Comprehensive Guide to Marine Engine Repair Manuals

When it comes to maintaining watercraft propulsion systems, having access to comprehensive guidance is essential. These resources provide valuable insights into the intricate components that make up the power mechanisms used in various vessels. By consulting these references, users can enhance their knowledge and skills, leading to improved performance and longevity of the equipment.

Moreover, such documents often outline troubleshooting strategies, preventive measures, and techniques for effective servicing. Engaging with this information empowers boat owners and technicians alike to tackle issues with confidence and precision. It creates a solid foundation for understanding the essential functions and requirements of propulsion systems, ensuring that every outing on the water is safe and enjoyable.

Incorporating these resources into regular maintenance routines is not just about fixing problems as they arise; it’s about fostering a proactive approach to vessel management. This mindset ultimately contributes to better efficiency, reduced operational costs, and a more satisfying experience for all who navigate the waters.

Understanding the various types of propulsion systems used in watercraft is essential for anyone involved in the upkeep of these vital components. Each category of these power sources has unique characteristics, advantages, and challenges. Recognizing these differences aids in selecting the right approach for maintenance and troubleshooting.

There are several primary classifications of these power sources:

- Two-Stroke Systems: Known for their simplicity and lightweight design, these systems operate on a two-stroke cycle, making them efficient for smaller vessels.

- Four-Stroke Systems: More complex and generally more fuel-efficient, these systems utilize a four-stroke cycle, making them ideal for larger crafts and extended operations.

- Diesel Variants: Typically found in larger vessels, these robust systems are praised for their durability and fuel efficiency, suitable for long voyages.

- Gasoline Units: Often used in smaller boats, these units provide quick acceleration and are easier to maintain, although they may consume more fuel.

Each of these propulsion systems requires specific knowledge and techniques for effective maintenance. Familiarity with their operational principles is crucial for diagnosing issues and ensuring optimal performance.

Common Issues with Marine Engines

Owning a watercraft comes with its own set of challenges, especially when it comes to maintaining optimal performance. Understanding frequent complications can greatly aid in timely interventions, preventing minor setbacks from escalating into significant troubles.

Frequent Complications

Several recurring problems are often observed, each requiring different approaches for resolution:

- Overheating due to cooling system failures.

- Starting difficulties stemming from battery or ignition issues.

- Fuel supply interruptions caused by clogged filters.

- Excessive vibrations indicating potential alignment issues.

- Leaks from various seals and gaskets affecting overall efficiency.

Preventive Measures

Implementing certain practices can help mitigate these issues:

- Regular inspections to identify early signs of wear.

- Routine maintenance of the fuel and cooling systems.

- Consistent monitoring of fluid levels and conditions.

- Utilization of quality components during any replacements.

Essential Tools for Engine Repair

Having the right instruments is crucial for successfully maintaining and fixing mechanical systems. A well-equipped toolkit can significantly enhance efficiency and ensure tasks are performed accurately. This section outlines the key items that every technician should consider for effective service.

- Socket Set: A comprehensive socket set allows for easy access to various fasteners.

- Wrenches: Adjustable wrenches and combination wrenches are essential for loosening or tightening bolts.

- Torque Wrench: This tool ensures that fasteners are tightened to the manufacturer’s specifications, preventing damage.

- Screwdriver Set: A variety of screwdrivers, including flathead and Phillips, is necessary for different types of screws.

- Pliers: Needle-nose pliers and locking pliers help grasp and manipulate small components.

In addition to these basics, specific instruments can improve workflow:

- Multimeter: Useful for diagnosing electrical issues and ensuring proper voltage levels.

- Compression Tester: This device measures the compression in cylinders, indicating the health of the internal components.

- Oil Filter Wrench: Designed to easily remove oil filters, it saves time and effort during maintenance.

Equipping a workspace with these necessary tools can lead to more efficient and effective service, ultimately enhancing the longevity and performance of the machinery.

Step-by-Step Repair Procedures

This section outlines a comprehensive approach to troubleshooting and maintaining your aquatic propulsion systems. Following systematic methods ensures that issues are identified and resolved efficiently, enhancing performance and longevity.

Begin by assessing the situation: Evaluate the symptoms and gather necessary tools and components. Proper preparation is crucial for an effective process.

Follow a structured approach: Each task should be executed in a logical sequence, from disassembly to inspection and finally reassembly. Make sure to document each step, noting any irregularities encountered along the way.

Conduct thorough checks: Inspect all parts meticulously for wear and damage. Replace any faulty components to avoid future complications. It is advisable to consult reference guides for specifications and standards.

Finalize the process: Once repairs are completed, conduct tests to ensure everything functions as intended. Monitoring performance after reassembly can help identify any remaining issues early on.

By adhering to these outlined procedures, individuals can achieve effective and lasting solutions for their aquatic machinery challenges.

Preventive Maintenance Tips

Regular upkeep is essential for ensuring the longevity and efficiency of your equipment. By implementing simple yet effective practices, you can minimize the risk of unexpected failures and enhance overall performance. This section provides valuable insights into maintaining your system in optimal condition.

Routine Inspections

Conducting frequent assessments allows you to identify potential issues before they escalate. Check for any signs of wear, leaks, or irregularities. Addressing minor concerns promptly can save significant time and resources in the long run.

Scheduled Cleanings

Keeping components clean is crucial for smooth operation. Regularly remove dirt, debris, and other contaminants that may hinder performance. This practice not only improves efficiency but also extends the lifespan of your equipment.

Safety Precautions During Repairs

Ensuring safety is paramount when conducting maintenance tasks. Proper precautions not only protect individuals involved in the work but also enhance the efficiency of the procedures. Adhering to safety measures can significantly reduce the risk of accidents and injuries in any setting.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is essential. This includes items such as gloves, safety goggles, and protective footwear. Utilizing PPE minimizes exposure to harmful substances and reduces the likelihood of injuries during various activities.

Work Environment Considerations

Maintaining a clean and organized workspace is crucial. Ensure that all tools are in proper condition and stored correctly to prevent accidents. Proper lighting is also important to enhance visibility and reduce the risk of mishaps. Taking these steps contributes to a safer and more effective working atmosphere.

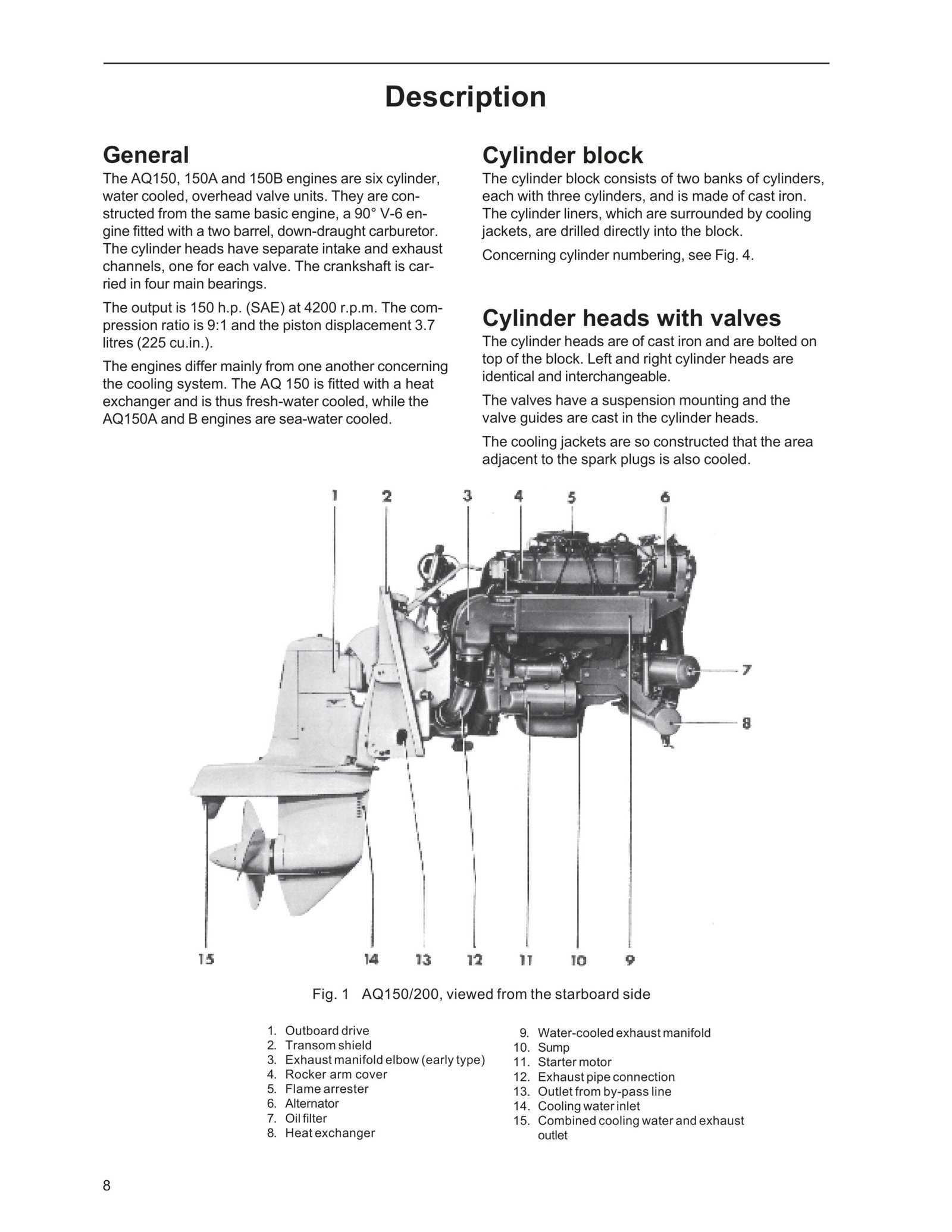

Identifying Engine Components

Understanding the various parts of a propulsion system is crucial for effective maintenance and troubleshooting. Each component plays a specific role in ensuring optimal performance and efficiency. By familiarizing oneself with these elements, one can enhance the overall functionality of the machinery.

Key components include the power unit, fuel delivery system, and cooling apparatus. Recognizing these parts helps in diagnosing issues more accurately. For example, the power unit generates the necessary force, while the fuel delivery system ensures proper combustion.

In addition, keeping track of auxiliary mechanisms such as exhaust systems and electrical systems can significantly aid in achieving peak performance. A thorough understanding of these elements not only aids in timely interventions but also prolongs the lifespan of the entire assembly.

Utilizing Diagnostic Tools Effectively

Efficient use of diagnostic instruments plays a crucial role in maintaining optimal performance and longevity of various mechanical systems. By leveraging these tools correctly, technicians can identify issues more swiftly and accurately, leading to timely interventions and enhanced reliability.

Types of Diagnostic Tools

- Multimeters: Essential for measuring voltage, current, and resistance.

- Oscilloscopes: Useful for visualizing electrical signals over time.

- Diagnostic Software: Provides detailed information about system performance and errors.

- Pressure Gauges: Critical for assessing pressure levels in different components.

Best Practices for Effective Usage

- Familiarize yourself with each tool’s features and functions to maximize its potential.

- Conduct regular calibration and maintenance on instruments to ensure accuracy.

- Document findings thoroughly for future reference and trend analysis.

- Combine data from multiple tools to gain a comprehensive understanding of system health.

Best Practices for Troubleshooting

Effective problem-solving techniques are essential for identifying and resolving issues efficiently. By following structured approaches and utilizing the right tools, individuals can enhance their troubleshooting skills and minimize downtime.

Here are some best practices to consider:

- Gather Information: Collect all relevant details about the problem before diving into diagnostics. Understanding the symptoms can provide valuable insights.

- Use Diagnostic Tools: Employ appropriate tools and equipment to assist in pinpointing the issue. These may include testers, gauges, and other devices.

- Follow a Systematic Approach: Approach the troubleshooting process step-by-step. This method helps ensure that no potential cause is overlooked.

- Consult Resources: Leverage available resources such as reference guides or forums where similar issues have been discussed.

- Document Findings: Keep a record of observations, steps taken, and results. Documentation can be invaluable for future reference or when seeking assistance.

By implementing these strategies, individuals can improve their troubleshooting efficiency and achieve more effective solutions.

Manufacturer-Specific Guidelines

When maintaining and servicing equipment, it is essential to follow the distinct protocols set forth by various producers. These instructions are tailored to optimize performance and ensure the longevity of the machinery. Adhering to these specific recommendations not only enhances functionality but also aids in troubleshooting potential issues.

Typically, these directives include:

- Specific tools required for disassembly and reassembly.

- Recommended maintenance intervals for various components.

- Detailed troubleshooting steps for common problems.

- Proper techniques for installation and adjustments.

- Safety precautions unique to the manufacturer’s design.

By following these guidelines, users can effectively manage their equipment and prevent costly malfunctions, ensuring reliable operation over time.

Resources for Further Learning

Expanding your knowledge in the field of aquatic machinery maintenance is essential for both novices and seasoned practitioners. Numerous platforms offer valuable insights, ranging from online courses to community forums, where individuals can share their experiences and solutions. Engaging with these resources enhances understanding and fosters a deeper appreciation for the intricacies of this domain.

| Resource Type | Recommended Platforms | Description |

|---|---|---|

| Online Courses | Coursera, Udemy | These platforms provide a variety of courses focusing on mechanical systems and maintenance practices, suitable for different skill levels. |

| Books | Amazon, Local Libraries | A wide range of literature covering foundational concepts and advanced techniques is available for those who prefer traditional learning methods. |

| Forums | Reddit, Specialty Communities | Online forums are great for exchanging ideas and troubleshooting problems with like-minded individuals and experts in the field. |

| Workshops | Local Community Colleges, Trade Schools | Hands-on workshops provide practical experience and direct guidance from experienced instructors, enhancing skill development. |

Repair Manual Formats and Availability

Understanding the various formats and access options for maintenance documentation is crucial for effective troubleshooting and servicing. These resources provide essential guidance, ensuring that users can efficiently perform necessary tasks and achieve optimal functionality.

Common Formats

- Digital Formats: Many users prefer electronic versions due to their accessibility and convenience. These can often be found as PDFs or in specialized software.

- Printed Guides: Hard copies remain popular for hands-on use, providing a tangible resource that can be consulted in various environments.

- Online Resources: Websites and forums offer a wealth of information, including user-generated content and downloadable files.

Where to Find Documentation

- Manufacturer Websites: Official sites typically host a range of documents available for download or purchase.

- Online Retailers: Various platforms offer both new and used copies of physical guides.

- Library Collections: Public and university libraries may have comprehensive archives of relevant documentation.