Comprehensive Guide to Mini Bike Repairs

Ensuring the optimal performance of compact two-wheeled vehicles requires a comprehensive understanding of their components and functionality. This section offers essential insights for enthusiasts and owners, focusing on common challenges and effective solutions. By familiarizing oneself with these aspects, riders can enhance their experience and prolong the life of their machines.

From the basics of operational checks to more complex adjustments, mastering these techniques is crucial. Whether it’s addressing minor issues or performing routine checks, having a systematic approach can significantly improve reliability. The following content is designed to empower individuals with the knowledge needed to tackle various tasks confidently.

Additionally, this guide emphasizes the importance of safety and preparation. Understanding the right tools and methods will not only facilitate repairs but also ensure a safer riding experience. By taking proactive measures, riders can enjoy their journeys with peace of mind, knowing they are equipped to handle potential obstacles.

Essential Tools for Mini Bike Repair

When maintaining a compact two-wheeled vehicle, having the right instruments at your disposal is crucial. The effectiveness of any maintenance task largely depends on the quality and appropriateness of your tools. A well-equipped workspace ensures that you can address a variety of issues efficiently and safely.

Wrenches are fundamental for loosening and tightening various components. A set that includes different sizes will accommodate a range of bolts and nuts, making your tasks much easier.

Screwdrivers in both flat and Phillips styles are necessary for securing and removing screws. Having a set with varying lengths can be beneficial for reaching different areas of your vehicle.

Pliers are versatile tools that can grip, twist, and cut wires or cables. Needle-nose pliers are particularly useful for accessing tight spots.

Socket sets provide a quick and effective way to work with bolts and nuts, allowing for a more secure fit compared to traditional wrenches.

Torque wrenches ensure that fasteners are tightened to the manufacturer’s specifications, preventing damage and ensuring safety.

Maintenance stands are essential for elevating the vehicle, providing you with better access and visibility while you work.

Equipping yourself with these basic instruments will not only facilitate smoother operations but also enhance your overall experience while working on your compact vehicle.

Understanding Your Mini Bike’s Components

To ensure optimal performance and longevity, it’s essential to familiarize yourself with the various elements that comprise your two-wheeled vehicle. Each part plays a crucial role in the overall functionality, making it vital to comprehend their individual contributions and interactions.

Key Elements of Your Vehicle

The primary components include the frame, engine, and wheels. The frame provides structural integrity, while the engine powers movement. The wheels facilitate motion and stability, directly influencing the ride experience. Understanding how these parts work together enhances your ability to maintain and enhance performance.

Maintenance and Care

Regular attention to these components can prevent common issues. Keeping the engine clean and well-lubricated, inspecting the frame for any signs of wear, and ensuring the wheels are properly inflated are all critical tasks. By doing so, you’ll not only prolong the lifespan of your vehicle but also enhance its safety and performance.

Common Issues and Solutions

This section addresses frequent problems encountered with compact two-wheeled vehicles and offers practical solutions to enhance performance and longevity.

-

Starting Difficulties:

If the vehicle fails to start, check the following:

- Ensure the fuel tank is filled.

- Inspect the battery connections for corrosion.

- Examine the ignition system for faults.

-

Unusual Noises:

Strange sounds can indicate underlying issues. Consider:

- Checking the chain tension and lubrication.

- Inspecting the wheel bearings for wear.

- Evaluating the engine for loose components.

-

Performance Issues:

If you experience a decrease in speed or acceleration, try the following:

- Clean or replace the air filter.

- Adjust the carburetor settings as needed.

- Ensure the tires are properly inflated.

-

Electrical Failures:

For problems with lights or indicators, check:

- All fuses and replace any that are blown.

- Connections in the wiring harness for loose or damaged wires.

- The battery voltage to ensure it is charged.

Routine Maintenance Practices

Regular upkeep is essential for ensuring the longevity and optimal performance of your two-wheeled vehicle. Adhering to a consistent maintenance schedule helps to prevent unexpected issues and enhances the overall riding experience. By focusing on key aspects of care, you can significantly extend the life of your machine.

Inspection of Key Components

Conducting thorough checks of vital elements such as the tires, brakes, and chain is crucial. Look for signs of wear, damage, or improper alignment. Maintaining correct tire pressure not only improves handling but also increases fuel efficiency. Regularly lubricating the chain ensures smooth operation and reduces the risk of failure.

Fluid Levels and Cleaning

Monitoring fluid levels, including oil and fuel, is a fundamental aspect of upkeep. Changing the oil at recommended intervals prevents engine wear and enhances performance. Additionally, keeping the exterior clean not only enhances aesthetics but also allows for easier identification of any potential issues, such as leaks or rust. A clean machine is a well-functioning machine.

Replacing Tires and Tubes

Changing the outer coverings and inner chambers of your two-wheeled vehicle is an essential maintenance task that enhances performance and safety. Regularly replacing these components not only improves ride quality but also prevents potential mishaps caused by wear and tear.

Gathering Necessary Tools

Before starting the process, ensure you have the appropriate tools at hand. You will need a tire lever, a pump, and possibly a patch kit for minor repairs. Having these items ready will streamline the procedure and minimize downtime.

Removing the Old Tire

Begin by loosening the wheel from the frame, ensuring it is securely positioned. Use the tire lever to gently pry the outer covering away from the rim. Work your way around the circumference, taking care not to damage the inner chamber during this process.

Installing the New Tire

Once the old outer covering is removed, inspect the rim for any debris or damage. Place the new outer covering onto the rim, starting at one side and gradually working your way around. Make sure it sits evenly and securely within the rim’s channel.

Inflating the Inner Chamber

With the new outer covering in place, insert the inner chamber. Inflate it slightly to ensure proper seating before fully inflating it to the recommended pressure. Check for any bulges or misalignments, adjusting as necessary to achieve a smooth finish.

Final Checks

Reattach the wheel to the frame and perform a visual inspection to confirm everything is in place. Take a moment to test the newly fitted components by spinning the wheel and ensuring it rotates freely without obstruction.

Adjusting Brakes for Safety

Ensuring the effectiveness of your stopping mechanisms is crucial for safe operation. Proper adjustment helps maintain optimal performance, allowing for responsive and reliable action when needed. This section provides guidance on fine-tuning these essential components to enhance safety.

Identifying the Right Tension

Begin by examining the tension of the stopping cables. Excessive slack can lead to delayed response, while too much tightness may cause premature wear. Adjust the tension until you achieve a comfortable balance, allowing for smooth operation without any resistance.

Checking Alignment and Condition

Next, inspect the alignment of the stopping elements. Misalignment can cause uneven wear and affect performance. Ensure that all parts are properly aligned and in good condition. Regular checks can prevent potential issues and ensure that the stopping mechanisms function effectively when needed.

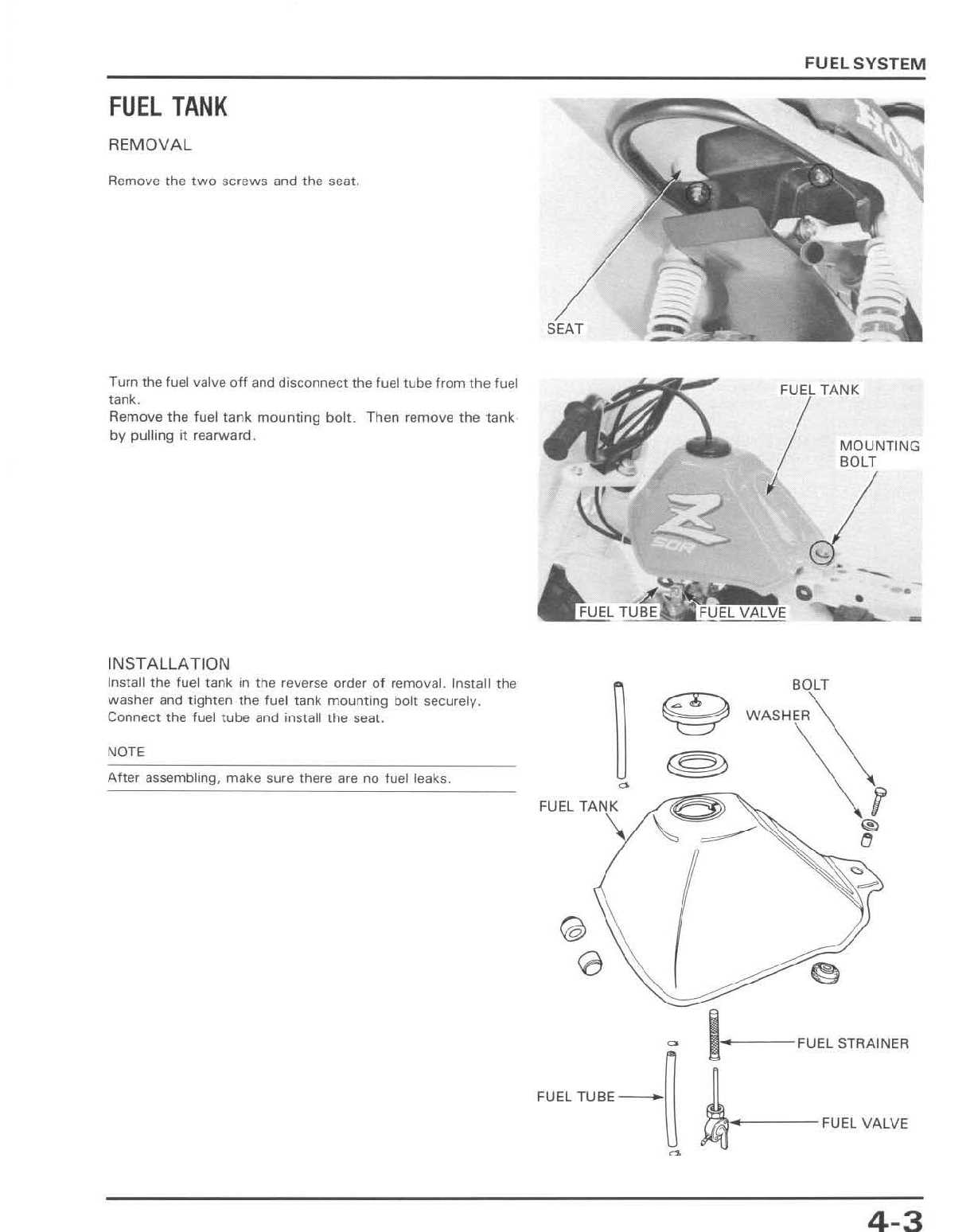

Fuel System Troubleshooting

The functionality of a combustion engine relies heavily on its fuel delivery mechanism. Issues within this system can lead to various performance problems. Identifying and resolving these complications is essential for optimal operation.

Common Symptoms of Fuel System Issues

When the fuel delivery system encounters difficulties, several symptoms may arise. These can include irregular engine performance, difficulty starting, or sudden stalling. It is crucial to observe these signs carefully to determine the root cause.

Troubleshooting Steps

To diagnose problems effectively, begin by checking the fuel tank for adequate levels and ensuring that the fuel is clean and free of contaminants. Next, inspect the fuel lines for any leaks or blockages that may hinder flow. Furthermore, examining the fuel filter is vital, as a clogged filter can restrict fuel supply, leading to engine malfunctions.

If these basic checks do not resolve the issue, consider evaluating the fuel pump’s functionality. A failing pump may not provide the necessary pressure for optimal engine performance. By systematically addressing these elements, you can effectively troubleshoot and resolve fuel system-related challenges.

Electrical System Overview

The electrical framework of a compact two-wheeler plays a crucial role in its overall functionality. This intricate system is responsible for powering various components, ensuring smooth operation and safety during rides. Understanding its key elements is essential for effective maintenance and troubleshooting.

At the core of this system is the battery, which provides the necessary energy to start the engine and power electrical accessories. A well-maintained battery is vital for optimal performance and longevity. Connected to the battery, the wiring harness serves as the main conduit for electrical flow, linking various parts such as the ignition system, lights, and gauges.

The ignition mechanism is another critical aspect, converting electrical energy into the spark needed to ignite the fuel-air mixture within the engine. Additionally, the charging system replenishes the battery while the vehicle is in operation, ensuring that all electrical components receive adequate power. Regular inspection and understanding of these elements can greatly enhance the reliability and safety of the ride.

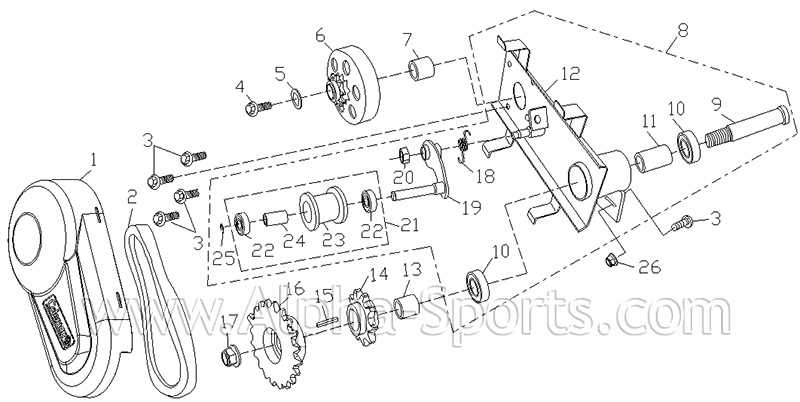

Chain and Sprocket Care

Maintaining the connection between power and movement is essential for optimal performance. Regular attention to this critical assembly ensures longevity and efficiency, preventing unnecessary wear and tear.

Inspection and Cleaning

Routine checks for signs of wear or damage are vital. Cleaning helps remove debris and lubricants that can cause friction and wear.

Lubrication Techniques

Applying the right lubricant enhances performance and reduces wear. Use a suitable product to keep the components functioning smoothly.

| Task | Frequency | Recommended Products |

|---|---|---|

| Inspection | Every 100 miles | Visual inspection, damage report |

| Cleaning | Every 200 miles | Chain cleaner, brush |

| Lubrication | After cleaning | Chain lubricant |

Upgrading Performance Parts

Enhancing the capabilities of your compact two-wheeled vehicle can significantly elevate your riding experience. By selecting appropriate components, you can improve speed, handling, and overall responsiveness. This section will explore various options for upgrading essential elements that contribute to better performance.

Key Components to Consider

- Engine Modifications: Upgrading the power unit can lead to noticeable increases in horsepower and torque.

- Exhaust Systems: Replacing the exhaust can enhance airflow, resulting in improved efficiency and sound.

- Suspension Upgrades: Adjusting the suspension system can provide better stability and comfort during rides.

Choosing the Right Parts

Selecting the best components requires careful consideration of compatibility and quality. Here are some tips:

- Research various brands and their offerings to find the most reliable options.

- Consult with experienced riders or forums to gather insights and recommendations.

- Ensure that any upgrades comply with local regulations and standards.

By making informed choices, you can significantly enhance the performance of your vehicle, ensuring a thrilling and enjoyable ride.

Cleaning and Lubrication Techniques

Maintaining the functionality of small vehicles requires regular attention to cleanliness and proper lubrication. These practices not only enhance performance but also extend the lifespan of various components. Effective techniques can prevent dirt accumulation and reduce friction, ensuring smoother operation and improved safety.

To begin the cleaning process, gather appropriate tools such as brushes, cloths, and cleaning solutions that are compatible with the materials used in the vehicle. Carefully remove any debris from the exterior and hard-to-reach areas, paying special attention to crevices where dirt can build up. After cleaning, ensure all surfaces are thoroughly dried to prevent moisture-related damage.

For lubrication, select high-quality oils or greases suitable for the specific parts being serviced. Apply the lubricant evenly, focusing on moving parts and areas prone to wear. Regularly check and refresh the lubrication to maintain optimal function. Following these techniques will help keep the small vehicle in top condition, enhancing both its performance and durability.

Preparing for Seasonal Storage

As the seasons change, it becomes essential to ensure that your two-wheeled vehicle is properly cared for before being set aside for an extended period. This preparation not only prolongs the life of the machine but also guarantees that it will be ready for use when the time comes to ride again.

Inspection and Cleaning

Begin by thoroughly inspecting the entire unit for any signs of wear or damage. Pay close attention to the tires, brakes, and chain. Cleaning is equally important; remove dirt, grime, and debris from all surfaces. A clean machine is less prone to corrosion and other issues that can arise during storage.

Fluid Maintenance

Check and replace any necessary fluids, such as fuel and oil. Fresh fluids will help prevent engine problems and ensure optimal performance. Additionally, consider adding a fuel stabilizer to the gas tank to avoid fuel degradation over time.