Toyota 1ZZ FE Engine Repair Guide

In this section, we delve into the fundamental processes needed to keep your vehicle’s core systems running smoothly. Ensuring the longevity of essential parts requires a systematic approach to servicing and understanding the unique requirements of each component. Through detailed insights, this guide aims to simplify complex procedures, offering practical knowledge for maintaining reliability and performance.

Key practices and step-by-step methods are provided to help you tackle regular upkeep, address potential issues early on, and enhance your understanding of the internal workings of the machinery. Whether you’re experienced or new to vehicle maintenance, this guide serves as a valuable reference for maintaining operational integrity over time.

Alongside essential upkeep recommendations, you’ll find useful tips on optimizing performance, identifying common challenges, and ensuring that each part functions as intended. With a focus on practical and accessible advice, the information here helps make complex tasks achievable, guiding you toward effective, hands-on maintenance solutions.

Toyota 1ZZ-FE Engine Repair Guide

Understanding the fundamentals of this vehicle’s power unit helps in performing effective maintenance and troubleshooting. With a solid grasp of its main parts and mechanisms, drivers can anticipate common issues and apply suitable solutions, promoting optimal performance and durability.

Basic Inspection: Regular assessment of key components is essential to keep this motor running smoothly. Checkpoints like the lubrication system, cooling mechanisms, and fuel supply are critical to monitor, as they directly impact the unit’s reliability and lifespan. Consistent maintenance reduces wear and improves efficiency.

Addressing Common Issues: Knowing how to recognize signs of potential issues, such as irregular sounds or drops in output, is vital. Detecting problems early minimizes risks and repair costs, ensuring longer service life and sustained reliability. Clear diagnostic steps can aid in pinpointing the source of problems effectively.

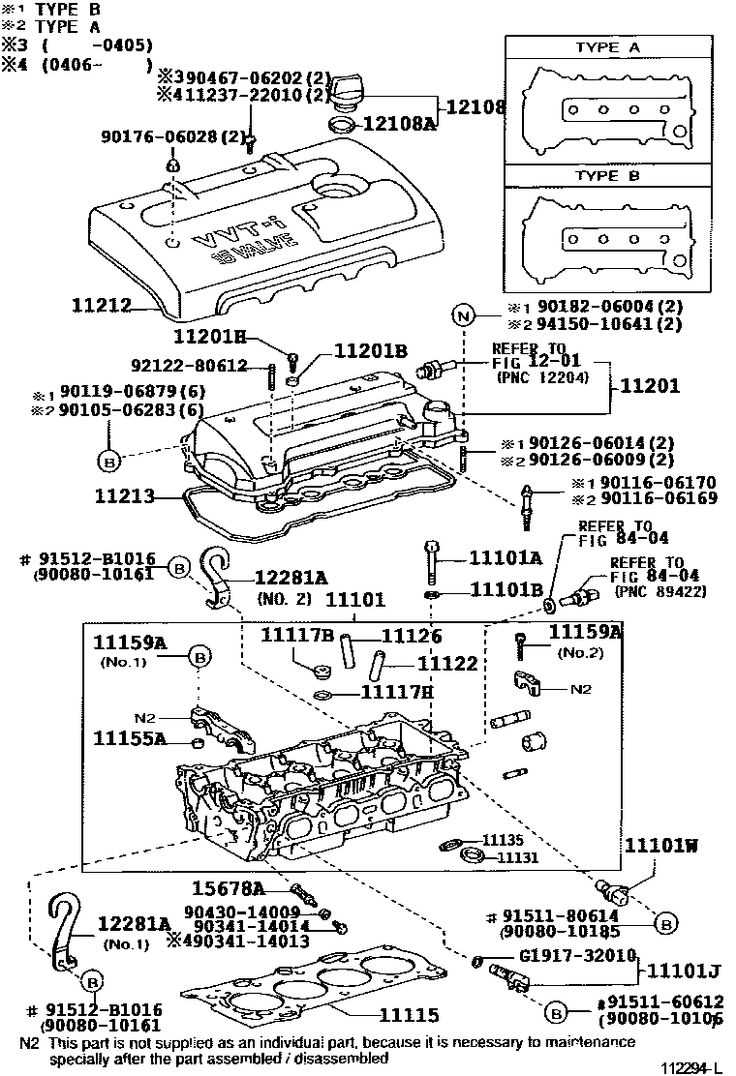

Component Care: Proper upkeep of elements like the cylinder head, timing mechanisms, and intake system enhances the overall function. Periodic cleaning and adjustments, when needed, contribute to steady operation and help avoid extensive repairs. Careful handling and regular checks on these parts support consistent performance.

Engine Overview and Key Features

This section provides an insight into the design and functionality of a widely recognized compact power unit, highlighting its versatile applications and core strengths. The unit is known for its efficient performance, reliability, and balance between power and fuel economy, making it suitable for a variety of settings and needs.

| Feature | Description |

|---|---|

| Lightweight Structure | Built with a focus on reducing weight, this unit integrates materials that support durability while enhancing fuel efficiency and performance. |

| Variable Valve Timing | Equipped with technology that adjusts valve timing based on load, ensuring optimized fuel use and smoother operation across speeds. |

| Compact Design | Designed to fit into tighter spaces, this power unit maximizes space efficiency, benefiting both layout and maintenance accessibility. |

| High Fuel Efficiency | Engineered to achieve a balanced fuel-to-power ratio, prioritizing sustainability while maintaining robust output. |

| Low Emissions | Developed to meet emission standards with minimal exhaust output, contributing to a cleaner operation and environmental compliance. |

Common Issues and Diagnosing Faults

When dealing with vehicle performance challenges, certain recurring problems can arise that often signal underlying component wear or system inefficiencies. Identifying these early on helps maintain functionality and prevent more extensive issues over time.

Identifying Performance Symptoms

A range of signs, from reduced power output to unusual sounds, can indicate the need for closer inspection. If performance declines, diagnosing potential causes becomes essential. Possible issues may relate to fuel delivery, ignition timing, or air intake, each of which plays a critical role in overall operation.

Tools for Diagnosis

Reliable diagnostics often start with essential tools that can accurately assess component function and pinpoint faults. Using tools like compression testers, diagnostic scanners, and specialized gauges allows for efficient identification of problematic areas, offering insights into necessary adjustments or replacements.

Essential Tools for 1ZZ-FE Repair

Working on complex machinery requires a well-prepared set of equipment to ensure every step is handled with precision. Whether it’s a simple checkup or a more extensive overhaul, having the right instruments on hand makes the task smoother and significantly more effective.

Basic Hand Tools

A solid selection of hand tools is fundamental. Wrenches, sockets, and pliers of various sizes are indispensable for removing and reattaching components securely. Screwdrivers in both flathead and Phillips varieties, as well as torque wrenches, help in carefully adjusting fasteners to prevent over-tightening.

Specialized Equipment

Beyond the basics, specialized tools such as a pulley puller or a feeler gauge may be necessary for handling specific components. Additionally, using a quality engine hoist can greatly simplify work on more cumbersome parts. Precision measurement tools, like micrometers and dial indicators, also provide crucial accuracy for checking clearances and alignment during the process.

Disassembly Steps and Precautions

Disassembling mechanical systems requires careful planning and methodical attention to each component. A structured approach can help prevent accidental damage to sensitive parts and ensures a smooth reassembly process later on. Following established guidelines and maintaining an organized workspace are essential aspects of achieving successful results.

Step-by-Step Process: Begin by identifying and documenting the positioning of each component. Labeling parts and arranging them in the order of removal will aid in reassembly. Handle each part with care, particularly smaller and more delicate items, which are susceptible to wear and misalignment.

Key Precautions: When disassembling, avoid applying excessive force, as this may lead to unintended damage. Components may require specific tools for removal; using the correct tools helps maintain the integrity of each piece. Ensure that each part is free from contaminants and stored in a clean environment to prevent dirt and particles from compromising system performance during reassembly.

Note: Consistently checking for potential wear or deterioration during disassembly can highlight areas needing replacement or repair before the reassembly stage.

Piston and Cylinder Maintenance

Proper care and attention to the components involved in the combustion process are essential for optimal performance and longevity. This section emphasizes the significance of maintaining the internal parts that contribute to a vehicle’s overall functionality, ensuring smooth operation and preventing costly issues.

Inspection of Components

Regular examination of the pistons and cylinders is crucial to identify any signs of wear or damage. Look for irregularities such as scoring, scratches, or abnormal wear patterns that can indicate underlying problems. Timely detection can facilitate appropriate interventions, preserving the integrity of the assembly.

Cleaning and Lubrication

Maintaining cleanliness is vital for preventing debris accumulation, which can hinder performance. Utilize suitable cleaning agents to remove carbon deposits and other contaminants. Additionally, ensure that lubrication is applied adequately to reduce friction and wear, promoting a longer lifespan for these critical components. Effective lubrication contributes significantly to efficient operation and reliability.

Camshaft Timing and Alignment Tips

Accurate timing and alignment of the camshaft are crucial for optimal performance and efficiency of your vehicle’s power unit. Ensuring that these components are correctly positioned can prevent a range of issues, including misfiring and reduced power output. This section will cover essential practices and insights for achieving precise camshaft alignment.

Understanding Camshaft Timing

Camshaft timing refers to the synchronization between the camshaft and the crankshaft. This synchronization is vital for the proper operation of the intake and exhaust valves. The correct timing ensures that the valves open and close at the right intervals, allowing for optimal airflow and engine performance. It is essential to refer to the specifications provided by the manufacturer to set the timing accurately.

Alignment Techniques

Proper alignment of the camshaft is necessary to prevent undue wear and ensure smooth operation. Here are some techniques to assist in achieving correct alignment:

| Step | Description |

|---|---|

| 1 | Verify the alignment marks on the timing gear and camshaft. |

| 2 | Rotate the crankshaft to align the marks according to the specifications. |

| 3 | Check the tension on the timing chain or belt to ensure it is adequately tight. |

| 4 | Perform a final inspection to confirm that all components are properly seated and aligned. |

By following these tips and techniques, you can ensure that your camshaft is timed and aligned correctly, contributing to the overall efficiency and longevity of the power unit.

Fuel System Repair and Replacement

The fuel delivery system is crucial for optimal performance, requiring regular maintenance and timely interventions. Addressing issues within this system ensures proper fuel flow and enhances overall functionality. This section focuses on the key components, troubleshooting methods, and guidelines for effective substitution to maintain efficiency.

Key Components of the Fuel Delivery System

The primary elements that constitute the fuel delivery system include the fuel pump, injectors, fuel filter, and lines. Each part plays a significant role in ensuring that fuel reaches the combustion area efficiently. Understanding their functions is essential for diagnosing issues and implementing corrective actions.

Troubleshooting Common Issues

Identifying problems in the fuel system can often be accomplished through careful observation and systematic testing. Symptoms such as reduced performance, stalling, or starting difficulties may indicate underlying issues. Utilizing diagnostic tools can aid in pinpointing the exact cause of malfunctions.

| Component | Common Issues | Replacement Guidelines |

|---|---|---|

| Fuel Pump | Failure to start, noise | Check voltage, replace if faulty |

| Fuel Injectors | Uneven idling, misfire | Clean or replace as needed |

| Fuel Filter | Clogging, pressure drop | Replace according to schedule |

| Fuel Lines | Leaks, corrosion | Inspect and replace damaged sections |

Cooling System Troubleshooting Guide

The cooling system is crucial for maintaining optimal performance and longevity of a vehicle’s power source. Identifying and addressing issues within this system can prevent severe damage and ensure efficient operation. This guide offers insights into common problems and effective solutions to enhance the functionality of the cooling setup.

Below are some frequent symptoms that may indicate cooling system issues:

- Overheating of the power source

- Unusual noises from the cooling system

- Low coolant levels

- Coolant leaks under the vehicle

- Increased engine temperature gauge readings

When troubleshooting, consider the following steps:

- Check Coolant Levels: Ensure the coolant is at the recommended level. If it is low, refill it with the appropriate mixture.

- Inspect for Leaks: Examine hoses, clamps, and the radiator for any signs of coolant leaks. Repair or replace damaged components.

- Examine the Radiator: Ensure the radiator is not clogged or damaged. Clean or replace it if necessary.

- Test the Thermostat: If the vehicle overheats, the thermostat may be stuck closed. Test it and replace if it fails to open.

- Assess the Water Pump: Check for signs of wear or failure in the water pump. Listen for unusual noises that may indicate a problem.

By following these steps, vehicle owners can effectively troubleshoot and address common cooling system issues, ultimately enhancing the overall performance and reliability of their vehicle.

Oil System Care and Lubrication

Maintaining the lubrication system is crucial for ensuring optimal performance and longevity of your vehicle. Proper care and attention to this system can prevent premature wear and tear, as well as reduce the risk of major issues arising due to inadequate lubrication.

Importance of Regular Oil Changes

Regularly replacing the lubricating fluid is essential for the health of your vehicle. Over time, oil can become contaminated with dirt and debris, which may hinder its ability to protect vital components. Following the manufacturer’s guidelines on oil change intervals is advisable to ensure that the system remains efficient.

Checking Oil Levels and Quality

It is important to routinely check the fluid levels and quality. Low oil levels can lead to insufficient lubrication, while degraded oil may not perform its protective functions effectively. Utilize the dipstick to assess the level and look for signs of contamination, such as a gritty texture or unusual color.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Oil Change | Every 5,000 – 7,500 miles | Check manufacturer recommendations |

| Oil Level Check | Monthly | Ensure levels are within recommended range |

| Filter Replacement | Every other oil change | Use high-quality filters for best results |

Electrical Components and Wiring

This section provides an overview of the various electrical components and wiring systems found in the vehicle. Understanding these elements is essential for maintaining optimal functionality and ensuring safety during operation. Proper knowledge of wiring diagrams and component locations can facilitate troubleshooting and repairs.

Electrical systems are crucial for the efficient operation of numerous vehicle functions, including ignition, lighting, and communication. A comprehensive understanding of these systems aids in identifying issues and implementing effective solutions.

| Component | Description | Function |

|---|---|---|

| Battery | Stores electrical energy | Supplies power to start the vehicle and run electrical components |

| Alternator | Generates electrical power | Recharges the battery and powers electrical systems while the engine is running |

| Starter Motor | Engages the engine | Cranks the engine to initiate combustion |

| Fuses | Protective devices | Prevent overcurrent and protect electrical circuits |

| Wiring Harness | Network of cables | Connects various electrical components and facilitates communication |

Reassembly Process and Final Checks

The process of putting components back together after disassembly is crucial for ensuring optimal performance and reliability. This stage involves careful attention to detail, as each part must fit correctly and function as intended. Following a systematic approach will help prevent issues during operation.

Begin the reassembly by organizing all parts and tools to streamline the workflow. Check for any wear or damage on each component before installation. It is essential to follow the manufacturer’s specifications for torque settings and sequences to achieve a proper fit.

After all parts have been reassembled, conduct a series of final checks. These should include verifying that all fasteners are securely tightened and ensuring that all connections, such as electrical and fluid, are properly made. It is also advisable to inspect for any signs of leakage or misalignment.

Finally, perform a test run to monitor the assembly’s performance. Listen for unusual noises and watch for any irregularities. Addressing any concerns at this stage can save time and prevent further complications down the line.