Comprehensive Guide to Repairing Your Rollei 35

The allure of vintage photography often draws enthusiasts to explore the intricacies of classic devices. As technology advances, these timeless machines may require attention to ensure they continue to capture memories as they once did. This section aims to provide comprehensive insights into maintaining and rejuvenating these iconic instruments.

Whether you are an experienced technician or a curious hobbyist, understanding the essential components and mechanisms of these cameras is crucial. By delving into the nuances of their design, one can enhance functionality and longevity, ensuring that the ultimate experience in photography is preserved.

In this exploration, we will cover common issues, tips for effective troubleshooting, and best practices for upkeep. The knowledge gained here will empower you to tackle challenges with confidence, bringing your cherished device back to life and preserving its legacy for future generations.

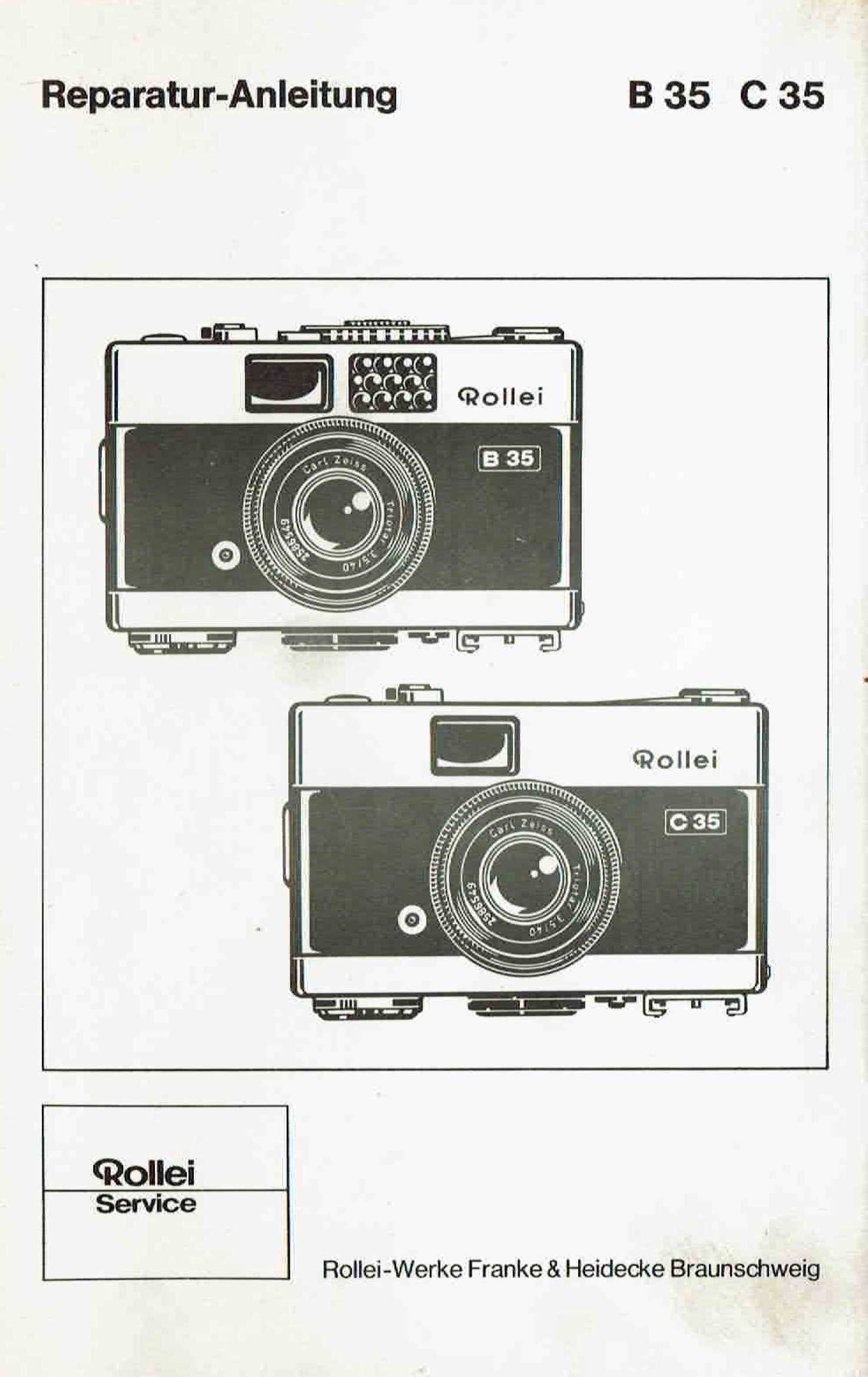

Overview of Rollei 35 Camera

This compact photographic device revolutionized the way enthusiasts approached photography in the 1960s. Its unique design and portability made it an iconic choice for those seeking high-quality images without the bulk of larger models.

Key features that contributed to its popularity include:

- Compact Size: The small dimensions allowed for easy transport, making it ideal for casual outings and travel.

- High-Quality Lens: Equipped with a precision lens, it delivered sharp and vibrant photographs.

- Simple Controls: The intuitive interface made it accessible to both amateurs and experienced photographers.

- Mechanical Reliability: Its sturdy construction ensured longevity and consistent performance.

Over the years, this model has become a sought-after item for collectors and photography aficionados alike, valued not only for its performance but also for its historical significance in the realm of film cameras.

Common Issues with Rollei 35

This section discusses frequent challenges faced by users of a certain compact camera model. These problems can affect functionality and overall user experience. Understanding these issues is essential for maintaining the device in optimal working condition.

1. Shutter Problems

One of the most prevalent issues is related to the shutter mechanism. Users often report inconsistent performance, which can lead to missed opportunities for capturing images.

| Symptom | Possible Cause | Suggested Action |

|---|---|---|

| Shutter not firing | Battery failure | Check and replace battery |

| Delayed shutter release | Sticking mechanism | Clean and lubricate |

| Inconsistent exposure | Faulty light meter | Calibrate or replace meter |

2. Lens Issues

Another common concern is related to the lens system. Users may experience focus problems or visible debris affecting image quality.

| Symptom | Possible Cause | Suggested Action |

|---|---|---|

| Out of focus images | Misalignment | Realign the lens assembly |

| Dust or scratches on lens | Improper storage | Clean or replace lens |

| Zoom issues | Worn gears | Inspect and replace gears |

Tools Needed for Repairs

When addressing issues with precision devices, having the right instruments at hand is crucial. Proper tools not only facilitate the process but also ensure that adjustments and replacements are carried out effectively without causing further damage. A well-equipped workspace can significantly enhance efficiency and outcomes.

Essential instruments for tackling technical challenges include a variety of screwdrivers, particularly small precision types, to handle delicate screws. Additionally, tweezers are invaluable for manipulating tiny components safely. A quality set of pliers is also important for gripping and bending parts as needed.

Moreover, a magnifying glass or jeweler’s loupe can help in inspecting intricate details that may be hard to see with the naked eye. Having a reliable multimeter on hand can assist in diagnosing electrical issues, while a cleaning kit ensures that any grime or debris is removed, maintaining optimal functionality.

In summary, a combination of precision tools and diagnostic equipment forms the foundation for successful interventions. Equipping oneself with the appropriate items enhances both the experience and the effectiveness of addressing any technical shortcomings.

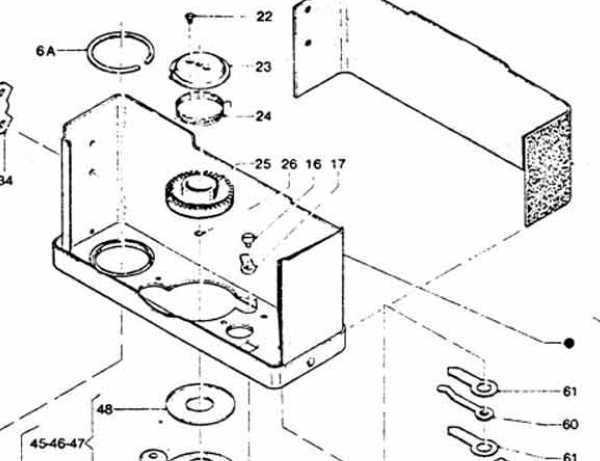

Step-by-Step Disassembly Guide

This section provides a comprehensive approach to taking apart a compact photographic device safely and effectively. Following these detailed instructions will help you access internal components without causing damage. Each step is crucial for ensuring that the reassembly process is straightforward.

1. Prepare Your Workspace: Start by selecting a clean, well-lit area. Gather necessary tools such as a small screwdriver set, tweezers, and a soft cloth to prevent scratches.

2. Remove the Outer Cover: Begin by unscrewing the exterior screws located at the base and sides. Keep these screws organized to simplify reassembly later.

3. Detach the Front Plate: Carefully pry away the front plate using a plastic opening tool. Take care not to damage any clips or fasteners.

4. Disconnect Internal Cables: Once the front plate is off, gently disconnect any visible cables. Note their positions for easy reconnection during reassembly.

5. Take Out the Lens Assembly: Unscrew the lens components while supporting them to avoid falling. This will give you access to the internal mechanism.

6. Access Internal Components: With the lens removed, locate additional screws securing the internal parts. Unscrew them and lift out the main assembly carefully.

7. Document Your Progress: Take photos or notes at each stage of disassembly to help with putting everything back together. This practice can prevent confusion later on.

8. Store Parts Safely: Place all removed components in labeled containers to ensure nothing gets lost or mixed up.

By following these steps methodically, you can safely disassemble the device, facilitating any needed maintenance or modifications.

Cleaning and Maintenance Tips

Regular upkeep is essential for ensuring optimal performance and longevity of photographic devices. Proper care not only enhances functionality but also preserves the aesthetic appeal of the equipment. This section provides valuable insights into effective cleaning and maintenance practices that can keep your gear in prime condition.

Before starting any cleaning process, gather the necessary supplies to avoid damage. It’s crucial to use appropriate tools and techniques tailored to specific components. Here’s a brief overview of essential tasks:

| Task | Description | Frequency |

|---|---|---|

| Lens Cleaning | Use a microfiber cloth and lens cleaner to remove dust and fingerprints from the lens surface. | Every use |

| Body Wipe | Gently wipe the exterior with a damp cloth to eliminate dirt and grime. | Weekly |

| Battery Check | Inspect and clean battery contacts to prevent corrosion and ensure reliable power. | Monthly |

| Shutter Mechanism | Test the shutter release and ensure smooth operation; if sticky, consult a professional. | As needed |

By adhering to these simple guidelines, users can significantly extend the life of their equipment while maintaining its performance and reliability. Regular attention to detail ensures that your device remains ready for any photographic opportunity.

Replacing the Light Seal Foam

Light seal foam is a crucial component in maintaining the integrity of a camera, as it prevents unwanted light from entering the body. Over time, this material can degrade, leading to potential exposure issues and compromised image quality. Addressing this problem is essential for ensuring optimal performance and longevity of your device.

To begin the process, carefully disassemble the necessary parts of the camera body to gain access to the foam seals. It’s important to take your time and keep track of all screws and components, as losing them can complicate reassembly.

Once exposed, remove the old foam using a pair of tweezers or a small knife, ensuring that no remnants remain. This step is critical, as any leftover material can interfere with the new seal. Clean the surface thoroughly with isopropyl alcohol to prepare it for the new foam.

Next, select a suitable replacement material. Foam sheets designed for camera sealing are available, and they come in various thicknesses. Cut the new foam to the required dimensions, making sure it fits snugly into the designated grooves.

After placing the new seals, carefully reassemble the camera. Double-check all components are securely fastened and ensure the new foam creates a tight barrier. This will help to maintain the internal environment of the camera and protect it from light leaks.

By following these steps, you can effectively replace the light seal foam, enhancing the functionality and durability of your equipment for years to come.

Fixing Film Transport Problems

Issues with the movement of film within a camera can lead to frustrating experiences for photographers. Understanding the common challenges and how to address them can help ensure smooth operation and reliable results. This section explores potential obstacles and their solutions.

Common Issues

- Film Jamming: Often caused by misalignment or debris within the mechanism.

- Slipping Film: May occur if the film is not correctly loaded or if the sprocket teeth are worn.

- Uneven Transport: Can result from damaged rollers or guides.

Troubleshooting Steps

- Inspect the Loading Area: Ensure the film is seated properly and that there are no obstructions.

- Clean the Mechanism: Use a soft brush or cloth to remove dust and debris from the transport path.

- Check Sprocket Teeth: Look for wear and tear, replacing any damaged components as necessary.

- Test Film Movement: Manually advance the film to see if it engages smoothly and evenly.

By following these guidelines, photographers can often resolve issues with film movement and restore their camera to optimal functionality.

Repairing the Lens Mechanism

The lens assembly of a compact camera plays a critical role in capturing sharp images. Over time, various issues may arise, such as jamming, misalignment, or wear, which can impede its functionality. Addressing these problems requires a systematic approach to ensure the optical system operates smoothly once more.

Disassembly and Inspection

Begin by carefully removing the outer casing to gain access to the lens components. Look for screws or clips that may be holding the assembly in place. Once disassembled, inspect the lens elements for dirt, debris, or signs of damage. A clean, unobstructed lens is essential for optimal performance.

Adjustment and Reassembly

After cleaning and addressing any visible issues, check the alignment of the internal mechanisms. If any parts are misaligned, gently reposition them to ensure they move freely. Once adjustments are made, reassemble the components in reverse order, ensuring everything is securely fastened. Testing the lens movement before finalizing the assembly will help confirm that all parts function correctly.

Adjusting the Shutter Speed

Achieving precise exposure is essential for capturing stunning images. The ability to fine-tune the timing of the shutter is a critical aspect of this process. This section will guide you through the methods of modifying the shutter duration to meet your creative needs.

Before beginning the adjustment, ensure that the camera is in a stable position. Check the current settings and prepare your tools for a seamless process. Understanding the interplay between light and shutter speed will help you achieve optimal results.

| Shutter Speed | Description | Common Use Cases |

|---|---|---|

| 1/1000 sec | Very fast exposure | Capturing fast-moving subjects |

| 1/250 sec | Fast exposure | General action shots |

| 1/60 sec | Moderate exposure | Indoor photography without flash |

| 1/30 sec | Slow exposure | Low-light conditions |

| 1 sec | Long exposure | Night photography and light trails |

Follow the steps outlined in this guide to make the necessary adjustments. Remember to test various settings to find the perfect balance for your specific shooting environment.

Calibrating the Exposure Meter

Ensuring accurate readings from the exposure meter is crucial for achieving optimal photographic results. This process involves adjusting the device to guarantee it provides reliable information about light levels, which influences exposure settings. Regular calibration helps maintain the performance of the meter, ultimately improving the quality of images captured.

Steps for Calibration

- Gather necessary tools: a reliable light source, a standard reference meter, and a screwdriver.

- Set up the light source in a controlled environment, ensuring consistent brightness.

- Compare readings between the exposure meter and the reference meter.

- If discrepancies are noted, carefully adjust the calibration screw until both meters align.

- Repeat the process to confirm accuracy after adjustments.

Tips for Accurate Calibration

- Perform the calibration in a dimly lit room to minimize external light interference.

- Allow the device to warm up before taking readings for more stable performance.

- Check calibration periodically, especially if the equipment has been subjected to physical shocks.

Reassembly and Testing Procedures

This section outlines the essential steps for putting the camera back together after disassembly, along with methods to ensure its functionality and performance. Proper reassembly is crucial for restoring the device to working order, while thorough testing guarantees that all components function as intended.

Reassembly Steps

Begin by organizing all components in the order they were removed, ensuring no parts are misplaced. Carefully align each section, starting from the internal mechanisms and progressing to the outer casing. Secure screws and fasteners without over-tightening, as this may lead to misalignment or damage. Once fully assembled, conduct a visual inspection for any noticeable gaps or irregularities that may indicate improper assembly.

Testing Procedures

After reassembly, it’s vital to perform a series of tests to confirm that the device operates correctly. Start with a power check; ensure that the camera powers on without issues. Next, test the shutter mechanism by taking several shots at different settings, observing for any inconsistencies in exposure or focus. Additionally, examine the viewfinder and any electronic features to verify their responsiveness. If any problems arise during testing, revisit the assembly steps to identify potential errors.