issues arising in the future.

Brake System Repair Techniques

Effective maintenance of the braking mechanism is crucial for ensuring safety and performance. Proper procedures for servicing the braking system can help in identifying issues early and maintaining optimal functionality. This section outlines various methods for addressing common problems associated with the braking system.

Regular inspection and replacement of components are essential steps in maintaining an effective braking system. Key components include brake pads, rotors, and fluid, all of which require careful monitoring and timely intervention.

| Component | Recommended Action | Frequency |

|---|---|---|

| Brake Pads | Inspect for wear; replace if less than 3 mm | Every 20,000 miles |

| Rotors | Check for grooves and warping; machine or replace as necessary | Every 40,000 miles |

| Brake Fluid | Flush and replace; ensure fluid is free of contaminants | Every 2 years |

In addition to regular maintenance, understanding the specific symptoms of braking issues is vital. Unusual noises, vibrations, or reduced responsiveness can indicate the need for immediate attention. Addressing these signs promptly can prevent further complications and ensure the system operates efficiently.

Transmission Maintenance and Repair

Proper upkeep of the transmission system is crucial for ensuring the longevity and efficiency of any vehicle. Regular inspections and timely interventions can prevent minor issues from escalating into significant problems, thereby enhancing performance and reliability.

Key maintenance tasks include fluid checks, filter replacements, and overall system evaluations. By adhering to a systematic schedule, vehicle owners can effectively manage the health of their transmission components.

| Task | Frequency | Description |

|---|---|---|

| Fluid Check | Every 30,000 miles | Inspect transmission fluid level and condition to ensure optimal operation. |

| Filter Replacement | Every 60,000 miles | Change the transmission filter to prevent debris buildup that can hinder performance. |

| System Inspection | Annually | Conduct a thorough evaluation of all transmission components for wear and damage. |

| Fluid Flush | Every 100,000 miles | Perform a complete fluid exchange to remove contaminants and refresh the system. |

By following these guidelines, vehicle operators can ensure that the transmission remains in peak condition, ultimately contributing to a smoother driving experience and enhanced safety on the road.

Suspension and Steering Insights

The suspension and steering systems are crucial components that significantly influence vehicle handling, comfort, and safety. Understanding their functionality and maintenance can lead to a more enjoyable driving experience. This section will explore key aspects of these systems, helping enthusiasts and technicians alike to enhance their knowledge and skills.

Key Components of Suspension

- Shock Absorbers: Vital for controlling the rebound and compression of the vehicle’s springs, ensuring a smooth ride.

- Coil Springs: Support the weight of the vehicle while allowing for necessary travel during road irregularities.

- Control Arms: Connect the chassis to the wheel assembly, enabling effective movement and alignment.

- Sway Bars: Help reduce body roll during cornering, improving stability and handling.

Steering System Fundamentals

- Steering Wheel: The primary interface for the driver, allowing for directional control.

- Steering Column: Connects the steering wheel to the steering mechanism, often incorporating safety features like collapsibility.

- Rack and Pinion: A common type of steering gear that converts rotational motion into linear movement, enhancing responsiveness.

- Power Steering: Assists the driver in steering efforts, making it easier to maneuver the vehicle.

Regular inspection and maintenance of these systems are essential to ensure optimal performance and safety. Addressing wear and tear promptly can prevent more significant issues down the road, keeping the vehicle in top condition for any journey.

Body and Interior Repairs

Maintaining the exterior and interior of a vehicle is essential for both aesthetics and functionality. This section addresses common issues and solutions associated with the vehicle’s structure and cabin. Proper attention to these areas ensures longevity and enhances the overall driving experience.

Exterior Damage Assessment: Evaluating the outer shell for dents, scratches, or corrosion is the first step. Minor imperfections can often be remedied with polishing compounds or touch-up paint. For more significant damage, replacement panels or professional bodywork may be necessary.

Interior Upkeep: The interior environment plays a crucial role in comfort and usability. Regular cleaning and conditioning of surfaces, such as upholstery and dashboards, help prevent wear and maintain a pleasant atmosphere. In cases of severe damage, replacing components like seats or trim may be required.

Preventive Measures: Regular inspections and timely maintenance can significantly reduce the likelihood of extensive repairs. Applying protective coatings to the exterior and using mats inside can safeguard against wear and tear, prolonging the life of both body and interior elements.

Tools Required for Repairs

Having the right equipment is essential for performing maintenance tasks effectively and safely. A well-equipped workspace not only facilitates the process but also enhances the quality of the work done. Various instruments will be needed to address common issues that may arise, ensuring that each component functions optimally.

Basic hand tools such as wrenches, screwdrivers, and pliers are fundamental for most tasks. Additionally, specialized tools, like diagnostic scanners, can aid in identifying underlying problems efficiently. Safety gear, including gloves and goggles, should also be included to protect against potential hazards while working.

Investing in high-quality equipment can significantly improve both the efficiency and effectiveness of the tasks at hand. Ensuring all necessary items are available before starting a project can save time and minimize frustration during the repair process.

Safety Precautions for DIY Repairs

Engaging in maintenance tasks at home can be rewarding, yet it is essential to prioritize safety to prevent accidents and injuries. Understanding the necessary precautions ensures a secure working environment, allowing for a more effective and enjoyable experience.

Essential Safety Measures

- Always wear appropriate personal protective equipment, including gloves, goggles, and a mask, to shield yourself from potential hazards.

- Ensure your workspace is well-ventilated to minimize exposure to harmful fumes and vapors.

- Keep your tools organized and in good condition, as this reduces the risk of accidents.

- Disconnect the power source before starting any electrical work to avoid shocks.

Working with Fluids and Chemicals

- Use containers to collect any leaking fluids, preventing spills that could create slippery surfaces.

- Store hazardous substances in clearly labeled, secure containers to avoid accidental exposure.

- Dispose of waste materials according to local regulations to minimize environmental impact.

By adhering to these guidelines, individuals can significantly reduce risks associated with home maintenance tasks, ensuring a safer and more productive environment.

Upgrading Parts and Accessories

Enhancing your vehicle’s components can significantly improve performance, aesthetics, and overall driving experience. This section focuses on various upgrades available for automotive enthusiasts looking to customize and optimize their vehicles.

Performance Enhancements

Upgrading engine components, exhaust systems, and suspension can lead to better handling and increased power output. Many aftermarket parts are designed to enhance efficiency and responsiveness, providing a more engaging driving experience.

Interior and Exterior Modifications

Improving interior comfort and exterior appearance can also be achieved through targeted upgrades. From advanced audio systems to stylish body kits, these enhancements allow for personalization that reflects the owner’s taste.

| Upgrade Type | Description | Benefits |

|---|---|---|

| Performance Parts | Includes exhaust systems, air intakes, and tuners. | Increased horsepower and torque. |

| Suspension Kits | Upgrades to shock absorbers and springs. | Improved handling and ride quality. |

| Audio Systems | Upgraded speakers and head units. | Enhanced sound quality and features. |

| Body Kits | Aesthetic modifications for style. | Improved aerodynamics and visual appeal. |

Resources for Further Assistance

When seeking guidance for vehicle maintenance and troubleshooting, a variety of resources can provide valuable support. These tools range from online forums to official service guides, ensuring that enthusiasts and owners alike have access to the necessary information for effective problem-solving.

Online Communities

- Automotive forums where users share experiences and solutions.

- Social media groups dedicated to specific vehicle types, fostering discussion and advice.

- Video tutorials on platforms like YouTube, demonstrating repair techniques and tips.

Official Documentation

- Manufacturer websites often offer downloadable guides and specifications.

- Technical bulletins that address common issues and updates.

- Specialized publications and reference books available at local libraries or bookstores.