Comprehensive Guide to John Deere 2305 Service and Repair

This section provides an in-depth exploration of the essential practices required to maintain agricultural machinery effectively. By understanding the intricate systems and components, operators can ensure optimal performance and longevity of their equipment.

Proper upkeep not only enhances functionality but also contributes to safety and efficiency during operations. Regular assessments and timely interventions play a crucial role in preventing unexpected breakdowns, ultimately leading to smoother workflows and increased productivity.

Throughout this guide, you will find detailed insights and procedures that equip users with the knowledge necessary to tackle various maintenance tasks confidently. Emphasizing the importance of proactive care, this resource serves as a valuable reference for anyone looking to enhance their machinery management skills.

Regular upkeep is essential for ensuring optimal performance and longevity of equipment. Implementing a consistent maintenance routine not only prevents unexpected breakdowns but also enhances efficiency. This section outlines fundamental practices that should be integrated into any maintenance schedule.

| Task | Frequency | Description |

|---|---|---|

| Fluid Checks | Monthly | Inspect all fluid levels, including oil and coolant, to ensure they are within recommended ranges. |

| Filter Replacement | Every 100 hours | Replace air, fuel, and hydraulic filters to maintain system efficiency and performance. |

| Belts and Hoses Inspection | Every season | Examine belts and hoses for wear and tear, replacing any that show signs of damage. |

| Battery Maintenance | Monthly | Check battery terminals for corrosion and ensure connections are secure. Test battery performance regularly. |

| Tire Pressure Check | Bi-weekly | Monitor tire pressure and tread condition to ensure optimal traction and stability. |

Incorporating these practices into a regular schedule can significantly enhance the reliability and efficiency of machinery, contributing to smoother operations and reduced costs over time.

Understanding the Repair Manual

The guidance document for machinery is an essential resource that provides crucial insights into maintenance procedures and troubleshooting techniques. It serves as a comprehensive reference for users, helping them navigate various tasks effectively while ensuring optimal performance of the equipment.

Key Components of the Guidance Document

This document typically includes several vital sections, each designed to facilitate user comprehension and operational efficiency. Here are some core elements often found within:

| Section | Description |

|---|---|

| Introduction | An overview of the equipment’s specifications and intended use. |

| Maintenance Schedule | Recommended timelines for regular checks and procedures to ensure longevity. |

| Troubleshooting Guide | A systematic approach to identifying and resolving common issues. |

| Parts List | A comprehensive inventory of components, including part numbers and specifications. |

Importance of Following the Guidance

Adhering to the recommendations outlined in this resource is critical for maintaining the functionality and efficiency of the machinery. Regular consultation of the guidance document not only extends the lifespan of the equipment but also enhances safety for the user, reducing the likelihood of accidents due to improper handling or maintenance.

Essential Tools for Repairs

When undertaking maintenance tasks, having the right instruments at your disposal is crucial for ensuring efficiency and precision. This section highlights the fundamental equipment that can significantly aid in addressing various mechanical issues. From basic hand tools to specialized devices, each plays a pivotal role in achieving effective outcomes.

Hand Tools

Basic hand tools such as wrenches, screwdrivers, and pliers are indispensable for any maintenance job. These tools allow for the tightening and loosening of bolts, adjusting components, and performing routine checks. Investing in a quality set ensures durability and reliability during use.

Diagnostic Equipment

Advanced diagnostic tools provide insights into the condition of various systems. These include multimeters, pressure gauges, and code readers. Utilizing such equipment enables quick identification of faults, streamlining the troubleshooting process and minimizing downtime.

Troubleshooting Common Issues

Identifying and resolving frequent challenges is essential for maintaining optimal functionality of agricultural machinery. Understanding the root causes of malfunctions can save time and prevent extensive damage. This section provides insights into common problems and effective strategies for addressing them.

Engine Performance Problems

When the engine exhibits reduced power or fails to start, it is crucial to check the fuel supply, air filters, and ignition system. Clogged filters or faulty spark plugs can hinder performance, necessitating prompt inspection and replacement if necessary. Ensuring that the fuel is clean and adequately reaching the engine is fundamental to restoring its functionality.

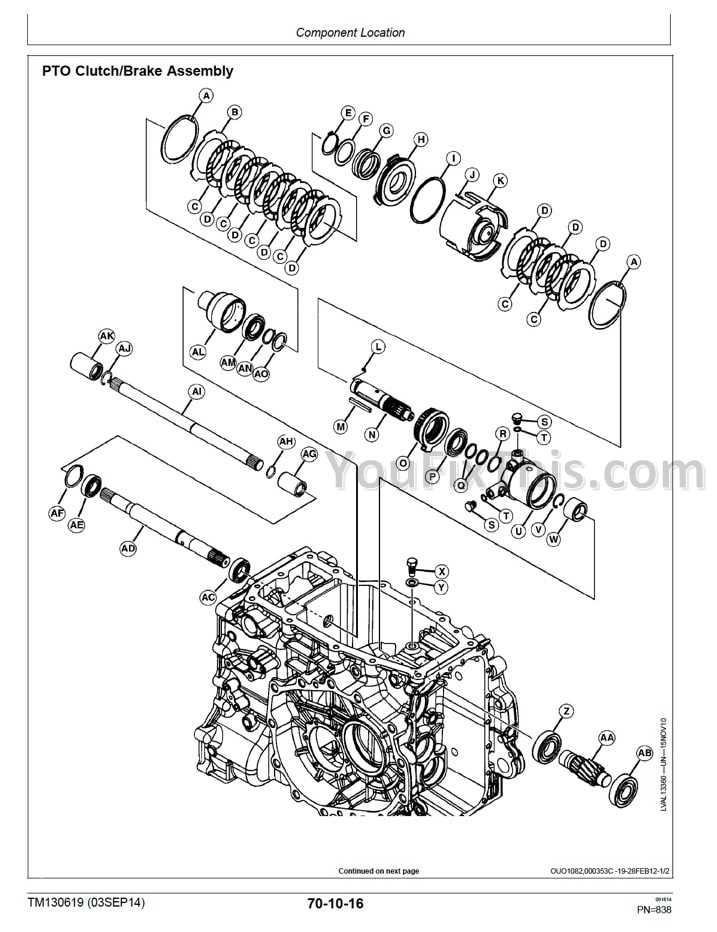

Hydraulic System Failures

If the hydraulic system is unresponsive or operates inefficiently, examine the fluid levels and look for leaks in hoses and connections. Contaminated fluid or air trapped in the system can also lead to diminished performance. Regular maintenance of the hydraulic components ensures smooth operation and prolongs the lifespan of the equipment.

Fluid Replacement Guidelines

Maintaining optimal performance in machinery requires regular monitoring and timely replacement of various liquids essential for operation. Proper fluid management not only enhances efficiency but also prolongs the lifespan of components, reducing the likelihood of unexpected failures.

1. Engine Oil: Ensure to check the oil level frequently. Replace it according to the manufacturer’s recommendations, typically every 50 to 100 hours of operation. When changing, use high-quality oil suitable for the engine type.

2. Coolant: Regularly inspect the coolant level and condition. Replace it every two years or as indicated by the maintenance schedule. Always use the recommended mixture of antifreeze and water to ensure proper thermal regulation.

3. Hydraulic Fluid: Check the hydraulic fluid level and top off as needed. Replace the fluid at regular intervals, usually every 1,000 hours of use, to maintain optimal hydraulic performance and protect system components.

4. Transmission Fluid: Monitor the transmission fluid level regularly. It is advisable to replace it every 400 to 600 hours of operation to ensure smooth gear shifting and prevent wear on transmission parts.

Adhering to these guidelines will ensure that your equipment remains in top condition, enabling you to tackle tasks effectively and efficiently.

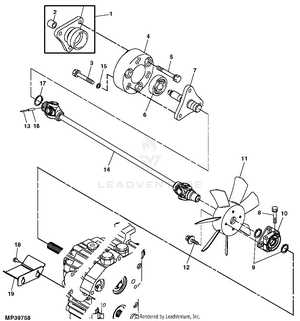

Electrical System Insights

The electrical system of a compact utility vehicle plays a crucial role in ensuring optimal performance and functionality. Understanding the components and their interconnections is vital for maintaining efficiency and reliability. This section delves into the intricacies of the vehicle’s power distribution, highlighting essential features that support both operational needs and user convenience.

At the core of the electrical setup lies the battery, which serves as the primary power source. Its condition directly influences the starting capabilities and overall functionality of various systems. Regular checks and maintenance are essential to avoid unexpected failures.

Additionally, fuses play a significant role in protecting the electrical components from overloads. Familiarity with their locations and specifications is key to troubleshooting issues effectively. Understanding the wiring harness and its routing can also aid in diagnosing potential problems and ensuring a safe operation.

Furthermore, the integration of sensors and control modules enhances the vehicle’s functionality, providing feedback and allowing for automated adjustments. Mastering the interaction between these elements not only aids in immediate repairs but also supports long-term reliability and performance.

Hydraulic System Maintenance Tips

Regular upkeep of hydraulic systems is essential for ensuring optimal performance and longevity of machinery. Proper care helps prevent costly breakdowns and maintains efficiency in operation. This section provides practical advice on how to effectively maintain hydraulic components.

Firstly, routine inspections should be conducted to check for leaks, corrosion, and wear. Early detection of these issues can save time and resources. It is advisable to regularly examine hoses and connections, as they are common points for potential failures.

Additionally, keeping hydraulic fluid at the appropriate levels is crucial. Low fluid levels can lead to air entering the system, resulting in inefficient operation and possible damage. Monitoring fluid quality is equally important; contaminated fluid can cause significant harm to components. Regularly changing the hydraulic fluid as recommended by the manufacturer is key to maintaining system health.

Furthermore, ensure that filters are replaced periodically. Clogged filters can restrict fluid flow and lead to increased pressure, which may harm various parts of the system. Establishing a maintenance schedule can help keep track of these essential tasks.

Lastly, proper operation techniques should be emphasized. Avoiding sudden movements and excessive loads can prolong the lifespan of hydraulic systems. Training operators on best practices contributes significantly to the overall maintenance strategy.

Best Practices for Engine Care

Proper maintenance of an engine is essential for ensuring optimal performance and longevity. Adopting a routine that emphasizes cleanliness, timely inspections, and appropriate fluid management can significantly enhance efficiency and prevent unexpected failures.

Regular Inspections

- Check oil levels frequently and top off as needed to maintain optimal lubrication.

- Inspect air filters regularly to ensure they are clean and free from obstructions.

- Examine belts and hoses for signs of wear or damage to prevent breakdowns.

Fluid Management

- Change engine oil as recommended by the manufacturer to avoid sludge build-up.

- Replace coolant periodically to prevent overheating and corrosion.

- Monitor hydraulic fluid levels to ensure smooth operation of hydraulic systems.

By following these best practices, owners can significantly improve the reliability and lifespan of their engines, reducing the likelihood of costly repairs and downtime.

Parts Replacement Recommendations

Ensuring the longevity and optimal performance of your machinery requires timely and effective component replacements. This section highlights essential suggestions for maintaining key elements, emphasizing the importance of using high-quality parts to prevent further issues.

Critical Components to Monitor

Regular inspections should focus on items that experience significant wear and tear, such as belts, filters, and hydraulic hoses. Belts should be replaced if signs of fraying or cracking are present, as these can lead to operational failures. Filters must be changed periodically to maintain proper fluid flow and prevent contaminants from causing damage.

Best Practices for Replacement

When replacing components, always refer to specifications for compatible parts. Utilizing genuine components is recommended to ensure proper fit and function. Additionally, following the manufacturer’s guidelines for installation will enhance the reliability and efficiency of your equipment.

Resources for Further Assistance

When working on complex machinery, having access to reliable sources of information can greatly enhance your understanding and troubleshooting capabilities. Various platforms offer valuable insights, documentation, and community support that can assist you in effectively addressing challenges you may encounter.

Online Communities and Forums

Engaging with fellow enthusiasts and professionals in online forums can provide practical advice and firsthand experiences. Here are some notable platforms:

| Community | Description |

|---|---|

| TractorByNet | A large forum dedicated to discussing a wide range of agricultural and gardening equipment. |

| Subreddits related to machinery offer a space for users to ask questions and share knowledge. | |

| Green Tractor Talk | A forum specifically focused on various brands and models, providing a wealth of shared experiences. |

Official Manufacturer Resources

Official websites often provide comprehensive resources, including product specifications, troubleshooting guides, and contact information for expert help. Utilizing these resources ensures that you are accessing accurate and up-to-date information relevant to your needs.