Comprehensive Guide to Repairing the 5610 Ford Tractor

Effective upkeep of agricultural equipment is crucial for optimal performance and longevity. Understanding the intricacies of these powerful machines enables operators to address issues swiftly and maintain productivity. This section aims to provide essential insights and strategies for ensuring your machinery runs smoothly.

In the realm of heavy-duty farming equipment, having access to comprehensive resources can make a significant difference. Knowledge of troubleshooting techniques, routine inspections, and part replacements empowers users to tackle common challenges. By leveraging expert advice, operators can enhance their skills and extend the lifespan of their machinery.

Equipping oneself with the right information transforms daunting repair tasks into manageable projects. Whether it’s addressing minor malfunctions or conducting major overhauls, a solid foundation of guidance ensures that farmers can maintain their investment effectively. This guide serves as a vital tool for anyone seeking to master the care of their agricultural assets.

Understanding the Ford 5610 Tractor

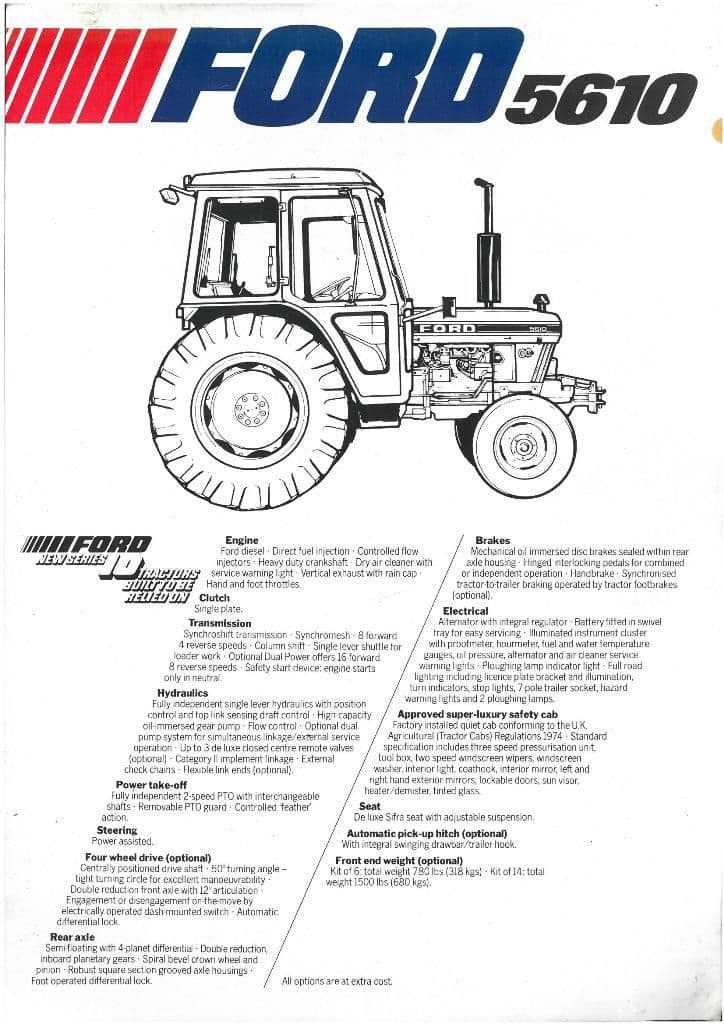

This section aims to provide a comprehensive overview of a specific agricultural vehicle that has gained recognition for its reliability and efficiency in various farming tasks. Its design and engineering cater to both seasoned professionals and newcomers in the field of agriculture.

The model is equipped with a powerful engine that ensures optimal performance, enabling users to tackle a range of tasks, from plowing fields to transporting materials. Key features such as hydraulic systems and customizable attachments enhance its versatility, making it suitable for diverse agricultural applications.

Regular maintenance and knowledge of its components are essential for ensuring longevity and efficiency. Understanding the operational aspects and troubleshooting common issues can greatly enhance productivity and minimize downtime. Investing time in familiarizing oneself with this vehicle’s functions can lead to significant improvements in farming operations.

Common Issues with Ford 5610

Maintaining agricultural machinery can often reveal a variety of challenges that operators must address. Understanding these frequent problems is essential for ensuring longevity and optimal performance. This section will highlight some prevalent concerns that users encounter with this particular model.

Engine Overheating: One of the most reported issues is overheating. This can stem from inadequate coolant levels, blocked radiators, or failing thermostats. Regular checks of the cooling system can help mitigate this problem.

Electrical Failures: Electrical system malfunctions are also common. Issues such as faulty wiring, dead batteries, or malfunctioning alternators can lead to starting difficulties. Routine inspections can help identify potential electrical faults before they escalate.

Hydraulic System Leaks: Hydraulic systems are crucial for functionality, yet leaks can develop over time. Regular monitoring of hoses and connections can prevent significant downtime and costly repairs.

Transmission Problems: Gear shifting issues may arise due to low fluid levels or worn components. Ensuring proper maintenance of the transmission fluid can help maintain smooth operation.

Tire Wear: Uneven tire wear is another concern that can impact performance. Proper inflation and regular rotation can prolong tire life and enhance traction.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires consistent upkeep and attention to detail. Regular maintenance not only extends the life of your machinery but also enhances its performance, leading to greater productivity and reduced costs over time. Below are essential tips to help you maintain your equipment effectively.

Routine Inspections

Conducting periodic checks is crucial. Regularly examine key components such as fluids, filters, and belts for any signs of wear or damage. Addressing minor issues promptly can prevent more significant problems in the future. Additionally, ensure that all fasteners are tightened and that connections are secure.

Proper Cleaning Techniques

Keeping your machinery clean is vital for its longevity. Accumulated dirt and debris can lead to overheating and other operational issues. Use appropriate cleaning solutions to remove grime without damaging surfaces. Be sure to pay special attention to the cooling system, as it is essential for efficient performance. Regularly clearing out any blockages can make a significant difference.

By implementing these practices, you can help ensure that your equipment remains reliable and efficient for years to come.

Essential Tools for Repairing Tractors

Maintaining and fixing heavy machinery requires a set of specific implements to ensure efficiency and safety. Having the right tools not only simplifies the process but also enhances the longevity of the equipment. This section explores the fundamental instruments that every mechanic should consider essential for their toolkit.

Wrenches and sockets are indispensable for loosening and tightening bolts, providing the necessary torque to secure components. A quality set of pliers is crucial for gripping, twisting, and cutting various materials. Additionally, screwdrivers of different types and sizes allow for precision adjustments in tight spaces.

Diagnostic devices play a vital role in identifying issues, enabling technicians to troubleshoot effectively. A reliable jack and stands are necessary for lifting equipment safely during inspections and repairs. Moreover, an assortment of hammers and mallets can assist in aligning parts without causing damage.

Safety gear, including gloves and goggles, is equally important, ensuring protection from potential hazards while working. Lastly, organization tools like toolboxes and magnetic trays help keep everything in order, allowing for a smoother workflow. With these essentials, any mechanic can tackle challenges with confidence and skill.

How to Diagnose Engine Problems

Identifying issues within an engine requires a systematic approach to isolate and analyze symptoms. By observing performance changes, unusual noises, or operational inconsistencies, one can narrow down the potential causes. This section will guide you through essential steps and tools needed for effective diagnostics.

Begin by collecting as much information as possible about the engine’s performance. Take note of any irregularities, such as difficulty starting, loss of power, or excessive emissions. The following table outlines common symptoms and possible underlying issues.

| Symptom | Possible Cause |

|---|---|

| Engine won’t start | Battery failure, faulty ignition system, fuel delivery issues |

| Loss of power | Clogged air filter, fuel restrictions, ignition problems |

| Unusual noises | Worn components, loose parts, lubrication failure |

| Excessive smoke | Oil leaks, fuel mixture issues, internal damage |

After identifying symptoms, utilize diagnostic tools such as an OBD-II scanner, multimeter, and compression tester to gather precise data. Each tool helps pinpoint specific faults, leading to more accurate solutions. Remember, a methodical approach can save time and resources in the long run.

Transmission Troubleshooting Guide

This section aims to provide insights and solutions for common issues related to the gear shifting system. Understanding these problems can enhance performance and prolong the lifespan of your machinery. By identifying symptoms early, you can take the necessary steps to mitigate further complications.

Common Symptoms

There are several indicators that may suggest a malfunction within the transmission system. If you experience difficulty shifting gears, unusual noises during operation, or a noticeable decrease in power transfer, it is essential to investigate these issues promptly. Fluid leaks around the transmission area can also signal potential problems that require immediate attention.

Troubleshooting Steps

To address these issues, start by checking the fluid levels and condition. Low or dirty fluid can lead to inadequate lubrication and shifting problems. If the fluid appears contaminated, consider performing a thorough replacement. Next, inspect the linkage and cables for any signs of wear or misalignment. Regular maintenance of these components is crucial to ensure smooth operation.

Electrical System Checks and Fixes

Ensuring the reliability of an electrical system is essential for optimal performance. Regular inspections can help identify potential issues before they escalate. This section outlines crucial steps to diagnose and resolve common electrical problems, enhancing overall functionality.

Begin by examining the battery connections for any signs of corrosion or loose terminals. A secure and clean connection is vital for proper power delivery. If the battery appears weak, consider testing its voltage to determine if it needs charging or replacement.

Next, inspect the wiring for frays, breaks, or signs of wear. Damaged wires can lead to short circuits or intermittent power loss. If any issues are detected, it’s important to repair or replace the affected sections promptly to maintain safety and efficiency.

Check all fuses and relays to ensure they are functioning correctly. A blown fuse can disrupt the entire electrical circuit, leading to failure of various components. Replace any faulty fuses and test the circuit to confirm restoration of power.

Finally, assess the functionality of all electrical components, such as lights, gauges, and ignition systems. If any items are not operating as intended, further investigation may be necessary. Utilizing a multimeter can aid in pinpointing specific faults, allowing for targeted repairs.

Hydraulic System Maintenance Techniques

Maintaining the hydraulic system is essential for ensuring optimal performance and longevity of your machinery. Regular upkeep can prevent costly repairs and enhance efficiency. This section outlines effective methods for maintaining the hydraulic components, ensuring they operate smoothly and reliably.

Regular Inspections

Routine inspections are crucial for identifying potential issues before they escalate. Consider the following steps:

- Check for leaks in hoses and connections.

- Inspect fluid levels and quality.

- Examine filters for clogs and damage.

- Look for signs of wear on components.

Fluid Maintenance

Maintaining proper fluid levels and quality is vital for the hydraulic system’s health. Follow these guidelines:

- Regularly check and replenish hydraulic fluid to the recommended levels.

- Change the fluid at intervals specified by the manufacturer.

- Use fluids that meet the required specifications to prevent degradation of system components.

- Monitor fluid color and consistency; dark or contaminated fluid may indicate a problem.

Replacing Key Components: A Step-by-Step

Maintaining machinery requires a clear understanding of its essential parts and the proper techniques for their replacement. This guide provides a systematic approach to swapping out vital components, ensuring that the equipment remains in optimal working condition. Following these steps can help avoid common pitfalls and extend the lifespan of your machinery.

Preparation Steps

- Gather necessary tools: Ensure you have all required tools and replacement parts ready.

- Read instructions: Familiarize yourself with the component specifications and procedures.

- Safety first: Wear appropriate protective gear to safeguard against injuries.

Replacement Process

- Disconnect power: Always start by shutting off the power supply to prevent accidental activation.

- Remove the old component: Carefully detach the malfunctioning part, noting how it is connected.

- Inspect surrounding areas: Check for any damage or wear that may have caused the failure.

- Install the new component: Position the new part as per the manufacturer’s guidelines.

- Reconnect everything: Ensure all connections are secure before restoring power.

- Test functionality: After installation, run a check to confirm that everything operates correctly.

By adhering to these steps, you can effectively replace key parts, minimizing downtime and enhancing performance.

Finding Genuine Parts for Repairs

When maintaining machinery, sourcing authentic components is crucial for ensuring optimal performance and longevity. Utilizing original parts not only enhances functionality but also contributes to the overall reliability of the equipment. This section focuses on strategies for locating high-quality replacements that adhere to manufacturer standards.

One effective approach is to consult with authorized dealers or distributors who specialize in the specific brand. These vendors typically offer a range of genuine components and can provide valuable insights into the compatibility and specifications of each part. Additionally, they often have access to the latest inventory, ensuring that the required items are readily available.

Another resource is online platforms dedicated to agricultural machinery, where original components can be sourced from reputable sellers. It is essential to verify the credibility of these sellers by checking customer reviews and ratings to avoid counterfeit items that may compromise the equipment’s performance.

Participating in community forums and local groups focused on machinery maintenance can also yield useful recommendations. Experienced users often share their insights on where to find reliable parts and may even offer suggestions based on personal experiences.

In summary, investing time in finding authentic components is a fundamental step in preserving the efficiency and durability of equipment. By leveraging trusted sources and community knowledge, operators can ensure that they are equipped with the best possible parts for their maintenance needs.

Using the Repair Manual Effectively

Utilizing a comprehensive guide can significantly enhance the maintenance and restoration process of your machinery. To maximize the benefits of such a resource, it’s essential to approach it with a strategic mindset. Here are some effective practices to consider:

- Familiarize Yourself with the Structure: Understand how the content is organized. This typically includes sections on troubleshooting, assembly, and specifications.

- Identify Key Topics: Focus on the areas that are most relevant to your needs. Highlight sections related to common issues or regular maintenance tasks.

- Make Notes: Jot down important details or tips that resonate with your experiences. This can help you retain information and refer back to it easily.

- Follow Step-by-Step Instructions: Adhere to the outlined procedures carefully. Skipping steps can lead to complications or misunderstandings.

- Utilize Visual Aids: Pay attention to diagrams and illustrations that accompany the text. They can provide clarity on complex processes.

By implementing these strategies, you can enhance your proficiency in managing your equipment, ensuring better performance and longevity.

Safety Precautions During Repairs

Ensuring safety during maintenance activities is crucial to prevent accidents and injuries. Proper precautions not only protect the individual performing the tasks but also safeguard the equipment involved. By adhering to certain guidelines, one can create a secure environment that promotes efficiency and well-being.

Personal Protective Equipment

Wearing appropriate personal protective gear is essential. Items such as gloves, goggles, and steel-toed boots provide necessary defense against potential hazards. Always inspect your gear before starting any work to ensure it is in good condition.

Work Area Safety

Maintain a clean and organized workspace. Clear away any unnecessary tools and materials to minimize the risk of tripping or mishaps. Ensure adequate lighting and ventilation, especially when working with chemicals or heavy machinery.

Upgrades to Enhance Performance

Improving the efficiency and output of your machinery can lead to significant gains in productivity. By implementing various enhancements, operators can optimize performance, increase durability, and reduce operational costs. These modifications not only elevate power but also improve overall functionality, ensuring that equipment meets the demands of modern tasks.

Engine Enhancements

One of the most effective ways to boost performance is by upgrading the engine components. Consider installing a high-performance air intake system to increase airflow and enhance combustion efficiency. Coupling this with an upgraded exhaust system can further improve power output while reducing emissions. Additionally, reprogramming the engine control unit can optimize fuel delivery and ignition timing for better responsiveness.

Transmission Improvements

Modifying the transmission can lead to smoother shifting and improved torque management. Installing a high-capacity clutch allows for greater torque transfer, making it easier to handle heavier loads. Furthermore, utilizing synthetic lubricants in the transmission system can reduce friction, leading to more efficient power transfer and longer component life. These upgrades contribute to a more reliable and responsive operating experience.