Comprehensive Guide to Repairing ZF 6WG200 Transmission

The complexities of modern vehicle systems often necessitate a deep dive into their internal workings. Ensuring optimal performance requires a comprehensive grasp of how these components function and interact with one another. Proper maintenance and restoration are essential to extending the lifespan of these intricate assemblies.

For enthusiasts and professionals alike, mastering the art of rejuvenating such mechanisms can lead to significant improvements in efficiency and reliability. This exploration delves into the intricacies of diagnosing issues, disassembling units, and implementing effective solutions. Emphasis is placed on best practices that enhance both understanding and execution.

Throughout this guide, you will find detailed insights into essential techniques and tools required for successful overhauls. From identifying common problems to executing precise adjustments, each step is designed to empower you with the knowledge needed to tackle these challenges confidently. Join us as we navigate the fascinating world of mechanical revitalization.

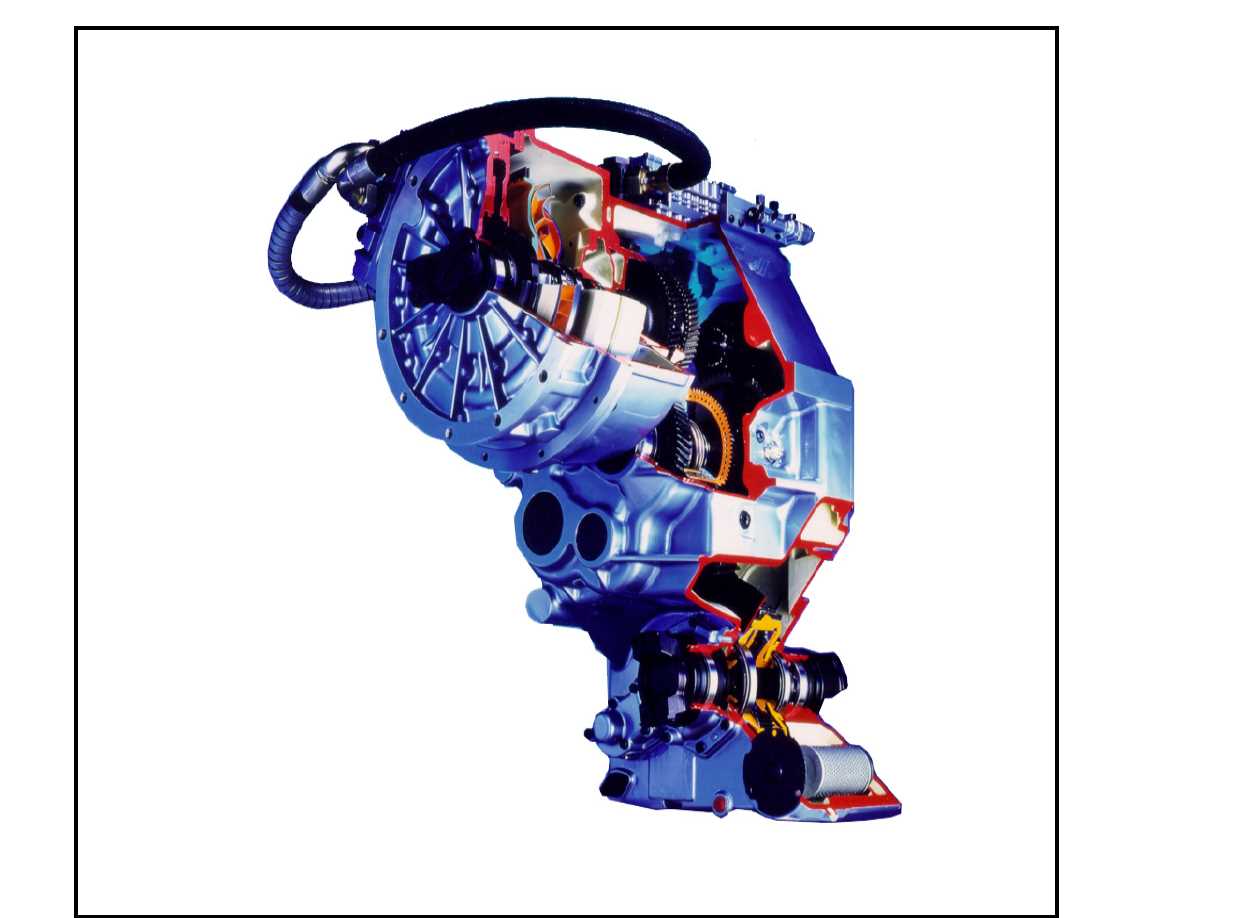

Zf 6wg200 Transmission Overview

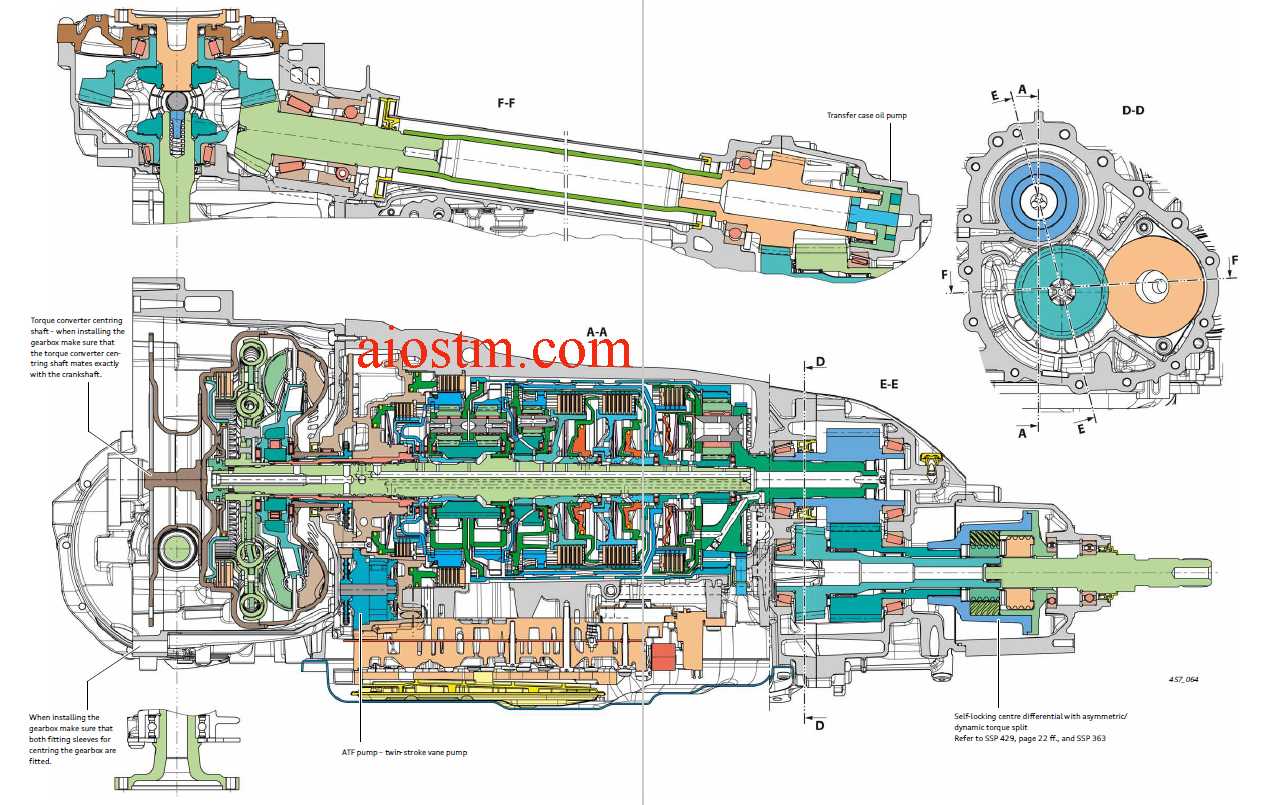

The ZF 6WG200 system represents a sophisticated engineering achievement, designed to enhance performance and efficiency in various vehicles. This innovative assembly is engineered to manage power delivery seamlessly, ensuring optimal functionality across diverse driving conditions.

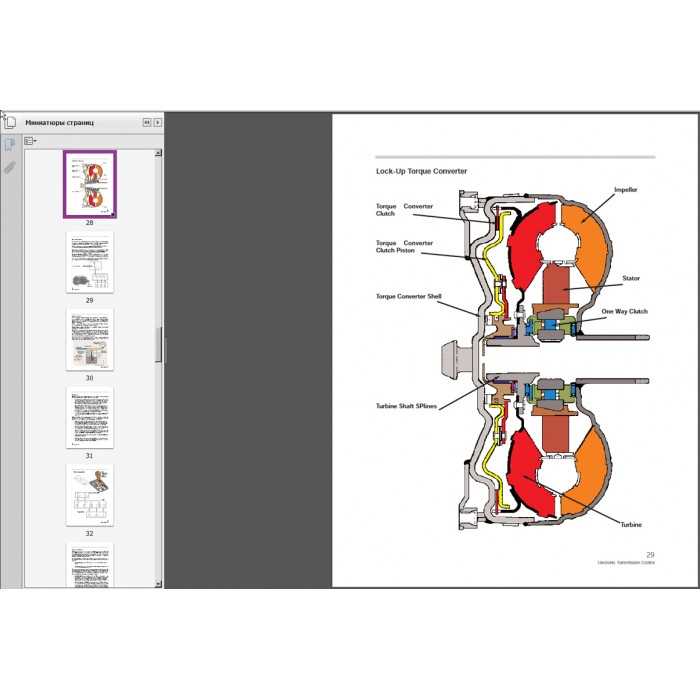

Key Features: One of the standout characteristics of this system is its ability to handle a broad range of torque requirements, making it suitable for both light and heavy-duty applications. The integration of advanced technologies contributes to smooth gear changes, reducing wear and tear while improving overall durability.

Applications: Found in numerous automotive platforms, this assembly is particularly favored in commercial and industrial vehicles, where reliability and performance are paramount. Its design accommodates high levels of stress, making it a preferred choice for demanding environments.

Overall, the ZF 6WG200 unit exemplifies modern engineering prowess, marrying functionality with efficiency to meet the needs of today’s diverse automotive landscape.

Common Issues and Symptoms

Understanding the frequent problems associated with automotive gear systems is essential for effective diagnosis and resolution. Various signs may indicate underlying issues that require attention. Identifying these symptoms early can prevent more severe complications and enhance vehicle performance.

Slipping Gears: One of the most common indicators is the feeling of gears slipping unexpectedly. This can lead to reduced power transfer and may hinder acceleration.

Noisy Operation: Unusual sounds, such as grinding or whining, often signal internal component wear or misalignment. These noises can indicate that parts are not engaging correctly.

Fluid Leaks: Puddles of liquid beneath the vehicle may suggest a leak from seals or gaskets. Low fluid levels can severely impact functionality and should be addressed promptly.

Delayed Engagement: A noticeable lag when shifting from park to drive can indicate problems with the system’s response. This delay can affect overall drivability.

Warning Lights: Dashboard alerts related to the drivetrain should never be ignored. These signals often indicate that the system needs immediate inspection to prevent further damage.

By recognizing these symptoms early, vehicle owners can take proactive steps to maintain optimal performance and avoid costly repairs.

Step-by-Step Repair Process

This section outlines a systematic approach to address issues related to the complex mechanism of gear shifting systems. By following these detailed instructions, you can effectively troubleshoot and resolve common problems, ensuring optimal performance.

- Preparation:

- Gather necessary tools and materials.

- Ensure a clean and organized workspace.

- Review safety protocols before beginning.

- Diagnosis:

- Conduct a thorough inspection of the unit.

- Identify any visible signs of wear or damage.

- Utilize diagnostic equipment to assess performance issues.

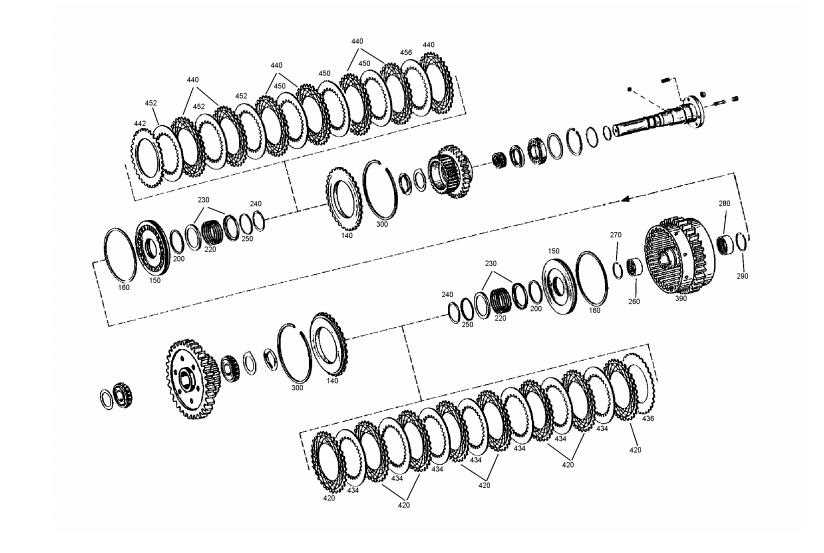

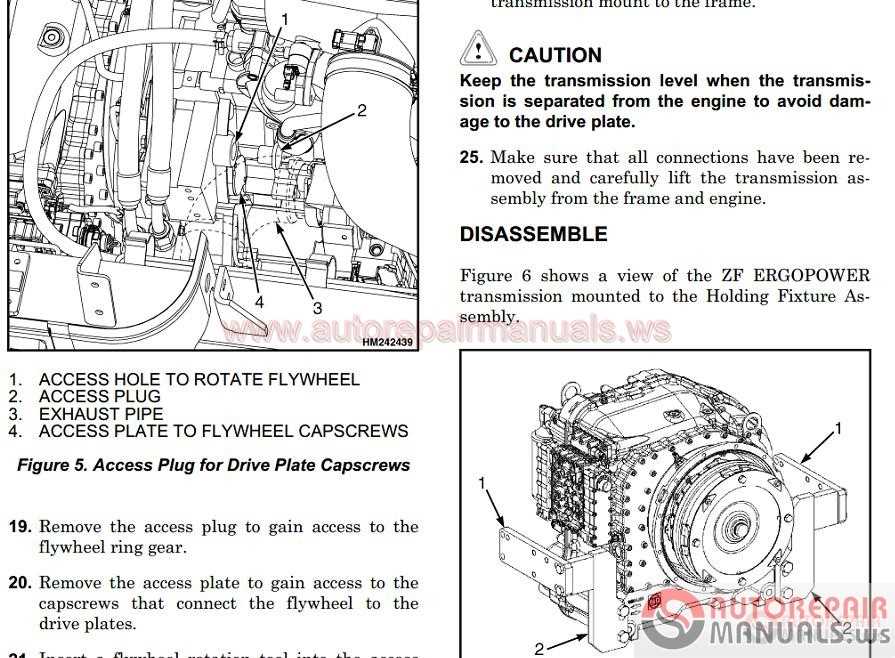

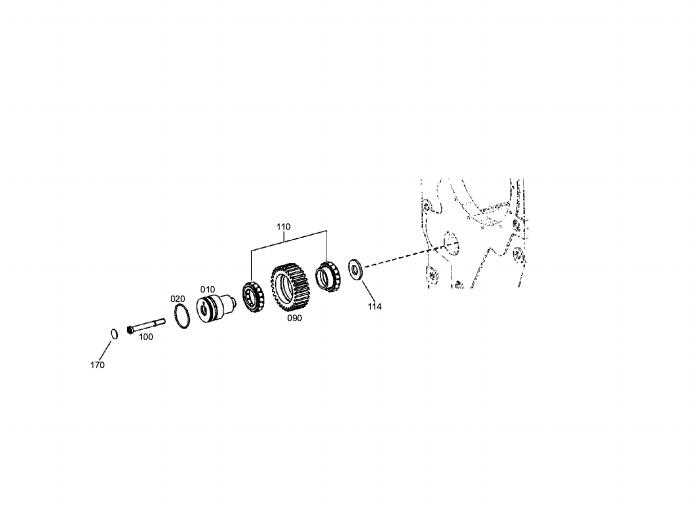

- Disassembly:

- Carefully detach components according to the established sequence.

- Keep track of all screws and parts for reassembly.

- Document any irregularities noted during disassembly.

- Component Inspection:

- Examine each part for signs of wear, cracking, or malfunction.

- Measure tolerances using appropriate tools.

- Replace any damaged or worn components as necessary.

- Reassembly:

- Follow the reverse order of disassembly carefully.

- Ensure all components are securely fastened.

- Double-check alignment and integrity of parts.

- Testing:

- Reconnect the unit and conduct initial tests.

- Monitor performance under various conditions.

- Address any remaining issues promptly.

By adhering to these steps, you can enhance the functionality and reliability of the system, ensuring it meets performance standards.

Essential Tools for Repair

When tackling complex mechanical systems, having the right equipment is crucial for success. The appropriate tools not only enhance efficiency but also ensure precision during the process. This section highlights the must-have instruments that every technician should consider when engaging in overhauls and maintenance tasks.

Basic Hand Tools

Starting with the essentials, a solid collection of hand tools is vital. These items allow for initial disassembly and adjustments with ease.

| Tool | Purpose |

|---|---|

| Socket Set | For loosening and tightening fasteners |

| Wrenches | For gripping and turning nuts and bolts |

| Screwdrivers | For handling various types of screws |

| Pliers | For gripping, twisting, and cutting |

Specialized Equipment

Beyond the basics, specialized tools facilitate more intricate operations. These instruments are designed for specific tasks, providing the necessary leverage and precision.

| Tool | Function |

|---|---|

| Torque Wrench | To apply precise torque to fasteners |

| Transmission Jack | For safely lifting and lowering components |

| Fluid Extractor | For draining and filling fluids accurately |

| Diagnostic Scanner | To identify issues and monitor systems |

Preventative Maintenance Tips

Maintaining the longevity and efficiency of your vehicle’s powertrain system is essential for optimal performance. Regular check-ups and timely interventions can prevent significant issues, ensuring smooth operation and reducing the likelihood of costly repairs. Implementing a proactive maintenance strategy not only enhances reliability but also extends the life of vital components.

Regular Fluid Checks

Consistently inspecting and replacing fluids is crucial for preserving the internal workings of your vehicle. Ensure that oils, coolants, and other essential fluids are at appropriate levels and free from contaminants. Pay attention to any signs of leakage or discoloration, as these may indicate underlying problems that require immediate attention.

Routine Inspections

Conducting regular inspections of your vehicle’s systems can help identify wear and tear before it escalates into a serious issue. Focus on key areas such as seals, gaskets, and hoses for signs of degradation. Additionally, checking for unusual noises or vibrations during operation can provide early warnings of potential failures.

Fluid Types and Specifications

Choosing the right liquids for optimal performance is crucial in any mechanical system. Each type of fluid plays a specific role in ensuring smooth operation and longevity of components. Understanding the different categories and their requirements can significantly impact overall efficiency.

Here are the primary categories of fluids commonly used:

- Hydraulic Fluids: Essential for transferring power and lubricating moving parts.

- Cooling Fluids: Maintain optimal temperatures to prevent overheating and ensure effective heat dissipation.

- Lubricants: Reduce friction between surfaces, enhancing wear resistance and extending service life.

Specifications for each type can vary widely based on application and manufacturer recommendations. Key factors to consider include:

- Viscosity: The thickness of the fluid, which affects flow and pressure. Choose fluids with appropriate viscosity grades based on operating conditions.

- Thermal Stability: The ability to maintain performance under high temperatures, preventing breakdown or degradation.

- Additive Packages: Various chemicals may be included to enhance performance, such as anti-wear agents, corrosion inhibitors, and detergents.

Always refer to the specifications outlined by the manufacturer to ensure compatibility and optimal performance of your equipment.

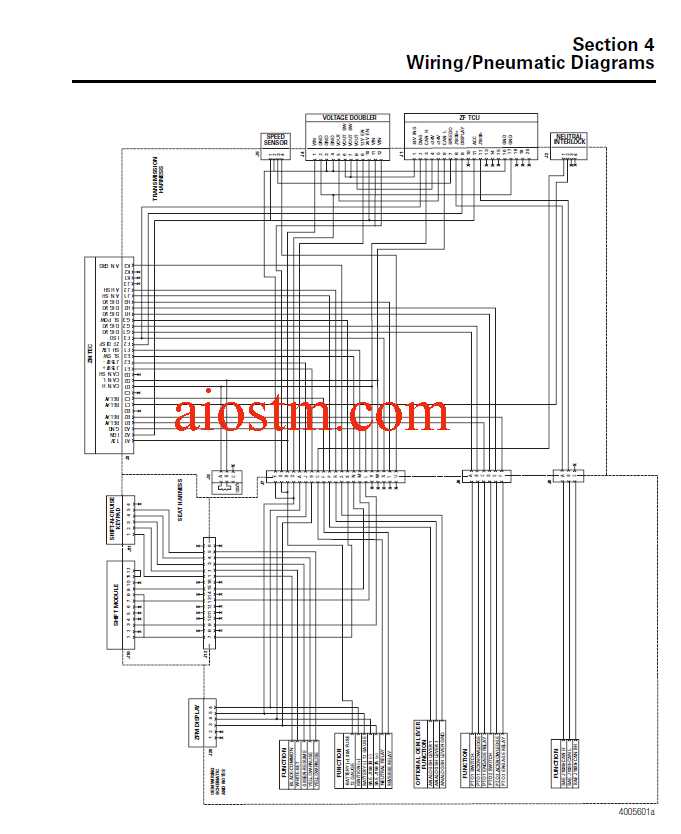

Diagnostic Procedures Explained

Understanding the process of identifying issues within complex machinery is crucial for ensuring optimal performance. This section delves into various strategies and methods utilized to pinpoint malfunctions effectively. Through systematic examination and testing, technicians can uncover underlying problems that may not be immediately apparent.

Common Diagnostic Techniques

Several techniques are employed to assess the condition of mechanical systems. Visual inspections often serve as the first step, allowing for the identification of obvious signs of wear or damage. Additionally, electronic diagnostic tools can provide valuable data, revealing error codes and performance metrics that inform further analysis.

Interpreting Diagnostic Results

Once data has been collected, interpreting the results accurately is vital. Data analysis involves cross-referencing findings with manufacturer specifications and historical performance records. This process enables technicians to develop a clear understanding of the issues at hand and formulate effective solutions. Utilizing a methodical approach ensures that all potential factors are considered, leading to more reliable outcomes.

Replacement Parts and Costs

This section explores the essential components required for a successful overhaul of a specific automotive system, along with their associated expenses. Understanding these elements is crucial for budgeting and ensuring optimal performance post-installation.

Common Components

Identifying the frequently needed parts is vital for any restoration project. Below is a list of typical components that may require replacement along with their estimated costs.

| Part Name | Estimated Cost ($) |

|---|---|

| Clutch Assembly | 250 |

| Fluid Seal | 15 |

| Gear Set | 600 |

| Torque Converter | 300 |

| Filter Kit | 50 |

Budget Considerations

When planning for an overhaul, it’s essential to factor in not only the costs of parts but also labor and additional materials. Allocating an appropriate budget will ensure a smoother process and better end results.

Professional vs. DIY Repairs

When it comes to fixing complex machinery, enthusiasts often face the decision between hiring experts or tackling the job themselves. Each approach has its own merits and drawbacks, impacting the outcome, cost, and time involved.

Choosing professional assistance can offer several advantages:

- Expertise: Professionals possess specialized knowledge and experience.

- Tools: They have access to advanced equipment that may not be available to the average person.

- Time Efficiency: Experts can often complete the job more quickly due to their familiarity with the process.

- Warranty: Professional services often provide guarantees on their work, offering peace of mind.

On the other hand, opting for a do-it-yourself approach also has its appeal:

- Cost Savings: Handling the task independently can significantly reduce expenses.

- Learning Opportunity: DIY projects can enhance skills and knowledge about the system.

- Flexibility: Individuals can work at their own pace, accommodating personal schedules.

- Personal Satisfaction: Successfully completing a project can be a rewarding experience.

Ultimately, the decision hinges on factors such as the complexity of the issue, personal skills, and available resources. Weighing the pros and cons of each option can guide individuals toward the most suitable choice for their situation.

Frequently Asked Questions

This section addresses common inquiries related to the maintenance and troubleshooting of specific automotive components. It aims to provide clarity and assist users in navigating various challenges they may encounter during their service processes.

What are the signs that my component needs attention?

Users often notice unusual noises, shifting issues, or fluid leaks as indicators that their system may require inspection or service. Promptly addressing these symptoms can prevent further complications.

How often should I perform maintenance?

Regular maintenance is essential for optimal performance. It is generally recommended to follow the manufacturer’s guidelines regarding intervals for inspections and service to ensure longevity.

Can I perform maintenance myself, or should I seek professional help?

While some tasks can be managed by knowledgeable individuals, certain complex issues may require the expertise of a professional. Assess your skill level and the complexity of the task before deciding.

What tools do I need for basic servicing?

Essential tools typically include wrenches, screwdrivers, and specialized equipment. Having the right tools on hand simplifies the process and enhances safety.

Where can I find detailed guidance for specific issues?

Comprehensive resources, including manuals and online forums, can provide valuable information. These materials often cover a range of topics, from basic troubleshooting to advanced repair techniques.