Comprehensive Guide to Repairing the 1998 Lexus GS400

This section offers an in-depth overview of essential guidelines and procedures for maintaining a high-performance vehicle. By following systematic practices, vehicle owners can ensure longevity and optimal functionality. Understanding the intricacies of automotive systems is vital for troubleshooting and effective upkeep.

Within these guidelines, users will find valuable insights into routine inspections, parts replacements, and preventive measures. Emphasizing a proactive approach not only enhances safety but also improves overall driving experience. A well-maintained vehicle not only performs better but also retains its value over time.

Equipped with practical advice and expert tips, this resource aims to empower vehicle enthusiasts and everyday users alike. Whether tackling minor adjustments or preparing for significant service tasks, having access to structured information can make all the difference in achieving successful outcomes.

Ensuring optimal performance and longevity of a vehicle requires consistent upkeep and attention to detail. This section outlines fundamental strategies for maintaining a high-performance sedan, focusing on critical practices that can enhance the overall driving experience.

1. Regular Fluid Checks

Monitoring various fluids is essential for maintaining a vehicle’s efficiency. Here are the key fluids to check:

- Engine oil

- Coolant

- Brake fluid

- Transmission fluid

2. Tire Maintenance

Proper tire care ensures safety and improves fuel efficiency. Key practices include:

- Regular pressure checks

- Tread depth assessment

- Rotating tires every 5,000 miles

3. Battery Health

A well-maintained battery is crucial for reliable starts. Consider the following:

- Inspect terminals for corrosion

- Test battery voltage regularly

- Replace the battery every 3-5 years

4. Brake System Inspection

Regular checks of the braking system enhance safety. Important aspects to review include:

- Brake pad thickness

- Fluid level in the reservoir

- Brake line integrity

5. Air Filter Replacement

A clean air filter improves engine performance and efficiency. Recommendations include:

- Replace every 15,000 to 30,000 miles

- Check for dirt and debris regularly

6. Light Bulb Functionality

Ensuring all lights are functional is vital for safety. Check the following:

- Headlights

- Brake lights

- Turn signals

7. Exhaust System Monitoring

A properly functioning exhaust system minimizes emissions. Regular checks should include:

- Inspect for leaks

- Check for unusual noises

8. Suspension System Care

The suspension system affects ride quality and handling. Key inspection points include:

- Shock absorber condition

- Spring integrity

- Alignment checks

9. Timing Belt Inspection

A worn timing belt can lead to serious engine damage. Recommendations are:

- Replace every 60,000 to 100,000 miles

- Inspect for cracks and wear

10. Regular Wash and Wax

Maintaining the vehicle’s exterior prevents corrosion. Consider these practices:

- Wash regularly to remove dirt and grime

- Wax every few months for protection

11. Interior Care

Keeping the interior clean enhances comfort and resale value. Key practices include:

- Vacuum regularly

- Use appropriate cleaners for upholstery

Understanding Common Mechanical Issues

Vehicles often encounter various mechanical challenges that can impact their performance and longevity. Recognizing these common problems is essential for maintaining reliability and safety. This section delves into frequent issues that may arise, offering insights into their causes and potential solutions.

| Issue | Symptoms | Possible Causes |

|---|---|---|

| Engine Overheating | Warning light, steam from hood | Low coolant, faulty thermostat |

| Transmission Slipping | Delayed shifts, RPM spikes | Low fluid levels, worn components |

| Brake Problems | Squeaking noise, reduced responsiveness | Worn pads, air in lines |

| Suspension Issues | Bumpy ride, uneven tire wear | Worn shocks, damaged springs |

Step-by-Step Engine Repair Guide

This section provides a comprehensive approach to addressing common engine issues, offering clear instructions to assist enthusiasts and professionals alike. Following these steps will ensure a thorough understanding of the process, making it easier to tackle repairs effectively.

1. Preparation

Begin by gathering the necessary tools and materials. Ensure you have a clean workspace to facilitate the repair process. Familiarize yourself with the engine layout and the specific components you will be working on.

2. Diagnostics

Identify the symptoms of the problem. Utilize diagnostic equipment to check for error codes and analyze engine performance. This will help pinpoint the exact issues that need attention.

3. Disassembly

Carefully remove components such as the intake manifold and valve covers. Take note of the order and placement of each part, as this will be crucial for reassembly. Store small parts in labeled containers to avoid confusion.

4. Inspection

Examine all visible engine parts for wear or damage. Pay close attention to gaskets, seals, and belts. Replace any worn components to prevent future issues.

5. Reassembly

Once repairs or replacements are complete, begin reassembling the engine. Follow the reverse order of disassembly, ensuring each component is secured properly. Double-check all connections for leaks.

6. Testing

After reassembly, conduct a thorough test to ensure the engine operates smoothly. Monitor for any unusual noises or warning lights. If everything checks out, you have successfully completed the engine repair process.

Transmission Troubleshooting Techniques

Understanding the complexities of a vehicle’s transmission system is crucial for effective diagnostics and maintenance. By recognizing common symptoms and employing systematic approaches, one can identify issues before they escalate into significant problems. This section outlines essential troubleshooting techniques that facilitate the assessment of transmission performance.

Identifying Symptoms

Common signs of transmission troubles include unusual noises, slipping gears, or delayed engagement. Listening carefully to the sounds emitted during operation can provide insights into underlying issues. Additionally, monitoring the vehicle’s behavior during shifting can help pinpoint specific malfunctions.

Systematic Diagnostic Approaches

Begin by checking fluid levels and quality, as low or contaminated fluid can lead to poor performance. Using a diagnostic scanner can also assist in retrieving error codes, which provide valuable information about potential faults. Furthermore, a thorough inspection of external components, such as wiring and connections, can reveal issues affecting overall function.

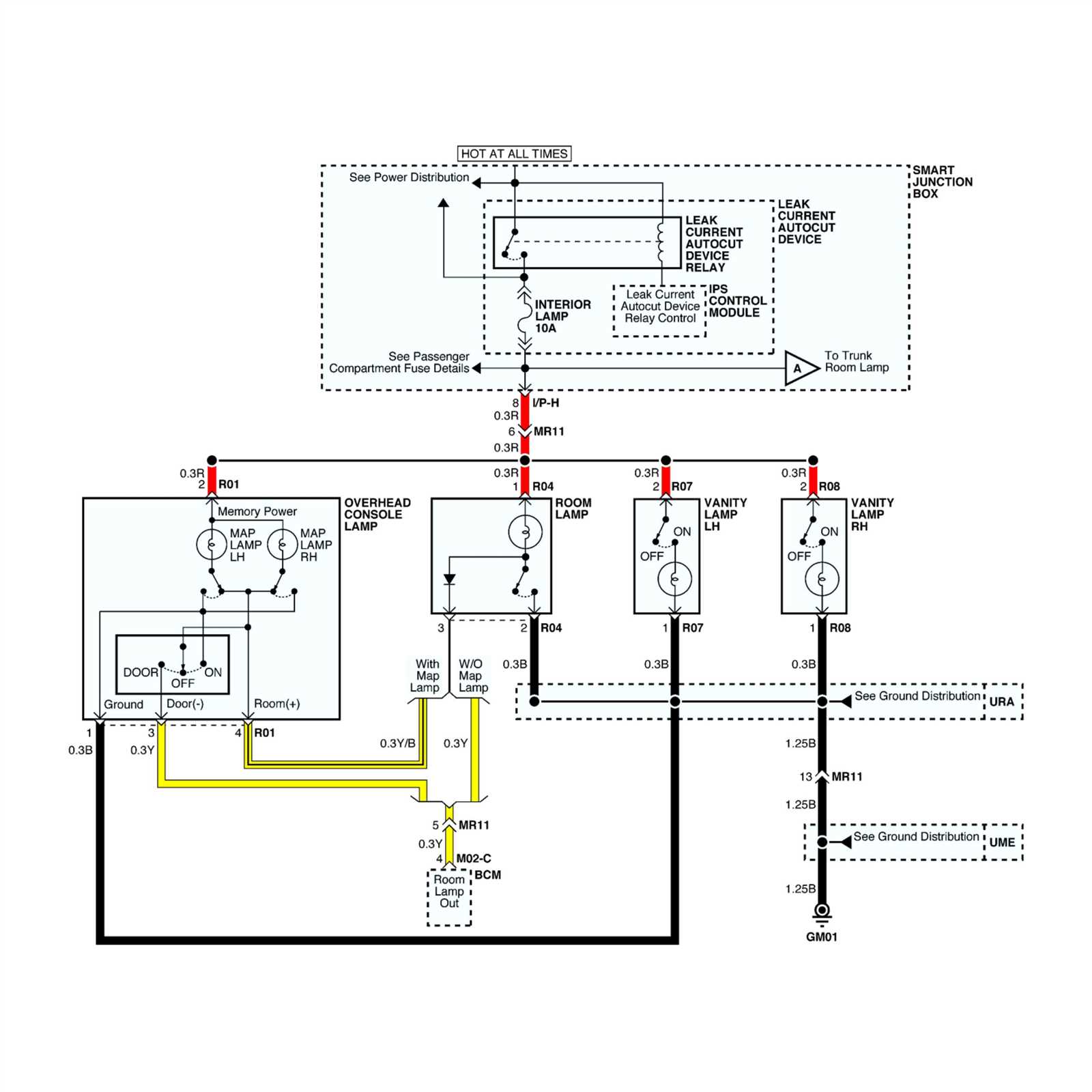

Electrical System Diagnostics Explained

Understanding the intricacies of a vehicle’s electrical network is essential for effective troubleshooting. This section delves into methods and tools utilized for identifying issues within the electrical framework, ensuring optimal performance and reliability.

Common Diagnostic Tools: Various instruments, such as multimeters and oscilloscopes, play a crucial role in diagnosing electrical problems. These tools help technicians measure voltage, current, and resistance, providing insights into the functionality of different components.

Symptoms of Electrical Malfunctions: Symptoms like flickering lights, irregular instrument readings, or difficulty starting can indicate underlying electrical issues. Recognizing these signs early can prevent more significant problems down the line.

Diagnostic Process: The diagnostic process typically involves systematic checks, starting from the battery and working through circuits and components. By following a structured approach, technicians can pinpoint failures and implement effective solutions.

Suspension and Steering Adjustments

Proper alignment and calibration of the suspension and steering systems are crucial for optimal vehicle performance and safety. Adjustments in these areas can enhance handling, improve ride comfort, and extend the lifespan of components. This section outlines essential techniques for maintaining these systems effectively.

Alignment Procedures

To ensure that the vehicle tracks straight and true, regular alignment checks are necessary. This involves adjusting the angles of the wheels to the manufacturer’s specifications. Misalignment can lead to uneven tire wear, steering drift, and compromised handling. A professional alignment service typically includes adjustments to camber, caster, and toe angles.

Steering System Calibration

Maintaining the steering system involves checking and adjusting components such as the rack and pinion, tie rods, and steering column. Proper calibration ensures responsive steering and reduces wear on parts. Regular inspection for play in the steering wheel and any unusual noises can help identify issues before they lead to significant problems.

Brake System Inspection Procedures

Ensuring the proper functionality of the braking system is crucial for vehicle safety and performance. Regular inspections help identify potential issues, maintain optimal operation, and enhance the longevity of components. This section outlines essential steps for evaluating the braking system, focusing on critical elements that require attention during the inspection process.

Begin by visually examining the brake pads and rotors for signs of wear or damage. Look for uneven surfaces, cracks, or significant thinning of the pads. Next, check the brake fluid level and quality, ensuring it meets the manufacturer’s specifications. Contaminated or low fluid can lead to diminished braking performance.

Inspect brake lines and hoses for any leaks, abrasions, or signs of deterioration. Ensure that connections are secure and free from corrosion. Additionally, assess the functionality of the brake calipers and cylinders by testing their movement and responsiveness. Listen for unusual noises during operation, which may indicate underlying issues.

Finally, perform a test drive to evaluate the overall braking performance. Pay attention to responsiveness, vibrations, or pulling to one side, which could suggest a misalignment or uneven wear. Following these procedures will help ensure a safe and reliable braking system.

Cooling System Maintenance Recommendations

Regular upkeep of the cooling system is crucial for ensuring optimal engine performance and longevity. This system plays a vital role in regulating engine temperature, preventing overheating, and maintaining overall efficiency. Implementing effective maintenance practices can significantly enhance the reliability of your vehicle.

First, it is essential to check the coolant levels periodically. Low coolant can lead to severe engine issues, so topping it off with the appropriate mixture is vital. Additionally, inspecting for leaks in hoses and connections should be part of routine checks, as leaks can compromise the system’s effectiveness.

Flushing the cooling system at regular intervals helps remove accumulated debris and contaminants. This process not only enhances the coolant’s effectiveness but also prolongs the lifespan of the components involved. Furthermore, replacing the coolant as recommended ensures that the system operates at its best, preventing corrosion and buildup.

Lastly, keeping an eye on the thermostat and water pump functionality is important. Any signs of malfunction, such as fluctuating temperatures or unusual noises, should prompt immediate inspection. Proper maintenance of these components contributes significantly to the overall health of the cooling system.

Exhaust System Repairs and Upgrades

The exhaust system plays a crucial role in a vehicle’s performance and efficiency. Proper maintenance and enhancements can significantly improve engine output and reduce emissions. This section will explore essential repairs and potential upgrades to ensure optimal functionality of the exhaust setup.

Common issues with the exhaust system often include leaks, rust, and blockages. Identifying these problems early can prevent more severe damage and costly repairs. Regular inspections and prompt attention to any signs of wear can extend the lifespan of the components.

For those looking to enhance performance, upgrading parts such as mufflers, catalytic converters, or exhaust pipes can yield noticeable improvements. High-performance options can increase airflow, resulting in enhanced power and efficiency. Additionally, considering materials like stainless steel can provide durability and resistance to corrosion.

Always consult with a qualified technician before making modifications, as improper installations can lead to performance issues and void warranties. Investing in the right upgrades will not only improve vehicle performance but also contribute to a better driving experience.

Interior and Exterior Care Instructions

Proper maintenance of both the interior and exterior surfaces of your vehicle is essential for preserving its aesthetics and longevity. Regular care not only enhances the overall appearance but also protects against wear and tear, ensuring a comfortable and enjoyable driving experience.

Exterior Maintenance

To keep the outer surfaces looking pristine, consider the following practices:

- Wash the vehicle regularly to remove dirt and contaminants.

- Apply wax every few months to protect the paint and add shine.

- Check and clean the wheels and tires to maintain a polished look.

Interior Maintenance

For the interior, routine upkeep is vital for comfort and cleanliness:

- Vacuum the upholstery and carpets to eliminate dust and debris.

- Use appropriate cleaners for leather or fabric to avoid damage.

- Keep surfaces free from clutter to enhance the driving experience.

| Task | Frequency |

|---|---|

| Exterior Wash | Every 2 weeks |

| Wax Application | Every 3 months |

| Interior Vacuuming | Weekly |

Utilizing OEM Parts for Repairs

When addressing vehicle maintenance and restoration, opting for original equipment manufacturer components is a wise choice. These parts are crafted to meet specific standards, ensuring compatibility and reliability, which can significantly enhance the overall performance of the automobile.

Choosing OEM components offers several advantages:

- Quality Assurance: Manufactured to original specifications, guaranteeing superior quality.

- Perfect Fit: Designed specifically for the vehicle, ensuring seamless integration.

- Durability: Typically built to last longer than aftermarket alternatives, reducing the need for frequent replacements.

- Warranty Protection: Often come with manufacturer warranties, providing peace of mind.

For optimal results, sourcing these components from authorized dealers is recommended. This ensures authenticity and avoids potential issues associated with counterfeit parts. Additionally, maintaining a record of all parts used can assist in future servicing and uphold the vehicle’s value.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is essential for both the individual performing the work and the vehicle itself. Adhering to specific guidelines can help prevent accidents and enhance the efficiency of the repair process.

Essential Safety Guidelines

- Always wear appropriate personal protective equipment, such as gloves and safety glasses.

- Ensure the workspace is well-ventilated to avoid inhalation of harmful fumes.

- Keep a fire extinguisher nearby, especially when working with flammable substances.

- Disconnect the battery to prevent electrical shocks before beginning any work.

- Use jack stands when lifting the vehicle to ensure stability and safety.

Tools and Environment

- Check that all tools are in good condition and appropriate for the task.

- Maintain a clean and organized workspace to reduce the risk of accidents.

- Follow the manufacturer’s guidelines and specifications for safety procedures.