Comprehensive Guide to Rotary Engine Repair

In the realm of high-performance vehicles, understanding the intricacies of unique propulsion systems is essential for enthusiasts and professionals alike. This section delves into the nuances of maintaining and rejuvenating these remarkable power sources, offering insights that are crucial for optimal functionality. With a focus on systematic approaches, it emphasizes the importance of thorough knowledge and precision in the upkeep of these sophisticated mechanisms.

Maintenance and troubleshooting are paramount for ensuring longevity and peak performance. Whether you are an experienced technician or a passionate hobbyist, having a well-structured resource at your disposal can significantly enhance your ability to diagnose issues and implement effective solutions. The following segments will equip you with vital techniques and tips for addressing common challenges.

Additionally, this guide provides a detailed exploration of essential components, highlighting their roles and interconnections within the system. From initial assessments to advanced modifications, each section is designed to foster a deeper understanding of how to care for these intricate assemblies. Embrace the journey of knowledge as you learn to navigate the complexities of power generation.

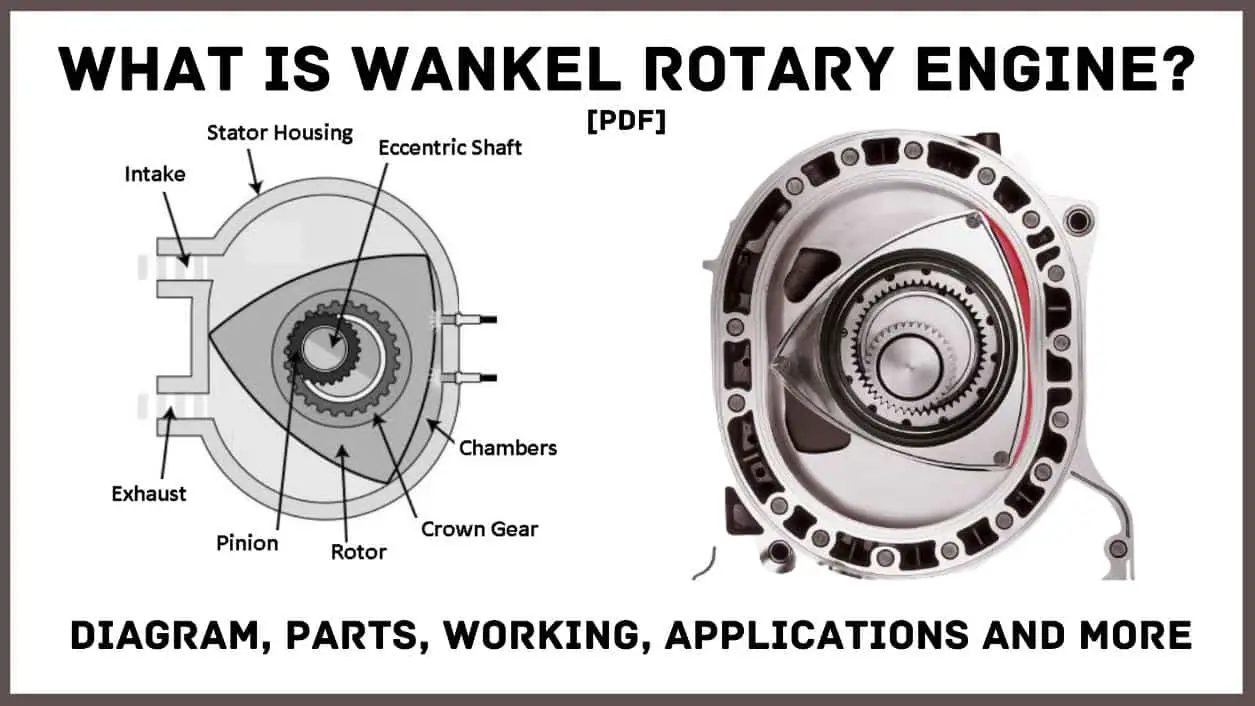

Understanding Rotary Engine Mechanics

The intricacies of a unique power generation system rely on a distinctive design that sets it apart from traditional configurations. This section delves into the fundamental principles that govern its operation, exploring how its components interact to deliver efficient performance. A deep understanding of these mechanics is essential for anyone looking to appreciate the nuances of this innovative approach to motion generation.

Core Components and Their Functions

At the heart of this system lies a series of crucial elements, each playing a vital role in the overall functionality. Below is a summary of the primary components and their specific purposes:

| Component | Function |

|---|---|

| Housing | Encloses and supports the internal parts while maintaining necessary clearances. |

| Rotor | Acts as the primary moving part, converting fuel energy into mechanical motion. |

| Seals | Ensure proper compression and prevent the escape of gases during operation. |

| Intake System | Facilitates the entry of air and fuel mixture into the chamber for combustion. |

| Exhaust System | Allows for the expulsion of combustion gases, maintaining efficiency and performance. |

Operational Dynamics

The operational dynamics of this system are characterized by a unique sequence of events that occurs during each cycle. Understanding these interactions can illuminate the efficiency and potential challenges associated with this design. Key processes include the intake of the air-fuel mixture, compression, combustion, and exhaust, all occurring in a highly coordinated manner. This synchronization ensures optimal energy conversion and performance, making it essential to grasp these mechanics for anyone involved in its maintenance or enhancement.

Common Issues with Rotary Engines

Engines with a unique design often encounter specific challenges that can impact performance and longevity. Understanding these common pitfalls is crucial for maintaining optimal functionality and ensuring a smooth driving experience. Awareness of typical problems allows for proactive measures, ultimately enhancing reliability.

Power Loss and Poor Performance

One prevalent concern is a noticeable decrease in power output. This can stem from various factors, including inadequate sealing of combustion chambers or issues with the fuel delivery system. Regular diagnostics and timely interventions can mitigate these issues and restore expected performance levels.

Overheating and Cooling Problems

Another frequent issue involves overheating, which can lead to significant damage if left unaddressed. The cooling system’s efficiency is vital; any leaks or failures in the cooling mechanism can exacerbate heat-related problems. Routine inspections of hoses, coolant levels, and radiator conditions are essential in preventing overheating and ensuring safe operation.

Essential Tools for Repairs

When embarking on the journey of maintenance and refurbishment, having the right instruments at your disposal is crucial. Each task requires specific gear to ensure efficiency and precision, making it imperative to be well-equipped. Below, we outline the indispensable tools that form the backbone of any successful refurbishment endeavor.

Basic Hand Tools

Fundamental hand tools are the cornerstone of any workspace. These include items such as wrenches, screwdrivers, and pliers. Each of these tools serves a unique purpose, enabling you to tighten, loosen, and manipulate various components effectively. The right selection of sizes and types ensures that you can tackle both common and uncommon tasks with ease.

Specialized Instruments

In addition to basic tools, certain specialized instruments are essential for more complex procedures. Torque wrenches allow for precise tightening to manufacturer specifications, while gauge tools help in assessing critical measurements. Having access to diagnostic devices can also streamline the troubleshooting process, making it easier to identify issues quickly and accurately.

Step-by-Step Repair Process

This section outlines a systematic approach to addressing common issues, ensuring optimal performance and longevity. Following a structured sequence can significantly enhance the effectiveness of the task, making it easier to pinpoint problems and implement solutions.

1. Preparation: Gather all necessary tools and materials. Familiarize yourself with the components involved, ensuring a clear understanding of each part’s function.

2. Disassembly: Carefully dismantle the unit, taking note of the order of parts. Document any specific configurations to facilitate reassembly.

3. Inspection: Examine each component for signs of wear or damage. Look for cracks, corrosion, or any irregularities that could affect functionality.

4. Cleaning: Remove dirt and grime from all parts. Use appropriate solvents and brushes to ensure every surface is clean and free of contaminants.

5. Replacement: Identify and replace any faulty components. Utilize high-quality parts to guarantee reliability and performance.

6. Reassembly: Follow your earlier documentation to put the unit back together. Ensure that all connections are secure and correctly oriented.

7. Testing: Conduct a series of tests to verify that everything is functioning as intended. Monitor for any unusual sounds or performance issues.

8. Final Checks: After testing, perform a thorough review of all systems. Confirm that all tools are removed and that the workspace is clean.

Maintenance Tips for Longevity

Ensuring the durability and performance of your vehicle requires consistent care and attention. By following a few essential practices, you can significantly extend the lifespan of its core components, enhancing both efficiency and reliability over time.

Regular Inspection: Conducting routine checks is crucial. Examine critical parts for wear and tear, and address any issues promptly to prevent further damage.

Optimal Lubrication: Keeping moving parts well-lubricated reduces friction and heat buildup. Use high-quality oils that meet recommended specifications for the best results.

Cooling System Maintenance: A well-functioning cooling system is vital. Regularly check coolant levels and replace fluids as needed to avoid overheating and maintain optimal temperatures.

Fuel Quality: Always use high-grade fuel that meets your vehicle’s requirements. Contaminated or low-quality fuel can lead to performance issues and damage over time.

Routine Cleaning: Dirt and debris can accumulate in various areas, affecting performance. Periodically clean intake and exhaust pathways to ensure smooth airflow and efficient operation.

Timely Replacement of Parts: Adhering to manufacturer-recommended schedules for part replacements can prevent unexpected failures. Always be proactive in changing filters, seals, and other consumables.

Driving Habits: Adopt gentle driving practices to minimize stress on components. Avoid abrupt accelerations and high-rev situations that can lead to premature wear.

By implementing these strategies, you can foster a healthier environment for your vehicle’s vital systems, ultimately contributing to its longevity and performance.

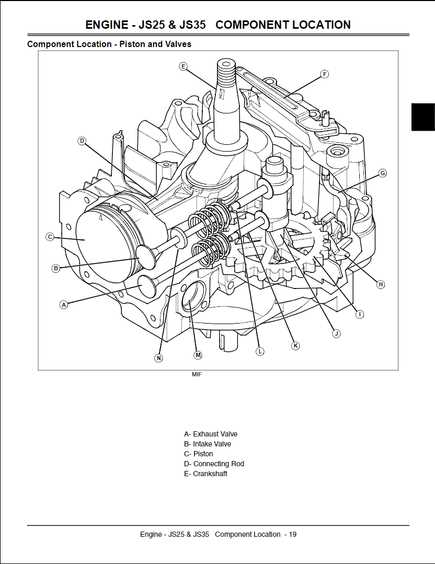

Identifying Engine Components

Understanding the various parts of a power unit is crucial for effective maintenance and optimal performance. Each section plays a specific role in the overall functionality, and recognizing these elements will aid in troubleshooting and enhancements. This segment will focus on key components and their significance within the assembly.

Main Parts Overview

- Housing: The outer shell that protects internal elements from external factors.

- Chambers: Spaces where the combustion process occurs, critical for power generation.

- Seals: Components that prevent leakage of fluids, ensuring efficiency.

- Rotors: Moving parts that facilitate the conversion of fuel energy into mechanical power.

- Intake and Exhaust Systems: Pathways for air intake and exhaust expulsion, vital for airflow management.

Tools for Identification

Identifying parts accurately can be achieved with the right tools:

- Manuals: Reference guides providing detailed descriptions and diagrams.

- Diagnostic Tools: Devices that can help pinpoint issues within the structure.

- Visual Aids: Charts and images that illustrate component placement and function.

Being familiar with these components and the tools available will empower you to undertake effective assessments and improvements in performance.

Overhauling vs. Minor Repairs

When it comes to maintaining mechanical systems, understanding the difference between extensive refurbishments and smaller-scale fixes is crucial. Both approaches serve specific purposes and are essential for ensuring optimal performance and longevity.

Extensive refurbishments typically involve comprehensive examinations and replacements of major components. This process often includes:

- Disassembling the unit completely

- Inspecting all parts for wear and damage

- Reconditioning or replacing critical components

- Reassembling and calibrating the system to factory specifications

On the other hand, smaller-scale fixes focus on addressing specific issues without the need for total disassembly. These may involve:

- Tightening loose connections

- Replacing worn-out seals or gaskets

- Cleaning components to improve functionality

- Adjusting settings for better performance

Choosing between these methods often depends on the extent of wear and the specific symptoms presented. While minor fixes can provide quick solutions, overhauling may be necessary for maintaining overall integrity and preventing future complications.

Engine Performance Optimization Techniques

Enhancing the efficiency and power output of a power unit involves a variety of strategies and methods. These techniques aim to maximize the potential of the system while ensuring reliability and longevity. By implementing a combination of adjustments, drivers can experience improved responsiveness, fuel economy, and overall satisfaction with their vehicle’s performance.

Key Techniques for Enhancement

- Tuning Adjustments: Fine-tuning the fuel-air mixture and ignition timing can lead to significant improvements in performance.

- Exhaust System Upgrades: Upgrading the exhaust components can reduce back pressure and enhance flow, resulting in better engine breathing.

- Intake Modifications: Installing high-performance air filters and intake systems can optimize airflow into the combustion chamber.

- Weight Reduction: Reducing unnecessary weight from the vehicle can improve acceleration and handling.

Maintenance Practices

- Regularly changing oil and filters to ensure optimal lubrication and cleanliness.

- Monitoring tire pressure and maintaining proper alignment for improved traction and efficiency.

- Keeping the cooling system in check to prevent overheating and maintain consistent performance.

- Inspecting and replacing worn components, such as spark plugs and belts, to prevent performance issues.

Implementing these strategies can significantly contribute to enhanced performance, providing a more enjoyable and efficient driving experience.

Cost Considerations in Repairing

Understanding the financial aspects of maintenance is crucial for any vehicle owner. Various factors influence the overall expenditure, from the complexity of the task to the availability of components. By evaluating these elements, one can make informed decisions that align with their budget while ensuring optimal performance.

Parts and Labor Expenses

The cost of replacement components can vary significantly based on brand and quality. Additionally, labor charges depend on the expertise of the technician and the time required for the service. It is advisable to seek quotes from multiple sources to gain insight into the prevailing market rates.

Long-term Value vs. Immediate Costs

While some repairs may seem costly upfront, considering the long-term benefits is essential. Investing in high-quality parts and skilled service can lead to better reliability and lower maintenance needs in the future. Balancing immediate financial outlay with potential savings can ultimately influence the decision-making process.

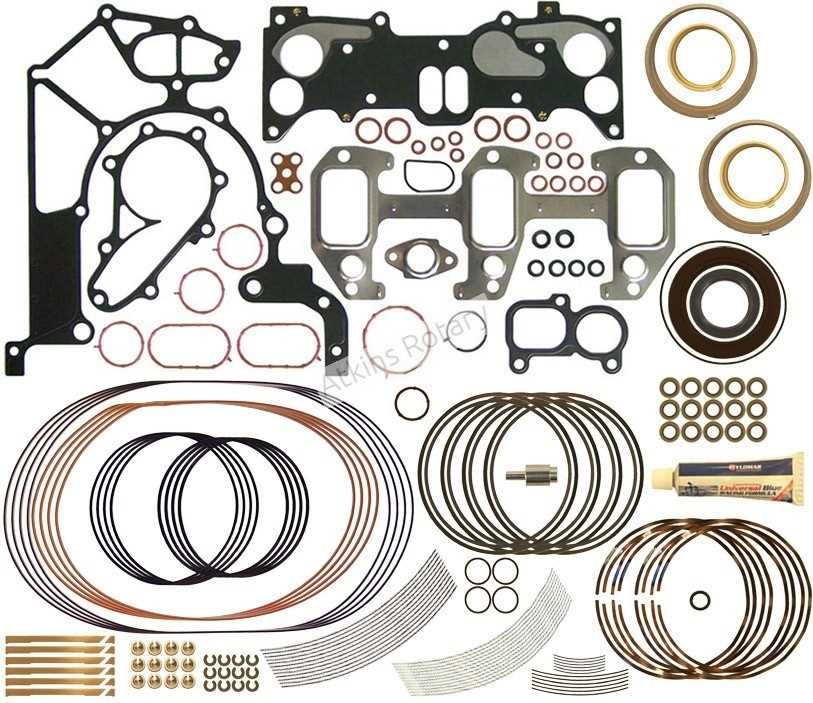

Choosing the Right Replacement Parts

When it comes to maintaining optimal performance, selecting appropriate components is crucial. The right parts not only enhance functionality but also ensure longevity and reliability. This section focuses on key considerations to help you make informed choices in sourcing replacements.

Understanding Quality Standards

Before purchasing, familiarize yourself with the various quality benchmarks in the market. Parts can vary significantly in durability and performance. Always opt for components that meet or exceed industry specifications, as these will provide better reliability in the long run. OEM parts, which are manufactured by the original producer, often guarantee a perfect fit and performance level.

Evaluating Compatibility

It is essential to ensure that the selected components are compatible with your specific setup. Check the part numbers and specifications carefully. Using incompatible parts can lead to poor performance or even damage. Always consult product manuals or trusted sources to confirm compatibility before making a purchase.

Safety Precautions During Repairs

Ensuring safety while performing maintenance tasks is paramount. By adhering to established guidelines, you can mitigate risks associated with handling complex machinery and components. This section outlines essential practices to follow for a secure working environment.

| Precaution | Description |

|---|---|

| Personal Protective Equipment (PPE) | Always wear appropriate gear, including gloves, goggles, and masks to safeguard against injuries and exposure to harmful substances. |

| Work Area Organization | Keep your workspace clean and organized to prevent accidents caused by clutter or misplaced tools. |

| Proper Ventilation | Ensure adequate airflow in the area to minimize inhalation of fumes or harmful vapors. |

| Tool Inspection | Regularly check tools for damage or wear to avoid malfunction during use, which could lead to injuries. |

| Secure Components | Always ensure that parts are securely held in place before starting any work to avoid unexpected movement. |

By following these safety measures, you can enhance your protection and create a more efficient working atmosphere, allowing for a more successful and secure maintenance experience.