Essential Guide to Homelite Chainsaw Repairs

Proper upkeep of outdoor power equipment is essential for optimal performance and longevity. Understanding how to address common issues can significantly enhance the efficiency of your tools. This section aims to provide valuable insights into ensuring your equipment runs smoothly and effectively.

Regular checks and timely interventions are key to preventing more significant problems down the line. Familiarizing yourself with the components and mechanisms involved allows for easier troubleshooting and maintenance. By being proactive, you can extend the life of your equipment and improve its reliability.

In this guide, you will find a range of techniques and recommendations that empower you to tackle minor issues independently. Knowledge is power, and equipping yourself with the right information can save time and resources. Whether you are a seasoned user or new to outdoor tools, this content is designed to assist you in achieving optimal functionality.

Understanding frequent challenges encountered with these devices can greatly enhance their performance and longevity. Recognizing symptoms early helps in effective troubleshooting and maintaining efficiency.

Typical Problems

- Engine starts but stalls quickly

- Difficulty in starting the machine

- Unusual noise during operation

- Excessive vibration

Potential Causes

- Poor fuel quality

- Clogged air filter

- Worn spark plug

- Improper chain tension

Addressing these issues systematically can lead to effective solutions and prolong the lifespan of the equipment.

Essential Tools for Repairs

When undertaking maintenance tasks, having the right instruments at your disposal is crucial for achieving effective results. The proper tools not only enhance efficiency but also ensure safety during the process. Understanding the various essential implements can significantly aid in troubleshooting and fixing mechanical issues.

Basic Hand Tools

Starting with fundamental hand tools, a quality set of wrenches, screwdrivers, and pliers is indispensable. These items facilitate various tasks, such as loosening or tightening components and making adjustments. Investing in durable tools ensures longevity and reliability when handling repairs.

Specialized Equipment

In addition to basic hand tools, specific devices can further streamline the maintenance process. Items like torque wrenches and chain tension gauges help in achieving precise settings, which are vital for optimal performance. Utilizing specialized equipment can simplify tasks and enhance the overall effectiveness of the maintenance efforts.

Step-by-Step Troubleshooting Guide

This section provides a systematic approach to identifying and resolving common issues that may arise during the operation of your equipment. By following these steps, you can efficiently diagnose problems and implement appropriate solutions to ensure optimal performance.

Common Issues and Solutions

| Problem | Possible Causes | Suggested Solutions |

|---|---|---|

| Difficulty starting | Fuel issues, clogged air filter | Check fuel levels and replace old fuel; clean or replace the air filter. |

| Inconsistent power | Dirty spark plug, fuel mixture | Inspect and clean the spark plug; ensure the correct fuel mixture is used. |

| Excessive vibration | Loose components, dull cutting edge | Tighten loose parts; sharpen or replace the cutting tool. |

Final Checks

After troubleshooting, conduct a thorough inspection to confirm that all issues have been addressed. Regular maintenance can help prevent future complications and extend the life of your equipment.

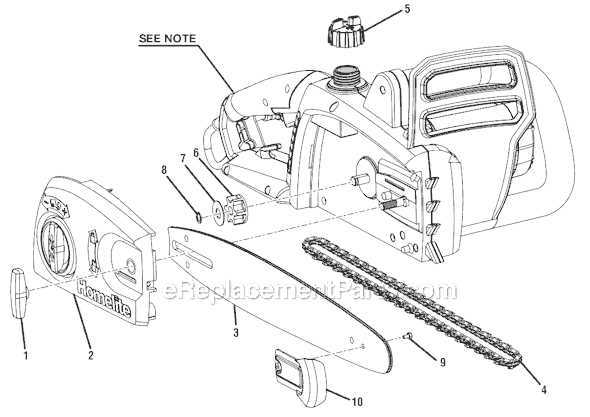

Replacing the Chainsaw Chain

Changing the cutting component of your equipment is an essential maintenance task that ensures efficient operation and safety during use. Proper installation is crucial for optimal performance and longevity.

Follow these steps for a smooth replacement process:

- Gather necessary tools: a suitable replacement component, a wrench, and protective gear.

- Disconnect the power source to ensure safety.

- Locate the tensioning mechanism, which is often near the guide bar.

- Loosen the tension by turning the adjustment screw counterclockwise.

- Remove the worn component by taking off the guide bar.

- Install the new cutting component, ensuring it is oriented correctly.

- Reattach the guide bar securely.

- Tighten the tensioning mechanism by turning the screw clockwise until the new part is taut.

- Reconnect the power source and perform a brief test to ensure everything is functioning properly.

Regularly checking and replacing this part will not only enhance performance but also improve safety during operation.

Maintaining the Spark Plug

Regular upkeep of the ignition component is crucial for optimal engine performance. This part plays a significant role in ensuring efficient fuel combustion, contributing to the overall functionality of your equipment. Proper care can prevent issues and extend the lifespan of the engine.

Inspection of the spark plug should be conducted frequently. Look for signs of wear, such as deposits or erosion on the electrode. If the component appears dirty, cleaning it can help restore functionality. A thorough examination will help you identify if it requires replacement or simply cleaning.

Cleaning can be accomplished using a wire brush or specialized cleaning tools. Ensure that any debris is removed from the insulator and electrode. After cleaning, check the gap between the electrodes using a feeler gauge; this gap should meet the manufacturer’s specifications to ensure proper ignition.

Replacement may be necessary if the spark plug shows significant damage or wear. Always select a compatible component that matches the specifications required for your engine. Installing a new plug is straightforward: simply remove the old one and securely fasten the new one in place, ensuring a tight fit without over-torquing.

Cleaning the Air Filter

Maintaining optimal performance in your equipment is crucial, and a clean air filter plays a significant role in this process. Regularly checking and cleaning the air intake component can prevent issues related to airflow and ensure your device operates smoothly.

Steps for Effective Cleaning

Begin by removing the air filter from its housing. Use a soft brush or compressed air to eliminate dust and debris. If the filter is excessively dirty, consider washing it with mild soap and water, then allowing it to dry completely before reinserting it.

Importance of Regular Maintenance

Regular upkeep of the air filtration system not only enhances performance but also extends the lifespan of your equipment. A well-maintained filter allows for proper airflow, improving efficiency and reducing the risk of overheating.

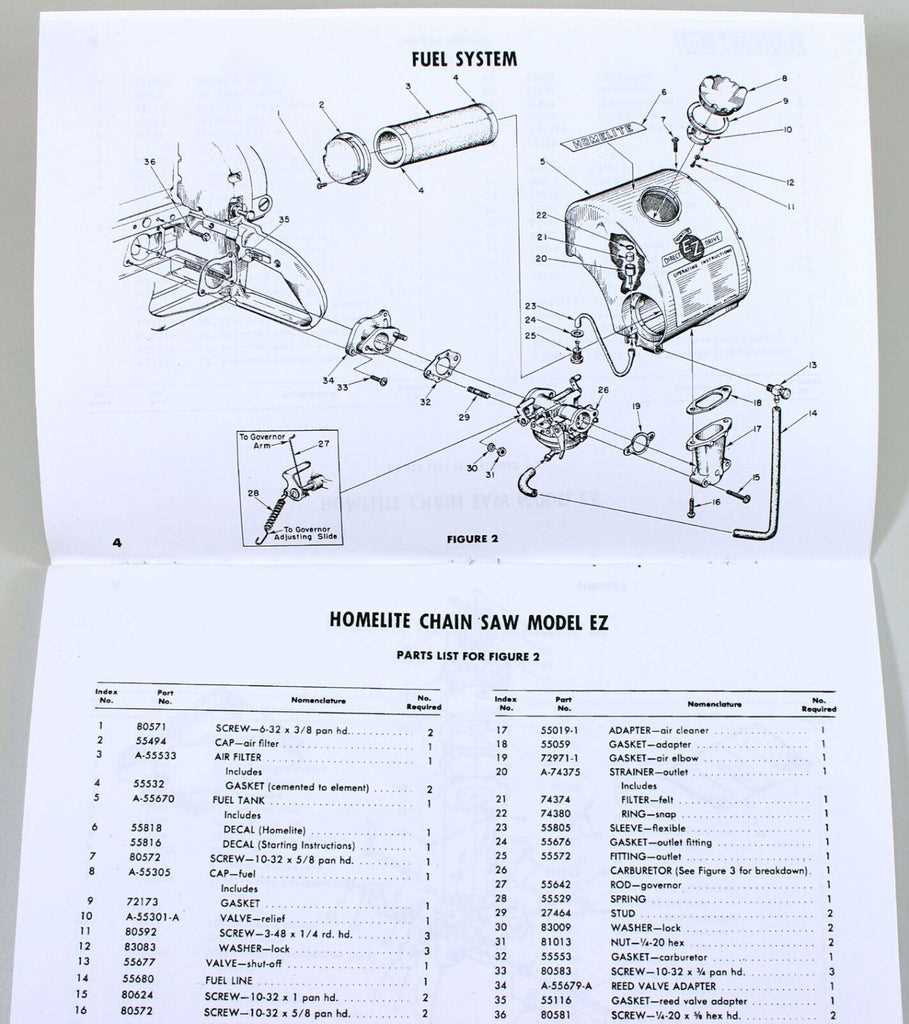

Adjusting the Carburetor Settings

Fine-tuning the fuel mixture is crucial for optimal performance of your equipment. Proper adjustments ensure smooth operation and enhance efficiency. Understanding the basics of the adjustment process can significantly improve functionality.

Essential Tools Required

- Screwdriver

- Tachometer

- Fuel mixture

- Cleaning cloth

Adjustment Process

- Start the engine and allow it to warm up.

- Locate the adjustment screws on the carburetor.

- Using the screwdriver, turn the H (high speed) screw to set the maximum RPM.

- Adjust the L (low speed) screw for smooth idle operation.

- Ensure that the engine responds well to throttle changes.

- Fine-tune both settings as necessary for optimal performance.

Regular maintenance and periodic adjustments will help prolong the lifespan of your equipment and ensure it operates efficiently.

Safety Precautions During Repairs

Ensuring a safe environment while working on mechanical devices is essential for preventing accidents and injuries. Adhering to proper guidelines not only protects the individual performing the work but also safeguards the tools and surrounding area.

Personal Protective Equipment

Wearing appropriate personal protective gear is crucial. This includes gloves to protect hands from sharp edges and debris, goggles to shield eyes from flying particles, and ear protection to minimize noise exposure. Ensure that clothing is fitted snugly to avoid entanglement with moving parts.

Work Area Organization

A well-organized workspace contributes to safety. Keep the area clean and free from clutter to reduce the risk of slips and falls. All tools should be easily accessible and in good condition. It’s advisable to have a fire extinguisher nearby when working with flammable substances.

Identifying Electrical Problems

Understanding issues related to electrical components is crucial for maintaining optimal performance. Recognizing the signs of malfunction can prevent further damage and ensure safe operation.

Common Symptoms of Electrical Issues

- Unresponsive power switch

- Inconsistent starting behavior

- Frequent blown fuses

- Unusual noises during operation

- Visible damage to wiring

Steps to Diagnose Electrical Failures

- Check the power source for continuity.

- Inspect connections for corrosion or looseness.

- Test the functionality of switches and triggers.

- Examine components for any signs of overheating.

- Utilize a multimeter to measure voltage levels.

How to Sharpen the Chainsaw Blade

Keeping the cutting tool in optimal condition is essential for efficient performance. A well-maintained edge not only enhances cutting efficiency but also prolongs the lifespan of the equipment. Here’s a guide to effectively sharpen the blade, ensuring smooth operation.

- Gather the Necessary Tools:

- File or sharpening tool

- Depth gauge tool

- Protective gloves

- Clamping device (optional)

- Secure the Equipment:

Before starting, ensure that the device is turned off and securely placed on a stable surface. Using a clamping device can help stabilize it while you work.

- Examine the Blade:

Inspect the cutting edge for any signs of wear or damage. Identifying areas that require more attention will guide your sharpening process.

- Begin Sharpening:

Using the file or sharpening tool, follow the angle of the existing edge. Apply even pressure, working from the base to the tip of the blade. Repeat this process on each tooth.

- Check and Adjust Depth:

Utilize the depth gauge tool to ensure that the depth is appropriate. Adjust as necessary to maintain optimal cutting performance.

- Clean Up:

After sharpening, clean the blade and surrounding area to remove any debris or metal filings. Proper maintenance contributes to better performance.

Regularly checking and sharpening the cutting edge will help maintain performance and efficiency. Following these steps will ensure that the tool remains in top condition for all your cutting needs.

Oil System Maintenance Tips

Proper upkeep of the lubrication system is essential for optimal performance and longevity of your equipment. Ensuring that the oil is clean and flowing correctly can prevent unnecessary wear and tear.

Regular Inspection

Frequent checks of the oil system can help identify potential issues before they escalate. Here are some key points to consider:

- Examine oil levels regularly to ensure adequate lubrication.

- Look for signs of leaks around seals and hoses.

- Check the oil filter for clogs or contamination.

Proper Oil Selection

Selecting the right type of oil is crucial for maintaining efficiency. Consider the following:

- Use oil recommended by the manufacturer for optimal performance.

- Be aware of the viscosity rating suitable for your climate and usage conditions.

- Avoid mixing different types of oil to maintain consistency.

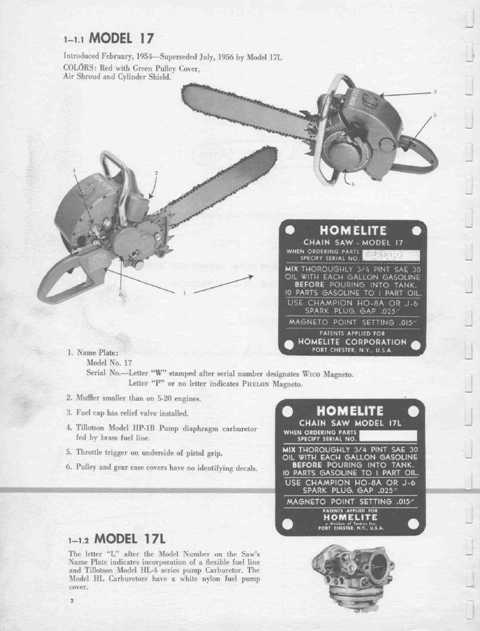

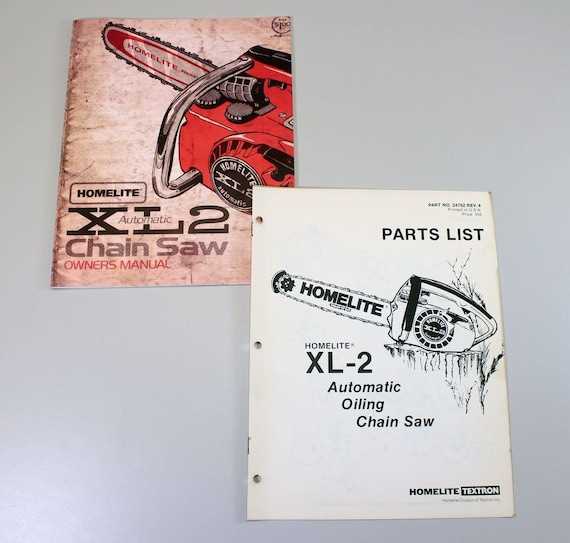

Finding Replacement Parts Easily

When it comes to maintaining outdoor equipment, locating suitable components can significantly enhance performance and longevity. Understanding where to find the right items is crucial for effective upkeep.

One of the best approaches is to explore local hardware stores, which often stock a variety of essential parts. These establishments may have knowledgeable staff who can assist in identifying the right components for your needs.

Additionally, online retailers provide a vast selection, allowing you to compare prices and availability. Websites dedicated to tool accessories often feature user reviews, helping you make informed choices about the quality of the parts.

Another valuable resource is manufacturer websites. They frequently offer catalogs or parts lists, making it easier to pinpoint the specific components required. This can save time and ensure that you acquire genuine parts for optimal functionality.

Lastly, consider joining online forums or communities where enthusiasts gather. These platforms can be excellent for sharing tips and finding recommendations on where to purchase reliable components.